Escolar Documentos

Profissional Documentos

Cultura Documentos

Kollmorgen Nema23 PowermaxII Catalog

Enviado por

ElectromateDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Kollmorgen Nema23 PowermaxII Catalog

Enviado por

ElectromateDireitos autorais:

Formatos disponíveis

599-95 Step Mtrs Sel Gd.

out

11/15/00

1:44 PM

Page 39

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

POWERMAX II

All-in-one molded stator

assembly

Neodymium-iron-boron

rotor magnets

Exposed laminations aid

thermal dissipation

Integral electrical receptacle

provides high retention force of

mating connector8 flying leads

are standard option

Rugged end bell, encapsulated

windings and electrical

connector utilize high-tech

polymer

Class B insulation

New end bell runs cooler;

encoder life is enhanced

Many drive shaft

modifications available

Optional encoders and

rear shaft extensions

Precision ground rotor

OD and honed stator ID for

concentric air gap

Largest available shaft diameter

(0.375") on a NEMA 23 stepper

withstands high radial and axial

loads, supports numerous shaft

modifications

Octagonal shape simplifies

automated assembly

NEMA Size 23 mounting

POWERMAX II motors

MODEL NUMBER CODE

P

Type

P=Standard

M=Enhanced

(n/a half stack)

Size

2=NEMA 23

(2.25"across flats)

Number of Stacks

H=Half stack

1=1 Stack

2=2 Stacks

Mounting

N=NEMA

S=Special

Available Sigmax technology

adds flux concentrating samarium

cobalt stator magnets for highest

torque and acceleration

Oversized 30mm bearings

increase bearing fatigue

life (L10) 400% over typical

22mm bearings

Construction

R=Regular

S=Special

L N N

N S

Winding Type

A...per assigned letter

S=Special

Termination

X=Receptacle

F=8 Flying leads

S=Special

For X (receptacle) designation,

mating leaded connectors may

be ordered separately.

Optional GRN/YEL ground wire

available. See p. 52

Rotor Type

L=Standard

J=Low inertia

(n/a half stack)

Shaft Configuration

(Diameter & Length)

N=Single

D=Double

S=Special

0 0

Sequence Number

Insert 00 if all parts

are standard. Factory

assigned if any parts

are custom.

Encoder Option

NS=No Feedback

Use encoders below. You must specify

shaft configuration D (double ended)

Caution: An encoder with line

driver output may be

required for use with some

step motor controls.

M1=Encoder mounting provisions

HD=Encoder 500ppr

HJ=Encoder 512ppr

SS=Special, call factory

Shaft Modifications

N=Smooth

F=Flat

S=Special

The example model number above indicates a standard NEMA 23 frame motor with a one stack rotor. This motor is equipped with a standard

NEMA mount, regular construction, receptacle and an A winding. It also has a standard rotor, a smooth single-ended shaft and no encoder or

encoder mounting provisions.

HOW TO ORDER

Review the Motor Model Number Code to assure that all options are designated. Dimensions, connections and phasing diagrams start on

page 49. Encoder mounting options are on page 53.

www.pacsci.com

39

599-95 Step Mtrs Sel Gd.out

11/15/00

1:44 PM

Page 38

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

OWERMAX II sets the world

performance standard for NEMA 23

step motors. At up to 253 oz-in.

holding torque, you wont find a more

powerful two inch stepper.

With POWERMAX II you also gain

the cost advantages of design for

manufacturability (DFM) and North

Americas most advanced step motor

manufacturing line.

That makes POWERMAX II

economical without sacrificing

features - such as long life bearings,

high temperature insulation and

quality magnet materials.

Plus DFM means we can build

POWERMAX II to your specifications,

in the volumes you need, according

to your JIT or other delivery

schedule.

Standard

Standard POWERMAX II motors

come in half, single and two stacks

that provide holding torques from 42

to 253 oz-in.

POWERMAX II

FEATURES

BENEFITS

Two Year Warranty

High quality, dependable operation

New Polymer Encapsulated Stator

Exceptional thermal dissipation

New Polymer End Bell with Threaded

Inserts

End bell runs cooler, provides greater

flexibility in mounting encoder and brake

options

Largest Available Shaft Diameter on a

NEMA 23 Stepper

Withstands high radial and axial loads.

Supports numerous shaft modifications.

Oversized 30mm Bearings

Increases bearing fatigue life (L10), extends

motor life, reduces downtime

Sigmax Technology

Increases available torque

Optional Low Inertia Rotor

Produces the highest acceleration rate

possible

Optional Solid Rotor

High low speed torque, fast settling,

superior stiffness and damping

Precision Ground Rotor OD and Honed

Stator ID for Concentric Air Gap in an

Economical Motor Design

High quality performance in an economical

motor design.

Exposed Laminations Aids Thermal

Dissipation

Improved heat dissipation extends

motor life, reduces downtime.

High Performance Gearheads

Increases torque range in a reliable,

complete package

Custom

POWERMAX II proves that an

economical step motor doesnt have

to limit your options. Its just the

opposite, thanks to flexible

manufacturing.

Whether you require a simple

drive shaft flat or an integral lead

screw, POWERMAX II motors are

made to order.

38

www.pacsci.com

599-95 Step Mtrs Sel Gd.out

11/15/00

1:45 PM

Page 44

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

POWERMAX II MOTOR TECHNOLOGY

Pacific Scientific developed POWERMAX II to be the

best cost/performance value available in hybrid step

motors.

Thats why youll find so many standard

POWERMAX II models in the universal NEMA 23

frame size. With POWERMAX II, you can tailor motor

torque, acceleration and inertia to every axis of your

design. And you can do this economically too, using

a single mounting configuration and the driver of your

choice.

Does your application require that extra measure of

performance? Then consider the POWERMAX II M

Series, featuring the patented Sigmax technology.*

Samarium cobalt magnets in M Series motors

concentrate magnetic flux at desired points between

the rotor and stator. Sigmax technology optimizes flux

paths to increase torque production and current

utilization over conventional hybrid designs.

M SERIES ENHANCED HYBRID

SIGMAX TECHNOLOGY

P SERIES STANDARD HYBRID

S

Stator

Stator

Non-torque

producing flux

Rare earth magnet

inserts

Focusing flux

Torque producing

flux

Concentrated torque

producing flux

Rotor

Rotor

Patented Sigmax

technology* redirects magnetic

flux to inhibit leakage and

optimize torque production.

Typical paths of flux transfer

in an energized conventional

hybrid step motor. Some flux

leakage occurs in normal

operation.

* Sigmax technology is covered by U.S. patents

4,712,028, 4,713,470, 4,763,034 and 4,827,164.

TECHNICAL OVERVIEW

Types

POWERMAX II M Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hybrid step motors with rare earth magnets

in the stator teeth

POWERMAX II P Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hybrid step motors

Rotor construction

POWERMAX II M and P Series;

with L rotor designates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Laminated

(high speed efficiency)

POWERMAX II M and P Series;

with J rotor designates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Low mass/low inertia (fast start/stop,

high acceleration)

Windings

A, B, C, D, E, F, G . . . . . . .

Phases

......................

Full steps per revolution . . . . . . . . . . .

Full step angle . . . . . . . . . . . . . . . . . . .

Angular accuracy

POWERMAX II M and M J

POWERMAX II P and P J

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Standard winding to match any application

2

200

1.8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5% of one step, no load,

non-cumulative

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3% of one step, no load,

non-cumulative

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -20 to 40C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . NEMA Class B, 130C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 Megohms @500V dc and 25C

Operating temperature . . . . . . . . . . . . .

Insulation . . . . . . . . . . . . . . . . . . . . .

Insulation resistance . . . . . . . . . . . . . .

Shaft load ratings

Max. radial load (at center of std. shaft extension) . . . . . . . . . . . . . . . . . 20 lb.

Max. axial load (on front shaft extension toward motor) . . . . . . . . . . . . . 13 lb.

Bearing life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Since large bearings (30 mm) are used,

life is typically about 4 times that of 22 mm

or smaller bearings used on other NEMA

Size 23 motors. POWERMAX II bearing fatigue

life (L10) exceeds 10,000 hours at any rotational

speed up to 10,000 full steps/second if

operated within the max. radial and axial

loads specified above.

Encoder options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See page 53.

44

www.pacsci.com

599-95 Step Mtrs Sel Gd.out

11/15/00

1:45 PM

Page 45

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

POWERMAX II HYBRIDS

NEMA 23 FRAME (2.3")Ratings and Characteristics

Review the Model Number Code on page 39 to assure that all options are designated. Dimensions, connections and phasing diagrams are on

page 49. In addition to those below, motors with characteristics for specific performance requirements are offered. Contact factory for more details.

Torque range:

42-61 oz-in.

.29-.43 Nm

P2HNXXH-LXX-XX-00

P2HNXXH-LXX-XX-00

P2HNXXH-LXX-XX-00

STANDARD

P2H Series

1/2 rotor stack

P2HNXXB-LXX-XX-00

P2HNXXB-LXX-XX-00

P2HNXXB-LXX-XX-00

Unipolar

Motor

Model Number

Parallel

Rated Currents are in

descending order

Series

Connection

5.2

2.6

3.68

0.22

0.90

0.44

0.5

1.9

0.5

59 (0.42)

59 (0.42)

42 (0.29)

2.6

1.3

1.84

0.76

3.04

1.52

1.9

7.6

1.9

P2HNXXF-LXX-XX-00

P2HNXXF-LXX-XX-00

P2HNXXF-LXX-XX-00

Phase

Rated

Inductance

Current/

Phase

Thermal

Rotor

(2 phases on)

Phase Resistance

Detent Resistance

Inertia

Weight

oz-in (Nm)

(ohms)

(mH)

Torque

oz-in-S2

10%

(amps DC)

10%

Typical

oz-in (Nm) (oC/watt) (kgm2 x 10-3) lbs (kg)

59 (0.42)

59 (0.42)

42 (0.29)

P2HNXXC-LXX-XX-00

P2HNXXC-LXX-XX-00

P2HNXXC-LXX-XX-00

Holding

Torque

61 (0.43)

61 (0.43)

43 (0.30)

2.5

1.25

1.77

0.84

3.36

1.68

2.3

9.2

2.3

60 (0.42)

60 (0.42)

42 (0.30)

1.61

0.80

1.10

1.92

7.68

3.84

5.1

20.4

5.1

All ratings typical and at 25C unless otherwise noted.

An X in the Model Number Code indicates an undefined option.

Colored letter indicates winding. See Model Number Code on page

39.

See Model Number Code on page 39, optional leaded connectors

on page 52 and connection information on page 52.

With rated current applied. Windings at 130C and motor

unmounted and in still air at 40C (without heat sink).

www.pacsci.com

2.5

(0.018)

6.6

0.0010

(0.007)

1.0

(0.45)

Windings at 130C and motor in still air at 40C (without heat sink).

Operation of these motors above rated current may cause

demagnetization. Contact factory.

Small signal inductance as measured with impedance bridge at

1kHz, 1 amp.

Thermal resistance measured with motor hanging in still air

(unmounted).

45

599-95 Step Mtrs Sel Gd.out

11/15/00

1:45 PM

Page 46

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

POWERMAX II HYBRIDS

NEMA 23 FRAME (2.3")Ratings and Characteristics (Cont)

Review the Model Number Code, page 39, to assure that all options are designated. Dimensions, connections

and phasing diagrams are on page 49. In addition to those below, motors with characteristics for specific

performance requirements are offered. Contact factory for more details.

Torque range:

95-144 oz-in.

.67-1.02 Nm

M21NXXA-LXX-XX-00

M21NXXA-LXX-XX-00

M21NXXA-LXX-XX-00

SIGMAX

M21 Series

1 rotor stack

M21NXXB-LXX-XX-00

M21NXXB-LXX-XX-00

M21NXXB-LXX-XX-00

M21NXXC-LXX-XX-00

M21NXXC-LXX-XX-00

M21NXXC-LXX-XX-00

M21NXXD-LXX-XX-00

M21NXXD-LXX-XX-00

M21NXXD-LXX-XX-00

Torque range:

77-116 oz-in.

.54-.82 Nm

P21NXXA-LXX-XX-00

P21NXXA-LXX-XX-00

P21NXXA-LXX-XX-00

STANDARD

P21 Series

1 rotor stack

P21NXXB-LXX-XX-00

P21NXXB-LXX-XX-00

P21NXXB-LXX-XX-00

Unipolar

Motor

Model Number

Parallel

Rated Currents are in

descending order

Series

Connection

5.6

2.8

4.0

0.23

0.92

0.46

0.7

2.8

0.7

137 (0.97)

137 (0.97)

97 (0.68)

4.6

2.3

3.3

0.32

1.28

0.64

1.0

4.0

1.0

144 (1.02)

144 (1.02)

102 (0.72)

3.5

1.75

2.5

0.53

2.12

1.06

2.0

8.0

2.0

135 (0.95)

135 (0.95)

95 (0.67)

1.51

0.76

1.07

2.61

10.4

5.22

8.7

34.8

8.7

114 (0.81)

114 (0.81)

81 (0.57)

5.6

2.8

4.0

0.23

0.92

0.46

0.8

3.2

0.8

111 (0.79)

111 (0.79)

79 (0.55)

4.6

2.3

3.3

0.32

1.28

0.64

1.1

4.4

1.1

P21NXXD-LXX-XX-00

P21NXXD-LXX-XX-00

P21NXXD-LXX-XX-00

Phase

Rated

Inductance

Current/

Phase

Thermal

Rotor

(2 phases on)

Phase Resistance

Detent Resistance

Inertia

Weight

oz-in (Nm)

(ohms)

(mH)

Torque

oz-in-S2

10%

(amps DC)

10%

Typical

oz-in (Nm) (oC/watt) (kgm2 x 10-3) lbs (kg)

142 (1.00)

142 (1.00)

100 (0.71)

P21NXXC-LXX-XX-00

P21NXXC-LXX-XX-00

P21NXXC-LXX-XX-00

Holding

Torque

116 (0.82)

116 (0.82)

82 (0.58)

3.5

1.75

2.5

0.53

2.12

1.06

2.3

9.2

2.3

109 (0.77)

109 (0.77)

77 (0.54)

1.51

0.76

1.07

2.61

10.4

5.22

10.3

41.2

10.3

All ratings typical and at 25C unless otherwise noted.

An X in the Model Number Code indicates an undefined

option. Colored letter indicates winding. See Model Number

Code on page 39.

See Model Number Code on page 39, optional leaded

connectors on page 52 and connection information on

page 52.

9.4

(0.066)

5.5

0.0017

(0.012)

1.5

(0.68)

4

(0.028)

5.5

0.0017

(0.012)

1.5

(0.68)

Windings at 130C and motor in still air at 40C (without heat sink).

Operation of these motors above rated current may cause

demagnetization. Contact factory.

Small signal inductance as measured with impedance bridge at

1kHz, 1 amp.

Thermal resistance measured with motor hanging in still air

(unmounted).

With rated current applied. Windings at 130C and motor

unmounted and in still air at 40C (without heat sink).

46

www.pacsci.com

599-95 Step Mtrs Sel Gd.out

11/15/00

1:45 PM

Page 47

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

POWERMAX II HYBRIDS

NEMA 23 FRAME (2.3")Ratings and Characteristics (Cont.)

Review the Model Number Code, page 39, to assure that all options are designated. Dimensions, connections and

phasing diagrams are on page 49. In addition to those below, motors with characteristics for specific performance

requirements are offered. Contact factory for more details.

Torque range:

161-253 oz-in.

1.13-1.79 Nm

M22NXXA-LXX-XX-00

M22NXXA-LXX-XX-00

M22NXXA-LXX-XX-00

SIGMAX

M22 Series

2 rotor stack

M22NXXB-LXX-XX-00

M22NXXB-LXX-XX-00

M22NXXB-LXX-XX-00

M22NXXC-LXX-XX-00

M22NXXC-LXX-XX-00

M22NXXC-LXX-XX-00

M22NXXD-LXX-XX-00

M22NXXD-LXX-XX-00

M22NXXD-LXX-XX-00

M22NXXE-LXX-XX-00

M22NXXE-LXX-XX-00

M22NXXE-LXX-XX-00

Torque range:

138-214 oz-in.

.97-1.51 Nm

P22NXXA-LXX-XX-00

P22NXXA-LXX-XX-00

P22NXXA-LXX-XX-00

STANDARD

P22 Series

2 rotor stack

P22NXXB-LXX-XX-00

P22NXXB-LXX-XX-00

P22NXXB-LXX-XX-00

P22NXXC-LXX-XX-00

P22NXXC-LXX-XX-00

P22NXXC-LXX-XX-00

P22NXXD-LXX-XX-00

P22NXXD-LXX-XX-00

P22NXXD-LXX-XX-00

P22NXXE-LXX-XX-00

P22NXXE-LXX-XX-00

P22NXXE-LXX-XX-00

Unipolar

Motor

Model Number

Parallel

Rated Currents are in

descending order

Series

Connection

Holding

Torque

Phase

Rated

Inductance

Current/

Phase

Thermal

Rotor

(2 phases on)

Phase Resistance

Detent Resistance

Inertia

Weight

oz-in (Nm)

(ohms)

(mH)

Torque

oz-in-S2

10%

(amps DC)

10%

Typical

oz-in (Nm) (oC/watt) (kgm2 x 10-3) lbs (kg)

230 (1.62)

230 (1.62)

163 (1.15)

6.5

3.3

4.6

0.21

0.84

0.42

0.7

2.8

0.7

253 (1.79)

253 (1.79)

179 (1.26)

4.6

2.3

3.3

0.38

1.52

0.76

1.7

6.8

1.7

238 (1.68)

238 (1.68)

168 (1.19)

3.1

1.55

2.2

0.78

3.12

1.56

3.1

12.4

3.1

238 (1.68)

238 (1.68)

168 (1.19)

2.5

1.25

1.77

1.22

4.88

2.44

5.0

20.0

5.0

227 (1.60)

227 (1.60)

161 (1.13)

1.64

0.82

1.16

2.71

10.8

5.42

10.1

40.4

10.1

197 (1.39)

197 (1.39)

139 (0.98)

6.5

3.3

4.6

0.21

0.84

0.42

0.8

3.2

0.8

214 (1.51)

214 (1.51)

151 (1.07)

4.6

2.3

3.3

0.38

1.52

0.76

2.1

8.4

2.1

203 (1.43)

203 (1.43)

144 (1.01)

3.1

1.55

2.2

0.78

3.12

1.56

3.9

15.6

3.9

203 (1.43)

203 (1.43)

144 (1.01)

2.5

1.25

1.77

1.22

4.88

2.44

6.2

24.8

6.2

195 (1.38)

195 (1.38)

138 (0.97)

1.64

0.82

1.16

All ratings typical and at 25C unless otherwise noted.

An X in the Model Number Code indicates an undefined option.

Colored letter indicates winding. See Model Number Code on page 39.

See Model Number Code on page 39 optional leaded connectors on

page 52 and connection information on page 52.

With rated current applied. Windings at 130C and motor unmounted

and in still air at 40C (without heat sink).

www.pacsci.com

2.7

10.8

5.4

17

(0.12)

4.5

0.0036

(0.025)

2.5

(1.13)

7

(0.049)

4.5

0.0036

(0.025)

2.5

(1.13)

12.6

50.4

12.6

Windings at 130C and motor in still air at 40C (without heat sink).

Operation of these motors above rated current may cause

demagnetization. Contact factory.

Small signal inductance as measured with impedance bridge at

1kHz, 1 amp.

Thermal resistance measured with motor hanging in still air

(unmounted).

47

599-95 Step Mtrs Sel Gd.out

11/15/00

1:45 PM

Page 48

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

POWERMAX II

HYBRIDS WITH LOW INERTIA

ROTORS

ROTOR INERTIA CHARACTERISTICS . . . POWERMAX II motors

Single and double stack POWERMAX II motors are

ACCELERATION COMPARISON

available with both standard and low inertia rotors.

Choose low inertia to produce the highest

acceleration rates possible.

Double Stack

Single Stack

Model

Rotor Type

Inertia

oz-in-S2 x 10-3/

kgm2 x 10-3

Theoretical

Normalized

Acceleration

comparison

P21NRXX-L

Standard

1.68/0.010

P21NRXX-J

Low inertia

1.30/0.008

1.27

M21NRXX-L

Standard

1.68/0.010

1.23

M21NRXX-J

Low inertia

1.30/0.008

1.59

P22NRXX-L

Standard

3.57/0.022

P22NRXX-J

Low inertia

2.59/0.016

1.30

M22NRXX-L

Standard

3.57/0.022

1.18

M22NRXX-J

Low inertia

2.59/0.016

1.63

Low inertia rotors not offered for half stack models

Low inertia rotor

Comparative values for normalized acceleration of unloaded motors. Base value is standard

hybrid motor with standard rotor, indicated for single and double stack lengths.

Standard rotor

Actual acceleration capability depends on load, velocity profile and driver power.

Comparisons made with 90C temperature rise using bipolar driver.

NEMA 23 FRAME (2.3")Ratings and Characteristics

Review the Model Number Code, page 39, to assure that all options are designated. Dimensions, connections and phasing diagrams start on

page 49. In addition to those below, all 1 and 2 stack "L" construction windings, page 59, and custom windings for specific performance

requirements are available with low inertia rotors. Contact factory for more details.

Torque range:

99-140 oz-in.

.70-.99 Nm

SIGMAX

M21 Series

1 rotor stack

Torque range:

79-111 oz-in.

.55-.78 Nm

STANDARD

P21Series

1 rotor stack

Torque range:

178-252 oz-in.

1.26-1.78 Nm

SIGMAX

M22 Series

2 rotor stack

Torque range:

142-201 oz-in.

1.00-1.42 Nm

STANDARD

P22 Series

2 rotor stack

P21NXXA-JXX-XX-00

P21NXXA-JXX-XX-00

P21NXXA-JXX-XX-00

M22NXXB-JXX-XX-00

M22NXXB-JXX-XX-00

M22NXXB-JXX-XX-00

P22NXXB-JXX-XX-00

P22NXXB-JXX-XX-00

P22NXXB-JXX-XX-00

Unipolar

M21NXXA-JXX-XX-00

M21NXXA-JXX-XX-00

M21NXXA-JXX-XX-00

Series

Motor

Model Number

Parallel

Connection

Holding

Torque

Phase

Rated

Inductance

Current/

Phase

Thermal

Rotor

(2 phases on)

Phase Resistance

Detent Resistance

Inertia

Weight

oz-in (Nm)

(ohms)

(mH)

Torque

oz-in-S2

10%

(amps DC)

10%

Typical

oz-in (Nm) (oC/watt) (kgm2 x 10-3) lbs (kg)

140 (0.99)

140 (0.99)

99 (0.70)

5.6

2.8

4.0

0.7

2.8

0.7

9.4

(0.066)

111 (0.78)

111 (0.78)

79 (0.55)

5.6

2.8

4.0

0.23

0.92

0.46

0.9

3.6

0.9

4

(0.028)

252 (1.78)

252 (1.78)

178 (1.26)

4.6

2.3

3.3

0.38

1.52

0.76

1.5

6.0

1.5

17

(0.12)

201 (1.42)

201 (1.42)

142 (1.00)

4.6

2.3

3.3

All ratings typical and at 25C unless otherwise noted.

An X in the Model Number Code indicates an undefined option. Colored

letter indicates winding. See Model Number Code on page 39.

See Model Number Code on page 39, optional leaded connectors on page

52 and connection information on page 52.

With rated current applied. Windings at 130C and motor unmounted and in

still air at 40C (without heat sink).

48

0.23

0.92

0.46

0.38

1.52

0.76

1.8

7.2

1.8

5.5

0.0013

(0.009)

1.5

(0.68)

4.5

0.0026

(0.018)

2.5

(1.13)

7

(0.049)

Windings at 130C and motor in still air at 40C (without heat sink).

Operation of these motors above rated current may cause

demagnetization. Contact factory

Small signal inductance as measured with impedance bridge at

1kHz, 1 amp.

Thermal resistance measured with motor hanging in still air

(unmounted).

www.pacsci.com

599-95 Step Mtrs Sel Gd.out

11/15/00

1:45 PM

Page 49

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

DIMENSIONS. . .(POWERMAX II

in. (metric dim. for ref. only)

HYBRIDS) mm

87654321

2.25)

(57,10)

(2X 1.85)

(46,99)

.48 MAX. (12,19) WITH MATING

CONNECTOR PLUGGED IN

4X .200 (5,080) THRU

EQUALLY SPACED ON A

2.625 (66,670) B.C.

.99 MAX

25,20

.18 MAX. (4,57)

MOTOR ONLY

(2X 45)

6,35 0,000

-0,013

.2500 0,000

-.0005

+.0000

.2500 .0005

6,35 +0,000

0,013

.002

.002

0,051

(.20)

5,08

.055

1,400

-A38,1 0,05

1.500 .002

.003 A

0,077

.81

20,60

(2.44)

(62,00)

.75 .04

19,1 1,02

L MAX.

.003 A

0,077

Motor

Model

STANDARD SHAFT OPTIONS

L

Max.

1.60

40,7

2.06

52,3

3.10

78,7

P2H

P or M21

P or M22

ENCODER OPTION

1. Shaft modifications also available. See page 39.

2. Optional flat available on front shaft as shown.

.50

12,7

.219

5,56

See page 53 for encoder/mounting specifications.

USABLE

FLAT

AGILENT

TECHNOLOGIES

ENCODER

Optional rear shaft extension available as shown. Same

diameter as front shaft extension.

.72

18,29

(1.812)

(46,02)

CONNECTION INFORMATION . . .Terminations and phase sequencing

PHASE A

NOTE: Phase sequencing direction of rotation as viewed from mounting end of motor.

6

8 LEAD

2

5

1

DRIVER CONNECTION

DRIVER CONNECTION

8

STEP

CCW

47

CCW

A

A

+V

3

CW

Bipolar full step

GND

GND

O GND GND

O GND

4

1

STEP

PHASE B

4-Lead connection

(Bipolar)

+V

6-Lead connection

(Unipolar)

GND

GND

O GND

CW

O GND

GND

D

Unipolar full step

Notes:

0

+

GND

=

=

=

=

off or open

positive current flow

negative current flow

ground

www.pacsci.com

49

599-95 Step Mtrs Sel Gd.out

11/15/00

1:45 PM

Page 50

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

POWERMAX II Flying Lead Motor Connection Informations

CONNECTION

LEAD COLOR

DRIVER

CONNECTION

4-LEAD BIPOLAR

BIPOLAR

SERIES

BLK

ORG

RED

YEL

WHT/BLK & WHT/ORG

WHT/RED & WHT/YE

WHT/RED & WHT/YEL

A

A

B

B

4-LEAD BIPOLAR

BIPOLAR

PARALLEL

BLK & WHT/ORG

ORG & WHT/BLK

RED & WHT/YEL

YEL & WHT/RED

A

A

B

B

BLK

ORG

RED

YEL

WHT/BLK & WHT/ORG

WHT/RED & WHT/YEL

A

B

C

D

+V

+V

6-LEAD UNIPOLAR

UNIPOLAR

CONNECTION INFORMATION . . .Terminations and phase sequencing

NOTE: Phase sequencing direction of rotation as viewed from mounting end of motor.

DRIVER CONNECTION

A

STEP

A

Blk

CCW

Wht/Blk

+V

Wht/Org

GND O

GND O

O GND GND O

O GND

Org

PHASE A

Red Wht/ Wht/

Red Yel

Yel

Blk

GND

GND

O GND

CW

O GND

GND

Wht/Blk

Unipolar full step

6-Lead connection

(Unipolar)

Wht/Org

Org

Red Wht/ Wht/

Red Yel

Yel

DRIVER CONNECTION

PHASE B

8 lead motor

(reference only

A

Blk

STEP

Blk

Wht/Blk

Wht/Blk

Wht/Org

Wht/Org

Org

CCW

Org

Red Wht/ Wht/

Red Yel

Red

Yel

50

CW

4

B

PARALLEL

4-Lead motor

(Bipolar)

Yel

Wht/

Yel

B

SERIES

=

=

=

=

Wht/

Red

0

+

GND

Notes:

1

Bipolar full step

off or open

positive current flow

negative current flow

ground

www.pacsci.com

599-95 Step Mtrs Sel Gd.out

11/15/00

1:45 PM

Page 51

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

POWERMAX II Flying Lead Motor

(57,10)

( 2.25)

(.25)

(2X 1.85)

(46,99)

(6,35)

12.0 MIN

(304,8)

4X .200 (5,080) THRU

EQUALLY SPACED ON A

2.625 (66,670) B.C.

(26,92)

(1.06)

(2X 45)

6,35 + 0,000

- 0,013

.2500 + 0,000

- .0005

+.0000

.2500 .0005

6,35 +0,000

0,013

.002

.002

0,051

(.20)

5,08

.055

1,400

-A38,1 0,05

1.500 .002

.003 A

0,076

.81

20,60

(2.44)

(62,00)

L MAX.

.75 .04

19,10 1,02

.003 A

0,076

Motor

Model

P2H

P or M21

P or M22

L

Max.

1.60

40,7

2.06

52,4

3.10

78,8

NOTES:

Flexible rubber boot may be bent as

shown. Normal height 1.0 inch (25,4)

www.pacsci.com

51

599-95 Step Mtrs Sel Gd.out

11/15/00

1:45 PM

Page 52

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

POWERMAX II

CONNECTION

INFORMATION . . .

. . . Optional leaded connectors

Four different leaded connectors are available from

Pacific Scientific. Order the GW part number as a

separate item.

Part

Number

GW0000F

(8 Lead)

Pin No.

Connector/Leadwire

Assembly

Lead Colors

Driver

Connection

bipolar

series

6

1

8

3

2&5

4&7

Black

Orange

Red

Yellow

Wht/Blk & Wht/Org

Wht/Red & Wht/Yel

A

A

B

B

none

none

bipolar

parallel

6

1

8

3

Blk & Wht/Org

Org & Wht/Blk

Red & Wht/Yel

Yel & Wht/Red

A

A

B

B

unipolar

6

1

8

3

2&5

4&7

Black

Orange

Red

Yellow

Wht/Blk & Wht/Org

Wht/Red & Wht/Yel

A

B

C

D

+V

+V

unipolar

6

1

8

3

2&5

4&7

Black

Orange

Red

Yellow

Wht/Blk & Org

Wht/Red & Yel

A

B

C

D

+V

+V

bipolar

parallel

6

1

8

3

Black

Orange

Red

Yellow

A

A

B

B

Black

Orange

Red

Yellow

A

A

B

B

Phase

Connection

GW0000E

(6 Lead)

GW0000H

(4 Lead)

GW0000L

(4 Lead)

bipolar

series

&

&

&

&

&

&

&

&

5

2

7

4

5

2

7

4

6

1

8

3

Typical leaded connector (4-lead shown)

.25

Optional Ground Wire

+.00

.06

#22 AWG,

PVC LEADS

12.0

+2.0

0.0

. . . Optional mating connector only

A separate mating connector housing and strain relief cover

are available from Pacific Scientific or AMP. The

user attaches leads to the connector.

ITEM

STANDARD HOUSING

STANDARD COVER

52

PACIFIC

SCIENTIFIC

GP00012

GP00013

NOTES:

GROUND LABEL PLACED IN

FRONT OF GROUND SCREW.

GREEN/YELLOW SAFETY

EARTH CONDUCTOR (18AWG).

See page 39 for ordering information.

AMP

641653-8

643077-8

www.pacsci.com

599-95 Step Mtrs Sel Gd.out

11/15/00

1:45 PM

Page 53

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

ENCODER OPTIONS

NEMA 23 ENCODER OPTION

The standard encoder offered on the NEMA 23

motor is the Agilent Technologies HEDS 5600 series.

NON-LINE DRIVER ENCODER

2.05

1.812

ENCODER

1.03

MAX.

ENCODER OUTPUT

FOR CW DIRECTION OF ROTATION WHEN

VIEWED FROM MOTOR DRIVE SHAFT END.

(COMPLEMENTS NOT SHOWN) MIN. EDGE

SEPARATION 45. INDEX GATED TO A AND B.

CHANNEL A

CHANNEL B

PIN

12 345

INDEX (Z)

.44

.108

18.0

MIN.

5X

LEADS 1

1.18

PIN

1

2

3

4

5

COLOR

BLACK

BLUE

WHITE

RED

BROWN

FUNCTION

GROUND

Z

A

+5V

B

PARAMETERS

TYPE

ENCODER OPTION

PULSES PER REVOLUTION

SUPPLY VOLTAGE

OUTPUT FORMAT

NON-LINE DRIVER

INCREMENTAL

HD

500

HJ

512

+5V 10% @ 85 mA MAX.

DUAL CHANNEL QUADRATURE AND

INDEX

OUTPUT TYPE

SQUARE WAVE TTL COMPATIBLE

FREQUENCY RESPONSE:

DATA

INDEX

ROTOR INERTIA

WEIGHT

100 kHz

100 kHz

5 x 10-7 lb-in-S2

0.08 lb.

ENCODER MOUNTING PROVISION ONLY = M1

FOR AGILENT TECHNOLOGIES HEDS 5600 SERIES OR SIMILAR.

2X 2-56 UNC-2B

.170 MIN. DEEP

EQUALLY SPACED

ON A 1.812 B.C.

( 1.1812)

+.0000

SHAFT DIA. .2500 - .0005

SHAFT LENGTH .75 .06

NOTES:

Leads are terminated with Agilent Technologies

HEDS-8903 connector.

TYPICAL @ 25 C

www.pacsci.com

53

Você também pode gostar

- Powermax Powerpac GBDocumento23 páginasPowermax Powerpac GBghodghod123Ainda não há avaliações

- ABB MotorsDocumento22 páginasABB MotorsKhaled HassanAinda não há avaliações

- Stepper Catalog en-US RevC enDocumento148 páginasStepper Catalog en-US RevC enJorge JuarezAinda não há avaliações

- Kollmorgen Nema23 Special Purpose SpecsheetDocumento3 páginasKollmorgen Nema23 Special Purpose SpecsheetElectromateAinda não há avaliações

- Stepper Motors Catalog en-US RevADocumento146 páginasStepper Motors Catalog en-US RevAYazeed MomaniAinda não há avaliações

- N23 Industrial Grade MotorsDocumento5 páginasN23 Industrial Grade Motorszhifeng yanAinda não há avaliações

- Resumen de Accionamientos de Velocidad Variable SIEMENSDocumento75 páginasResumen de Accionamientos de Velocidad Variable SIEMENSrjinjanAinda não há avaliações

- Ametek MCG Stepper CatalogDocumento34 páginasAmetek MCG Stepper CatalogElectromateAinda não há avaliações

- LT Motors AC Generators DC Motors Drives CatalogDocumento76 páginasLT Motors AC Generators DC Motors Drives CatalogSaravanan Mani100% (1)

- CMC Brushless Servo Motor 2011 CatalogDocumento4 páginasCMC Brushless Servo Motor 2011 CatalogServo2GoAinda não há avaliações

- CMC Brushless Servo Motor 2011 CatalogDocumento4 páginasCMC Brushless Servo Motor 2011 CatalogElectromateAinda não há avaliações

- Molded Case Circuit Breakers Vol04 - Tab02Documento432 páginasMolded Case Circuit Breakers Vol04 - Tab02susanalopzAinda não há avaliações

- Catálogo Motores Iman PermanenteDocumento32 páginasCatálogo Motores Iman Permanentemass72Ainda não há avaliações

- CG HT Motors CatalogueDocumento34 páginasCG HT Motors Cataloguetopazamp123100% (3)

- WEG DC Motors 50019095 Brochure EnglishDocumento8 páginasWEG DC Motors 50019095 Brochure EnglishRamon Da MattaAinda não há avaliações

- BrushlessDocumento141 páginasBrushlessalysonmicheaalaAinda não há avaliações

- Kollmorgen CT Series Step Motors CatalogDocumento16 páginasKollmorgen CT Series Step Motors CatalogElectromateAinda não há avaliações

- Leeson DC MotorDocumento36 páginasLeeson DC MotorchenshivaAinda não há avaliações

- Cartepillar C32 Diesel Oilfield Generator SetDocumento4 páginasCartepillar C32 Diesel Oilfield Generator SetJesus Enrique Figueroa GilAinda não há avaliações

- Cuttler Hammer BreakersDocumento66 páginasCuttler Hammer BreakersedgarlimasAinda não há avaliações

- 2015 Marine CatalogDocumento21 páginas2015 Marine CatalogFaraz HaiderAinda não há avaliações

- Our Range of Printed MotorsDocumento2 páginasOur Range of Printed MotorsjimvidiAinda não há avaliações

- Electrocraft Legacy CatalogDocumento59 páginasElectrocraft Legacy CatalogElectromateAinda não há avaliações

- SM Series Stepper MotorsDocumento7 páginasSM Series Stepper MotorsPham LongAinda não há avaliações

- Transnorm Motors: Low Voltage and High Voltage Design 200 KW Up To 1000 KWDocumento37 páginasTransnorm Motors: Low Voltage and High Voltage Design 200 KW Up To 1000 KWShivani GuptaAinda não há avaliações

- Magnetic Datasheets Barrierrs MicrodriveDocumento36 páginasMagnetic Datasheets Barrierrs MicrodriveJohnna CenaAinda não há avaliações

- Electric Motor - Iron Horse PDFDocumento68 páginasElectric Motor - Iron Horse PDFAriesFranandaPanjaitanAinda não há avaliações

- Caterpillar C32 Engine Specifications PDFDocumento3 páginasCaterpillar C32 Engine Specifications PDFJesus Enrique Figueroa GilAinda não há avaliações

- DC Motores - KinematicDocumento24 páginasDC Motores - KinematicWilfredo Rojo CastañoAinda não há avaliações

- Alteradores MarathonDocumento8 páginasAlteradores MarathonSalineñoApasionadoAinda não há avaliações

- TCI KMG Sine Wave FiltersDocumento8 páginasTCI KMG Sine Wave FiltersbudituxAinda não há avaliações

- LS CatalogueDocumento132 páginasLS Cataloguerudolf_laszlokAinda não há avaliações

- Breaker Cotalogo Completo FIDocumento430 páginasBreaker Cotalogo Completo FIjdrojasaAinda não há avaliações

- Performance Products CatalogDocumento248 páginasPerformance Products CatalogPedro Angel Alvarez Narvaez100% (1)

- Abb MotorDocumento38 páginasAbb MotorsanjayAinda não há avaliações

- Mosfets: Product GuideDocumento63 páginasMosfets: Product Guideihodiputah_510Ainda não há avaliações

- Motores Weg Catalogo CompletoDocumento72 páginasMotores Weg Catalogo CompletoMauricio KookcAinda não há avaliações

- Baldor DC ServoDocumento48 páginasBaldor DC Servod3xter100% (1)

- 23 Cb2000 Ls Varmeca enDocumento10 páginas23 Cb2000 Ls Varmeca enFlying2eagleAinda não há avaliações

- Servo-Motor Selection-Guide en-US 2006 PDFDocumento48 páginasServo-Motor Selection-Guide en-US 2006 PDFIsaac Gutierrez PayanAinda não há avaliações

- Powerpak HandbookDocumento0 páginaPowerpak HandbookPehr HedströmAinda não há avaliações

- Kollmorgen Powermax II CatalogDocumento4 páginasKollmorgen Powermax II CatalogElectromateAinda não há avaliações

- WEG WMO W60 Three Phase Electric Motor Nema Market 50084352 Brochure English WebDocumento64 páginasWEG WMO W60 Three Phase Electric Motor Nema Market 50084352 Brochure English WebFernando AlbornozAinda não há avaliações

- WEG Three Phase Induction Motors Master Line 50019089 Brochure EnglishDocumento12 páginasWEG Three Phase Induction Motors Master Line 50019089 Brochure EnglishEhsan MoheimaniAinda não há avaliações

- AKD-10 & 20 LV SwitchgearDocumento66 páginasAKD-10 & 20 LV SwitchgearFlo Mirca100% (1)

- Motor SpecsDocumento132 páginasMotor SpecsgrezmosAinda não há avaliações

- WEG W60 Three Phase Electric Motor Nema Market 50084352 Brochure English WebDocumento64 páginasWEG W60 Three Phase Electric Motor Nema Market 50084352 Brochure English WebCANH NGUYENAinda não há avaliações

- WEG DC Motor 678 Brochure EnglishDocumento8 páginasWEG DC Motor 678 Brochure EnglishS Sarath ChandraAinda não há avaliações

- Magnetic Particle Equipment Selection GuideDocumento16 páginasMagnetic Particle Equipment Selection GuideWellington S. FrançaAinda não há avaliações

- HAMMA Regatta Catalogue (2012)Documento18 páginasHAMMA Regatta Catalogue (2012)darrenwillsAinda não há avaliações

- Training Report On Sudir GensetsDocumento20 páginasTraining Report On Sudir GensetsAmanda Matthews50% (10)

- Lockformer Vulcan Catalog PDFDocumento6 páginasLockformer Vulcan Catalog PDFgvlaxmipathiAinda não há avaliações

- Emerson Motors CatalogueDocumento38 páginasEmerson Motors Cataloguedetroit44100% (1)

- GE Large Induction MotorsDocumento8 páginasGE Large Induction MotorsidontlikeebooksAinda não há avaliações

- SPECTRA - NEMA Molded Case Circuit Breakers - Application andDocumento51 páginasSPECTRA - NEMA Molded Case Circuit Breakers - Application andnaufrago69aAinda não há avaliações

- Weld Like a Pro: Beginning to Advanced TechniquesNo EverandWeld Like a Pro: Beginning to Advanced TechniquesNota: 4.5 de 5 estrelas4.5/5 (6)

- High-Performance GM LS-Series Cylinder Head GuideNo EverandHigh-Performance GM LS-Series Cylinder Head GuideNota: 4.5 de 5 estrelas4.5/5 (2)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsNo EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsNota: 5 de 5 estrelas5/5 (2)

- Introducing The New VLM-60 Absolute Multi-Turn Encoder From Netzer PrecisionDocumento1 páginaIntroducing The New VLM-60 Absolute Multi-Turn Encoder From Netzer PrecisionElectromateAinda não há avaliações

- Electromate Announces Pre-Order Availability of Universal Robots New UR30 Cobot Press ReleaseDocumento1 páginaElectromate Announces Pre-Order Availability of Universal Robots New UR30 Cobot Press ReleaseElectromateAinda não há avaliações

- Kollmorgen Debuts EKM Series Servo MotorsDocumento1 páginaKollmorgen Debuts EKM Series Servo MotorsElectromateAinda não há avaliações

- New LDL Programmable Linear Actuator From SMAC Moving Coil ActuatorsDocumento1 páginaNew LDL Programmable Linear Actuator From SMAC Moving Coil ActuatorsElectromateAinda não há avaliações

- Electromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaDocumento1 páginaElectromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaElectromateAinda não há avaliações

- Electromate® Made It Onto The 2021 List of Best Workplaces™ in Professional ServicesDocumento2 páginasElectromate® Made It Onto The 2021 List of Best Workplaces™ in Professional ServicesElectromateAinda não há avaliações

- Electromate Recertified As A Great Place To Work' Press ReleaseDocumento1 páginaElectromate Recertified As A Great Place To Work' Press ReleaseElectromateAinda não há avaliações

- Galil Achieves Prestigious UL-CSA Certification For Its Motion Controller SeriesDocumento1 páginaGalil Achieves Prestigious UL-CSA Certification For Its Motion Controller SeriesElectromateAinda não há avaliações

- Exor X5 Wireless Press ReleaseDocumento1 páginaExor X5 Wireless Press ReleaseElectromateAinda não há avaliações

- New High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesDocumento2 páginasNew High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesElectromateAinda não há avaliações

- AMC Release New Micro-Sized FlexPro Servo Drive Model FM060-60C-CMDocumento2 páginasAMC Release New Micro-Sized FlexPro Servo Drive Model FM060-60C-CMElectromateAinda não há avaliações

- Electromate Elated With Win at The 2022 Business Achievement AwardsDocumento2 páginasElectromate Elated With Win at The 2022 Business Achievement AwardsElectromateAinda não há avaliações

- Electromate Recertified For The 2021 Canada's Most Admired Corporate Cultures AwardDocumento2 páginasElectromate Recertified For The 2021 Canada's Most Admired Corporate Cultures AwardElectromateAinda não há avaliações

- Mecademic Robotics Releases New Firmware For Its Meca500 RobotDocumento2 páginasMecademic Robotics Releases New Firmware For Its Meca500 RobotElectromateAinda não há avaliações

- Electromate Extends Its Product Portfolio To Include Robots From MecademicDocumento1 páginaElectromate Extends Its Product Portfolio To Include Robots From MecademicElectromateAinda não há avaliações

- Meet The World's Most Precise Six-Axis RobotDocumento1 páginaMeet The World's Most Precise Six-Axis RobotElectromateAinda não há avaliações

- Electromate Made It To The 2021 List of Best Workplaces™ in Ontario Press ReleaseDocumento2 páginasElectromate Made It To The 2021 List of Best Workplaces™ in Ontario Press ReleaseElectromateAinda não há avaliações

- ADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesDocumento2 páginasADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesElectromateAinda não há avaliações

- New Robotic Cycloidal Gearbox From GAM - New Product Press ReleaseDocumento1 páginaNew Robotic Cycloidal Gearbox From GAM - New Product Press ReleaseElectromateAinda não há avaliações

- New Integrated Spindle Drives Available From JVLDocumento1 páginaNew Integrated Spindle Drives Available From JVLElectromateAinda não há avaliações

- Excellence Canada Announces Electromate Is A Recipient of The 2021 Canadian Business Excellence Awards For Private BusinessesDocumento2 páginasExcellence Canada Announces Electromate Is A Recipient of The 2021 Canadian Business Excellence Awards For Private BusinessesElectromateAinda não há avaliações

- POSITAL Kit Encoders Certified For Compliance With BiSS Interface StandardsDocumento1 páginaPOSITAL Kit Encoders Certified For Compliance With BiSS Interface StandardsElectromateAinda não há avaliações

- New LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsDocumento1 páginaNew LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsElectromateAinda não há avaliações

- New 100 Amps Peak FlexPro Servo Drives Available From AMCDocumento1 páginaNew 100 Amps Peak FlexPro Servo Drives Available From AMCElectromateAinda não há avaliações

- Electromate Extends Its Product Portfolio To Include Collaborative Robots Manufactured by Universal RobotsDocumento2 páginasElectromate Extends Its Product Portfolio To Include Collaborative Robots Manufactured by Universal RobotsElectromateAinda não há avaliações

- Maxon's New IDX Integrated Motor - Power at The Press of A ButtonDocumento1 páginaMaxon's New IDX Integrated Motor - Power at The Press of A ButtonElectromateAinda não há avaliações

- Electromate Recognized With 2021 AHTD Foundation AwardDocumento1 páginaElectromate Recognized With 2021 AHTD Foundation AwardElectromateAinda não há avaliações

- Netzer Introduce VLP-60 Two-Plate Ring Absolute Encoder For Harsh EnvironmentsDocumento1 páginaNetzer Introduce VLP-60 Two-Plate Ring Absolute Encoder For Harsh EnvironmentsElectromateAinda não há avaliações

- ADVANCED Motion Controls Releases The FM060-25-CMDocumento1 páginaADVANCED Motion Controls Releases The FM060-25-CMElectromateAinda não há avaliações

- Electromate Inc. Recognized As Canadas Most Admired Corporate Cultures For 2020Documento2 páginasElectromate Inc. Recognized As Canadas Most Admired Corporate Cultures For 2020ElectromateAinda não há avaliações

- B23 B24 User Manual PDFDocumento168 páginasB23 B24 User Manual PDFAurel BodenmannAinda não há avaliações

- Edexcel - IAS - Group 2 and Group 7 - 1Documento21 páginasEdexcel - IAS - Group 2 and Group 7 - 1mostafa barakatAinda não há avaliações

- Kvpy Pee PDFDocumento9 páginasKvpy Pee PDFstudysteps.inAinda não há avaliações

- Microcontroller-Based Power Monitoring for COE RoomsDocumento8 páginasMicrocontroller-Based Power Monitoring for COE Roomskenneth_molenilla1475Ainda não há avaliações

- Siemens Actuator M3K20FXNDocumento10 páginasSiemens Actuator M3K20FXNbasil christopherAinda não há avaliações

- 320, 320L Medicion de Presiones Bomba Hidraulica PDFDocumento181 páginas320, 320L Medicion de Presiones Bomba Hidraulica PDFrprim100% (2)

- محطات الطاقةDocumento22 páginasمحطات الطاقةJoe LewisAinda não há avaliações

- LT AB Cable GTPsDocumento3 páginasLT AB Cable GTPsnishant sainiAinda não há avaliações

- 42SL80 TrainingDocumento93 páginas42SL80 Trainingvmalvica67% (3)

- 9.6MVA - Technical Specifications For Inverter Duty TransformerDocumento7 páginas9.6MVA - Technical Specifications For Inverter Duty Transformerarunghandwal100% (2)

- Dolphin by EnOcean enDocumento16 páginasDolphin by EnOcean en刘嘉伟Ainda não há avaliações

- Introduction To The OpenDSSDocumento4 páginasIntroduction To The OpenDSSanoopeluvathingal100Ainda não há avaliações

- Indirect and Non-Calorimetric MethodsDocumento44 páginasIndirect and Non-Calorimetric MethodsMadhuvanti GowriAinda não há avaliações

- New Holland Cargador w170 B Tier III Na RepuestosDocumento555 páginasNew Holland Cargador w170 B Tier III Na Repuestosarmando vara chavez100% (2)

- Voltage Source InverterDocumento77 páginasVoltage Source InverterSaied Aly SalamahAinda não há avaliações

- Installation Instructions: Mico Basic 8.6Documento2 páginasInstallation Instructions: Mico Basic 8.6Servizio TecnicoAinda não há avaliações

- 3/27/2016 Portable AC On Rent Pune - Portable AC Rentals Pune - AC Rentals Pune On SulekhaDocumento3 páginas3/27/2016 Portable AC On Rent Pune - Portable AC Rentals Pune - AC Rentals Pune On SulekhadcoolsamAinda não há avaliações

- Metalux Hbled Standard Efficiency Specsheet - Hbled ld5 24se W Unv l850 Ed2 UDocumento5 páginasMetalux Hbled Standard Efficiency Specsheet - Hbled ld5 24se W Unv l850 Ed2 UDANIEL SALAZARAinda não há avaliações

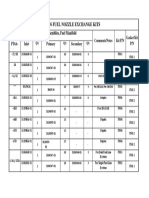

- Pt6 Fuel Nozzle Exchange Kits: Adapter Assemblies, Fuel ManifoldDocumento1 páginaPt6 Fuel Nozzle Exchange Kits: Adapter Assemblies, Fuel ManifoldBerchAinda não há avaliações

- Programator Orar - 292555GB-03Documento16 páginasProgramator Orar - 292555GB-03Daniel EneaAinda não há avaliações

- Dual Nature of Radiation and MatterDocumento6 páginasDual Nature of Radiation and Mattersub100% (1)

- Microstructural Characterization, Strengthening and Toughening Mechanisms of A Quenched and Tempered Steel Effect of Heat Treatment ParametersDocumento22 páginasMicrostructural Characterization, Strengthening and Toughening Mechanisms of A Quenched and Tempered Steel Effect of Heat Treatment ParametersAlmerindo JuniorAinda não há avaliações

- E PM 100Documento29 páginasE PM 100masoudAinda não há avaliações

- Specialist Water Supply Systems PP-R pipe system Ensure reliabilityDocumento16 páginasSpecialist Water Supply Systems PP-R pipe system Ensure reliabilitymabj68Ainda não há avaliações

- Fallout 1 ManualDocumento124 páginasFallout 1 ManualDave100% (1)

- Deepwater Training Seminar Presented ToDocumento36 páginasDeepwater Training Seminar Presented ToSergio Jesus MarquezAinda não há avaliações

- Sub Sea Hot Stab (Sub Sea High Pressure Quick Disconnect)Documento2 páginasSub Sea Hot Stab (Sub Sea High Pressure Quick Disconnect)estelauAinda não há avaliações

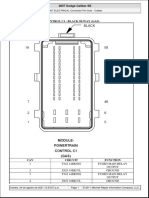

- Caliber Modulo PCM PinoutDocumento7 páginasCaliber Modulo PCM PinoutManuel Suarez100% (3)

- Repair and RehabilitationDocumento22 páginasRepair and RehabilitationConstro FacilitatorAinda não há avaliações

- Case 1088 Repair Manual (Crawler Excavator) PDFDocumento971 páginasCase 1088 Repair Manual (Crawler Excavator) PDFrida100% (7)