Escolar Documentos

Profissional Documentos

Cultura Documentos

G3520C Performance Data

Enviado por

bang bebetDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

G3520C Performance Data

Enviado por

bang bebetDireitos autorais:

Formatos disponíveis

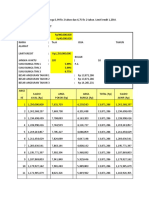

GAS ENGINE TECHNICAL DATA

G3520C

ENGINE SPEED (rpm):

COMPRESSION RATIO:

AFTERCOOLER TYPE:

AFTERCOOLER - STAGE 2 INLET (F):

AFTERCOOLER - STAGE 1 INLET (F):

JACKET WATER OUTLET (F):

ASPIRATION:

COOLING SYSTEM:

CONTROL SYSTEM:

EXHAUST MANIFOLD:

COMBUSTION:

NOx EMISSION LEVEL (g/bhp-hr NOx):

1200

11.3:1

SCAC

130

217

230

TA

JW+1AC, OC+2AC

ADEM3

DRY

Low Emission

0.5

RATING STRATEGY:

FUEL:

FUEL SYSTEM:

FUEL PRESSURE RANGE(psig):

FUEL METHANE NUMBER:

FUEL LHV (Btu/scf):

ALTITUDE CAPABILITY AT 77F INLET AIR TEMP. (ft):

APPLICATION:

POWER FACTOR:

VOLTAGE(V):

RATING

GENSET POWER

GENSET POWER

ENGINE POWER

GENERATOR EFFICIENCY

GENSET EFFICIENCY(@ 1.0 Power Factor)

THERMAL EFFICIENCY

TOTAL EFFICIENCY (@ 1.0 Power Factor)

(WITHOUT FAN)

(WITHOUT FAN)

(WITHOUT FAN)

(ISO 3046/1)

STANDARD

Low Energy

CAT LOW PRESSURE

WITH AIR FUEL RATIO CONTROL

1.5-5.0

140

500

1378

Genset

0.8

480-4160

NOTES

LOAD

100%

75%

50%

(1)(2)

(1)(2)

(2)

(1)

(3)

(4)

(5)

ekW

kVA

bhp

%

%

%

%

1600

2000

2242

95.7

38.8

39.1

77.9

1200

1500

1683

95.6

37.5

39.9

77.4

800

1000

1128

95.1

34.8

41.5

76.3

(6)

(6)

(6)

(7)

(7)

Btu/ekW-hr

Btu/ekW-hr

Btu/bhp-hr

ft3/min

lb/hr

scfm

in Hg(abs)

F

F

in Hg(abs)

F

BTDC

F

ft3/min

lb/hr

in H2O

in H2O

8907

9124

6511

4441

19691

487

107.2

378

142

93.5

142

28

903

12723

21863

10.04

20.07

9221

9446

6734

3372

14952

378

80.7

304

138

71.0

138

28

949

10008

16639

10.04

20.07

9895

10137

7189

2285

10130

271

54.8

218

136

49.1

136

28

986

7001

11336

10.04

20.07

g/bhp-hr

g/bhp-hr

g/bhp-hr

g/bhp-hr

g/bhp-hr

g/bhp-hr

g/bhp-hr

% DRY

0.50

4.22

5.63

0.85

0.56

0.42

747

8.8

1.68

0.50

4.35

6.37

0.96

0.64

0.43

773

8.5

1.64

0.50

4.49

7.49

1.12

0.75

0.43

794

8.4

1.55

188925

23554

6013

6995

67379

42685

5446

6176

1977

135157

22109

4823

6197

48302

30884

7

3904

1977

ENGINE DATA

GENSET FUEL CONSUMPTION

GENSET FUEL CONSUMPTION

ENGINE FUEL CONSUMPTION

AIR FLOW (77F, 14.7 psia)

AIR FLOW

FUEL FLOW (60F, 14.7 psia)

COMPRESSOR OUT PRESSURE

COMPRESSOR OUT TEMPERATURE

AFTERCOOLER AIR OUT TEMPERATURE

INLET MAN. PRESSURE

INLET MAN. TEMPERATURE

TIMING

EXHAUST TEMPERATURE - ENGINE OUTLET

EXHAUST GAS FLOW (@engine outlet temp, 14.5 psia)

EXHAUST GAS MASS FLOW

MAX INLET RESTRICTION

MAX EXHAUST RESTRICTION

(ISO 3046/1)

(NOMINAL)

(NOMINAL)

(WET)

(WET)

(MEASURED IN PLENUM)

(WET)

(WET)

(8)

(9)

(10)

(11)

(12)

(12)

(13)

(13)

EMISSIONS DATA - ENGINE OUT

NOx (as NO2)

CO

THC (mol. wt. of 15.84)

NMHC (mol. wt. of 15.84)

NMNEHC (VOCs) (mol. wt. of 15.84)

HCHO (Formaldehyde)

CO2

EXHAUST OXYGEN

LAMBDA

(14)(15)

(14)(16)

(14)(16)

(14)(16)

(14)(16)(17)

(14)(16)

(14)(16)

(14)(18)

(14)(18)

ENERGY BALANCE DATA

LHV INPUT

HEAT REJECTION TO JACKET WATER (JW)

HEAT REJECTION TO ATMOSPHERE

HEAT REJECTION TO LUBE OIL (OC)

HEAT REJECTION TO EXHAUST (LHV TO 77F)

HEAT REJECTION TO EXHAUST (LHV TO 350F)

HEAT REJECTION TO A/C - STAGE 1 (1AC)

HEAT REJECTION TO A/C - STAGE 2 (2AC)

PUMP POWER

(19)

(20)(28)

(21)

(22)(29)

(23)(24)

(23)

(25)(28)

(26)(29)

(27)

Btu/min

Btu/min

Btu/min

Btu/min

Btu/min

Btu/min

Btu/min

Btu/min

Btu/min

243312

29209

7210

7791

80268

48523

13344

8435

1977

CONDITIONS AND DEFINITIONS

Engine rating obtained and presented in accordance with ISO 3046/1. (Standard reference conditions of 77F, 29.60 in Hg barometric pressure.) No overload permitted at rating

shown. Consult the altitude deration factor chart for applications that exceed the rated altitude or temperature.

Emission levels are at engine exhaust flange prior to any after treatment. Values are based on engine operating at steady state conditions, adjusted to the specified NOx level at 100%

load. Tolerances specified are dependent upon fuel quality. Fuel methane number cannot vary more than 3.

For notes information consult page three.

Data generated by Gas Engine Rating Pro Version 4.04.00

Ref. Data Set DM5860-04-001, Printed 25Jun2013

Page 1 of 4

GAS ENGINE TECHNICAL DATA

G3520C

FUEL USAGE GUIDE

CAT METHANE NUMBER

SET POINT TIMING

DERATION FACTOR

110

120

130

140

150

24

26

28

30

ALTITUDE DERATION FACTORS AT RATED SPEED

INLET

AIR

TEMP

F

130

120

110

100

90

80

70

60

50

0.96

0.93

0.89

0.86

0.83

0.79

0.76

0.73

0.70

0.68

0.65

0.62

0.60

0.98

0.94

0.91

0.87

0.84

0.81

0.78

0.75

0.72

0.69

0.66

0.64

0.61

0.96

0.92

0.89

0.85

0.82

0.79

0.76

0.73

0.70

0.67

0.65

0.62

0.98

0.94

0.90

0.87

0.84

0.80

0.77

0.74

0.71

0.69

0.66

0.63

0.99

0.96

0.92

0.89

0.85

0.82

0.79

0.76

0.73

0.70

0.67

0.64

0.97

0.94

0.90

0.87

0.83

0.80

0.77

0.74

0.71

0.68

0.65

0.99

0.96

0.92

0.88

0.85

0.82

0.79

0.75

0.72

0.69

0.67

0.97

0.94

0.90

0.87

0.83

0.80

0.77

0.74

0.71

0.68

0.99

0.96

0.92

0.88

0.85

0.82

0.78

0.75

0.72

0.69

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

11000

12000

ALTITUDE (FEET ABOVE SEA LEVEL)

AFTERCOOLER HEAT REJECTION FACTORS

(ACHRF)

INLET

AIR

TEMP

F

130

120

110

100

90

80

70

60

50

1.33

1.37

1.39

1.39

1.39

1.39

1.39

1.39

1.39

1.39

1.39

1.39

1.39

1.26

1.31

1.33

1.33

1.33

1.33

1.33

1.33

1.33

1.33

1.33

1.33

1.33

1.19

1.24

1.26

1.26

1.26

1.26

1.26

1.26

1.26

1.26

1.26

1.26

1.26

1.13

1.17

1.19

1.19

1.19

1.19

1.19

1.19

1.19

1.19

1.19

1.19

1.19

1.06

1.11

1.13

1.13

1.13

1.13

1.13

1.13

1.13

1.13

1.13

1.13

1.13

1.04

1.06

1.06

1.06

1.06

1.06

1.06

1.06

1.06

1.06

1.06

1.06

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

11000

12000

ALTITUDE (FEET ABOVE SEA LEVEL)

Data generated by Gas Engine Rating Pro Version 4.04.00

Ref. Data Set DM5860-04-001, Printed 25Jun2013

Page 2 of 4

G3520C

GAS ENGINE TECHNICAL DATA

FUEL USAGE GUIDE:

This table shows the derate factor and full load set point timing required for a given fuel. Note that deration and set point timing reduction may be required as the methane number

decreases. Methane number is a scale to measure detonation characteristics of various fuels. The methane number of a fuel is determined by using the Caterpillar methane number

calculation program.

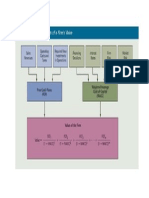

ALTITUDE DERATION FACTORS:

This table shows the deration required for various air inlet temperatures and altitudes. Use this information along with the fuel usage guide chart to help determine actual engine power for

your site.

ACTUAL ENGINE RATING:

To determine the actual rating of the engine at site conditions, one must consider separately, limitations due to fuel characteristics and air system limitations. The Fuel Usage Guide

deration establishes fuel limitations. The Altitude/Temperature deration factors and RPC (reference the Caterpillar Methane Program) establish air system limitations. RPC comes into

play when the Altitude/Temperature deration is less than 1.0 (100%). Under this condition, add the two factors together. When the site conditions do not require an Altitude/

Temperature derate (factor is 1.0), it is assumed the turbocharger has sufficient capability to overcome the low fuel relative power, and RPC is ignored. To determine the actual power

available, take the lowest rating between 1) and 2).

1) Fuel Usage Guide Deration

2) 1-((1-Altitude/Temperature Deration) + (1-RPC))

AFTERCOOLER HEAT REJECTION FACTORS(ACHRF):

To maintain a constant air inlet manifold temperature, as the inlet air temperature goes up, so must the heat rejection. As altitude increases, the turbocharger must work harder to

overcome the lower atmospheric pressure. This increases the amount of heat that must be removed from the inlet air by the aftercooler. Use the aftercooler heat rejection factor (ACHRF)

to adjust for inlet air temp and altitude conditions. See notes 28 and 29 for application of this factor in calculating the heat exchanger sizing criteria. Failure to properly account for these

factors could result in detonation and cause the engine to shutdown or fail.

INLET AND EXHAUST RESTRICTIONS FOR ALTITUDE CAPABILITY:

The altitude derate chart is based on the maximum inlet and exhaust restrictions provided on page 1. Contact factory for restrictions over the specified values. Heavy Derates for higher

restrictions will apply.

NOTES:

1. Generator efficiencies, power factor, and voltage are based on standard generator. [Genset Power (ekW) is calculated as: Engine Power (bkW) x Generator Efficiency], [Genset Power

(kVA) is calculated as: Engine Power (bkW) x Generator Efficiency / Power Factor]

2. Rating is with two engine driven water pumps. Tolerance is (+)3, (-)0% of full load.

3. ISO 3046/1 Genset efficiency tolerance is (+)0, (-)5% of full load % efficiency value based on a 1.0 power factor.

4. Thermal Efficiency is calculated based on energy recovery from the jacket water, 1st stage aftercooler, and exhaust to 350F with engine operation at ISO 3046/1 Genset Efficiency,

and assumes unburned fuel is converted in an oxidation catalyst.

5. Total efficiency is calculated as: Genset Efficiency + Thermal Efficiency. Tolerance is 10% of full load data.

6. ISO 3046/1 Genset fuel consumption tolerance is (+)5, (-)0% of full load data. Nominal genset and engine fuel consumption tolerance is 2.5% of full load data.

7. Air flow value is on a 'wet' basis. Flow is a nominal value with a tolerance of 5 %.

8. Inlet manifold pressure is a nominal value with a tolerance of 5 %.

9. Inlet manifold temperature is a nominal value with a tolerance of 9F.

10. Timing indicated is for use with the minimum fuel methane number specified. Consult the appropriate fuel usage guide for timing at other methane numbers.

11. Exhaust temperature is a nominal value with a tolerance of (+)63F, (-)54F.

12. Exhaust flow value is on a 'wet' basis. Flow is a nominal value with a tolerance of 6 %.

13. Inlet and Exhaust Restrictions are maximum allowed values at the corresponding loads. Increasing restrictions beyond what is specified will result in a significant engine derate.

14. Emissions data is at engine exhaust flange prior to any after treatment.

15. NOx tolerances are 18% of specified value.

16. CO, CO2, THC, NMHC, NMNEHC, and HCHO values are "Not to Exceed" levels. THC, NMHC, and NMNEHC do not include aldehydes.

17. VOCs - Volatile organic compounds as defined in US EPA 40 CFR 60, subpart JJJJ

18. Exhaust Oxygen tolerance is 0.5; Lambda tolerance is 0.05. Lambda and Exhaust Oxygen level are the result of adjusting the engine to operate at the specified NOx level.

19. LHV rate tolerance is 2.5%.

20. Heat rejection to jacket water value displayed includes heat to jacket water alone. Value is based on treated water. Tolerance is 10% of full load data.

21. Heat rejection to atmosphere based on treated water. Tolerance is 50% of full load data.

22. Lube oil heat rate based on treated water. Tolerance is 20% of full load data.

23. Exhaust heat rate based on treated water. Tolerance is 10% of full load data.

24. Heat rejection to exhaust (LHV to 77F) value shown includes unburned fuel and is not intended to be used for sizing or recovery calculations.

25. Heat rejection to A/C - Stage 1 based on treated water. Tolerance is 5% of full load data.

26. Heat rejection to A/C - Stage 2 based on treated water. Tolerance is 5% of full load data.

27. Pump power includes engine driven jacket water and aftercooler water pumps. Engine brake power includes effects of pump power.

28. Total Jacket Water Circuit heat rejection is calculated as: (JW x 1.1) + (1AC x 1.05) + [0.9 x (1AC + 2AC) x (ACHRF - 1) x 1.05]. Heat exchanger sizing criterion is maximum

circuit heat rejection at site conditions, with applied tolerances. A cooling system safety factor may be multiplied by the total circuit heat rejection to provide additional margin.

29. Total Second Stage Aftercooler Circuit heat rejection is calculated as: (OC x 1.2) + (2AC x 1.05) + [(1AC + 2AC) x 0.1 x (ACHRF - 1) x 1.05]. Heat exchanger sizing criterion is

maximum circuit heat rejection at site conditions, with applied tolerances. A cooling system safety factor may be multiplied by the total circuit heat rejection to provide additional margin.

Data generated by Gas Engine Rating Pro Version 4.04.00

Ref. Data Set DM5860-04-001, Printed 25Jun2013

Page 3 of 4

GAS ENGINE TECHNICAL DATA

G3520C

FREE FIELD MECHANICAL & EXHAUST NOISE

MECHANICAL: Sound Power (1/3 Octave Frequencies)

Gen Power

Without Fan

ekW

1600

1200

800

Percent

Load

%

100

75

50

Engine

Power

bhp

2242

1683

1128

Overall

dB(A)

116.6

115.5

113.7

100 Hz

dB(A)

77.2

76.3

73.8

125 Hz

dB(A)

87.0

84.2

81.0

160 Hz

dB(A)

87.7

84.9

80.4

200 Hz

dB(A)

90.3

88.9

87.2

250 Hz

dB(A)

96.5

93.3

90.5

315 Hz

dB(A)

98.1

97.2

93.2

400 Hz

dB(A)

98.9

94.3

92.4

500 Hz

dB(A)

101.2

99.0

98.1

630 Hz

dB(A)

93.8

92.5

90.5

800 Hz

dB(A)

102.6

100.8

99.6

1.6 kHz

dB(A)

108.6

105.7

104.2

2 kHz

dB(A)

105.5

104.3

105.6

2.5 kHz

dB(A)

103.2

101.2

99.7

3.15 kHz

dB(A)

102.6

101.1

100.1

4 kHz

dB(A)

101.3

100.1

98.8

5 kHz

dB(A)

101.0

100.1

98.9

6.3 kHz

dB(A)

101.1

100.7

102.7

8 kHz

dB(A)

106.1

110.6

98.0

10 kHz

dB(A)

109.8

99.2

95.2

125 Hz

dB(A)

98.1

96.7

95.0

160 Hz

dB(A)

98.0

96.0

93.9

200 Hz

dB(A)

88.1

92.9

89.4

250 Hz

dB(A)

106.8

110.8

108.0

315 Hz

dB(A)

97.7

99.0

96.1

400 Hz

dB(A)

106.0

105.5

101.8

500 Hz

dB(A)

100.2

97.8

94.2

630 Hz

dB(A)

94.2

95.8

94.8

800 Hz

dB(A)

102.5

102.1

98.8

1.6 kHz

dB(A)

101.7

101.6

98.5

2 kHz

dB(A)

101.9

98.9

95.1

2.5 kHz

dB(A)

104.9

103.0

101.0

3.15 kHz

dB(A)

106.9

105.2

103.9

4 kHz

dB(A)

107.2

105.9

103.9

5 kHz

dB(A)

107.4

106.6

103.9

6.3 kHz

dB(A)

105.8

105.3

101.3

8 kHz

dB(A)

104.7

101.0

101.5

10 kHz

dB(A)

107.9

105.8

100.8

MECHANICAL: Sound Power (1/3 Octave Frequencies)

Gen Power

Without Fan

ekW

1600

1200

800

Percent

Load

%

100

75

50

Engine

Power

bhp

2242

1683

1128

1 kHz

dB(A)

107.9

107.9

108.2

1.25 kHz

dB(A)

105.6

103.4

101.3

EXHAUST: Sound Power (1/3 Octave Frequencies)

Gen Power

Without Fan

ekW

1600

1200

800

Percent

Load

%

100

75

50

Engine

Power

bhp

2242

1683

1128

Overall

dB(A)

117.6

117.1

114.8

100 Hz

dB(A)

107.2

106.8

106.3

EXHAUST: Sound Power (1/3 Octave Frequencies)

Gen Power

Without Fan

ekW

1600

1200

800

Percent

Load

%

100

75

50

Engine

Power

bhp

2242

1683

1128

1 kHz

dB(A)

100.4

97.9

94.7

1.25 kHz

dB(A)

102.1

100.9

97.6

SOUND PARAMETER DEFINITION:

Sound Power Level Data - DM8702-01

Sound power is defined as the total sound energy emanating from a source irrespective of direction or distance. Sound power level data is presented under two index headings:

Sound power level -- Mechanical

Sound power level -- Exhaust

Mechanical: Sound power level data is calculated in accordance with ISO 6798. The data is recorded with the exhaust sound source isolated.

Exhaust: Sound power level data is calculated in accordance with ISO 6798 Annex A.

Measurements made in accordance with ISO 6798 for engine and exhaust sound level only. No cooling system noise is included unless specifically indicated. Sound level data is

indicative of noise levels recorded on one engine sample in a survey grade 3 environment.

How an engine is packaged, installed and the site acoustical environment will affect the site specific sound levels. For site specific sound level guarantees, sound data collection needs

to be done on-site or under similar conditions.

Data generated by Gas Engine Rating Pro Version 4.04.00

Ref. Data Set DM5860-04-001, Printed 25Jun2013

Page 4 of 4

Você também pode gostar

- Skala Angsuran AnnuitetDocumento3 páginasSkala Angsuran Annuitetbang bebetAinda não há avaliações

- Jensen & MeckingDocumento3 páginasJensen & Meckingbang bebetAinda não há avaliações

- CVP AnalysisDocumento6 páginasCVP Analysisbang bebetAinda não há avaliações

- KPMG - Indonesian TaxDocumento13 páginasKPMG - Indonesian Taxbang bebetAinda não há avaliações

- Basics of Discounted Cash Flow ValuationDocumento11 páginasBasics of Discounted Cash Flow Valuationgagan585Ainda não há avaliações

- 11 SureshKolamalaDocumento17 páginas11 SureshKolamalaAhmad ZikriAinda não há avaliações

- Rencana Kuliah1Documento1 páginaRencana Kuliah1TamaAinda não há avaliações

- Balance-Sheet US GAAPDocumento1 páginaBalance-Sheet US GAAPvishnuAinda não há avaliações

- The Cogeneration PrincipleDocumento1 páginaThe Cogeneration Principlebang bebetAinda não há avaliações

- Capital BudgetingDocumento50 páginasCapital Budgetingbang bebetAinda não há avaliações

- FCFEDocumento7 páginasFCFEbang bebetAinda não há avaliações

- Firm's ValueDocumento1 páginaFirm's Valuebang bebetAinda não há avaliações

- Finance and Accounting ManagerDocumento3 páginasFinance and Accounting Managerbang bebetAinda não há avaliações

- Financial Model - InfrastructureDocumento5 páginasFinancial Model - Infrastructurebang bebetAinda não há avaliações

- Financial Model - InfrastructureDocumento5 páginasFinancial Model - Infrastructurebang bebetAinda não há avaliações

- Coal Conversion FactsDocumento2 páginasCoal Conversion FactsJagadish PatraAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Mis Ce2201Documento2 páginasMis Ce2201Ashan ShamikaAinda não há avaliações

- HYDRAULICS Day 1Documento13 páginasHYDRAULICS Day 1Gerald OrtizAinda não há avaliações

- Clutches & Brakes PDFDocumento75 páginasClutches & Brakes PDFSHAMANAND TELIAinda não há avaliações

- 2.2.34. Thermal Analysis: Temperature Calibration. It Can Be Performed Using CertifiedDocumento3 páginas2.2.34. Thermal Analysis: Temperature Calibration. It Can Be Performed Using CertifiedDaniela PopaAinda não há avaliações

- B.sc. Electronics Honours SyllabusDocumento10 páginasB.sc. Electronics Honours Syllabussiddhartharay007Ainda não há avaliações

- (2023) Design, Flow Characteristics and Performance Evaluation of Bioinspired Heat Exchangers Based On Triply Periodic Minimal SurfacesDocumento13 páginas(2023) Design, Flow Characteristics and Performance Evaluation of Bioinspired Heat Exchangers Based On Triply Periodic Minimal Surfaces오지윤Ainda não há avaliações

- Atmospheric, Oceanic and Terrestrial Processes (Lec3)Documento32 páginasAtmospheric, Oceanic and Terrestrial Processes (Lec3)kiedd_04100% (1)

- Chapter 2: Earth in SpaceDocumento75 páginasChapter 2: Earth in SpaceKen AguilaAinda não há avaliações

- Doctoral Thesis by S ChaterjeeDocumento159 páginasDoctoral Thesis by S ChaterjeeSaikat ChaterjeeAinda não há avaliações

- TK-ALCOZAP-2020-01-06-Rev. DDocumento65 páginasTK-ALCOZAP-2020-01-06-Rev. DDaniel Gómez100% (1)

- 6.fluid Mechanics-1-10Documento10 páginas6.fluid Mechanics-1-10Vijeesh VijayalayamAinda não há avaliações

- Maxifloor MFT 323 SL Epoxy CoatingDocumento2 páginasMaxifloor MFT 323 SL Epoxy CoatinganggaAinda não há avaliações

- The University of Calgary: Schulich School of EngineeringDocumento9 páginasThe University of Calgary: Schulich School of EngineeringAzizi3ameelAinda não há avaliações

- Gear SystemDocumento57 páginasGear SystemWilson LimAinda não há avaliações

- AcetophenoneDocumento1 páginaAcetophenoneDinda Melissa ArdiAinda não há avaliações

- DPP (Not Distributed)Documento28 páginasDPP (Not Distributed)Raju SinghAinda não há avaliações

- Ra 51350Documento32 páginasRa 51350lcandoAinda não há avaliações

- Filament-Wound "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) PipeDocumento6 páginasFilament-Wound "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) PipeShaker QaidiAinda não há avaliações

- Designand Performanceof Soft Ground Improvement Using PVDwithandwithout Vacuum ConsolidationDocumento17 páginasDesignand Performanceof Soft Ground Improvement Using PVDwithandwithout Vacuum ConsolidationShadabAinda não há avaliações

- RSXYP16 30KJY1 SiE00 07 Part 1 - Service Manuals - EnglishDocumento193 páginasRSXYP16 30KJY1 SiE00 07 Part 1 - Service Manuals - EnglishghenceaAinda não há avaliações

- Verify Laws of Illumination Lab - IDocumento2 páginasVerify Laws of Illumination Lab - ISK ASHIKAinda não há avaliações

- Chiller Carrier 30XA-400Documento26 páginasChiller Carrier 30XA-400EdwinRamirezAinda não há avaliações

- PHY131 - Tutorial 1Documento3 páginasPHY131 - Tutorial 1ieyaaaAinda não há avaliações

- 2005-021 MotwaniDocumento6 páginas2005-021 Motwanialexander100% (1)

- Lectures On Quantum Mechanics For Mathematics Students Student Mathematical LibraryDocumento124 páginasLectures On Quantum Mechanics For Mathematics Students Student Mathematical LibrarywillmateAinda não há avaliações

- Ip21 Hw10 SolDocumento4 páginasIp21 Hw10 Sol吳昭亮Ainda não há avaliações

- Heat Exchangers-Principles and Design Rev1 PDFDocumento68 páginasHeat Exchangers-Principles and Design Rev1 PDFroyAinda não há avaliações

- Galvanic Cell Notation and Half-Cell PotentialsDocumento3 páginasGalvanic Cell Notation and Half-Cell PotentialsAngates1Ainda não há avaliações

- Physics 12 - Vector Kinematics Practice Test KeyDocumento4 páginasPhysics 12 - Vector Kinematics Practice Test KeyAnna Marthea VeronichaAinda não há avaliações

- Semiconductor Assembly ProcessDocumento22 páginasSemiconductor Assembly Processlabacahin100% (1)