Escolar Documentos

Profissional Documentos

Cultura Documentos

Fcee 2007-10-111-121 Sand Equivalent and Methylene Blue Value

Enviado por

Hussein BeqaiDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Fcee 2007-10-111-121 Sand Equivalent and Methylene Blue Value

Enviado por

Hussein BeqaiDireitos autorais:

Formatos disponíveis

FOUNDATIONS OF CIVIL AND ENVIRONMENTAL ENGINEERING

No. 10

2007

A. NIKOLAIDES*, E. MANTHOS, M. SARAFIDOU

Aristotle University of Thessaloniki, Department of Civil Engineering

54006 Thessaloniki, Greece

SAND EQUIVALENT AND METHYLENE BLUE VALUE OF

AGGREGATES FOR HIGHWAY ENGINEERING

Received: 24 April 2007

Accepted: 22 November 2007

The suitability of the aggregates for the construction of base course and asphalt

layers of a pavement is determined by various parameters-properties. One of these properties is aggregate cleanliness. The two basic tests that determine the cleanliness of the

aggregates are the sand equivalent test and the methylene blue test. In the present paper,

firstly, a reference is being made to the two tests and to the limits used by international

standards. Secondly, relevant results are presented from a significant number of limestone and non-limestone aggregates. From the results obtained it is concluded that some

aggregates with acceptable sand equivalent value do not satisfy the methylene blue requirement. Similarly, aggregates that do not satisfy the sand equivalent requirement are

suitable to be used in highway engineering.

Key words: Aggregates, Sand Equivalent, Methylene Blue Test

1. INTRODUCTION

One of the basic parameters for achieving proper pavement construction

is the suitability of the aggregates used in the unbound and bitumen bound layers. This suitability depends on various parameters related to physical and mechanical characteristics of the aggregates. One basic parameter is their cleanliness from clay materials.

*

Corresponding author. Tel.: 0030-2310-995759; fax: 0030-2310-995764

E-mail address: anik@civil.auth.gr (A. Nikolaides)

Publishing House of Poznan University of Technology, Pozna 2007

ISSN 1642-9303

112

A. Nikolaides, E. Manthos, M. Sarafidou

It is important to determine whether the clay materials are harmful to the

performance of the pavement layers. The harmful materials are susceptible to

moisture i.e. they absorb moisture causing swelling and debonding of the bitumen from the aggregates. Thus, the question raised is: How to detect the presence of clay particles and how to determine whether they are harmful or not.

The laboratory tests that give the answers to the above are the well known

sand equivalent test and the less well known methylene blue test.

In this paper, after a brief explanation of swelling-expansion mechanism, a reference is made to the two tests and to the limits proposed and used by international standards. Secondly, relevant useful results are presented from a significant number of limestone and non-limestone aggregates sampled from Central

and Northern Greece.

2. SWELLING EXPANSION OF CLAY

In highway engineering the general term - clay is used to describe very

small particles that may have a detrimental effect on the performance of unbound and bound materials. In terms of grain size, clay refers to particles less

than 2m in diameter. The structures of the common clay minerals are made up

of combinations of two simple structural units, the silicon tetrahedron and the

aluminum or magnesium octahedron [1, 2].

Clay materials occur in small particle sizes and their unit cells ordinarily

have a residual negative charge in their surface. When clay particles are placed

in water, the space between the particles is taken over by water molecules,

which behave as dipoles with a negative pole, the oxygen atom a positive pole

and the two atoms of hydrogen. At the same time the presence of the negatively

charged clay materials and the dipoles of water, leads to the development of

electro molecular forces which attract and hold the dipoles of water. The

charged surface and the distributed charge around the particles are together

termed the diffuse double layer [2].

Clay particles are multi layer formations. The distance between layers and

the presence of free cations in the interlayer space are the main reasons for the

swelling or not of clay. These two characteristics vary between the clay minerals. The presence of free cations results in the absorption of water dipoles to the

interlayer, so that chemical balance is achieved. When the distance between the

layers is small, the attractive forces among the layers are powerful and overwin

the absorption of water, so swelling does not occur. On the contrary, when the

distance between the layers is significant, the interlayer bonds are weak. In this

case, the absorption of water in the interlayer occurs and continues until the

bonds fail. At that time, the clay particles are separated and rearranged and

Sand equivalent and methylene blue value of aggregates for highway engineering

113

swelling is observed. The magnitude of the phenomenon depends on other factors too which can act individually or together and magnify or decrease the major mechanisms that are mentioned above. Such factors are the density of the

surface charge, the type and the valence of the cations, the concentration of the

electrolytes and the dielectric constant [2].

As it is concluded from the above, swelling depends on the type of clay

mineral. Swelling minerals are considered to be the minerals of the smectite

group with a major representative -the montmorillonite. Non swelling clay minerals are : the pyrophyllite, the margarite and the illite.

3. LABORATORY TESTS

3.1 Sand equivalent test

The objective of the test is to quickly evaluate the relative portion of clay

in the sand that is to be used in unbound and bituminous bound layers. A low

value of sand equivalent characterize the fine aggregate as dirty and indicates

that possibly the clay materials are harmful.

The test is carried out on the 0/2mm fraction in fine aggregates according

to the EN 933-8 specification [3]. From a representative portion of sand, a sample of 120gr is taken and is poured into a plastic graduated cylinder. Then, a

washing solution of calcium chloride is added into the cylinder, until it reaches

the height of almost 100 mm. The cylinder is left for 101 min to soak the test

sample. At the end of the 10 min period the cylinder is sealed and shaked for a

period of 301 sec. The shaking can be done by hand or by a shaker. After the

shaking the cylinder is replaced in an upright vertical position and more solution

of calcium chloride is added. The adding stops when the level of the liquid

reaches the upper mark of the 3800.25 mm. The cylinder is left to settle, without disturbance and free from vibration for 200.25min. At the end of this period, the heights of the sand (hs) and clay (hc) are measured. The sand equivalent

value is determined by equation 1:

SE = (hs / hc ) x100

(1)

For a specific aggregate, two cylinders are used. The sand equivalent

value is calculated as the average of the values of the two cylinders and is recorded to the nearest whole number.

The minimum values of sand equivalent specified by various specifications for unbound and bound layers are given in Table 1.

114

A. Nikolaides, E. Manthos, M. Sarafidou

Table 1. Specification limit values for the sand equivalent

Revised Greek

ASTM

Greek

Specifications(a)

2940

Aggregates for:

Specs

ASTM

[5]

3515

Bituminous mixtures for

55

50

wearing courses

55

Bituminous base course

50

50

Unbound base course

50

35

40

Unbound sub-base course

40

35 (30)

Cold bituminous mixtures

- for wearing course

55

- for binder or base layer

45

Surface dressing

55

(a) To be authorized [6]

French

specs.[7]

60

50

40 or 50

or 60

50

60

3.2 Methylene blue test

The methylene blue test is executed in order to determine whether the

clay minerals are active and harmful. The active clay materials expand, depending on the moisture content. Methylene blue test is the only test that gives this

information accurately and quickly. The test is carried out according to the EN

933-09 [4].

An appropriate quantity of the aggregate is dried (200g-210g of the

0/2mm fraction or 300.1g of the 0/0.125 mm fraction) and placed in a beaker

with 500 ml of demineralized water. The mixture is stirred for 5 min. At the end

of the 5 minute period, 5 ml of the methylene blue dye solution is added. The

new mixture is stirred again for 1 min. Then, a stain test is executed. The stain

test is carried out by dipping a glass rod into the mixture and then allowing a

drop of the mixture to fall onto a filter paper. If the test portion has absorbed all

the dye, the drop on the filter paper appears as a spot of blue stained grains surrounded by a colorless halo. The test is considered positive when the central

spot is surrounded by a light blue halo, with a thickness of almost 1 mm. If after

the addition of the 5 ml of the methylene blue dye solution a halo does not appear, 5 ml of the dye solution is added, the mixture is stirred again and a test

spot is carried out. If again, a halo does not appear the procedure is repeated, in

exactly the same way, until the halo appears. The halo must remain visible for 5

min in order to consider that the test has been finished. If the halo disappears at

the first 4 minutes another 5 ml of the dye solution is added. If it disappears

during the fifth minute, only 2 ml of the dye solution is added. After the test is

finished, the total volume Vi of the methylene blue dye solution which was used

for the formation of the halo (retained visible for 5 minutes) is recorded to the

nearest 1 ml.

Sand equivalent and methylene blue value of aggregates for highway engineering

115

The Methylene blue value MB, recorded in grams of dye solution per

kilograms of the aggregate of the 0/2mm fraction is given by equation 2:

MB = (Vi / M i ) x10

g/kg

(2)

Where Mi is the mass of the sample in grams and Vi is the total volume added in

milliliters

In case that the 0/0.125mm fraction is used the result is recorded as MBF.

In every case, the methylene blue value is recorded to the nearest 0.1 g of the

dye solution per kilogram of aggregate fraction.

At present, there arent many countries that have included this test as an

acceptance requirement in their specifications. France, USA and now Greece are

some of the few countries that have implemented this test in their National

specifications. The limit values required are as shown in Table 2.

Table 2. Permissible Methylene Blue values according to international specifications

Greek SpecificaFrench specifications

ISSA(a)

tions (EOAE) (b)

TB 145

NF XP P 18-540 [7]

Aggregates for:

[9]

Unbound and bituminous bound

layers

Wearing courses

F (c)

2.0 whenS.E.<60

2.5 whenS.E.<50

3.0 when S.E.<40

10

3.0

10

10

10

Concrete

1

10

Railway works

1 2

Micro-surfacing

(slurry seal) and

2

10

10 or 7

10

cold mixtures

(a) ISSA= International Slurry Seal Association, USA [8]

(b) EOAE= Egnatia Odos S.A. (Major State owned construction company)

(c) The test is performed on a 0/0.075 aggregate fraction

4. AGGREGATES TESTED

The aggregates examined in this paper come from 15 quarries, situated

around Central and Northern Greece. In addition to the above, one steel slug

was also tested. Eight of the samples were limestone aggregates and seven were

non limestone aggregates suitable for wearing courses with respect to their

hardness. Table 3 shows the region of the aggregate quarry and the correspond-

116

A. Nikolaides, E. Manthos, M. Sarafidou

ing numbering assigned. It is mentioned, that samples 15-1 to 15-7 from quarry

No. 15 are collected from stockpiles having different storage period while samples 15-8 to 15-14 are collected from constructed unbound layers. The reason

for this was the fact that early sand equivalent tests showed a changing behavior

in sand equivalent value with sampling time after crushing.

Prior to sand equivalent and methylene blue testing, all samples except

No. 15, an analysis of particle size distribution was made, considering that samples belonged to the sand fraction. The particle size gradations for the limestone

aggregates are shown in Figure 1 and for the non limestone aggregates and the

slug in Figure 2. The gradation envelops shown on both figures are the recommended limits of the sand fraction for producing asphalt concrete.

As it can be seen, the particle size distribution varies among sand from

different quarries. Variability was also observed on the percentage of the filler

content. The percentage of the filler content varied between 8.5% to18.9%, for

the limestone aggregates, and 4.5% to 12.5%, for the non limestone aggregates.

Table 3. Regions of aggregate origin and notationification of quarries

Limestone aggregates

Non limestone aggregates

Region of origin

Notification

Region of origin Notification

Evros A, Northern Greece

1

Evros, Northern Greece

9

Volos, Central Greece

10

Thessaloniki, Northern

2-1 & 2-2

Greece

Kavala, Northern Greece

3

Ioannina, Central Greece

11

Evros B, Northern Greece

4

Grevena, Northern

12

Greece

Ioannina A, Central Greece

5

Kilkis, Northern Greece

13

Ioannina B, Central Greece

6

Pella, Northern Greece

14

15-1 to 15-7

Thessaloniki, Northern

and 15-8 to

Evros C, Northern Greece

7

Greece

15-14

Ioannina C, Central Greece

8

Steel slug, Northern

16

Greece

Sand equivalent and methylene blue value of aggregates for highway engineering

100

0.063

0.25

0.5

1.18

117

4.75 6.3

90

Persentage passing (%)

80

Sand limits according to-100

70

60

7

50

3

40

30

2

20

8

10

0

0.063

0.25

1.18

0.5

4.75

6.3

S ieves (mm)

Figure 1 Sieve analysis of limestone aggregates (sand)

0.063

100

0.25

0.5

1.18

4.75

6.3

Persentage passing (%)

90

80

70

Sand limits according to -100

11

60

10

50

16

40

30

14

13

12

20

10

0

0.063

0.25

0.5

1.18

4.75 6.3

S ieves (mm)

Figure 2 Sieve analysis for non limestone aggregates (sand)

5. LABORATORY RESULTS

The results obtained from the sand equivalent (SE) and methylene blue

(MB) tests carried out are summarized in Table 4.

118

A. Nikolaides, E. Manthos, M. Sarafidou

Quarry

1

2-1

2-2

3

4

5

6

7

8

Table 4. Sand equivalent and methylene blue results

Limestone aggregates

Non limestone aggregate

S.E

MB

MBF

Quarry

S.E

MB

MBF

68

0.5

1.7

54

11.3

16.7

9

69

0.5

3.3

43

3.8

11.7

10

74

0.3

2.6

59

1.3

3.3

11

76

0.3

1.7

81

1.8

6.7

12

79

1.3

3.3

55

2.3

5.0

13

58

0.5

1.7

90

2.8

8.3

14

5.0,

5.0,

1.8,

1.8,

45, 40,

5.6,

5.0,

2.0,

1.8,

15-1 to

30, 41,

61

0.8

3.3

5.0,

5.0,

1.8,

1.8,

34, 36,

15-7

3.3,

0.8

40

2.5, 2.6,

5.0, 6.1,

22, 22,

2.7, 2.2,

6.7, 5.0,

23, 24,

15-8 to

70

0.3

1.7

1.9, 1.9,

5.0, 5.0,

22, 49,

15-14

2.0

5.0

48

80

0.3

1.7

16

77

0.3

1.7

6. DISCUSSION

6.1 Sand Equivalent Test

the sand equivalent values of the limestone aggregates tested varied from

58 to 80. Similarly, for the non-limestone aggregates the sand equivalent values

varied from 22 to 90 respectively. According to the Greek Specifications all

limestone aggregates tested are suitable for use in highway engineering.

As far as the non-limestone aggregates are concerned, only some of them

are suitable for unbound and bituminous bound layers. In particular, only five

out of eight materials examined, could be considered suitable for highway engineering according to sand equivalent criterion. Among the rest of the non limestone materials, the aggregate from quarry No. 10 is suitable only for sub-base

layer and . 9 is suitable for both unbound layers, but not for bituminous mixtures. Aggregate . 15, because of its low and variable values obtained, is not

acceptable neither for unbound nor bituminous bound layers.

6.2 Methylene Blue Test

The methylene blue values (MB) of the limestone aggregates varied from

0.3 to 1.3, when fraction 0/2mm was used. Similarly, the methylene blue values,

when fraction 0/0.125mm was used (MBF), varied from 1.7 to 3.3.

Sand equivalent and methylene blue value of aggregates for highway engineering

119

For the non-limestone aggregates tested, the methylene blue values (MB)

varied from 0.3 to 11.3 when 0/2mm fraction was used and the MBF from 1.7 to

16.7 when fraction 0/0.125mm was used.

According to French Standards and the draft Greek Specifications, all

limestone and non-limestone aggregates, apart from . 9 and . 10, are suitable for both unbound and bituminous bound layers. The aggregates from quarries . 9 and . 10 are thought to be unsuitable as they contain harmful clay

materials (swelling).

It is worth noticing that the aggregates from quarries . 9 and . 10

were found to be suitable if only the sand equivalent criterion was taken into

consideration. On the contrary, the aggregate from quarry . 15 was found

unsuitable according to the sand equivalent criterion, alone. However, the aggregates from this quarry, despite its low to very low sand equivalent values are

suitable according to the methylene blue criterion. This is because although they

contain excessive amount of very fine particles (2m), the particles are not

active and harmful to pavement construction.

According to the above mentioned facts it is concluded that the application of the sand equivalent criterion alone is not safe. It could lead to the acceptance of an unsuitable aggregate or to the rejection of a suitable aggregate. The

first affects the quality of works while the second affects the economy of the

construction and the environmental intrusion. When additionally taking into

considerationthe methylene blue criterion, proper use of natural materials is

achieved. This reflects the economy of the construction cost and the protection

of the environment. It must be remembered that hard and durable materials,

suitable for wearing courses, in particular, are scarce in nature.

7. CORRELATION BETWEEN THE SAND EQUIVALENT

AND METHYLENE BLUE VALUES

The results of sand equivalent and methylene blue values (MBF) obtained

are plotted in Figure 3.

When examining the relation between the two measures it was found that

there is no correlation. The same applies if the results obtained from fraction

0/2mm were considered. This was more or less expected due to the different

nature of the two tests.

What could be said for certain is that limestone aggregates with acceptable sand equivalent value, they surely satisfy the methylene blue criterion.

120

A. Nikolaides, E. Manthos, M. Sarafidou

100

Limestone aggregates

90

Non Limestone aggregates

MBF Limit

Sand Equivalent, %

80

70

60

50

40

30

20

0

10

11

12

13

14

15

16

17

18

Methylene blue value, F

Figure 3 Sand equivalent and Methylene blue results

However, this is not the case for hard and durable non-limestone aggregates. There are cases where although the sand equivalent criterion is satisfied,

the aggregates may contain harmful clay materials and hence not satisfying the

methylene blue criterion. Therefore, it can be said that for non-limestone aggregates both tests must be carried out and both criteria must be applied and the

acceptance decision should be based on the methylene blue criterion.

8. CONCLUSIONS

1.

2.

3.

4.

From the results obtained in this study the conclusions are as follows:

The limestone aggregates produced from crushing clean parent rocks posses

high sand equivalent values.

The sand equivalent test is not a reliable test to determine whether or not

any aggregate material is suitable for pavement construction.

For the determination of suitability of a limestone aggregate, if sand equivalent criterion is satisfied, it is not necessary to perform the methylene blue

test.

As for the determination of suitability of a non limestone aggregate, both

tests must be performed and in case the sand equivalent criterion is not sat-

Sand equivalent and methylene blue value of aggregates for highway engineering

5.

6.

7.

8.

121

isfied the acceptance or rejection should be based on the methylene blue criterion.

Depending on which fraction of material is preferable to be used in the methylene blue test, there seems to be no important difference, since the results

in both cases provide the same information. However, using the fraction

0/0.125mm, smaller dispersion of the results and better repeatability were

observed.

Based on the finding of (5) it is recommended to use the fraction

0/0.125mm, when the filler content in the aggregate mixture is 3%. If the

filler content in the aggregate mixture is <3%, fraction 0/2mm may be used

to run the methylene blue test.

Among the quarries examined it was observed that there is a big variability

in relation to the aggregate gradation of the produced sands. This is not a

convenient situation for a highway engineer.

As expected the filler content in the limestone sands grows constantly as

opposed to the filler content in the non limestone sands.

REFERENCES

1. A. Nikolaides, Highway Engineering: Pavements, Materials, Quality control, 2nd edition, A.F. Nikolaides, Thessaloniki, Greece

2. Mitcell James K. Fundamentals of soil behavior, 2nd edition, USA, John

Wiley & Sons Inc. 1993.

3. 933-08. Test for geometrical properties of aggregates Part 8: Assessment of fines-Sand equivalent test

4. 933-09. Test for geometrical properties of aggregates Part 9: Assessment of fines-Methylene blue test

5. ISSA TB No 145, Methylene Blue Test. USA

6. Normalisation Fransaise XP P 18-540. AFNOR.Granulats. 1997

7. Revised Greek Specifications, A-100 and O-100, Aggregates for asphalt con

crete and unbound layers, Submitted for authorization

8. PTP A-265 and O-155, Aggregates for asphalt concrete and unbound layers,

Ministry of Public Works, Athens, 1966

9. Technical Note, 354/12/29.8.03, Egnatia Odos S.A., 2003

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- BS en 480-10-2009Documento11 páginasBS en 480-10-2009Hussein BeqaiAinda não há avaliações

- Company Certifications Fire Classifications Product ApprovalsDocumento4 páginasCompany Certifications Fire Classifications Product ApprovalsHussein BeqaiAinda não há avaliações

- Preparation For Program of Action For The Improvement of The Safety of The Roads in LebanonDocumento20 páginasPreparation For Program of Action For The Improvement of The Safety of The Roads in LebanonHussein BeqaiAinda não há avaliações

- Solvent Cements For Poly (Vinyl Chloride) (PVC) Plastic Piping SystemsDocumento5 páginasSolvent Cements For Poly (Vinyl Chloride) (PVC) Plastic Piping SystemsHussein BeqaiAinda não há avaliações

- BS en 14146 Dynamic Modulus of ElasticityDocumento19 páginasBS en 14146 Dynamic Modulus of ElasticityHussein BeqaiAinda não há avaliações

- Concrete Slump TestDocumento6 páginasConcrete Slump TestHussein BeqaiAinda não há avaliações

- Steel Castings, Carbon, For General ApplicationDocumento4 páginasSteel Castings, Carbon, For General ApplicationHussein BeqaiAinda não há avaliações

- D5731-08 Standard Test Method For Determination of The Point Load Strength Index of Rock and Application To Rock Strength ClassificationsDocumento12 páginasD5731-08 Standard Test Method For Determination of The Point Load Strength Index of Rock and Application To Rock Strength ClassificationsHussein BeqaiAinda não há avaliações

- Making and Curing Concrete Test Specimens in The Laboratory Astm C192Documento6 páginasMaking and Curing Concrete Test Specimens in The Laboratory Astm C192Hussein BeqaiAinda não há avaliações

- BsDocumento33 páginasBsHussein BeqaiAinda não há avaliações

- D624-00 (2012) Standard Test Method For Tear StrengthDocumento9 páginasD624-00 (2012) Standard Test Method For Tear StrengthHussein BeqaiAinda não há avaliações

- DIS Standard Geomembranes METRICDocumento30 páginasDIS Standard Geomembranes METRICHussein BeqaiAinda não há avaliações

- C221 Pipe DrainageDocumento24 páginasC221 Pipe DrainageHussein BeqaiAinda não há avaliações

- ACI Shrinkage CalculationDocumento15 páginasACI Shrinkage CalculationHussein BeqaiAinda não há avaliações

- Ad-A234 566Documento186 páginasAd-A234 566Hussein BeqaiAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Buenos Aires, Argentina Sabe/Aep Rnpzrwy31: JeppesenDocumento1 páginaBuenos Aires, Argentina Sabe/Aep Rnpzrwy31: Jeppesenfrancisco buschiazzoAinda não há avaliações

- 1SC0 2PF Exam-Paper 20180616Documento20 páginas1SC0 2PF Exam-Paper 20180616Thasanya AlgamaAinda não há avaliações

- Cayenne 5Documento17 páginasCayenne 5Marcelo AndradeAinda não há avaliações

- 4-6 Practice: The Quadratic Formula and The DiscriminantDocumento1 página4-6 Practice: The Quadratic Formula and The Discriminantasdfasdfasdfasdfasdf0% (1)

- Math 9 Textbook AnswersDocumento43 páginasMath 9 Textbook AnswersMehak GillAinda não há avaliações

- Cost Center Budget Availability Control - S - 4 HANA 1909Documento24 páginasCost Center Budget Availability Control - S - 4 HANA 1909sekhar dattaAinda não há avaliações

- GENERAL PHYSICS 2 - Q3 - Week 2Documento22 páginasGENERAL PHYSICS 2 - Q3 - Week 2vrejie46Ainda não há avaliações

- 04 Extended Graphics DesignDocumento34 páginas04 Extended Graphics DesignEngenheiro AmoedoAinda não há avaliações

- XML SerializationDocumento4 páginasXML Serializationapi-3748960Ainda não há avaliações

- Modern Age Waste Water ProblemsDocumento364 páginasModern Age Waste Water Problemsromaehab201912Ainda não há avaliações

- Enhancement of IDoc TypeDocumento12 páginasEnhancement of IDoc TypeRakesh RaiAinda não há avaliações

- Structure Lab Manual FullDocumento318 páginasStructure Lab Manual FullRodrigo Requelme BorjaAinda não há avaliações

- Devlopment and Analysis of Natural Banana Fiber CompositeDocumento3 páginasDevlopment and Analysis of Natural Banana Fiber CompositeEditor IJRITCCAinda não há avaliações

- Flue Gas Analysis in IndustryDocumento150 páginasFlue Gas Analysis in Industryblack_knight728Ainda não há avaliações

- Calculation Sheet Boiler Control BuildingDocumento35 páginasCalculation Sheet Boiler Control BuildingKhamal Rachmanda AdamAinda não há avaliações

- 13 EGWDC 2012 CompresscoDocumento17 páginas13 EGWDC 2012 CompresscoVeky Pamintu100% (1)

- Carbanions Carbocations and CarboradicalsDocumento21 páginasCarbanions Carbocations and CarboradicalsAnaAmaruAinda não há avaliações

- Infinix NOTE 5 Stylus Quick Guide: Together We Can!Documento16 páginasInfinix NOTE 5 Stylus Quick Guide: Together We Can!LescribeurAinda não há avaliações

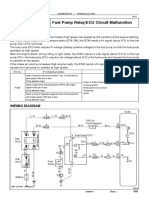

- DTC P1200 Fuel Pump Relay/ECU Circuit MalfunctionDocumento4 páginasDTC P1200 Fuel Pump Relay/ECU Circuit MalfunctiononealAinda não há avaliações

- Camshaft Recommendation FormDocumento3 páginasCamshaft Recommendation Formcrower_scribdAinda não há avaliações

- Simple MachinesDocumento25 páginasSimple MachinesMay ArispeAinda não há avaliações

- BMG Idle CatlogueDocumento20 páginasBMG Idle Catloguechintan mistryAinda não há avaliações

- Codigo Ficheros PHPDocumento33 páginasCodigo Ficheros PHPm_montielAinda não há avaliações

- Code Division DuplexingDocumento19 páginasCode Division DuplexingNitin SakpalAinda não há avaliações

- Efectele Pe Termen Lung Ale Alaptatului OMSDocumento74 páginasEfectele Pe Termen Lung Ale Alaptatului OMSbobocraiAinda não há avaliações

- Reducing The Efficiency Gap by Optimal Allocation Using Modified Assignment Problem For Apparel Industry in Sri LankaDocumento1 páginaReducing The Efficiency Gap by Optimal Allocation Using Modified Assignment Problem For Apparel Industry in Sri LankaShivam BhandariAinda não há avaliações

- Unit 1Documento29 páginasUnit 1Biswajit MishraAinda não há avaliações

- Squall (Better) Training Manual: ModelsDocumento83 páginasSquall (Better) Training Manual: ModelsSilomo-saka MambaAinda não há avaliações

- Electric Power Applications, Engine & Generator SizingDocumento120 páginasElectric Power Applications, Engine & Generator SizingDIPPOSAinda não há avaliações

- AssociationBetweenBRAFV600EMutationand MortalityDocumento9 páginasAssociationBetweenBRAFV600EMutationand MortalityMade RusmanaAinda não há avaliações