Escolar Documentos

Profissional Documentos

Cultura Documentos

Weight Calculation

Enviado por

Jebin Abraham0 notas0% acharam este documento útil (0 voto)

65 visualizações2 páginasfsf

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentofsf

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

65 visualizações2 páginasWeight Calculation

Enviado por

Jebin Abrahamfsf

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 2

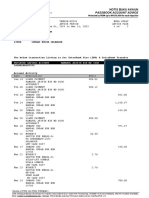

Calculation of Weight of Product

ATLAS SPECIALTY METALS

insert dimensions for the required product shape in orange boxes,

then read off the weight in the red boxes at right.

Material:

Note - Densities shown in green boxes are typical. Add specific density

under "others" for different materials.

sheet / plate

flat bar

coil

round

bar / wire

density:

Thickness (mm)

Width (mm)

Thickness (mm)

Width (mm)

copper

alloys

(Note)

8470

aluminium

alloys

(Note)

2700

others

(Note)

7.9000

Length (m)

1

kg:

kg/m:

Diameter (mm)

Length (m)

A/F (mm)

Length (m)

A/F (mm)

1

Length (m)

A/F (mm)

Length (m)

kg:

square bar

hex bar

kg:

kg:

oct bar

1

Length (m)

kg:

1

Length (m)

kg:

ID (mm)

1

Length (m)

kg:

WT (mm)

kg:

Thickness (mm)

Leg 1 (mm)

OD (mm)

OD (mm)

Leg 2 (mm)

angle bar

hollow bar

round

tube / pipe

square / rect

tube / pipe

carbon &

ferritic austenitic

stainless stainless

steels

steels

7800

7900

TECHNICAL SERVICES DEPT.

Side 1 (mm)

Side 2 (mm)

WT (mm)

Length (m)

1

kg:

Note: All results are approximate. Refer to second sheet for calculation fomulas.

www.atlasmetals.com.au

revised 6/03/2006

PJM

ATLAS SPECIALTY METALS

TECHNICAL SERVICES DEPT.

Formulas for Mass Calculation

Product

Mass (kg/m)

Round bar and wire

= 0.00000079 x dens x D

Hexagonal bar

= 0.000000866 x dens x F

Octagonal bar

= 0.0000008284 x dens x F

Hollow round - tube and pipe

= 0.00000314 x dens x (D - t) x t

Square / Rectangular tube or hollow section

= 0.000001 x dens x 2 x (S1 + S2 - 2 x t) x t

Hollow bar

= 0.0000007854 x dens x (D - d)

Flat product

= 0.000001 x dens x T x W

Angle bar

= 0.000001 x dens x (L1 + L2 - t) x t)

D - Diameter or Outside Diameter (mm)

d - Inside Diameter (mm)

S1 and S2 - side dimensions of square or rectangular hollows (mm)

t - Wall Thickness of tube or pipe (mm)

T - flat product Thickness (mm)

W - flat product Width (mm)

F - Across Flats of a Hexagon or Octagon (mm)

L1 & L2 - Angle bar Leg lengths (mm)

t - Angle bar leg thickness (mm)

Notes

1. These are approximate and actual weights may vary due to specific grade and dimension tolerances.

2. Austenitic stainless steels have slightly higher densities than carbon steels. Consult tables for exact calculations.

3. Dimensional tolerances are particularly wide for hot rolled products, such as plate, pipe.and black bar.

4. Theoretical densities are used for all calculations, and the result is a theoretical mass. This takes no account

of dimensional tolerances.

5. "Billing weights" are often used in commercial quotations - such as 8177 for austenitic stainless steel.

This value accounts for a predominantly + tolerance for plate. It's justification for other products is less obvious.

6. Hollow round includes pipe and tube (specified by OD and WT).

7. Flat product includes plate, sheet, strip, coil and flat bar

Densities

Carbon steel 7800

Stainless steel (austenitic) 7900

Aluminium alloys 2700

Copper (alloy 385) 8470

Peter Moore 31/01/2006

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Harmony Guide DatabaseDocumento7 páginasHarmony Guide DatabaseAya SakamotoAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Query PrintDocumento1 páginaQuery PrintJebin AbrahamAinda não há avaliações

- Design Example For Beams With Web Openings2 - Google SearchDocumento2 páginasDesign Example For Beams With Web Openings2 - Google SearchJebin AbrahamAinda não há avaliações

- Aisi Cold Formed Steel Design Manual PDF - Google SearchDocumento2 páginasAisi Cold Formed Steel Design Manual PDF - Google SearchJebin AbrahamAinda não há avaliações

- Design Example For Beams With Web Openings - Google SearchDocumento2 páginasDesign Example For Beams With Web Openings - Google SearchJebin AbrahamAinda não há avaliações

- @AB CD EB Cfghi C JK L GMHND Ompgd MD EB Cfghi CD Mqqarcs TD 23 $, 3 $Documento2 páginas@AB CD EB Cfghi C JK L GMHND Ompgd MD EB Cfghi CD Mqqarcs TD 23 $, 3 $Jebin AbrahamAinda não há avaliações

- Free Eye Chart PDFDocumento1 páginaFree Eye Chart PDFJebin AbrahamAinda não há avaliações

- Dolphy - Skylikes Yahoo India Search ResultsDocumento2 páginasDolphy - Skylikes Yahoo India Search ResultsJebin AbrahamAinda não há avaliações

- Why Use Dishes in Pressure Vessels - Google SearchDocumento2 páginasWhy Use Dishes in Pressure Vessels - Google SearchJebin AbrahamAinda não há avaliações

- Engineering Mechanics by Beer and Johnston PDF - Google SearchDocumento2 páginasEngineering Mechanics by Beer and Johnston PDF - Google SearchJebin Abraham25% (12)

- Gantry Crane Design - Google SearchDocumento2 páginasGantry Crane Design - Google SearchJebin AbrahamAinda não há avaliações

- Sheet Metal Forming PPT - Google SearchDocumento2 páginasSheet Metal Forming PPT - Google SearchJebin AbrahamAinda não há avaliações

- Gantry Crane Design Calculations - Google SearchDocumento2 páginasGantry Crane Design Calculations - Google SearchJebin Abraham100% (1)

- Blank Size Formula For Sheet Metal Forming - Google SearchDocumento2 páginasBlank Size Formula For Sheet Metal Forming - Google SearchJebin AbrahamAinda não há avaliações

- Mechanism - Google Search PDFDocumento2 páginasMechanism - Google Search PDFJebin AbrahamAinda não há avaliações

- Calculate Shape Factor of Box Furnace - Google SearchDocumento2 páginasCalculate Shape Factor of Box Furnace - Google SearchJebin Abraham100% (1)

- How Can I Stop Showing - A Document Named - Xxx..Documento17 páginasHow Can I Stop Showing - A Document Named - Xxx..Jebin AbrahamAinda não há avaliações

- 1.4.5. Step 4: Setting Up The CFD Simulation in ANSYS FLUENTDocumento16 páginas1.4.5. Step 4: Setting Up The CFD Simulation in ANSYS FLUENTJebin AbrahamAinda não há avaliações

- Thermal and Fluent Analysis in Ansys - Google SearchDocumento2 páginasThermal and Fluent Analysis in Ansys - Google SearchJebin AbrahamAinda não há avaliações

- C. Cone, Energy Management For Industrial Furnaces, Wiley, New York, 1980Documento2 páginasC. Cone, Energy Management For Industrial Furnaces, Wiley, New York, 1980Jebin AbrahamAinda não há avaliações

- Bis Pipe Standards - Google SearchDocumento1 páginaBis Pipe Standards - Google SearchJebin AbrahamAinda não há avaliações

- Solidworks Cools Tricks - Google SearchDocumento1 páginaSolidworks Cools Tricks - Google SearchJebin AbrahamAinda não há avaliações

- Convection - Google SearchDocumento2 páginasConvection - Google SearchJebin AbrahamAinda não há avaliações

- Thermocouple Calibration Furnace Youtube - Google SearchDocumento2 páginasThermocouple Calibration Furnace Youtube - Google SearchJebin AbrahamAinda não há avaliações

- Convection Between 2 Conduction CalculationDocumento2 páginasConvection Between 2 Conduction CalculationJebin AbrahamAinda não há avaliações

- Research Article: Impeller Design of A Centrifugal Fan With Blade OptimizationDocumento17 páginasResearch Article: Impeller Design of A Centrifugal Fan With Blade OptimizationJebin AbrahamAinda não há avaliações

- Sheet CalculationDocumento2 páginasSheet CalculationJebin AbrahamAinda não há avaliações

- Convective Heat Transfer Coefficient of Air in Industrial Furnace - Google SearchDocumento2 páginasConvective Heat Transfer Coefficient of Air in Industrial Furnace - Google SearchJebin AbrahamAinda não há avaliações

- Design and Performance of Vertical ShaftsDocumento1 páginaDesign and Performance of Vertical ShaftsJebin AbrahamAinda não há avaliações

- Input and Output Statements PDFDocumento11 páginasInput and Output Statements PDFRajendra BuchadeAinda não há avaliações

- Review Rachna WasteDocumento9 páginasReview Rachna WasteSanjeet DuhanAinda não há avaliações

- Using Impact IX49 and 61 With Nektar DAW Integration 1.1Documento21 páginasUsing Impact IX49 and 61 With Nektar DAW Integration 1.1Eko SeynAinda não há avaliações

- N6867e PXLP 3000Documento7 páginasN6867e PXLP 3000talaporriAinda não há avaliações

- Swanand 2009Documento3 páginasSwanand 2009maverick2929Ainda não há avaliações

- Quemador BrahmaDocumento4 páginasQuemador BrahmaClaudio VerdeAinda não há avaliações

- Placa 9 - SHUTTLE A14RV08 - 71R-A14RV4-T840 - REV A0 10ABR2012Documento39 páginasPlaca 9 - SHUTTLE A14RV08 - 71R-A14RV4-T840 - REV A0 10ABR2012Sergio GalliAinda não há avaliações

- Selecting Appropriate Instructional Materials For Edukasyong Pantahanan at Pangkabuhayan/ Technology and Livelihood EducationDocumento35 páginasSelecting Appropriate Instructional Materials For Edukasyong Pantahanan at Pangkabuhayan/ Technology and Livelihood EducationJhenn Mhen Yhon100% (1)

- Apps Android StudioDocumento12 páginasApps Android StudioDaniel AlcocerAinda não há avaliações

- GoodElearning TOGAF Poster 46 - Adapting The ADMDocumento1 páginaGoodElearning TOGAF Poster 46 - Adapting The ADMFabian HidalgoAinda não há avaliações

- Florida Motor Fuel Tax Relief Act of 2022Documento9 páginasFlorida Motor Fuel Tax Relief Act of 2022ABC Action NewsAinda não há avaliações

- Content Analysis of Studies On Cpec Coverage: A Comparative Study of Pakistani and Chinese NewspapersDocumento18 páginasContent Analysis of Studies On Cpec Coverage: A Comparative Study of Pakistani and Chinese NewspapersfarhanAinda não há avaliações

- Evolution DBQDocumento4 páginasEvolution DBQCharles JordanAinda não há avaliações

- DJF 41032 Manufacturing Workshop Practice 3 Plastic Lab: Mini Project (Transfer Moulding)Documento7 páginasDJF 41032 Manufacturing Workshop Practice 3 Plastic Lab: Mini Project (Transfer Moulding)Lokhman HakimAinda não há avaliações

- EE 8602 - Protection and Switchgear Unit I - MCQ BankDocumento11 páginasEE 8602 - Protection and Switchgear Unit I - MCQ Bankpoonam yadavAinda não há avaliações

- Each Life Raft Must Contain A Few ItemsDocumento2 páginasEach Life Raft Must Contain A Few ItemsMar SundayAinda não há avaliações

- Motive 27Tmx: Data SheetDocumento2 páginasMotive 27Tmx: Data SheetUlisesGómezAinda não há avaliações

- The Theory of Production and Cost: Chapter FourDocumento32 páginasThe Theory of Production and Cost: Chapter FourOromay Elias100% (1)

- RHB Islamic Bank BerhadDocumento2 páginasRHB Islamic Bank BerhadVape Hut KlangAinda não há avaliações

- 2014 Abidetal. TheoreticalPerspectiveofCorporateGovernance BulletinofBusinessDocumento11 páginas2014 Abidetal. TheoreticalPerspectiveofCorporateGovernance BulletinofBusinessOne PlusAinda não há avaliações

- Exp - P7 - UPCTDocumento11 páginasExp - P7 - UPCTSiddesh PatilAinda não há avaliações

- 09-11-2016 University Exam PaperDocumento34 páginas09-11-2016 University Exam PaperSirisha AsadiAinda não há avaliações

- The Adoption of e Procurement in Tanzani PDFDocumento5 páginasThe Adoption of e Procurement in Tanzani PDFDangyi GodSeesAinda não há avaliações

- Electric PotentialDocumento26 páginasElectric PotentialGlitchAinda não há avaliações

- Time Table & Instruction For Candidate - Faculty of Sci & TechDocumento3 páginasTime Table & Instruction For Candidate - Faculty of Sci & TechDeepshikha Mehta joshiAinda não há avaliações

- Lesson 2 (Probability of An Event)Documento4 páginasLesson 2 (Probability of An Event)MarlAinda não há avaliações

- Pursuit of Performance Findings From The 2014 Miller Heiman Sales Best Practices StudyDocumento37 páginasPursuit of Performance Findings From The 2014 Miller Heiman Sales Best Practices StudyLoredanaAinda não há avaliações

- In Search of Begum Akhtar PDFDocumento42 páginasIn Search of Begum Akhtar PDFsreyas1273Ainda não há avaliações

- ARCASIA Students Design Competition TORDocumento4 páginasARCASIA Students Design Competition TORDeena McgeeAinda não há avaliações