Escolar Documentos

Profissional Documentos

Cultura Documentos

24 14 PDF

Enviado por

barukomkssDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

24 14 PDF

Enviado por

barukomkssDireitos autorais:

Formatos disponíveis

Power Transmission

Installation and Operating Instructions for

Rigid Shaft Couplings RWK 500

E 06.694e

Schaberweg 30-34

61348 Bad Homburg

Germany

Telephone +49 6172 275-0

Telefax +49 6172 275-275

www.ringspann.com

mailbox@ringspann.com

Installation and Operating Instructions

for Rigid Shaft Couplings RWK 500

issue:: 04.02.2013

version: 01

drawn.: FK

checked.: Ei

E 06.694 e

Pages : 5

page: 2

IMPORTANT

Please read these instructions carefully before installing and operating the product. Your particular

attention is drawn to the notes on safety.

These installation and operating instructions are valid on condition that the product meets the selection criteria for its proper use. Selection and design of the product is not the subject of these installation and operating instructions.

Disregarding or misinterpreting these installation and operating instructions invalidates any product

liability or warranty by RINGSPANN; the same applies if the product is taken apart or changed.

These installation and operating instructions should be kept in a safe place and should accompany

the product if it is passed on to others -either on its own or as part of a machine- to make it accessible

to the user.

SAFETY NOTICE

Installation and operation of this product should only be carried out by skilled personnel.

Repairs may only be carried out by the manufacturer or accredited RINGSPANN agents.

If a malfunction is indicated, the product or the machine into which it is installed, should be

stopped immediately and either RINGSPANN or an accredited RINGSPANN agent should be informed.

Switch off the power supply before commencing work on electrical components.

Rotating machine elements must be protected by the purchaser to prevent accidental contact.

Supplies abroad are subject to the safety laws prevailing in those countries.

Installation and Operating Instructions

for Rigid Shaft Couplings RWK 500

issue:: 04.02.2013

1.

version: 01

drawn.: FK

checked.: Ei

E 06.694 e

Pages : 5

page: 3

General information

1.1 Function:

RWK 500 Cone Clamping Elements are clamping connection for backlash free fastening of shaft

ends. By tightening clamping screws surfaces are pulled together generating radial forces; these

forces create a frictional connection between the Cone Clamping Element and the shaft as well

as the hub. Torques or axial forces can be transmitted via the Cone Clamping Element to the

ends of shafts.

1.2 General safety instructions:

Caution! Danger of injury!

The immediate vicinity of the rotating shrink disc must be kept clear of body

parts, hair, clothing and other objects at all times.

2.

Configuration and function

3.

RWK 500 Cone Clamping Elements consist of a slotted inner ring 1 with outside cone, a pressure

flange 2 with inside cone, a threaded flange 3 with inside cone as well as a number of clamping

screws 4. By tightening the clamping screws are drawn against each pressure flange and threaded flange. Radial clamping forces are generated by the conical surfaces which are dependent on

the torques of the clamping screws, the cone angel and the friction coefficients at the screws and

conical surface. The radial clamping forces press the outer ring into the hub bore and the inner

rings onto the shaft and create a friction connection at the respective contact surfaces. In this

way, torque and/or axial force can be transmitted between the shaft and the hub.

.

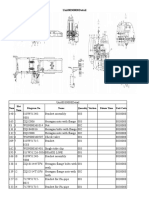

Diagram (cross-section) and parts list

2

1

3

4.

Pos.

1

2

3

4

Nomenclature

Inner ring

Discharge flange

Threaded flange

Clamping screw

Proper use

The RWK 500 Cone Clamping Elements are intended for installation between two shaft ends. They

are intended solely for the friction-tight connection of shafts for the purpose of transmitting torque

and axial forces. Use for any other purpose is regarded as improper use. RINGSPANN accepts

no liability for damages resulting from improper use and associated risks shall be borne by the

user.

5.

Improper use

The RWK 500 Cone Clamping Elements are not suitable for:

the direct mounting of hollow shafts to solid shafts or

as torque-limiting safety devices.

6.

Condition as delivered

The clamping elements are wrapped in anti-corrosive packing material.

Installation and Operating Instructions

for Rigid Shaft Couplings RWK 500

issue:: 04.02.2013

7.

version: 01

drawn.: FK

checked.: Ei

E 06.694 e

Pages : 5

page: 4

Technical requirements for safe operation

In order to achieve full transmission of torque and/or axial forces, tolerance on contact-pressure

surfaces

may not exceed tolerance class h8 for shafts

In addition, pressure-contact surfaces on shafts and hubs must have a mean peak-to-valley

height Ra < 3,2 m.

Shaft and hub must be manufactured from materials with the following mechanical properties:

E-module about 170 kN/mm

The shaft ends must L1, the load-bearing axial width of the discharge flange or threaded flange, at

least overlap.

8.

Installation

8.1 Clean the contact surfaces between on the ends of shafts thoroughly.

8.2 Apply a light coat of oil to the clamping element.

Do not use oil which contains molybdenum disulphide or high-pressure additives,

and do not use grease!

8.3 Loosen the clamping screws by several revolutions by hand in a crosswise sequence.

8.3 Clamping element to be connected to the shaft ends.

8.4 Tighten diametrically opposed clamping screws by hand whilst aligning the cone clamping

element so that the discharge flange and the threaded flanges lie parallel to each other.

8.5 Tighten the clamping screws clockwise with full tightening torque Ms with a torque wrench.

Tighten the clamping screws uniformly revolution at a time. Repeat the process until no screw turns at the full tightening torque of Ms.

Replace missing or damaged clamping screws with equivalent screws of quality grade 12.9!

9.

Disassembly

9.1 Part-release the clamping screws evenly in stages in order to avoid any tilting of the discharge flange and the threaded flange.

Do not remove clamping screws completely from threaded bores under any

circumstances, as this poses the risk of injury!

9.7 When working with reusable cone clamping elements, lubricate all contact surfaces, the

threads on the clamping screws and the contact surfaces of the screw head with a light coat

of oil.

Do not use oil containing molybdenum sulphide or high-pressure additives

grease of any kind.

10. Maintenance

RLK 500 Cone Clamping Elements are maintenance-free. However, signs of settling may appear

in connections during operation. We therefore recommend checking the tightness of the clamping

screws each time maintenance is performed on the machine.

Installation and Operating Instructions

for Rigid Shaft Couplings RWK 500

issue:: 04.02.2013

version: 01

drawn.: FK

11. Tightening torque Ms

Size

dxD

Clamping screws

Tightening torque

Ms

[Nm]

[mm]

14 x 45

M 6

16

15 x 45

M 6

16

16 x 45

M 6

16

17 x 45

M 6

16

18 x 50

M 6

16

19 x 50

M 6

16

20 x 50

M 6

16

22 x 55

M 6

16

24 x 55

M 6

16

25 x 55

M 6

16

28 x 60

M 6

16

30 x 60

M 6

16

32 x 75

M 8

37

35 x 75

M 8

37

38 x 75

M 8

37

40 x 75

M 8

37

42 x 85

M 8

37

45 x 85

M 8

37

48 x 90

M 8

37

50 x 90

M 8

37

55 x 95

M 8

37

60 x 100

M 8

37

65 x 105

M 8

37

70 x 115

M 10

73

75 x 120

M 10

73

80 x 125

M 10

73

90 x 135

M 10

73

100 x 155

M 12

126

checked.: Ei

E 06.694 e

Pages : 5

page: 5

Você também pode gostar

- V3i9 Ijertv3is090001 PDFDocumento3 páginasV3i9 Ijertv3is090001 PDFbarukomkssAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- NGR - Ohm Calc Trafo 5MVA-20kVDocumento6 páginasNGR - Ohm Calc Trafo 5MVA-20kVbarukomkssAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- AWSPipeWeld - American Welding SocietyDocumento2 páginasAWSPipeWeld - American Welding Societybarukomkss100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Kobelco - Kobe Steel PDFDocumento6 páginasKobelco - Kobe Steel PDFbarukomkssAinda não há avaliações

- Corrosion Rate Calculator: All CountriesDocumento1 páginaCorrosion Rate Calculator: All CountriesbarukomkssAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Power Transmission: Schaberweg 30-34 61348 Bad Homburg Germany Telephone +49 6172 275-0 Telefax +49 6172 275-275Documento5 páginasPower Transmission: Schaberweg 30-34 61348 Bad Homburg Germany Telephone +49 6172 275-0 Telefax +49 6172 275-275barukomkssAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Jembatan Bellie PDFDocumento2 páginasJembatan Bellie PDFbarukomkssAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- RTe BookGSDCalculatorDocumento5 páginasRTe BookGSDCalculatorbarukomkssAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Power Transmission: Schaberweg 30-34 61348 Bad Homburg Germany Telephone +49 6172 275-0 Telefax +49 6172 275-275Documento5 páginasPower Transmission: Schaberweg 30-34 61348 Bad Homburg Germany Telephone +49 6172 275-0 Telefax +49 6172 275-275barukomkssAinda não há avaliações

- Power Transmission: Schaberweg 30-34 61348 Bad Homburg Germany Telephone +49 6172 275-0 Telefax +49 6172 275-275Documento5 páginasPower Transmission: Schaberweg 30-34 61348 Bad Homburg Germany Telephone +49 6172 275-0 Telefax +49 6172 275-275barukomkssAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- BSM Vol 1 Sec 15 Aug 2007 PDFDocumento2 páginasBSM Vol 1 Sec 15 Aug 2007 PDFbarukomkssAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Pro & Contra Hydropower: AdvantagesDocumento16 páginasPro & Contra Hydropower: AdvantagesbarukomkssAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Porosity by MassDocumento1 páginaPorosity by MassbarukomkssAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- HourGlass ErrorDocumento10 páginasHourGlass ErrorbarukomkssAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- DEORE XT Front Chainwheel: A-TypeDocumento1 páginaDEORE XT Front Chainwheel: A-TypeDona LeanoAinda não há avaliações

- Annex B Currently Recommended Illuminance Cate-Gories and Values For Industrial Lighting Design (Target Maintained Levels)Documento3 páginasAnnex B Currently Recommended Illuminance Cate-Gories and Values For Industrial Lighting Design (Target Maintained Levels)Rahul MandalAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Model 95: Installation Manual Ultrasonic Log Scanning SystemDocumento72 páginasModel 95: Installation Manual Ultrasonic Log Scanning SystemRodrigo AcuñaAinda não há avaliações

- Hydra Series: Choke ValveDocumento8 páginasHydra Series: Choke ValveJorge EduardoAinda não há avaliações

- Design of Bolted JointsDocumento30 páginasDesign of Bolted JointsKrishna VamsiAinda não há avaliações

- Mechanics of DB PDF 3Documento6 páginasMechanics of DB PDF 3eysAinda não há avaliações

- The Evolution of Chamfer Cutting: Cover StoryDocumento2 páginasThe Evolution of Chamfer Cutting: Cover StorythisisjineshAinda não há avaliações

- Sheet Metal Design in SolidworksDocumento27 páginasSheet Metal Design in SolidworkstnchsgAinda não há avaliações

- MT - Office Structural CA SetDocumento55 páginasMT - Office Structural CA SetAzeemuddin Gulam MohammedAinda não há avaliações

- Formwork Safety Checklist During ConstructionDocumento3 páginasFormwork Safety Checklist During Constructionテレブリコ ジェファーソンAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- N/S: V180B 50000 ': 86756277 Spare Parts ManualDocumento24 páginasN/S: V180B 50000 ': 86756277 Spare Parts ManualSerkanAl100% (2)

- Unit8030008Detail: Num Hot Num Diagram No. Name Quantity Vertion Disuse Time Unit CodeDocumento3 páginasUnit8030008Detail: Num Hot Num Diagram No. Name Quantity Vertion Disuse Time Unit CodeChen PeterAinda não há avaliações

- 8904 Operating Instructions A4VGDocumento40 páginas8904 Operating Instructions A4VGEduardo Cramer100% (1)

- Chiller MCQDocumento3 páginasChiller MCQHibaAinda não há avaliações

- Integral Joint Tubing (TTRD) : General RequirementsDocumento5 páginasIntegral Joint Tubing (TTRD) : General Requirementsislam atifAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Spare Parts List: Hydraulic BreakersDocumento44 páginasSpare Parts List: Hydraulic Breakersahmed emadAinda não há avaliações

- B.tech 2nd Yr Result Analysis Even Sem 2021-22Documento8 páginasB.tech 2nd Yr Result Analysis Even Sem 2021-22Akansha SrivastavaAinda não há avaliações

- Steam Traps Wiki Seminar2Documento7 páginasSteam Traps Wiki Seminar2Ram KumaarAinda não há avaliações

- Thamilvendhan Vetrinambi: QA/QC Inspector - (Welding)Documento2 páginasThamilvendhan Vetrinambi: QA/QC Inspector - (Welding)Paul PhiliphsAinda não há avaliações

- Purchase Department Sample Data-VDocumento8 páginasPurchase Department Sample Data-VBhuvnesh BatraAinda não há avaliações

- Steam Turbine Hydraulic Servomotor For Description Main and Reheat Control ValvesDocumento2 páginasSteam Turbine Hydraulic Servomotor For Description Main and Reheat Control Valvesparthibanemails5779Ainda não há avaliações

- Albrecht Precision Drill Chucks: The World'S Most Consistently Accurate Drill ChucksDocumento10 páginasAlbrecht Precision Drill Chucks: The World'S Most Consistently Accurate Drill ChucksfgrefeAinda não há avaliações

- GSD - C General Service Centrifugal Pump Brochure EN Oct18Documento4 páginasGSD - C General Service Centrifugal Pump Brochure EN Oct18rafaelberaldiAinda não há avaliações

- GA5FF - tcm266 646875Documento1 páginaGA5FF - tcm266 646875peterpunk75Ainda não há avaliações

- PNC Model Ref Pag. Brand Notes: BRASIERA 80/100L E900 XP BRATT PAN 80/100L E900 XPDocumento12 páginasPNC Model Ref Pag. Brand Notes: BRASIERA 80/100L E900 XP BRATT PAN 80/100L E900 XPZackyExlipzAinda não há avaliações

- General Tool Set Hose PDFDocumento3 páginasGeneral Tool Set Hose PDFRAMON CALDERONAinda não há avaliações

- New Imb Gudang Jne Lintas TimurDocumento4 páginasNew Imb Gudang Jne Lintas TimurariesibaraniAinda não há avaliações

- Ritter m9 UltraclaveDocumento1 páginaRitter m9 Ultraclaveelectronico1000Ainda não há avaliações

- American Grooved NRS Gate ValveDocumento1 páginaAmerican Grooved NRS Gate Valvemourad laatatAinda não há avaliações

- Raashika Industries PVT LTD Cateloge 2 1602852975456641 PDFDocumento12 páginasRaashika Industries PVT LTD Cateloge 2 1602852975456641 PDFvelu.gAinda não há avaliações

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNo EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNota: 4.5 de 5 estrelas4.5/5 (27)