Escolar Documentos

Profissional Documentos

Cultura Documentos

Pulverizers

Enviado por

Humayun Rashid KhanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Pulverizers

Enviado por

Humayun Rashid KhanDireitos autorais:

Formatos disponíveis

Coal Plant O&M

To optimize performance,

begin at the pulverizers

A systematic, performance-driven maintenance program for optimizing combustion can achieve great results. The challenge for an O&M staff is deciding which proven strategy and tactics for reducing NOx and improving

plant reliability to adapt and implement. The structured approach presented here has proven its worth at several plants that have wrestled with

problems similar to yours.

By Richard F. (Dick) Storm, PE, and Stephen K. Storm, Storm Technologies Inc.

1. Room for improvement. The heat rate of most older coal-fired steam plants could

be lowered by improving their combustion air and fuel systems. Source: Storm Technologies

11,000

9,500

February 2007 POWER

9,000

8,500

8,000

7,500

7,000

6,500

6,000

8,210

1960

8,500

1968

www.powermag.com

8,800

8,540

1995

Year

2003

Approximate average for entire U.S. fleet

of large pulverized coal units

Opportunity for improvement by performance-driven

maintenance of boiler controllable variables

10,000

Heat rate capability of typical

2,400 psi/1,000F/1,000F

subcritical unit

10,500

10,500

Average of

top 10 plants

burners, overfire air systems, and other furnace solutions

have enabled major reductions in NOx

emissions, from 0.5 to 1.5 lb/million

Btu to less than 0.15 lb/million Btu.

n Many boilers designed to fire eastern

and midwestern bituminous coals

have been adapted to burn lowersulfur Powder River Basin coal at reduced production costs.

n Pulverizers designed for coals with a

Hardgrove Grindability Index (HGI) of

50 to 60 are today working with coals

that have an HGI in the low 40s.

n Additions of electrostatic precipitator fields and back-end retrofits of

baghouses, selective catalytic and

noncatalytic reduction systems, and

scrubbers have become commonplace.

n Distributed control systems and advanced electronic hardware and software have modernized and optimized

boiler operations.

n Public and regulatory pressures are

leaning toward mandatory CO2 emissions caps.

ates at a heat rate of about 10,500 Btu/kWh.

Yet a subcritical (2,400 psi/1,000F/1,000F)

unit is capable of operating at least 10%

more efficiently, at a heat rate of 9,500 Btu/

kWh (Figure 1). There are many proven

ways to improve a boilers performance by

continuously optimizing its controllable

variables (see the box on page 38). This

article explores opportunities for raising a

units efficiency by improving the performance of its pulverizers.

Storm Technologys experience has demonstrated that, of the 20 key O&M controllable variables with the greatest impact on

unit heat rate (see the box on page 40),

most involve the furnaces burner belt.

Essentially (and most often), in a plant operating at its lowest possible heat rate, the

combustion airflows, pulverizers, fuel line

balancing, burners, and air heaters will all

be optimized.

Despite all the changes in regulations,

equipment, fuels, and combustion controls

over the past few decades, one thing has

Typical best supercritical

units with low-NOx

burners actual

n Low-NOx

Typical new

supercritical

unit designs

Tighter pollution control has been a

common thread in the major evolutionary development of coal-fired generation over the past 30 years:

Eddystone

Station #1 design

Change is in the air

time NOx and SO2 emissions limits have

been steadily ratcheted down (see box).

Today, operators no longer wonder whether

permissible levels will continue to fall but,

rather, when and by how much.

The newest fork in coal-fired generations path forward is determining how to

capture plant emissions of carbon dioxide

(CO2) whennot ifthe gas is regulated

as a pollutant. Some advocate widespread

installations of unproven integrated gasification combined cycle (IGCC) technology

ASAP, to prepare it as a long-term solution.

Others say building fleets of super-efficient

supercritical and ultrasupercritical-pressure

and -temperature plants would be a timelier, more prudent, and more cost-effective

alternative. But while regulators, Congress,

and the courts wrestle with the question of

what to do about greenhouse gases, one thing

remains clear: CO2 emissions could be lowered considerably by raising the efficiency of

the existing U.S. fleet of 1,100+ coal plants.

Todays average U.S. PC-fired plant oper-

Heat rate (Btu/kWh)

ptimizing combustion in pulverized

coal (PC)-fired boilers today is more

important today than ever. It is well

known that the average American PC plant

is over 30 years old and that over its life-

2005

2006

9,500

37

Coal Plant O&M

not changed in evaluating pulverizer performance: You need to get the inputs right!

Table 1 breaks down the potential heat

rate improvements achievable from giving

your pulverizer and related systems a good

tune-up.

13 ways to optimize

combustion of boilers

with low-NOx burners

Reversal of fortune

Before moving on to some prescriptions for

pulverizer optimization, consider the internal

configuration of a typical, 1970s-vintage 600MW PC-fired boiler (Figure 2). The top of

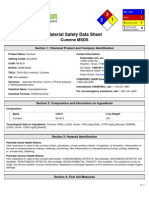

Table 1. Pulverizer improvements are significant and easy to

accomplish. Source: Storm Technologies

1. The excess-oxygen level at the furnace exit must be 2% minimum

(and preferably 3%).

Controllable O&M variable

Air in-leakage (reduce)

Primary airflow (optimize)

2. The fuel lines to the burners should

be balanced by a clean air test

accurate to 2% or better.

4. The flow rates of fuel lines should

be within 10% of each other.

5. At least 75% of the fuel particles

in the lines should be fine enough

to pass through a 200-mesh screen.

Less than 0.1% of the particles

should be able to pass a 50-mesh

screen.

50

Pulverizer performance, fuel line

balance (optimize)

Air heater leakage (reduce)

3. The fuel lines should be balanced

by a dirty air test (using a highvelocity probe) accurate to 5% or

better.

Heat rate

improvement

potential

(Btu/kWh)

200

100

80

Coal pyrites rejects (reduce)

40

LOI (minimize)

80

Desuperheating spray water

flows (minimize)

50

Total

600

the burner belt is about 55 feet below the nose

arch, or furnace exit. For optimal production

and environmental performance, combustion

must be 99% complete by the time its products are passing over the superheater and

reheater surfaces. The flue gases are moving

swiftly; the residence time in the furnace of

the primary air/coal mixture that entered the

furnace at the top burner level is less than 2

seconds. Usually, residence time from the top

burners to the nose arch is more like 1 second.

Remembering the shortness of this interval is

important when it is essential to minimize

NOx emissions and when firing fuels with

high levels of iron and sodium in their ash.

Common in-furnace NOx-reduction solutions include using low-NOx burners and

overfire air (OFA) systems to intentionally

stage or slow down combustion. Realizing

that delayed combustion is fundamental to the

design of all low-NOx burners and OFA systems helps in understanding why it is so important to optimize pulverizer performance.

For example, the ash-softening temperature

of a bituminous coal whose ash is high in iron

2. Burned to a crisp. In a typical thirty-something pulverized coal-fired boiler, 99+% of

combustion should be complete by the time the products of the process reach the convection

surfaces. Source: Storm Technologies

Flame quench zone

6. Primary airflow should be measured

and controlled with an accuracy of

3%.

7. Overfire air should likewise be

measured and controlled at 3%

accuracy.

Point at which combustion

should be completed

8. Primary air/fuel ratio should be

accurately controlled when above

minimum.

9. The minimum velocity within fuel

lines should be 3,300 feet per

minute.

Residence time

approximately 1-2 secs.

10. Mechanical tolerances of burners

and dampers should be 1/4 inch

or better.

11. Secondary air distribution to burners should be controlled with an accuracy of between 5% and 10%.

12. The fuel feed to pulverizers should

be smooth during load changes and

should be measured and controlled

as accurately as possible, preferably by gravimetric feeders equipped

with load cells.

From forced-draft fan

To stack

13. Fuel feed quality and size should be

consistent.

38

POWER February 2007

Coal Plant O&M

20 boiler variables that can be controlled by O&M practices to improve unit

heat rate

11. Air heater leakage. (Reduce it; the level for Ljungstrom regenerative air heaters should and can be less than 9%.)

12. Superheater outlet steam temperature.

13. Reheater outlet steam temperature.

14. Air heater exit gas temperature. (Correct it to a no leakage

basis and optimize it.)

15. Burner inputs tuning. (For lowest possible excess oxygen at

the boiler outlet and satisfactory NOx and LOI levels.)

16. Boiler exit (economizer exit) gas temperatures ideally between 650F and 750F, with zero air in-leakage (no dilution).

17. Cycle losses due to valve leak-through. (For spray water

valves, reheater drains to the condenser and superheater,

reheater drains and vents, andespeciallyany low-point

drains to the condenser or hotwell.)

18. Sootblowing frequency. (Optimized for maximum cleaning effect and minimal impact on heat rate.)

19. Steam purity. (Turbine deposits negatively impact unit heat

rate and capacity.)

20. Auxiliary power consumption. (Minimize it by optimizing

fan clearances, duct leakage, fuel and primary air system

performance.)

1.

2.

3.

4.

Flyash loss-on-ignition (LOI), or unburned carbon in ash.

Bottom ash carbon content.

Boiler and ductwork air in-leakage.

Primary airflow. (Measure and control more precisely, to reduced tempering airflows.)

5. Pulverizer air in-leakage on suction-fired mills. (Reduce it.)

6. Pulverizer throat size and geometry. (When optimized, reduces coal rejects and complements operation at lower primary

airflows, which reduces tempering airflow and total airflow

bypassing the secondary air heater.)

7. Secondary airflow. (When measured and controlled more

closely, it enables more precise control of furnace stoichiometryessential to low-NOx operation.)

8. Peak upper furnace exhaust gas temperatures. (When too

high, they foster popcorn ash carryover into the selective

catalytic reduction system and air preheater, excessive spray

water flows, and boiler slagging and fouling.)

9. Desuperheating spray water flow to the superheater. (Reduce

the level.)

10. Desuperheating spray water flow to the reheater. (Reduce the

level.)

content may be as much as 300 degrees F lower in a reducing (0%

oxygen) atmosphere than in an oxidizing environment.

Storm Technologies has found that when coal with high sulfur and

high iron content is fired with non-optimized inputs, excessive slagging occurs in the furnace due to the combination of coal chemistry

and secondary combustion. The key point to be made here is that

the effect of chemistry kicks in when the ash becomes sticky or

molten, and that happens at a lower temperature with fuel ash high

in iron content.

Low-NOx combustion deliberately consumes some of the furnace

residence time for staging combustion and, as a result, contributes to

more zones in the upper furnace being in an oxygen-deficient state.

Consequently, more slagging occurs and more sootblowing is needed

to remove the slag, which reduces heat transfer. Because increased

sootblowing increases tube erosion and shortens tube life, suboptimal

combustion contributes to reduced plant reliability and availability.

Double down

Suboptimal combustion also takes its toll on unit heat rate:

n

Each extra sootblowing cycle imposes an overhead cost on steam

cycle efficiency.

n The carryover of cinders into the air heater increases draft losses

and fan auxiliary power consumption. The increased air heater differential will then increase air in-leakage due to the fouling.

n In units retrofitted with low-NOx burners or an OFA system, combustion may be actively occurring higher in the furnace, creating

secondary combustion. This elevated center of combustion will

decrease waterwall heat absorption, elevating the peak furnace

exit gas temperature (FEGT). High FEGTs lower combustion efficiency and raise unit heat rate.

Given the extremely short furnace residence times and the staging

or slowing of combustion to reduce NOx formation at the source, it

CIRCLE 19 ON READER SERVICE CARD

40

POWER February 2007

Coal Plant O&M

is clear that combustion efficiency must be

maximized in the burner belt. Unnecessarily

high FEGTs can overheat superheater and reheater metals and cause higher-than-optimal

desuperheating spray water flows (imposing a

sizable heat rate penalty). Optimizing burner

belt performance requires more precise measurement of key boiler performance variables

and tighter control of the fuel:air ratio.

3. Stand in the corner. Corner-fired boilers utilize more of the total furnace for combustion and tend to have lower NOx emissions. Source: Storm Technologies

Nose arch

Focus on firing

By now, youre probably asking,What does

lowheat rate, low-NOx boiler performance

have to do with pulverizer operation? Plenty, as it turns out. Several significant factors

involved in optimizing combustion with

low-NOx burners are equally applicable to

corner-fired and wall-fired boilers.

Lets first consider corner-fired boilers,

which are considered inherently forgiving of

less-than-optimal combustion tuning. This

tolerance seems to derive from the fact that

in corner-fired boilers (Figure 3), the entire

furnace volume can be considered a single

burner into which fuel and air are injected

from the corners, creating a burning mass in

the center. The burning mass serves to reduce

peak temperatures. Meanwhile, tangential

injections from the corners impart swirl

to the fuel and combustion air at all burners; that creates a more homogeneous mix

of the products of combustion for fuel-rich

and fuel-lean burners. The tangential admission of the fuel and air also slightly increases

the residence time of a coal particle, from its

introduction into the furnace until its conversion to a burning carbon char particle that is

quenched to below 1,400F in the convection

pass.

The burning mass principle also reduces the intensity of combustion in the burner

belt, lowering natural NOx levels in the

process. Before low-NOx burner technology

was perfected, corner-fired boilers inherently produced less NOx than wall-fired boilers.

Modern, low-NOx designs stage combustion

not only vertically, but horizontally as well.

Learn from experience

Another proven way to reduce NOx emissions without imposing a heat rate penalty is

to apply high-momentum OFA through opposed nozzles in the upper furnace. Figure

4 shows the configuration of such a system,

as installed both at AES Corp.s 126-MW

Westover Plant in Johnson City, N.Y. (see

POWER, October 2006, p. 26) and Savannah

Electrics McIntosh Plant.

In Storm Technologies experience, wallfired boilers require fine-tuning of the fuel

and air inputs to the burner belt to optimize plant performance, response, and heat

rate. A good example is McIntosh Unit 1, a

February 2007 POWER

Carbon

burnout area

Separated

overfire air

Air-rich zone

Windbox

Fuel-rich zone

4. Over and above. NOx emissions can be reduced by applying high-momentum overfire

air through opposed nozzles in the upper furnace. Source: Storm Technologies

Overfire air zone

to complete

combustion

Stoichiometry = 1.15

Burner zone

Stoichiometry 1.00

41

Coal Plant O&M

5. Youre fired. McIntosh Plant Unit 1 before (L) and after (R) retrofit of a fan-boosted overfire air system. Source: Storm Technologies

1975-vintage, 175-MW unit with 16 front

wall-mounted burners (Figure 5, left). The

furnace division panel separated the eight

burners on the right side of the boiler from

the eight burners on the left. The 16 burners are arranged in four levels of four across.

A fan-boosted OFA system was retrofitted

to the unit (Figure 5, right) with excellent

results (Table 2). For McIntosh Unit 1, the

overall project included optimization of its

pulverizers, burners, combustion airflow

paths (primary, secondary, and OFA), and

improvements to the management and control functions of the systems.

This wall-fired unitwhich has an unforgiving furnace arrangement (furnace division panels and wall-mounted burners) and

a relatively short residence time (1 second

from the top burners to the nose arch)

validates the potential of using the tenets of

combustion optimization found in Table 1. It

has test-burned a wide range of coals from

South America, Central Appalachia, and the

Powder River Basin with good results.

Those results include improved reliability,

which must be quantified and factored into

the savings equation. Optimized combustion

has reduced slagging and fouling. Improved

fuel fineness, fuel distribution, and combustion air distribution also have contributed to

greater unit availability.

One less well-documented advantage of

greater fuel fineness (75% of coal particles

pass a 200-mesh screen, and none pass one

42

Table 2. Results of retrofitting a fan-boosted overfire air system to

Unit 1 of Savannah Electrics McIntosh Plant. Source: Storm Technologies

Variable

Coal fineness (percentage of <HGI coal

particles passing 200-mesh screen )

Clean airflow balance (distribution

imbalances)

Fuel flow balance (distribution

imbalances)

Air-fuel ratio (lb air/lb fuel)

Flyash loss-on-ignition with Eastern

bituminous coals

Flyash loss-on-ignition with low-rank

Venezuelan coals

Furnace exit gas temperature (average

FEGT/maximum FEGT)

Pre-retrofit

Post-retrofit

50%60%

75%80%

5%17%

<2%

20%

10%

>2.0

~1.8

16%22%

<10%

Not available

<15%

~2,250F/2,400F

<2,200F/2,300F

0.781.0

~0.28/0.36 (with 3 or 4 mills operating)

NOx (lb/mmBtu)

of 50 mesh) is reduced waterwall wastage. This type of corrosion becomes more

severe on boilers operating at supercritical

pressure and firing fuels with high sulfur

and iron content. Even boilers running at

1,600 to 1,800 psi can have their useful life

shortened considerably if their waterwalls

are exposed to highly aggressive fireside

corrodents of sulfur and iron in a reducing

environment.

Future shock

In fact, the industry can expect fireside

wastage to become more prevalent as more

30+-year-old plants install SO2 scrubbers

and then are converted to be capable of firing higher-sulfur coals. Why? The reason is

because most low-sulfur compliance coals

also have low iron content in their ash.

These coals are forgiving from the perspective of contributing to aggressive fireside corrosion of water walls and slagging.

Once a plant owner has spent the money

on a scrubber, he will be tempted to buy a

higher-sulfur fuel (with higher iron content

in its ash) for economic reasonsprimarily

escalating Western coal rail costs and improved Eastern coal cost-competitiveness.

POWER February 2007

Coal Plant O&M

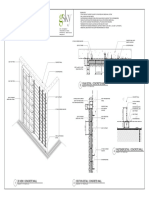

6. Walk the line.

March 2007

Special

Report: Design and

O&M of combined-cycle plants

Using gray water for condenser cooling

Preventing water hammer in

steam systems

Powering up energy equipment

exports

Harvey Research Issue: Ad-Q

advertising readership study

Closing Date:

February 22, 2007

April 2007

ELECTRIC POWER show

issue

Nuclear plant plans move

forward

Next-generation mercury monitors reviewed

Solving lubrication problems

Closing Date:

March 23, 2007

ACT NOW!

Reserve Your Ad

Contact your sales

representative

(listed on p. 2)

44

Loss

Heat lost in flue gases (%)

DELIVERS!

Economic plant operation requires operation in the narrow zone of

optimum combustion efficiency. Source: Storm Technologies

Unburned

fuel loss

Save

Loss

Zone of

optimum

combustion

efficiency

Operating here

results in excess heat

lost up the stack

Operating here

results in

wasted fuel

Excess air loss

Total air (%)

This reverse fuel switch trend is likely to

foster more slagging, fouling, and aggressive furnace tube corrosion.

Fortunately, there are options available

to prevent increases in slagging and fouling

that result from a reverse fuel switch. One

for minimizing fireside wastage is to optimize pulverizer performance to fuel fineness thats acceptable in all fuel lines at all

times. Storm Technologies standard minimum recommended fineness is greater than

75% of particles passing through a 200mesh screen and none through a 50-mesh

screen. Lowering superheater and reheater

metal temperatures, to reduce slagging and

fouling in the convection passes, is another

step than can be taken to improve unit reliability and burner belt combustion.

Finally, operating a unit at its maximum

efficiency and capacity should be an overriding economic objective. Optimizing pulverizer performance and burner belt inputs

can help reach that goal. So can diagnostic

performance testing of fuel lines, combustion airflows, and key upper furnace combustion parameters. When fuel line fineness

declines, and reducing environments are

found in the furnace, corrective action

should be taken immediately.

Cleaner coal-burner

To sum up, there are three significant ways

in which optimizing pulverizer performance

can contribute to a reduction in a coal-fired

boilers NOx emissions.

One. Release of fuel-bound nitrogen

in the burners devolatilization zone is enhanced by making coal particles smaller,

in effect increasing the overall fuel surface

area. Low-NOx burners are most effective

when theyre fed coal that has been finely

ground. Poor fineness traps fuel-bound

nitrogen within the carbon char particles,

beyond the reach of even the best low-NOx

burners.

Two. Fuel balance usually improves

with better fuel fineness. A powdery mixture of fine coal particles passing through

a pulverizer, classifier, and coal riffles (if

the unit is so equipped) will flow more uniformly when it is more finely ground. Such

fuels actually flow more like a gas when

entrained at the proper ratio in the primary

air stream. Fine coal particles mixed in the

transport air become more uniformly distributed than coarsely ground coal particles

at a similar air/fuel ratio.

Three. A more homogeneous mixture of

coal and air entering the burners will naturally reduce required excess air levels. By

reducing the total airflow and reducing the

excess air, thermal NOx production is reduced. The better the mixing of the combustion products in the available residence time,

the less extra air that has to be added to

create oxidizing zones in portions of the furnace that are fuel-rich (Figure 6). When these

peaks and valleys of free oxygen and high

temperatures are made more uniform, then it

becomes possible to reduce the total excess

air that has to be added to make up for imprecise fuel and air inputs into the burner belt. n

Dick Storm is president of Storm

Technologies (www. stormeng.com);

he can be reached at (704) 983-2040 or

skstorm1@aol.com. Stephen K. Storm is

a vice president of the company and its

manager of technical field services;

he can be reached at 704-983-2040

or skstorm1@aol.com.

POWER February 2007

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Comprehensive Training Service ProviderDocumento8 páginasA Comprehensive Training Service ProviderShuvo036Ainda não há avaliações

- Achieve Higher With E-Learning and Instructor-Led Training ServicesDocumento8 páginasAchieve Higher With E-Learning and Instructor-Led Training ServicesPravin Balasaheb GunjalAinda não há avaliações

- Performance Coordinator AdvertDocumento2 páginasPerformance Coordinator AdvertHumayun Rashid KhanAinda não há avaliações

- VPI-I Candidate Fair Processing NoticeDocumento4 páginasVPI-I Candidate Fair Processing NoticeHumayun Rashid KhanAinda não há avaliações

- Job Advert Consultant GeneralistDocumento1 páginaJob Advert Consultant GeneralistHumayun Rashid KhanAinda não há avaliações

- Water TreatmentDocumento1 páginaWater TreatmentHumayun Rashid KhanAinda não há avaliações

- Test Engineer New MaldenDocumento1 páginaTest Engineer New MaldenHumayun Rashid KhanAinda não há avaliações

- Mech Project Engineer Energy ResourceDocumento1 páginaMech Project Engineer Energy ResourceHumayun Rashid KhanAinda não há avaliações

- Job Advert Consultant GeneralistDocumento1 páginaJob Advert Consultant GeneralistHumayun Rashid KhanAinda não há avaliações

- Productio Coordinator Basic V3Documento1 páginaProductio Coordinator Basic V3Humayun Rashid KhanAinda não há avaliações

- VPI-I Candidate Fair Processing NoticeDocumento4 páginasVPI-I Candidate Fair Processing NoticeHumayun Rashid KhanAinda não há avaliações

- Test Engineer New MaldenDocumento1 páginaTest Engineer New MaldenHumayun Rashid KhanAinda não há avaliações

- ExercisesDocumento4 páginasExercisesjoanne peliasAinda não há avaliações

- Full Text 01Documento103 páginasFull Text 01Himanshu SharmaAinda não há avaliações

- Data Storage - Io Interface With PCI - USB - SCSI - COADocumento9 páginasData Storage - Io Interface With PCI - USB - SCSI - COAHumayun Rashid KhanAinda não há avaliações

- CEO Job DescriptionDocumento5 páginasCEO Job DescriptionHumayun Rashid KhanAinda não há avaliações

- Industrial Facilities. Bouygues Energies & Services Operates Across 80 Countries GloballyDocumento3 páginasIndustrial Facilities. Bouygues Energies & Services Operates Across 80 Countries GloballyHumayun Rashid KhanAinda não há avaliações

- Set and Achieve Goals with SMART TechniquesDocumento7 páginasSet and Achieve Goals with SMART TechniquesHumayun Rashid Khan100% (1)

- Boiler System Above and Below Creep RangeDocumento5 páginasBoiler System Above and Below Creep RangeHumayun Rashid KhanAinda não há avaliações

- EngineerDocumento38 páginasEngineerHumayun Rashid KhanAinda não há avaliações

- Short Term Operating Reserve StorDocumento6 páginasShort Term Operating Reserve StorHumayun Rashid KhanAinda não há avaliações

- Process Mechanical Performance EngineerDocumento1 páginaProcess Mechanical Performance EngineerHumayun Rashid KhanAinda não há avaliações

- Internet Protocol Suite: Application LayerDocumento2 páginasInternet Protocol Suite: Application LayerHumayun Rashid KhanAinda não há avaliações

- Company NameDocumento2 páginasCompany NameHumayun Rashid KhanAinda não há avaliações

- Part 4 CHP Operation-And-MaintenanceDocumento16 páginasPart 4 CHP Operation-And-MaintenanceLungisaniAinda não há avaliações

- 600 Flange Bolt Chart 1 PDFDocumento1 página600 Flange Bolt Chart 1 PDFRizalzi BachtiarAinda não há avaliações

- Building A New PlantDocumento6 páginasBuilding A New PlantHumayun Rashid KhanAinda não há avaliações

- Ins57p Info Driving LicencesDocumento28 páginasIns57p Info Driving LicencesHumayun Rashid KhanAinda não há avaliações

- Workplace Risk Assessmentdas Belt Rising Detection SystemDocumento2 páginasWorkplace Risk Assessmentdas Belt Rising Detection SystemHumayun Rashid KhanAinda não há avaliações

- Solve Ordefield Formula: Calculated FieldDocumento4 páginasSolve Ordefield Formula: Calculated FieldI LucianaAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Drilling Kicks and How to Prevent ThemDocumento14 páginasDrilling Kicks and How to Prevent ThemGhavban DavidAinda não há avaliações

- IGCSE-OL Geo CB Answers Theme 2 Natural EnvironmentDocumento55 páginasIGCSE-OL Geo CB Answers Theme 2 Natural Environmenttotola5341Ainda não há avaliações

- Client Project S.O Pipe DrawingDocumento5 páginasClient Project S.O Pipe DrawingAgus Umar FaruqAinda não há avaliações

- Lab Manual for Environmental EngineeringDocumento186 páginasLab Manual for Environmental EngineeringVamshi ChaitanyaAinda não há avaliações

- Methane Hydrate Deep Water Drilling HazardDocumento2 páginasMethane Hydrate Deep Water Drilling HazardJosé AlbertoAinda não há avaliações

- Oregon OSHA Fact Sheet: Eyewash and Safety Showers RequirementsDocumento2 páginasOregon OSHA Fact Sheet: Eyewash and Safety Showers RequirementsGian BanaresAinda não há avaliações

- Bedwellty House, Tredegar, Blaenau Gwent. Phase 1 Watching BriefDocumento38 páginasBedwellty House, Tredegar, Blaenau Gwent. Phase 1 Watching BriefAPAC LtdAinda não há avaliações

- Geology of KarnatakaDocumento36 páginasGeology of KarnatakasayoojAinda não há avaliações

- Gas detection guide for life and propertyDocumento6 páginasGas detection guide for life and propertyE.C.MADHUDUDHANA REDDYAinda não há avaliações

- Phytoremediation 150123100305 Conversion Gate02Documento49 páginasPhytoremediation 150123100305 Conversion Gate02Kumar MadhuAinda não há avaliações

- Grundfosliterature NB NBE NK NKE 60HzDocumento20 páginasGrundfosliterature NB NBE NK NKE 60HzCarla RamosAinda não há avaliações

- Case Study No. 7 - Contingency Plan of Manila WaterDocumento20 páginasCase Study No. 7 - Contingency Plan of Manila WaterpicefeatiAinda não há avaliações

- Chapter 4: Earth Materials and Processes: Exogenic ProcessDocumento67 páginasChapter 4: Earth Materials and Processes: Exogenic ProcessGwen Mara Tanggol100% (4)

- Click or Tap Here To Enter Text.: IIE Student Declaration: I Declare That The Work Submitted Is My OwnDocumento9 páginasClick or Tap Here To Enter Text.: IIE Student Declaration: I Declare That The Work Submitted Is My Ownkarina sharma100% (2)

- Water Saving Irrigation Tech., R.LampayanDocumento39 páginasWater Saving Irrigation Tech., R.LampayanThe Finest TeamAinda não há avaliações

- Adsorption Equilibrium, Kinetics, and Thermodynamic Studies of Fluoride Adsorbed by Tetrametallic Oxide AdsorbentDocumento16 páginasAdsorption Equilibrium, Kinetics, and Thermodynamic Studies of Fluoride Adsorbed by Tetrametallic Oxide AdsorbentSandraKayiii XoxoAinda não há avaliações

- PhotosynthesisDocumento5 páginasPhotosynthesisbluemonkeymei4921100% (1)

- The Steading Acredale Farm EyemouthDocumento22 páginasThe Steading Acredale Farm EyemouthBeavon ObwogeAinda não há avaliações

- Manual Cloro MerkDocumento1 páginaManual Cloro MerkzegoAinda não há avaliações

- Decoduct UPVC Conduits & Fittings Manufactured To BS 6099 & BS 4607 and BS EN 50086 / BS EN 61386 Price ListDocumento3 páginasDecoduct UPVC Conduits & Fittings Manufactured To BS 6099 & BS 4607 and BS EN 50086 / BS EN 61386 Price ListAly SamirAinda não há avaliações

- Introduction To Acid RainDocumento8 páginasIntroduction To Acid RainDevendarsingh rawatAinda não há avaliações

- Penetron Admix BrochureDocumento16 páginasPenetron Admix BrochureTatamulia Bumi Raya MallAinda não há avaliações

- Coal Based Granular Activated Carbon: ParametersDocumento1 páginaCoal Based Granular Activated Carbon: ParametersENDALKACHEW KERIEAinda não há avaliações

- 06 GestionambientalDocumento346 páginas06 GestionambientalÁngela RamosAinda não há avaliações

- Cumene MSDS: Section 1: Chemical Product and Company IdentificationDocumento5 páginasCumene MSDS: Section 1: Chemical Product and Company Identificationburhanettin_erdemAinda não há avaliações

- GSKY Green Wall Panel Installation on Concrete WallDocumento1 páginaGSKY Green Wall Panel Installation on Concrete WallAbbasi HussainAinda não há avaliações

- Air-Conditioning Fundamentals ExplainedDocumento6 páginasAir-Conditioning Fundamentals ExplainedMikaela Grace OrenseAinda não há avaliações

- Examen Funcional SLP 2222 - Reading Comprehension - PruebaDocumento6 páginasExamen Funcional SLP 2222 - Reading Comprehension - PruebajajimelAinda não há avaliações

- Starbucks Complete Training ManualDocumento43 páginasStarbucks Complete Training ManualGopal Alan100% (33)

- 10.6.1 Conexiones Domiciliarias de Agua Potable - Sector 1Documento1 página10.6.1 Conexiones Domiciliarias de Agua Potable - Sector 1Giovany Levano SaldañaAinda não há avaliações