Escolar Documentos

Profissional Documentos

Cultura Documentos

Slurry Sampling: Slurry Sampling For On-Line Analysis and Accounting

Enviado por

snarf273Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Slurry Sampling: Slurry Sampling For On-Line Analysis and Accounting

Enviado por

snarf273Direitos autorais:

Formatos disponíveis

Slurry sampling

Slurry sampling for on-line analysis and accounting

Outotec has over 50 years of experience in sampling

and can offer an extensive range of slurry samplers

Dependable on-line analyzer measurement of slurry

for practically all applications. The company offers

particle size and composition is not possible directly from

design and engineering of the complete sampling

a large process ow. Analyzers require a representative

system and consulting for its customers.

sample from most process streams.

Composite samples are collected for laboratory

Outotec sampling systems provide

analysis, whose results are used in metallurgical

High availability

balance accounting and product quality assurance.

Low maintenance

An integral part of sampling, often overlooked,

is the sample transport and delivery system to and from

Advantages

an analyzer.

Representative sample for on-line analysis

Representative sample for composite analysis

002 More out of ore!

Representative

sampling

Process

Primary

sampling

FAST LOOP 70300 l/min

COMPOSITE

COMPOSITE

Composite

SAMPLES

SAMPLES

samples

Homogeneity and mixing of process flows

All material in a process ow must have the same

Monitoring

and

control

probability of entering the sample. Turbulent ows

SECONDARY SAMPLING

MULTIPLEXING

SCREENING

DE-AERATION

FLOW CELL 25 l/min

Analysis

Calibration

samples

are required in typical process streams to maintain

the slurry in suspension (speed >1.5 m/s). Turbulence

keeps the slurry well mixed in contrast to dry solids

on a conveyer belt. The ner and lighter the solids in

the slurry, the more ideal is the mixing. Gravity begins

Isokinetic sampling

to play a signi cant role, when particles are above

100 m in size and/or are of high SG material. Mixing

For the correct representation of all particle sizes, the

is still very effective in the horizontal direction. Such

ow velocity of slurry into a cutter or nozzle must be

mixing enables the use of samplers with a simple

about the same as the velocity of the bulk ow around

robust xed cutter to acquire a representative sample.

the cutter or nozzle. If the sample ow into the cutter

or nozzle is too high, the sample will be biased with

Sampling for on-line analysis

ne material. Differences of 1 m/s are permissible for

slurries of normal particle size range.

An acquired sample must be representative of the

characteristic of the process stream being measured.

Sampling design

Therefore, broad-range particle size analysis requires

a representative sample in respect to the particle size,

First select a location from which to take a sample

while elemental analysis has to be representative in

based either on gravity or pressure ow, although

respect to the measured elemental composition.

sometimes both options are available. Closeness to

In vertical pressure pipes, a round nozzle in

the analyzer location is an advantage. Information on

the middle of the pipe can be used to extract a sample,

the process pipe, ow rates and the amount of sample

the ow being thoroughly mixed after a pump or a

required, determines the sampler type. Sample line

suitable length of vertical pipe (i.e. longer than

routing and sizing are essential for proper operation

10 x pipe's diameter).

and high availability of the analyzer system.

In horizontal gravity pipes or launders,

vertical cutters are used to take an equal slice of all

See the big picture

horizontal layers, which might have different contents

For what purpose is the sample required?

due to segregation by gravity.

What is the source of the slurry to be sampled

Metallurgical accounting

Accounting samples must represent the variations

and what is happening there?

What is the destination of the process stream

and sampled material?

Are any future changes expected to be in the

that occur in both process ow and solids content, in

process e.g. a signi cant increase or decrease in

addition to requirements for on-line analysis. Strictly

process ows?

speaking, a pressure pipe sampler with restricted

sample ow, cannot produce a sample suitable for

Does the material being sampled contain

signi cant amounts of trash, rocks, grinding

accounting purposes.

balls or acid?

n

Pay attention to the sampler location and correct

installation, since they can have a signi cant

effect on sample representativity.

More out of ore! 003

Primary

samplers

for pressure

flow

Representative sampling of process ows under pressure is possible when the sample pipe

diameter, length and routing are correctly designed.

When the process stream to be sampled is under

Advantages

pressure, the primary sample ow is determined by

sample pipe friction. Standard size nozzles are used in

In most cases, no extra pump is required to move

sample to the analyzer or composite sampler

samplers. Isokinetic samples are obtained by correct

sample pipe diameter, length and routing.

Gives representative sample from well mixed

process ow

the balance between sampler pressure head and

Limitations

n

Sample ow rate is not directly proportional to

process ow for composite sampling

A PSA pressure pipe sampler with

an optional automatic VSA valve

set for ushing. PSA samplers are

typically used at pump outlets.

ASA sector samplers are used to divide

small pressure ows. A sector sampler

can be delivered to take 25, 50 or 75% of

the process ow.

SPSA straight pressure

pipe sampler. Where it is

inconvenient to use a PSA

sampler in conventional

vertical position.

HCS sector samplers are used

to divide small horizontal ows.

One primary sample ow can be

divided between two analyzers

using a HCS sampler.

A SPA suction pipe sampler for sampling a

otation cell discharge box, with an automatic

VSA valve set for ushing.

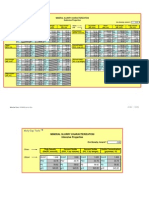

Process

location

Flow-rate

Pipe size

Sampler type

Note

Sample use

After pump or long

vertical pipe

>600 l/min

>100 mm

PSA pressure pipe

sampler (or SPSA)

After pump or long

vertical pipe

<600 l/min

100 mm

ASA sector sampler

Can take 25, 50 or

75% of ow

Analysis

Composite

Horizontal pipe,

no froth

>500 l/min

>100 mm

SPSA straight pressure

pipe sampler

Can also be used for

vertical pipes

Analysis

Horizontal pipe

<500 l/min

100 mm

HCS sector sampler

Can split sample

between analyzers

Analysis

Composite

Flotation cell

discharge box

All

N/A

SPA suction pipe sampler

Analysis

Composite

Analysis

004 More out of ore!

Primary samplers

for gravity flow

When the process stream is essentially at ambient pressure, a

vertical sample cutter can be used. The cutter opening must be

many times larger than the maximum particle size of sampled

slurry, at least 8 mm, but preferably >20 mm. The gravity primary

sample ow is not restricted, ensuring isokinetics at the

A LSA vertical cutter sampler with an optional

VSA automatic ushing valve set for process

ows at ambient pressure. A cyclone overow

is a typical LSA sampling point.

sampling point. The sample ow can be adjusted using an

adjustable cutter opening for pipe sizes up to 400 mm.

The sampler box design improves process ow

mixing prior to the sample cut. When representative isokinetic

sampling is applied, high process ows produce large primary

sample ows, which requires many sampling steps or innovative

sampling designs.

Advantages

n

Takes a representative sample from a vertically segregated

process ow

The sample ow rate of single stage samplers is directly

proportional to the process ow for composite and

accounting sampling

NLA non plug vertical cutter sampler with automatic mechanical cutter cleaner for ambient

pressure process ow containing trash. Victaulic

process pipe connections.

Limitations

n

A pump may be required to transport the sample to the

analyzer or composite sampler

Process

location

Flow-rate

m/h

Pipe size

Sampler

Note

Sample use

Nearly

horizontal

gravity pipe

251000

(1600)

600 mm

LSA or NLA vertical

cutter sampler

Flow >1000 m/h

requires a partly

blanked cutter

Analysis

Composite

Accounting

Gravity ow in

launder

<10002000

N/A

SKA vertical sample

cutter

Nearly

horizontal

gravity ow

>500

N/A

TSC two stage vertical

cutter sampler

Two Stage Cutter

allows broader

cutter opening than

LSA/NLA

Analysis

Composite

Nearly

horizontal

gravity pipe

or launder, no

froth

>350

250 mm

CPS primary sampler

Two stage sampler.

Requires control

from analyzer.

Restricted sample

ow.

Analysis

Composite

Horizontal pipe

<30

100 mm

HCS sector sampler

or LSA 80

Can split sample

between analyzers

Sample line

618

50 mm

ASD 50 adjustable

sample divider

Reduces primary

sample ow and

splits sample

Analysis

Composite

Accounting

Analysis

Composite

Accounting

Analysis

Composite

Accounting

More out of ore! 005

Sample ow from vertical cutters should not be restricted.

A SKA vertical cutter sampler for process

ows under ambient pressure in a launder.

An ASD adjustable sample divider located on top of a

PSI 500 analyzer multiplexer, allowing a large primary

sample ow to be used for easily settling slurry.

Two stage samplers for large process flows

Single stage sampler produces too high sample ow-rate from a large

process ow. Two stage samplers are able to provide a suitable sample

ow-rate for on-stream analysis.

A TSC two stage vertical cutter sampler for large process

ows under ambient pressure. The sampler can be installed

at a launder bottom or in a LSA style sampling box.

A CPS two stage sampler for high speed process ows.

The sample entering the tube is re-sampled using a

controlled syphon sampler.

006 More out of ore!

Metallurgical accounting sampling

MSA Multi-stage Metallurgical

A MSA 3/140 metallurgical sampler

with a pipe outlet.

Accounting Sampler

Operation of the sampler is based

on a combination of static multiple

cutter stages (depending on the

process ow), followed by a moving

crosscut sampler stage, which

produces the sample. The MSA

samplers can handle process ows

from 6018,000 m/h.

The MSA sampler can be

con gured to deliver a composite

sample or a continuous ow of

about 150 l/min, which is suitable

for Courier and PSI analyzers.

Analyzer controlled sampling by

the MSA samplers is also possible.

Model

Nominal

capacity m/h

Stages

Number

of static

cutters

Main

launder

width mm

Sample use

SSA 50

618

50

Accounting

LMC 50

618

none

50

Accounting

LMC 80

1860

none

80

Accounting

MSA 1/40

60180

none

400

Analysis

Accounting

MSA 2/50

180600

500

Analysis

Accounting

MSA 2/80

6001800

800

Analysis

Accounting

MSA 3/140 18006000

5/3

1400

Analysis

Accounting

MSA 3/200 600018000

5/4

2000

Analysis

Accounting

Composite sampling and filtering

The nal composite sample is taken

from the 150 l/min primary sample

ow by the secondary sampler in the

Courier on-stream analyzer system,

by a LMC 50 or 80 linear moving cutter

composite sampler or by a SSA 50

stand-alone composite sampler.

The composite sample can be

ltered using an optional VFU vacuum

sample lter unit. The VFU is selfA composite sampler SSA 50 with

sample lter and vacuum blower.

contained, equipped with a vacuum

blower and uses standard lter papers.

LMC 80 linear moving cutter

composite sampler.

More out of ore! 007

Controlled sampling

Controlled primary sampling

Process ow

by gravity

MSA sampler

On-stream analyzers have

traditionally used continuously

owing primary samples.

LSA sampler

Controlled sampling is a

Process ow

by gravity

built-in feature in new generation

Courier analyzers. The analyzer

can have an active role in controlling

the primary sample acquisition and

delivery to the analyzer. Remote

controlled sample valves are

Multiplexer

required and the desired sampling

A combination of continuous and

1900

Composite

sampling and

ltering

sequence has to be con gured.

controlled sample lines can be

used in the same analyzer system.

On-demand sampling

Analyzer

Probe

3050

Probe

Control Set

primary sample ow some time

1750

Analyzer scheduler starts the

PSA

sampler

before the next measurement

and/or composite sampling. After

De-multiplexer

stopped and the sample cutter

and sample line are ushed with

water. This radically improves the

availability of samples and reduces

5000

the volume of returned samples.

Automatically flushed

Options

sample lines

Flanges:

The primary sample usually ows

DIN 2576, AS 2129TABLE D, SABS

1123TABLE 10, ANSI B16.5150 lbs,

Victaulic

continuously, but is interrupted

at programmed intervals to ush

Lining:

the sampler nozzle or cutter and

Natural rubber as standard, other

the sample line. The ushing

materials as an option

is scheduled not to interfere

Cutters:

with normal measurements and

Wear areas rubber lined, hard

composite sampling cycle.

metals and ceramics as options

Sample valves:

Manual and automatic ush valves

are available

Sampling and sample presentation

are covered by several patents

and patent applications owned

by Outotec Oyj.

Courier is a registered

trademark of Outotec Oyj.

Specications subject to change

without notice. Please see

sampler data sheets and

installation drawings for

dimensions and details.

900

Process ow

by pressure

measurement the sample ow is

3020EN. Pinta/Libris, Helsinki, Finland. June 2007

Outotec, formerly Outokumpu Technology, is a worldwide technology

leader in minerals and metals processing, providing innovative and

environmentally sound solutions for a wide variety of customers in

minerals processing, iron and steel, aluminum and non-ferrous metals

industries. Outotec Oyj is listed on the Helsinki Stock Exchange.

automation@outotec.com

www.outotec.com

Copyright 2007 Outotec Oyj. All rights reserved.

Outotec and More out of ore! are registered trademarks of Outotec Oyj.

Você também pode gostar

- SamplingDocumento8 páginasSamplingSreedhar BellaryAinda não há avaliações

- OTE Slurry Sampling Eng WebDocumento8 páginasOTE Slurry Sampling Eng Webjazz_2012Ainda não há avaliações

- Low Res Courier 5i SL and Courier 6Documento12 páginasLow Res Courier 5i SL and Courier 6German ReyesAinda não há avaliações

- Truter Scaleup 2010Documento187 páginasTruter Scaleup 2010Mayra Jefferson MontoyaAinda não há avaliações

- Design of Experiments Via Taguchi Methods Orthogonal ArraysDocumento21 páginasDesign of Experiments Via Taguchi Methods Orthogonal ArraysRohan ViswanathAinda não há avaliações

- Muestreo MetalurgicoDocumento13 páginasMuestreo MetalurgicoPaulina Dixia MacarenaAinda não há avaliações

- Rebecca FlemingDocumento19 páginasRebecca Flemingavca65Ainda não há avaliações

- Chapter04 ButcherDocumento11 páginasChapter04 Butcherwilfredo trujillo100% (1)

- Fulltext01 PDFDocumento152 páginasFulltext01 PDFDaniAinda não há avaliações

- APCOMDocumento28 páginasAPCOMdouglasminasAinda não há avaliações

- Effect of MG 2+ and Ca 2+ As Divalent Seawater Cations On The Floatability of Molybdenite and Chalcopyrite PDFDocumento11 páginasEffect of MG 2+ and Ca 2+ As Divalent Seawater Cations On The Floatability of Molybdenite and Chalcopyrite PDFJoaquin Roa CabreraAinda não há avaliações

- Gas Dispersion Measurements in Flotation Cells: C.O. Gomez, J.A. FinchDocumento8 páginasGas Dispersion Measurements in Flotation Cells: C.O. Gomez, J.A. FinchwillyballAinda não há avaliações

- What Is A Taguchi Design (Also Called An Orthogonal Array) ?Documento11 páginasWhat Is A Taguchi Design (Also Called An Orthogonal Array) ?Nyssa SanAinda não há avaliações

- Celdas Autoaspirantes OutotecDocumento25 páginasCeldas Autoaspirantes OutotecfbaxterAinda não há avaliações

- Minerals Engineering: J. Yianatos, F. Contreras, P. Morales, F. Coddou, H. Elgueta, J. OrtízDocumento8 páginasMinerals Engineering: J. Yianatos, F. Contreras, P. Morales, F. Coddou, H. Elgueta, J. OrtízCristian Eduardo Ortega MoragaAinda não há avaliações

- Amelunxen Et Al 2013 - Float Test ProgramsDocumento23 páginasAmelunxen Et Al 2013 - Float Test ProgramspeilinlanAinda não há avaliações

- Decision TreeDocumento30 páginasDecision Treemounika reddyAinda não há avaliações

- Pocketbook 2016Documento390 páginasPocketbook 2016Saikotkhan0Ainda não há avaliações

- Ss Veeresh Project1 c1 and c2Documento19 páginasSs Veeresh Project1 c1 and c2ravibelavadiAinda não há avaliações

- 43-101 Technical Report Quimsacocha, February 2009Documento187 páginas43-101 Technical Report Quimsacocha, February 2009Marco Vinicio SotoAinda não há avaliações

- Cerro Corona InfoDocumento30 páginasCerro Corona InfoquinteroudinaAinda não há avaliações

- Resume Process Engineer May 2013Documento5 páginasResume Process Engineer May 2013Manolo Sallo ValenzuelaAinda não há avaliações

- Contributions To An Improved Understanding of The Flotation ProcessDocumento70 páginasContributions To An Improved Understanding of The Flotation Process4943900Ainda não há avaliações

- Juan YianatosDocumento22 páginasJuan Yianatosavca65Ainda não há avaliações

- A Strategy For The Identification of Optimal Flotation CircuitsDocumento12 páginasA Strategy For The Identification of Optimal Flotation CircuitsNataniel LinaresAinda não há avaliações

- Ore Sorting Molib Flow SheetDocumento10 páginasOre Sorting Molib Flow SheetMICHAEL CUETO MERCADOAinda não há avaliações

- Bolanitos Technical Report March 2016 PDFDocumento189 páginasBolanitos Technical Report March 2016 PDFFrancoPaúlTafoyaGurtzAinda não há avaliações

- Chapter 7 Sampling Methods 2013 Mineral ExplorationDocumento19 páginasChapter 7 Sampling Methods 2013 Mineral ExplorationCésarGeología100% (1)

- Comminucion de MineralesDocumento13 páginasComminucion de MineralesIrving Dirzo CarrilloAinda não há avaliações

- Information: Equipment To April, 1999 - Crushers I. Primary CrusherDocumento22 páginasInformation: Equipment To April, 1999 - Crushers I. Primary CrusherJose Carlos Garcia MamaniAinda não há avaliações

- Mineral Liberation AnalyzerDocumento16 páginasMineral Liberation Analyzernasho89Ainda não há avaliações

- Seminar PPT On PcaDocumento17 páginasSeminar PPT On Pcaprince SinghAinda não há avaliações

- Dimensionality Reduction: Principal Component Analysis (PCA)Documento11 páginasDimensionality Reduction: Principal Component Analysis (PCA)tanmayi nandirajuAinda não há avaliações

- Mineral SamplingDocumento31 páginasMineral SamplingYessica Botero VargasAinda não há avaliações

- Flotation Circuit Design Using A Geometallurgical ApproachDocumento10 páginasFlotation Circuit Design Using A Geometallurgical ApproachNataniel LinaresAinda não há avaliações

- The Frothbuster - A Solution To Frothing Thickeners Authors: Ian Arbuthnot - Outokumpu Technology Pty LTD Carla Kaboth - Normandy Mining LTD (Golden Grove)Documento2 páginasThe Frothbuster - A Solution To Frothing Thickeners Authors: Ian Arbuthnot - Outokumpu Technology Pty LTD Carla Kaboth - Normandy Mining LTD (Golden Grove)Víctor SandovskyAinda não há avaliações

- Paper - Comminution Case Study - ST - Ives PDFDocumento7 páginasPaper - Comminution Case Study - ST - Ives PDFdarwin_huaAinda não há avaliações

- Flowsheet 20simulation 20of 20solids 20processes PDFDocumento13 páginasFlowsheet 20simulation 20of 20solids 20processes PDFIman AkbariAinda não há avaliações

- 08 Flotation MachinesDocumento47 páginas08 Flotation MachinesNataliaPBDAinda não há avaliações

- Bulk Mineral Analysis of Heavy Mineral SandsDocumento27 páginasBulk Mineral Analysis of Heavy Mineral Sands4015johnfAinda não há avaliações

- Particle Size Effect On The Hydrophobicity and The Natural Floatability of MolybdeniteDocumento105 páginasParticle Size Effect On The Hydrophobicity and The Natural Floatability of MolybdeniteAgustín F. Correa100% (1)

- The Effect of Particle Size OnDocumento16 páginasThe Effect of Particle Size OnafnanAinda não há avaliações

- Mass Balances JKDocumento2 páginasMass Balances JKL Sergio Quiroz CastilloAinda não há avaliações

- S7 14 - 20 Douglas Teyhan - REVDocumento21 páginasS7 14 - 20 Douglas Teyhan - REVCesar Rodriguez GuzmanAinda não há avaliações

- 2015 WCSB7 Placer Gold SamplingDocumento8 páginas2015 WCSB7 Placer Gold SamplingDirceu NascimentoAinda não há avaliações

- VertiMill - Preparing The Feed Within Flotable Regime at Lower Specific EnergyDocumento9 páginasVertiMill - Preparing The Feed Within Flotable Regime at Lower Specific EnergyYesi CeballosAinda não há avaliações

- Design of Large Scale Mixer Settlers in SX Solvent Extraction CircuitsDocumento18 páginasDesign of Large Scale Mixer Settlers in SX Solvent Extraction CircuitsHamed PiriAinda não há avaliações

- Decision Tree PrintDocumento4 páginasDecision Tree PrintANKUR SharmaAinda não há avaliações

- Cavity Level's Effect On Cone Crusher Performance and ProductionDocumento11 páginasCavity Level's Effect On Cone Crusher Performance and ProductionMatías TamayoAinda não há avaliações

- Recuperqcion de Molibdenita Con Aceite AglomeranteDocumento7 páginasRecuperqcion de Molibdenita Con Aceite AglomeranteGema EscobedoAinda não há avaliações

- Scale Froth FlotationrevisedDocumento19 páginasScale Froth FlotationrevisedTrần Phước TrungAinda não há avaliações

- Research Report of Mineral Processing 2Documento17 páginasResearch Report of Mineral Processing 2MarcialAinda não há avaliações

- Data Mining ToolsDocumento31 páginasData Mining ToolsKrishna Dash100% (1)

- Industrial Use of Nitrogen in Flotation of MolybdeniteDocumento4 páginasIndustrial Use of Nitrogen in Flotation of MolybdenitedanisaAinda não há avaliações

- La Verde Tech ReportDocumento173 páginasLa Verde Tech ReportEliott Hidalgo MuñozAinda não há avaliações

- Sample Point Location 1701063211Documento8 páginasSample Point Location 1701063211dmbets15Ainda não há avaliações

- 2009 Issue25 SamplingDocumento3 páginas2009 Issue25 SamplingSreedhar BellaryAinda não há avaliações

- Dry Process Sampling A 3Documento9 páginasDry Process Sampling A 3Manuel Nyoka100% (1)

- Flowmeter Piping RequirementsDocumento13 páginasFlowmeter Piping RequirementsVinodKumarAinda não há avaliações

- Swas:: Sample ExtractionDocumento1 páginaSwas:: Sample ExtractionWaqas AleemAinda não há avaliações

- EpibrwDocumento12 páginasEpibrwsnarf273Ainda não há avaliações

- Less Is MoreDocumento3 páginasLess Is Moresnarf273Ainda não há avaliações

- Case Study: Minerals Processing SolutionsDocumento4 páginasCase Study: Minerals Processing Solutionssnarf273Ainda não há avaliações

- Utilities SlurriesDocumento2 páginasUtilities Slurriessnarf273Ainda não há avaliações

- Contact Cell Info - Gen PDFDocumento10 páginasContact Cell Info - Gen PDFsnarf273Ainda não há avaliações

- Courier HX: High-Performance On-Stream Solution Analyzer SystemDocumento8 páginasCourier HX: High-Performance On-Stream Solution Analyzer Systemsnarf273Ainda não há avaliações

- Media Charge TrajectoriesDocumento9 páginasMedia Charge Trajectoriessnarf273Ainda não há avaliações

- Ballsim ReverseDocumento58 páginasBallsim Reversesnarf273Ainda não há avaliações

- Scope:: About The Media Charge - Level Spreadsheet ..Documento4 páginasScope:: About The Media Charge - Level Spreadsheet ..snarf273Ainda não há avaliações

- Balsim DualDocumento53 páginasBalsim Dualsnarf273Ainda não há avaliações

- Ballsim OpenDocumento50 páginasBallsim Opensnarf273Ainda não há avaliações

- Mean Value of A Series Against A Fix Reference Value: Moly-Cop Tools (Version 2.0)Documento3 páginasMean Value of A Series Against A Fix Reference Value: Moly-Cop Tools (Version 2.0)snarf273Ainda não há avaliações

- BallParam BatchDocumento43 páginasBallParam Batchsnarf273Ainda não há avaliações

- Scope:: About The Ballbal - Reverse Spreadsheet ..Documento12 páginasScope:: About The Ballbal - Reverse Spreadsheet ..snarf273Ainda não há avaliações

- Utilities Size DistributionDocumento3 páginasUtilities Size Distributionsnarf273Ainda não há avaliações

- Scope:: About The Ballbal - Direct Spreadsheet ..Documento14 páginasScope:: About The Ballbal - Direct Spreadsheet ..snarf273Ainda não há avaliações

- Individual: DR Winnie Louis LeeDocumento27 páginasIndividual: DR Winnie Louis Leeedn_mj1645Ainda não há avaliações

- Lab - 17-WAN ConfigurationDocumento12 páginasLab - 17-WAN ConfigurationMuhammad Asghar Khan100% (1)

- HVAC Water TreatmentDocumento7 páginasHVAC Water TreatmentDuxToyAinda não há avaliações

- 2019 02 01 Racecar EngineeringDocumento100 páginas2019 02 01 Racecar EngineeringGregory Aguilera LopesAinda não há avaliações

- SMDocumento36 páginasSMharan2000Ainda não há avaliações

- The Relevance of YS/UTS RatioDocumento21 páginasThe Relevance of YS/UTS RatiocarrespmAinda não há avaliações

- D-1967 (Clean) Quilting Machine ManualDocumento33 páginasD-1967 (Clean) Quilting Machine Manualvalter craccoAinda não há avaliações

- Diesel GateDocumento41 páginasDiesel Gateanon_934477879100% (1)

- NB! This Price List Applies To Service Agreements, That Are Concluded With Nordea Bank AB Latvia BranchDocumento34 páginasNB! This Price List Applies To Service Agreements, That Are Concluded With Nordea Bank AB Latvia Branchwaraxe23Ainda não há avaliações

- IsCAN Labview DeveloperDocumento30 páginasIsCAN Labview Developerafsala1982Ainda não há avaliações

- MN5200 Issue1.1 APR2009Documento2 páginasMN5200 Issue1.1 APR2009Roger ReisAinda não há avaliações

- Pragmatic Electrical Engineering: FundamentalsDocumento201 páginasPragmatic Electrical Engineering: FundamentalsaminmominAinda não há avaliações

- 2012-13 Waste CalendarDocumento2 páginas2012-13 Waste CalendarOmar9998Ainda não há avaliações

- Railway-4 Permanent Way & Alignment (Lecture-4)Documento17 páginasRailway-4 Permanent Way & Alignment (Lecture-4)OBIDUR RAHMAN 1701085Ainda não há avaliações

- Sapthagiri College of Engineering: Tracing Manufacturing Processes Using Blockchain Based Token CompositionsDocumento19 páginasSapthagiri College of Engineering: Tracing Manufacturing Processes Using Blockchain Based Token CompositionsYashi FakeAinda não há avaliações

- Arun Et al-2019-ChemistrySelectDocumento8 páginasArun Et al-2019-ChemistrySelectRavi Kumar ARunAinda não há avaliações

- Simple Free-Energy InformationDocumento11 páginasSimple Free-Energy InformationDrago MelovAinda não há avaliações

- BX Tuner ManualDocumento4 páginasBX Tuner ManualdanielthemanAinda não há avaliações

- SystemVerilog DPI With SystemCDocumento17 páginasSystemVerilog DPI With SystemCSWAPNIL DWIVEDIAinda não há avaliações

- Etk 001 en de PDFDocumento740 páginasEtk 001 en de PDFBinh le Thanh0% (1)

- Fdot Precast Bent Cap Development and Implementation: AbstractDocumento10 páginasFdot Precast Bent Cap Development and Implementation: AbstractCongOanh PHANAinda não há avaliações

- ZX60-P105LNDocumento4 páginasZX60-P105LNMuhammad AsadAinda não há avaliações

- TA125Documento4 páginasTA125WaqasjamAinda não há avaliações

- Ad Agency SynopsisDocumento19 páginasAd Agency SynopsisRaj BangaloreAinda não há avaliações

- LennoxDocumento32 páginasLennoxCharly ColumbAinda não há avaliações

- PQ070XF02SZH: Features Outline DimensionsDocumento4 páginasPQ070XF02SZH: Features Outline DimensionsJulio Cesar CastilloAinda não há avaliações

- All The Wrong MovesDocumento13 páginasAll The Wrong Movesabhishek2006100% (1)

- ORF Issue Brief 309 SpaceLawDocumento12 páginasORF Issue Brief 309 SpaceLawNitish KumarAinda não há avaliações

- Water Tank Seat Slab DesignDocumento2 páginasWater Tank Seat Slab DesignMesfin Derbew100% (2)

- Workover Kill Fluid Density CalculationDocumento3 páginasWorkover Kill Fluid Density CalculationSanny Astari100% (1)