Escolar Documentos

Profissional Documentos

Cultura Documentos

Basf Sharontan 101216215349 Phpapp01

Enviado por

Soyeb HassanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Basf Sharontan 101216215349 Phpapp01

Enviado por

Soyeb HassanDireitos autorais:

Formatos disponíveis

BASF Textile Chemicals

Putting *FUTURE into Textiles.

Green Textile Operations

Bangkok

17 November 2010

Prepared by Sharon Tan

Textile Chemicals Putting FUTURE into Textiles.

Strong tradition

1865

1900

1925

1950

1975

2000

2004

2008

2009

CIBA ACQUISITION

BASF SE

THE CHEMICAL COMPANY

FROM LUDWIGSHAFEN TO THE WORLD

NEW BEGINNING AND PLASTICS AGE

NEW HIGH-PRESSURE SYNTHESES

THE AGE OF FERTILIZERS

THE AGE OF DYES

FOUNDING OF BASF

November 2010

Slide 2

Textile Chemicals Putting FUTURE into Textiles.

Organization of the BASF Group

6 business segments contain 14 operating divisions which bear the

operational responsibility and manage 72 global and regional business units

These in turn develop strategies for 80 product lines

Regional divisions contribute to the local development of BASFs business

and are responsible for optimizing the infrastructure

3 central divisions, 5 corporate departments and 9 Competence Centers

provide Group-wide services

November 2010

Slide 3

Textile Chemicals Putting FUTURE into Textiles.

Performance

Products

Functional

Solutions

Agricultural

Solutions

Oil & Gas

Inorganics

Performance

Polymers

Dispersions

& Pigments

Catalysts

Crop Protection

Oil & Gas

Petrochemicals

Polyurethanes

Care Chemicals

Construction

Chemicals

Paper Chemicals

Coatings

Chemicals

Plastics

BASF Segments

Intermediates

Performance

Chemicals

November 2010

Slide 4

Textile Chemicals Putting FUTURE into Textiles.

BASF: future-oriented partner of the textile

industry

Textile Expertise: for over 140 years since the foundation of BASF,

we have been a committed partner for the textile industry.

Sustainable Development: consumer safety and environmental

protection are our top priorities when developing new products or

solutions.

Shape the Future: continue shaping the future of the textile industry

together with our customers.

Putting *FUTURE into Textiles.

What does FUTURE mean for us today?

Consumer Safety, Resource Saving and Climate Protection: we find it

important to concentrate even more on these key fields of ecology to be ready

for future challenges.

November 2010

Slide 5

Textile Chemicals Putting FUTURE into Textiles.

Textile Chemicals

Putting *FUTURE into Textiles.

Consumer Safety

Resource Saving

Climate Protection

Commitment to shaping the future of the textile industry

November 2010

Slide 6

focusing on 3 key areas of ecology

Textile Chemicals Putting FUTURE into Textiles.

Textile Expertise

Innovative and eco-efficient solutions

Weaving

Pretreatment

Waxes

Sizing

products

November 2010

Detergents

Wetting agents

Extracting agents

Peroxide killer

Slide 7

Dyeing

Levelling agents

Oxidizing agents

Stripping agents

Optical brighteners

Printing

Printing binders

Pigments

Synth. thickeners

Emulsifiers

Finishing /

Coating

Resins

Catalysts

Softeners

Repellents

Coating compounds

Textile Chemicals Putting FUTURE into Textiles.

Putting *FUTURE into textiles

Consumer Safety

Resource Saving

Climate Protection

November 2010

Slide 8

Textile Chemicals Putting FUTURE into Textiles.

Ever thought about hazardous substances

a textile could contain?

Some of the substances

under discussion:

Phthalates

Azo dyes components

Pesticides

APEO

PVC

Allergenic Dyes

Formaldehyde

Biocides

November 2010

Slide 9

Textile Chemicals Putting FUTURE into Textiles.

Human Safety

Support from BASF

Standardized communication

Label on container

Safety data sheet

Technical information sheet

Product specifications

Transfer of application know-how

Technical service

Training

Correct and safe use

of chemicals

November 2010

Slide 10

Textile Chemicals Putting FUTURE into Textiles.

Human Safety

Support from BASF

Textile chemicals

compliant with regulations

compliant to *RSL

Monitoring of changes in legal

requirements and standards

Consultancy for customers

Frontrunner in R&D

Ecologically sound

product portfolio

November 2010

Slide 11

*Restricted substances lists

Textile Chemicals Putting FUTURE into Textiles.

Human safety

Formaldehyde

*IARC classification of formaldehyde being

carcinogenic to

humans (2004)

Oekotex 100 Standard lowered threshold for formaldehyde on

baby-wear to non detectable level (2008)

ECHA intends to classify formaldehyde as carcinogenic

More restrictions from legislation and retailers expected

* IARC = International Agency for Research on Cancer

**ECHA = European Chemical Agency

November 2010

Slide 12

Textile Chemicals Putting FUTURE into Textiles.

Putting *FUTURE into textiles

Consumer safety

BASF

is familiar with

current legal requirements

retailer needs

is continuously screening its

products to those standards and

adapts its portfolio accordingly

BASF helps you to avoid claims!

November 2010

Slide 13

Textile Chemicals Putting FUTURE into Textiles.

Putting *FUTURE into textiles

Consumer Safety

Resource Saving

Climate Protection

November 2010

Slide 14

Textile Chemicals Putting FUTURE into Textiles.

After-soaping agent Cyclanon X-CW new

Mode of action

Hydrolyzed

Reactive Dye

Soaping liquor

+

Cyclanon XC-W

9 Dyes are kept in

the soaping

liquor.

9 Thus the dyed

material is easily

cleaned

Salt, pH

Hydrolyzed

Reactive Dye

November 2010

Slide 15

Textile Chemicals Putting FUTURE into Textiles.

Application profile full shade

Total dyeing process

Process Time:

Saving of

40 minutes

Temp ( C)

With Cyclanon XC-W new

1

120

100

80

60

40

20

0

3,4

6

Cyclanon XC-W

1. Kieralon Jet B conc 1,0 %owf

Sodium Carbonate

0,5 g/l

Resource Saving:

2. Acetic Acid

3. Common Salt

Conventional

process

120

100

80

60

40

20

0

100

3,4

- 40 min

200

- 12 %

5

9%

50,0 g/l

4. Dyestuff

each 4 %

less process

time

300

400

500

Proxion Brill. Red H-EXL

Proxion Yellow H-EXL

less water consumption

Proxion Blue H-EXL

7

less energy consumption

5. Sodium Carbonate 20,0 g/l

(Dose 20 min.)

Temp ( C)

November 2010

1,0 g/l

6. Cyclanon XC-W new1,0 g/l

7. Surfactant

Slide 16

100

200

300

Time (minutes)

400

500

1,0 g/l

600

Textile Chemicals Putting FUTURE into Textiles.

Cost analysis full shade

Costs in Euro per batch (= 100 kg)

Total dyeing process

Total:

255

300

Total:

241

84

200

74

19

10

15

17

12

13

100

120

120

November 2010

Slide 17

Classical

process

Process based on

Cyclanon XC-W new

Fixed

Labour

Water

Chemicals

Energy

Dyes

Textile Chemicals Putting FUTURE into Textiles.

BASF technologies for resource savings

Pigment coloration systems

X Eco-Soft Printing, Color Fast Finish

Intelligent after-washing systems

X Cyclanon ECO Plus, Cyclanon X-CW NEW

Combining process steps

X Redex-Bleach, Palatex X-SD, Kieralon Antiperox PK

Recycling technologies

X Size recovery systems

Low temperature processes

X Ultraphor OBAs, BASF AP-Finish and

Fixapret resin LT

November 2010

Slide 18

Textile Chemicals Putting FUTURE into Textiles.

Putting *FUTURE into textiles

Resource saving

BASF

offers latest technologies based on

new chemical solutions

Supports its customers with

technical know-how to optimize

their production processes and

benchmark them with international

standards

BASF helps you saving costs!

November 2010

Slide 19

Textile Chemicals Putting FUTURE into Textiles.

Putting *FUTURE into textiles

Consumer Safety

Resource Saving

Climate Protection

November 2010

Slide 20

Textile Chemicals Putting FUTURE into Textiles.

Ever thought a textile could have an

impact on global warming?

Are there *GHG

emissions from

my textile?

November 2010

Slide 21

*GHG = Greenhouse-gas

Textile Chemicals Putting FUTURE into Textiles.

Global climate change

background

The phenomena of Global Warming and its possible influence

on the worlds climate is omnipresent in media around the world

Carbon dioxide (CO2) is one of the identified greenhouse gases

and considered to be the main contributor to global warming

( CO2 measured in carbon footprint )

Meanwhile politicians continue discussing causes and

consequences of CO2 emission, various enterprises have set-up

teams to develop strategies for potential CO2 emission reduction

programs

Various textile retailer/brands start analyzing their organizational

impact on global warming and defined reduction targets

November 2010

Slide 22

Textile Chemicals Putting FUTURE into Textiles.

Carbon Footprint Definition

Quantitative measure of the impact human activities have on Global Warming

in terms of the amount of green house gases produced

Carbon footprint is

Measured in kg CO2

Directly related emissions from energy use of fossil fuels

Assessed over the lifecycle of a operation, service or product

Carbon footprint is attributable to:

Individuals

November 2010

Slide 23

Organizations

Products

Textile Chemicals Putting FUTURE into Textiles.

Cotton T-Shirt

Production optimization

November 2010

Slide 24

Textile Chemicals Putting FUTURE into Textiles.

Cotton T-shirt

reduction of *GHG emission

g CO2 equivalent/T-Shirt

800

700

720 g CO2

- 9 % 650 g CO2

600

Aftersoaping

500

400

Neutralization

300

200

Reactive

Dyeing

100

0

Conventional process

Aftersoaping with XCW

Resource Saving:

- 40 min less process time

- 12% less water consumption

November 2010

Slide 25

* GHG = Greenhouse gas

Textile Chemicals Putting FUTURE into Textiles.

Putting *FUTURE into textiles

Climate protection

BASF

Detects market and industry trends

in an early stage

Together with its customers tries

to understand the impact textile

industry has on Climate Change

BASF supports you to be a

frontrunner in innovative topics!!

November 2010

Slide 26

Textile Chemicals Putting FUTURE into Textiles.

Putting *FUTURE into Textiles.

Thank you for your attention

Consumer Safety

November 2010

Slide 27

Resource Saving

Climate Protection

BASF Textile Chemicals

Putting *FUTURE into Textiles.

28

Textile Chemicals Putting FUTURE into Textiles.

Note:

The data contained in this publication are based on our current knowledge and experience. In view of the

many factors that may affect processing and application of our product, these data do not relieve

processors from carrying out their own investigations and tests; neither do these data imply any guarantee

of certain properties, nor the suitability of the product for a specific purpose. Any descriptions drawings,

photographs, data, proportions, weights, etc. given herein may change without prior information and do not

constitute the agreed contractual quality of the product. It is the responsibility of the recipient of our

products to ensure that any proprietary rights and existing laws and legislation are observed. Responsibility

for compliance with the requirements of the downstream textile market rests with the textile processor.

November 2010

Slide 29

Você também pode gostar

- Nternational Ournal of Ngineering Ciences & Esearch EchnologyDocumento7 páginasNternational Ournal of Ngineering Ciences & Esearch EchnologyAdnan PervaizAinda não há avaliações

- CilDocumento18 páginasCilRobby Setiabudi TjangAinda não há avaliações

- ZZZ ZZZDocumento11 páginasZZZ ZZZNghia Phan TrungAinda não há avaliações

- Issue Report For Requisition September 2020-2Documento11 páginasIssue Report For Requisition September 2020-2shironum hinAinda não há avaliações

- Archroma Passion For Printing 190606 NewDocumento10 páginasArchroma Passion For Printing 190606 NewSUDIPTA KARAinda não há avaliações

- Lava Soft MEC PDFDocumento4 páginasLava Soft MEC PDFSanakurinAinda não há avaliações

- Synozol Ultra Orange DS (Ver 1.0)Documento4 páginasSynozol Ultra Orange DS (Ver 1.0)Phan Van ThanhAinda não há avaliações

- Sera Merc C-MNFDocumento9 páginasSera Merc C-MNFRafiqul AlamAinda não há avaliações

- Alkasil SE PDFDocumento2 páginasAlkasil SE PDFmd.ziaul hasanAinda não há avaliações

- Corafix Jet Black GDRDocumento3 páginasCorafix Jet Black GDRDHRUVAinda não há avaliações

- BASF Auxiliaries For Textile PrintingDocumento12 páginasBASF Auxiliaries For Textile PrintingjosefAinda não há avaliações

- Leatex-Shunsol RHDocumento1 páginaLeatex-Shunsol RHDyeing DyeingAinda não há avaliações

- Epple - MSDS - RED 131758Documento7 páginasEpple - MSDS - RED 131758Annie KasAinda não há avaliações

- Novacron Navy W-BDocumento18 páginasNovacron Navy W-BKarim GaberAinda não há avaliações

- Matexil Dadlp Msds 0013Documento4 páginasMatexil Dadlp Msds 0013psivakumar menakamillsAinda não há avaliações

- Rifacophor Byb Conc. 400%: Special PropertiesDocumento4 páginasRifacophor Byb Conc. 400%: Special Propertieshamidrahmany3657Ainda não há avaliações

- Sapamine: SEW Textile SoftenerDocumento5 páginasSapamine: SEW Textile SoftenersaskoAinda não há avaliações

- Stabilol PDocumento2 páginasStabilol PMuhammad Aasim HassanAinda não há avaliações

- INVENTORY CHECK For HIGG 2020Documento7 páginasINVENTORY CHECK For HIGG 2020Dyeing Dyeing100% (1)

- Effects of Salt On Dyeing of Cotton Fabric With Different Types of Reactive DyesDocumento6 páginasEffects of Salt On Dyeing of Cotton Fabric With Different Types of Reactive Dyesahmed samirAinda não há avaliações

- Office Code: (All Column Values)Documento2 páginasOffice Code: (All Column Values)samrat_77Ainda não há avaliações

- Tanede RFH-B: Environmentally Friendly Reduction Clearing AgentDocumento3 páginasTanede RFH-B: Environmentally Friendly Reduction Clearing Agentangee paolaAinda não há avaliações

- Carpet Brochure 2 POLYAMIDE Single PagesDocumento16 páginasCarpet Brochure 2 POLYAMIDE Single PagesNguyễn Huy CườngAinda não há avaliações

- Garmon 2022Documento2 páginasGarmon 2022Mahadi Hassan TusherAinda não há avaliações

- ListDocumento65 páginasListtuhin mollaAinda não há avaliações

- Perrustol Vno New - eDocumento2 páginasPerrustol Vno New - eNghia Phan TrungAinda não há avaliações

- Regester Chemical ListDocumento9 páginasRegester Chemical ListHassaan MansoorAinda não há avaliações

- Antistain RDL 2 - SDSDocumento10 páginasAntistain RDL 2 - SDSchoton_iii0% (1)

- Bozzetto ZDHCDocumento7 páginasBozzetto ZDHCEngr Zulfiqar NagoriAinda não há avaliações

- Softner Compatibility TestDocumento8 páginasSoftner Compatibility TestDyeing DyeingAinda não há avaliações

- Garmon 2022.............Documento9 páginasGarmon 2022.............Mahadi Hassan TusherAinda não há avaliações

- Brochure ZytexDocumento12 páginasBrochure ZytexKinjal PatelAinda não há avaliações

- NICCA CHEMICAL Group - Commitment To The Zero Discharge of Hazardous Chemicals Manufacturing Restricted Substances List - Ver.2.7Documento15 páginasNICCA CHEMICAL Group - Commitment To The Zero Discharge of Hazardous Chemicals Manufacturing Restricted Substances List - Ver.2.7Md. Siddiqur RahmanAinda não há avaliações

- ByravDocumento18 páginasByravHarun VenkatAinda não há avaliações

- Zyperse DLS: Dispersing, Leveling and Soaping AgentDocumento4 páginasZyperse DLS: Dispersing, Leveling and Soaping AgentVinod ShelkeAinda não há avaliações

- Resil GarmentsbrochureDocumento16 páginasResil GarmentsbrochureSupriya NandaAinda não há avaliações

- CatalogDocumento60 páginasCatalogmatakelAinda não há avaliações

- Synozol RED HF 3B Synozol Yellow K3RS Synozol RED K3BSDocumento10 páginasSynozol RED HF 3B Synozol Yellow K3RS Synozol RED K3BStuhin mollaAinda não há avaliações

- New Dimensions of SoftnessDocumento9 páginasNew Dimensions of SoftnessEugene PaiAinda não há avaliações

- Dyeing CalculationDocumento4 páginasDyeing CalculationIftakharul IslamAinda não há avaliações

- Adalin 4791-2Documento3 páginasAdalin 4791-2Muhammad Aasim HassanAinda não há avaliações

- Sandoclean LFDI LiqDocumento2 páginasSandoclean LFDI Liqriqpwri1120% (1)

- AlbatexdsiDocumento6 páginasAlbatexdsiShahzad Raza100% (1)

- Effects of Chemical Structure of Silicone Polyethers Used As Fabric Softener Additives On Selected Utility Properties of Cotton FabricDocumento7 páginasEffects of Chemical Structure of Silicone Polyethers Used As Fabric Softener Additives On Selected Utility Properties of Cotton FabricMubashir ZulfiqarAinda não há avaliações

- Coralene Red Xfbn-NondgDocumento3 páginasCoralene Red Xfbn-NondgAdnan PervaizAinda não há avaliações

- Novacron Yellow F-4GDocumento9 páginasNovacron Yellow F-4GDINAAinda não há avaliações

- GOTS 6.0 Positive List 6 Pulcra GMBHDocumento7 páginasGOTS 6.0 Positive List 6 Pulcra GMBHNirjhor ShikderAinda não há avaliações

- Ecodye: Ecodye - The Dyeing RevolutionDocumento4 páginasEcodye: Ecodye - The Dyeing RevolutionRamzi HajjajiAinda não há avaliações

- Eriopon R Liq. MSDSDocumento10 páginasEriopon R Liq. MSDSraju_hosssenAinda não há avaliações

- Brij - CrodaDocumento4 páginasBrij - Crodafgsdfgsdfg50% (2)

- Section 1: Identification of The Substance/Mixture and of The Company/UndertakingDocumento7 páginasSection 1: Identification of The Substance/Mixture and of The Company/Undertakingsy mahAinda não há avaliações

- Depsolube Aca-Lq - (TH) PTT0397 GHS MSDSDocumento10 páginasDepsolube Aca-Lq - (TH) PTT0397 GHS MSDSMayank DhawanAinda não há avaliações

- Chemical Test FormedDocumento57 páginasChemical Test FormedMD Ashraful MD AshrafulAinda não há avaliações

- Resilient PretreatmentDocumento44 páginasResilient PretreatmentHrishikesh DhawadshikarAinda não há avaliações

- Pigments Dyes Product Range2015Documento29 páginasPigments Dyes Product Range2015Badre AalamAinda não há avaliações

- Optavon Mex: Highly Effective Complexing Agent of Versatile Application During All Pretreatment ProcessesDocumento2 páginasOptavon Mex: Highly Effective Complexing Agent of Versatile Application During All Pretreatment ProcessesRezoanul HaqueAinda não há avaliações

- Garment Product CatalogueDocumento24 páginasGarment Product CatalogueM.MuthumanickamAinda não há avaliações

- All-Cleaner Production in The Textile Industry, Lessons From The Danish ExperienceDocumento16 páginasAll-Cleaner Production in The Textile Industry, Lessons From The Danish ExperienceNattaya PunrattanasinAinda não há avaliações

- Guidelines and Legislation For Dye House Ef Uents: C. Hessel, C. Allegre, M. Maisseu, F. Charbit, P. MoulinDocumento10 páginasGuidelines and Legislation For Dye House Ef Uents: C. Hessel, C. Allegre, M. Maisseu, F. Charbit, P. MoulinDinesh VermaAinda não há avaliações

- An Overview of Textiles Processing and Related Environmental ConcernsDocumento31 páginasAn Overview of Textiles Processing and Related Environmental ConcernsDinesh BhirangiAinda não há avaliações

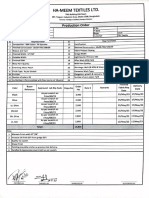

- 309 - 16,385 Yds-FK TextileDocumento1 página309 - 16,385 Yds-FK TextileSoyeb HassanAinda não há avaliações

- 006 - 1,26,000 Yds-SanjanaDocumento2 páginas006 - 1,26,000 Yds-SanjanaSoyeb HassanAinda não há avaliações

- Offer APRNO-22-05027 1Documento1 páginaOffer APRNO-22-05027 1Soyeb HassanAinda não há avaliações

- 004 4,000 Yds-ParamountDocumento2 páginas004 4,000 Yds-ParamountSoyeb HassanAinda não há avaliações

- 007 - 46,000 Yds-Sanzana LocalDocumento2 páginas007 - 46,000 Yds-Sanzana LocalSoyeb HassanAinda não há avaliações

- 0081 - 13,800 Yds-F.RDocumento1 página0081 - 13,800 Yds-F.RSoyeb HassanAinda não há avaliações

- Bpo 447 PDFDocumento1 páginaBpo 447 PDFSoyeb HassanAinda não há avaliações

- LPP ReconsilationDocumento1 páginaLPP ReconsilationSoyeb HassanAinda não há avaliações

- TYDFL Marketing ProfileDocumento1 páginaTYDFL Marketing ProfileSoyeb HassanAinda não há avaliações

- BCI Membership FormDocumento13 páginasBCI Membership FormSoyeb Hassan100% (1)

- 21SS Fabric Lead Time Chart-HoorainDocumento4 páginas21SS Fabric Lead Time Chart-HoorainSoyeb HassanAinda não há avaliações

- Monthly Delivery PlanDocumento1 páginaMonthly Delivery PlanSoyeb HassanAinda não há avaliações

- Ami Hobo Sokal Belar Pakhi Sobar Aghe Kosum Bage Utbo Ami JegeDocumento1 páginaAmi Hobo Sokal Belar Pakhi Sobar Aghe Kosum Bage Utbo Ami JegeSoyeb HassanAinda não há avaliações

- How To Find Yarn Count From Fabric GSM - KnitDocumento2 páginasHow To Find Yarn Count From Fabric GSM - KnitSoyeb HassanAinda não há avaliações

- Siemens Drive FaultDocumento249 páginasSiemens Drive Faultfendi_3606100% (1)

- Pictures of Electronic ComponentsDocumento5 páginasPictures of Electronic ComponentsSoyeb HassanAinda não há avaliações

- GSM Calculation For Woven FabricDocumento3 páginasGSM Calculation For Woven FabricSoyeb HassanAinda não há avaliações

- Old PI STGDocumento8 páginasOld PI STGSoyeb HassanAinda não há avaliações

- Tokyo Street Duty ScheduleDocumento1 páginaTokyo Street Duty ScheduleSoyeb HassanAinda não há avaliações

- Calculate Crimp Percentage of Woven FabricDocumento2 páginasCalculate Crimp Percentage of Woven FabricSoyeb HassanAinda não há avaliações

- CV Mohammad Soyeb HassanDocumento3 páginasCV Mohammad Soyeb HassanSoyeb HassanAinda não há avaliações

- S7-400 SpecificationDocumento152 páginasS7-400 Specificationmgkso706Ainda não há avaliações

- Report414-2dp Cpu ProgramDocumento1 páginaReport414-2dp Cpu ProgramSoyeb HassanAinda não há avaliações

- Siemens Drive FaultDocumento249 páginasSiemens Drive Faultfendi_3606100% (1)

- Higher Algebra - Hall & KnightDocumento593 páginasHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Making SoftwareDocumento54 páginasMaking SoftwareM Ramdhan FebrianAinda não há avaliações

- Higher Algebra - Hall & KnightDocumento593 páginasHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Pan Boiling-Methods and MechanismDocumento42 páginasPan Boiling-Methods and MechanismAkhilesh Dhar Diwedi100% (5)

- Amgen Inc. v. F. Hoffmann-LaRoche LTD Et Al - Document No. 560Documento10 páginasAmgen Inc. v. F. Hoffmann-LaRoche LTD Et Al - Document No. 560Justia.comAinda não há avaliações

- 3 Bio-Medical Waste ManagementDocumento69 páginas3 Bio-Medical Waste ManagementHarshaWakodkarAinda não há avaliações

- Damping Off DiseasesDocumento4 páginasDamping Off DiseasesCharlesAinda não há avaliações

- Electronic NoseDocumento10 páginasElectronic Noseapi-384576580% (5)

- AEL Surface Bulk Explosives 2016Documento16 páginasAEL Surface Bulk Explosives 2016DOC LABAinda não há avaliações

- Refrigeration Theory PDFDocumento48 páginasRefrigeration Theory PDFValentin LupascuAinda não há avaliações

- Wrought MetalsDocumento168 páginasWrought MetalsDr. Vikram SusilAinda não há avaliações

- Applicant Profile: A. Position For Which You Are ApplyingDocumento3 páginasApplicant Profile: A. Position For Which You Are ApplyingViệt Đặng XuânAinda não há avaliações

- JOC PeptidesDocumento14 páginasJOC PeptidesludoAinda não há avaliações

- Predicting Reservoir System AAPG 1999Documento156 páginasPredicting Reservoir System AAPG 1999anjumbukhari100% (1)

- Nasal Mucoadhesive Drug Delivery: Background, Applications, Trends and Future PerspectivesDocumento26 páginasNasal Mucoadhesive Drug Delivery: Background, Applications, Trends and Future PerspectivesEduardMartinezAinda não há avaliações

- GrindingDocumento85 páginasGrindingRevuru Srikant100% (1)

- Drinking Water MOHDocumento3 páginasDrinking Water MOHNur Amanina OmarAinda não há avaliações

- 01.03.01 Coolant TR0199-99-2091 - enDocumento18 páginas01.03.01 Coolant TR0199-99-2091 - enEhsanur Rahman100% (1)

- QuestionsDocumento5 páginasQuestionsTims WatsonsssAinda não há avaliações

- Chapter 1: Orientation To Pharmacology Test Bank: Multiple ChoiceDocumento2 páginasChapter 1: Orientation To Pharmacology Test Bank: Multiple ChoiceAnonymous kxXXVtcFwAinda não há avaliações

- CH2.2 - AlkeneDocumento48 páginasCH2.2 - AlkeneNur Ain SyuhadaAinda não há avaliações

- Ex Vivo Magnetic Resonance Imaging Using Hyaluronic Acid Fillers Differences Between Monophasic and Biphasic FillersDocumento4 páginasEx Vivo Magnetic Resonance Imaging Using Hyaluronic Acid Fillers Differences Between Monophasic and Biphasic FillersImanuel CristiantoAinda não há avaliações

- A Supplier Crater TrainingDocumento14 páginasA Supplier Crater TrainingP K Senthil KumarAinda não há avaliações

- General Chemistry 2 Asynchronous Activity 1Documento7 páginasGeneral Chemistry 2 Asynchronous Activity 1casinillojilianAinda não há avaliações

- Cracking Patterns and Ionisation EnergiesDocumento2 páginasCracking Patterns and Ionisation EnergiesWilliamRiveraAinda não há avaliações

- Work Instruction: Liquid Limit DeterminationDocumento4 páginasWork Instruction: Liquid Limit DeterminationCris LegaspiAinda não há avaliações

- Scheme of Work Science Stage 9 - 2018 - tcm143-353968Documento82 páginasScheme of Work Science Stage 9 - 2018 - tcm143-353968Arjun SrinivasanAinda não há avaliações

- CCR 3000 GTS Engine Repair ManualDocumento27 páginasCCR 3000 GTS Engine Repair ManualRicardo ChristianAinda não há avaliações

- Jis A-1102Documento17 páginasJis A-1102vu van linhAinda não há avaliações

- En10204 Certification For Steel PlatesDocumento6 páginasEn10204 Certification For Steel PlatesTree Tawee100% (1)

- Chapter 18Documento34 páginasChapter 18Sigmund PohanAinda não há avaliações

- Geopolymer Chemistry and ApplicationsDocumento1 páginaGeopolymer Chemistry and Applications6405easc0% (3)

- On Of: Final Report The Safety Assessment TEA-Lauryl SulfateDocumento25 páginasOn Of: Final Report The Safety Assessment TEA-Lauryl SulfateCarlos Gonzalez CastroAinda não há avaliações

- University of Chicago Press Fall 2009 Distributed TitlesNo EverandUniversity of Chicago Press Fall 2009 Distributed TitlesNota: 1 de 5 estrelas1/5 (1)