Escolar Documentos

Profissional Documentos

Cultura Documentos

Manholes

Enviado por

A.K.A. HajiDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Manholes

Enviado por

A.K.A. HajiDireitos autorais:

Formatos disponíveis

Underground Electric Distribution Standards

MANHOLES

I.

CAST-IN-PLACE STRUCTURES

I.1.

GENERAL

Cast-in-place structures are specified when existing cables or adjacent buildings, etc.

preclude the possibility of setting a pre-cast unit. This normally dictates that the excavation

be sheet piled and built around existing energized cables.

I.2.

DESIGN

I.2.1. Cast-in-place structures are individually designed by the Design Consultant based

on soil information, water levels, anticipated loading, etc.

I.2.2. The design consultant may require that a base course of several feet thickness and

extending beyond the perimeter of the structure by 18" to 24" be placed, or that the

structure be constructed on piling. This may or may not preclude the use of the

sheet piling to form the outer wall of the manhole.

I.3.

DESIGN CLASSES

The component parts of the structure may be designed in various ways as itemized below::

I.3.1.1. Pile Cap, rectangular or hexagonal.

I.3.1.2. Mat Foundation, rectangular or hexagonal.

I.3.2. Walls:

I.3.2.1. Bearing walls with 2 way reinforcement.

I.3.2.2. Walls designed for future knock-out with 2 way reinforcement and

plastered columns.

I.3.3. Top:

I.3.3.1. Elevated flat plate slab with 2 way reinforcement and angled

reinforcement around openings.

I.3.3.2. Elevated 2 way beam and slab.

I.3.4. Columns, Plastered, Rectangular:

I.3.4.1. Square tied reinforcement.

I.3.5. Access:

I.3.5.1. Pre-cast grade extension rings.

I.3.5.2. Curb, straight, reinforced with imbedded grate frame.

I.4.

ADDITIONAL ITEMS

Sump holes, pulling irons, ground rods, and duct bell ends will be installed in all manholes.

In addition, sump pump drain pipes will be installed in transformer vaults.

I.5.

CONSTRUCTION

Specifications for concrete work including formwork, shore removal and placement of

reinforcing steel are prescribed in the Concrete and Piles Section.

I.6.

MODIFYING EXISTING STRUCTURES

This work will consist of replacing portions of existing structures with one or more of the

design classes indicated above.

Revised: January 2013

Revised By: SGL

MANHOLES

IV-2 - Page 1 of 20

Approved By: RHS

Underground Electric Distribution Standards

I.7.

PLATING INSTRUCTIONS

To plate a cast-in-place structure, it is necessary to plate the following items separately,

obtaining quantities from the design consultants' plans.

Excavation

EXC ___ X ___ - ___

Forms

Rebar

Concrete

FORM REBAR - ___ * ___

CONC ___

MBLD-MH-NECK

BLD-MH-NECK.

Manhole Neck and Frame and Cover

I.8.

ADDITIONAL PLATES

PLATE

PULL-IRONS

GROUT-DUCT*C

GROUT-DUCT*H

MPUMP-MH

PUMP-MH

MCLEAN-MH

CLEAN-MH

MSTUB-OUT

STUB-OUT

II.

DESCRIPTION

UNIT

Installation of Pulling Irons

Fill and Seal Around Duct

(C=COLD, H=HOT)

EA

Pump out Manhole

EA

Clean out Manhole

EA

Drill Hole in Manhole Wall for up to

6" Duct, Grout around Duct

EA

EA

PRECAST STRUCTURES

II.1.

GENERAL

II.1.1. Includes well-pointing, sheeting, installation, backfilling, compaction and building of

neck, depth in feet indicated by option.

II.1.2. Pre-cast structures may be set in locations where there may or may not be existing

cables. Excavations may or may not need to be sheeted, but in most cases will

require well-pointing.

II.1.3. Excavations where there are existing cables must be large enough to allow the

bottom portion of the structure to be swung under the cables.

II.1.4. A driven ground rod megged to 25 OHMS or less is to be installed at each structure

location.

II.2.

INSTALLING SECTIONS

Pre-cast concrete sections shall be set so the structure will be vertical and with sections in

true alignment. Joint surfaces between the sections shall be sealed with a pre-molded

plastic joint sealer equal to "Ramnek" applied to the bottom section according to the structure

manufacturer's instructions.

II.3.

NON-SHRINK JOINTS

All holes in structures for entering pipes or ducts shall be thoroughly plugged with nonshrinking mortar, applied so there will be zero leakage around pipes and ducts. The mortar

will be finished smooth and flush with the ducts, pipes, etc. and the adjoining interior walls.

Revised: January 2013

Revised By: SGL

MANHOLES

IV-2 - Page 2 of 20

Approved By: RHS

Underground Electric Distribution Standards

III.

II.4.

DUCT TERMINATION

Plastic bell-ends will be installed on each duct flush with inside walls. If bell-ends with a

membrane to seal the duct are available they will be used.

II.5.

TEMPORARY DUCT SEALS

Once all duct entering the manhole is declared satisfactory, an expandable foam mixture, if

available, will be placed in each duct opening. This will provide a watertight, temporary seal

to prevent duct from becoming clogged and to prevent water from traveling between adjacent

manholes. If foam is not available, use proper size PVC conduit plug.

II.6.

ADDITIONAL PLATES

Listed below are plates not otherwise covered by a Construction Standard Plate and

Drawing.

Plate

Description

Unit

FOAM-DUCT Installing Expandable Foam

EA

MFOAM-DUCT Mixture in Duct Opening

I.CODBE001

2 PVC BELL END

EA

I.CODBE002

3 PVC BELL END

EA

I.CODBE003

4 PVC BELL END

EA

I.CODBE004

6 PVC BELL END

EA

I.CODRC001

3 - 2 PVC REDUCER COUPLING

EA

I.CODRC002

3 - 2-1/2 PVC REDUCER COUPLING

EA

I.CODRC042

4 - 2 PVC REDUCER COUPLING

EA

I.CODRC043

4 - 3 PVC REDUCER COUPLING

EA

I.CODRC062

6 - 2 PVC REDUCER COUPLING

EA

I.CODRC063

6 - 3 PVC REDUCER COUPLING

EA

I.CODRC064

6 - 4 PVC REDUCER COUPLING

EA

MANHOLE AND VAULT GRADE ADJUSTMENT

III.1.

GENERAL

III.1.1. For grade adjustment in setting a manhole frame, brick masonry shall be used on

top of the manhole or on top of a pre-cast concrete grade extension ring in

accordance with the drawings.

III.1.2. For grade adjustment of vault frames a cast-in-place concrete curb shall be

constructed on the vault top, the work under this section shall also include the

adjustment of existing structures.

III.2.

MATERIAL

III.2.1. Brick:

The brick shall be clay or shale brick, sound, hard and uniform in shape and size

meeting the requirements of ASTM Standard Specifications for Sewer Brick,

Designation C-32, Grade MM.

III.2.2. Mortar for Brickwork:

The mortar shall be composed of one part Portland Cement (ASTM C150-71, Type

I), and two parts washed silica sand (ASTM C144-70). Lime shall not be used.

Revised: January 2013

Revised By: SGL

MANHOLES

IV-2 - Page 3 of 20

Approved By: RHS

Underground Electric Distribution Standards

III.2.3. Concrete:

The concrete used in construction shall be as specified in the Project Documents.

III.2.4. Grade Extension Ring:

The standard grade extension ring has a 36" inside diameter, has a 6" wall and is

15" high. Rings 6" and 9" high are also available.

III.2.5. Frames and Covers:

Specifications for frames, grates, and covers are as specified by the Standards

Section.

III.3.

LAYING BRICKWORK

Only clean brick shall be used. All brick shall be saturated with water before being laid.

Each brick shall be laid in a full bed and joint of mortar without requiring subsequent grouting,

flushing, or filling and shall be thoroughly bonded.

III.4.

PLASTERING AND CURING BRICK-MASONRY

III.4.1. Outside faces of brick masonry shall be plastered with mortar from 1/4 inch to 3/8

inch thick. If required, the masonry shall be properly moistened prior to application

of the mortar.

III.4.2. The plaster shall be carefully spread and troweled so that all cracks are thoroughly

worked out.

III.4.3. After hardening, the plaster shall be carefully checked, by being tapped, for bond

and soundness. Unbonded or unsound plaster shall be removed and replaced.

III.4.4. Brick masonry and plaster shall be protected from too rapid drying by the use of

burlaps kept moist, or by other approved means, and shall be protected from the

weather and frost, all as required.

III.5.

SETTING MANHOLE FRAMES

III.5.1. Manhole frames and covers shall be set to conform accurately to the finished

ground or pavement surface as established by the drawings, unless otherwise

directed by the Engineer.

III.5.2. Frames shall be set concentric with the masonry and in a full bed of mortar so that

the space between the top of the manhole masonry and the bottom flanges of the

frame shall be completely filled and made water tight.

III.5.3. A ring of mortar at least one inch thick and pitched to shed water away from the

frame shall be placed around the outside of the bottom flange. Mortar shall extend

to the outer edge of the masonry and shall be finished smooth and flush with the top

of the flange.

III.6.

TRAFFIC BEARING COVERS

Grade adjustment of manholes subject to traffic shall be done according to City

Specifications. This requires that an 18 inch ring of 4000 PSI concrete, a minimum of 6

inches in thickness be poured around the frame. See Manhole Cover Adjustment Plate.

Revised: January 2013

Revised By: SGL

MANHOLES

IV-2 - Page 4 of 20

Approved By: RHS

Underground Electric Distribution Standards

III.7.

ADDITIONAL PLATES:

Listed below are plates not otherwise covered by a Construction Plate and Drawing.

PLATE

DESCRIPTION

UNIT

ADD-BRICK

One additional course of brick to adjust

EA

manhole frame and cover.

MADD-BRICK

Remove existing "Butterfly" manhole roof and

REP-BFLY-SP (See notes) replace it with a 1" thick steel plate (Grade B

EA

minimum - per ASTM A238-81).

REP-BFLY-SP Notes:

a. Steel plate to be cut one (1) foot longer and wider than interior dimensions of manhole.

b. Do not use this Plate for manholes larger than 4'x 6'.

c. 36" diameter hole to be cut in center of plate.

d. After all cuts are made coat both sides of steel plate with an asphalt base emulsion as per

ASTM-D1187-82

e. Use other appropriate Plates to build neck or adjust cover to grade.

IV.

MANHOLE ABANDONMENT

PLATE

MH-ABND

IV.1.

DESCRIPTION

See Notes Below

UNIT

CU FT

MANHOLE ABANDONMENT NOTES

IV.1.1. This construction plate provides for the abandonment of manholes, vaults, or other

underground structures which have no further use to JEA.

IV.1.2. This construction plate shall include all of the required operations as set forth in the

abandon manhole bid item in the manhole and duct bank unit price construction

contract. (Section VIII - Concrete Removal)

IV.1.3. The unit of measure shall be one (1) cubic foot. Measurements shall be the volume

of the interior of the manhole prior to demolition, expressed in cubic feet rounded off

to the next whole cubic foot. All materials shall be furnished by the contractor.

Revised: January 2013

Revised By: SGL

MANHOLES

IV-2 - Page 5 of 20

Approved By: RHS

Underground Electric Distribution Standards

SET-PVC-MH

MSET-PVC-MH

REINFORCED PLASTIC MANHOLE

NON TRAFFIC RATING

Maximum Allowed: 3-Cables, 3-Splices, Cable Size 1/0 Primary

MSET-PVC-MH OPTION:

INSTALLATION CONDITIONS:

C = Cold, New Construction

H = Hot, Construction around existing Cables

EXAMPLE: MSET-PVC-MH*C

ITEM

QTY

DESCRIPTION

MANHO005

HOKCA006

*NOTE:

Revised: January 2013

1

6

1 CU. YD.

MANHOLE, REINFORCED PLASTIC

HOOK, CABLE RACK

BASE COURSE *

A compacted base course footing shall be included in this plate. Footing shall be level, minimum of

one (1) foot deep, and extend a minimum of six (6) inches beyond the outside edges of the

manhole base. (+/- 4.0 x 6.0 x 1.0deep)

Revised By: SGL

MANHOLES

IV-2 - Page 6 of 20

Approved By: RHS

Underground Electric Distribution Standards

SET-4 X 6*_

PRE-CAST STRUCTURES

Maximum Allowed: 6-Cables; 6-Splices; Cable Size-1/0 Primary; 4 Stub-outs

MSET OPTIONS

DEPTH: Depth of excavation in feet indicated by option: 9, 10, 11, 12

INSTALLATION:

Installation condition indicated by option:

C - New construction (cold) or

H - Construction around existing cables (hot).

EXAMPLE: MSET-4X6*9C

SET OPTIONS

DEPTH: All manholes are to be set with two feet (2) of cover minimum above roof (Max 3).

INSTALLATION:

Installation condition indicated by option:

U - Undeveloped area (new) or

D - Developed area (existing).

EXAMPLE: SET-4X6*D

ITEM

QTY

DESCRIPTION

42

BRICK, COMMON

1

CEMENT, MORTAR, 96# BAG

COVMA001

1

COVER, MANHOLE

FRAMC001

1

FRAME, MANHOLE COVER

MANER003

1

GRADE EXTENSION RING

MANH0001

1

MANHOLE, PRECAST CONCRETE

AS REQUIRED BASE COURSE *

* NOTE:

A compacted base course footing shall be included in this plate.

Revised: January 2013

Revised By: SGL

MANHOLES

IV-2 - Page 7 of 20

Approved By: RHS

Underground Electric Distribution Standards

SET-6 X 9*_

PRE-CAST STRUCTURES

NOTE: Do Not Install 1000 MCM Cables In The 6x9 Manhole.

MSET OPTIONS

DEPTH: Depth of excavation in feet indicated by option: 9, 10, 11, 12

INSTALLATION:

Installation condition indicated by option:

C - New construction (cold) or

H - Construction around existing cables (hot).

Example: MSET-6X9*9C

SET OPTIONS

DEPTH: All manholes are to be set with two feet (2) of cover minimum above roof (Max 3).

INSTALLATION:

Installation condition indicated by option:

U - Undeveloped area (new) or

D - Developed area (existing).

Example: SET-6X9*D

ITEM

QTY

DESCRIPTION

84

BRICK, COMMON

2

CEMENT, MORTAR, 96# BAG

COVMA001

2

COVER, MANHOLE

FRAMC001

2

FRAME, MANHOLE COVER

MANER003

2

GRADE EXTENSION RING

MANH0006

1

MANHOLE, PRECAST CONCRETE

AS REQUIRED

BASE COURSE *

*NOTE:

A compacted base course footing shall be included in this plate.

Revised: January 2013

Revised By: SGL

MANHOLES

IV-2 - Page 8 of 20

Approved By: RHS

Underground Electric Distribution Standards

SET-6 X 12*_

PRE-CAST STRUCTURES

MSET OPTIONS

DEPTH: Depth of excavation in feet indicated by option: 10, 11, 12, 13

INSTALLATION:

Installation condition indicated by option:

C - New construction (cold) or

H - Construction around existing cables (hot).

Example: MSET-6X12*11C

SET OPTIONS

DEPTH: All manholes are to be set with two feet (2) of cover minimum above roof (Max 3).

INSTALLATION:

Installation condition indicated by option:

U - Undeveloped area (new) or

D - Developed area (existing).

Example: SET-6X12*D

ITEM

QTY

DESCRIPTION

84

BRICK, COMMON

2

CEMENT, MORTAR, 96# BAG

COVMA001

2

COVER, MANHOLE

FRAMC001

2

FRAME, MANHOLE COVER

MANER003

2

GRADE EXTENSION RING

MANH0002

1

MANHOLE, PRECAST CONCRETE

AS REQUIRED BASE COURSE *

*NOTE:A compacted base course footing shall be included in this plate.

Revised: January 2013

Revised By: SGL

MANHOLES

IV-2 - Page 9 of 20

Approved By: RHS

Underground Electric Distribution Standards

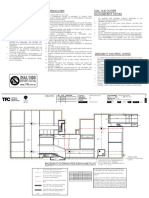

MSET 6 X 12 X 10*_

PRE-CAST STRUCTURES

7'

13'

4'-3"

3'-0"

SEE

BLD-MH-NECK

P LATE

3'-9"

11'

MSET OPTIONS

DEPTH: Depth of excavation in feet indicated by option: 13, 14, 15, 16

INSTALLATION:

Installation condition indicated by option:

C - New construction (cold) or

H - Construction around existing cables (hot).

EXAMPLE: MSET6X12X10*14C

ITEM

QTY

DESCRIPTION

84

BRICK, COMMON

2

CEMENT, MORTAR, 96# BAG

COVMA001

2

COVER, MANHOLE

FRAMC001

2

FRAME, MANHOLE COVER

MANER003

2

GRADE EXTENSION RING

MANH0002

1

MANHOLE, PRECAST CONCRETE

MANEX001

1

MANHOLE EXTENSION, PRECAST CONCRETE

AS REQUIRED BASE COURSE

Revised: January 2013

Revised By: SGL

MANHOLES

IV-2 - Page 10 of 20

Approved By: RHS

Underground Electric Distribution Standards

MSET-8 X 12*_

PRE-CAST STRUCTURES

9'

13'

7"

SEE

BLD-MH-NECK

PLATE

3'-6"

6"

3'-6"

7"

MSET OPTIONS

DEPTH: Depth of excavation in feet indicated by option: 10, 11, 12, 13

INSTALLATION:

Installation condition indicated by option:

C - New construction (cold) or

H - Construction around existing cables (hot).

EXAMPLE: MSET-8X12*13C

ITEM

QTY

DESCRIPTION

84

BRICK, COMMON

2

CEMENT, MORTAR, 96# BAG

COVMA001

2

COVER, MANHOLE

FRAMC001

2

FRAME, MANHOLE COVER

MANER003

2

GRADE EXTENSION RING

MANH0003

1

MANHOLE, PRECAST CONCRETE

AS REQUIRED BASE COURSE

Revised: January 2013

Revised By: SGL

MANHOLES

IV-2 - Page 11 of 20

Approved By: RHS

8'-2"

Underground Electric Distribution Standards

MSET-8 X 16*_

PRE-CAST STRUCTURES

MSET OPTIONS

DEPTH: Depth of excavation in feet indicated by option: 10, 11, 12, 13, 14

INSTALLATION:

Installation condition indicated by option:

C - New construction (cold) or

H - Construction around existing cables (hot).

Example: MSET-8X16*12C

ITEM

QTY

DESCRIPTION

GRAMH001

2

VENTILATED GRATE COVER

GRAMH002

2

FILLED GRATE COVER

FRAGR002

2

VENTILATED GRATE FRAME

FRAGR001

1

FILLED GRATE FRAME

MANHO004

1

VAULT, PRECAST CONCRETE

Revised: January 2013

Revised By: SGL

MANHOLES

IV-2 - Page 12 of 20

Approved By: RHS

Underground Electric Distribution Standards

SET-8 X 30*_

PRE-CAST STRUCTURES

MSET OPTIONS

DEPTH: Depth of excavation in feet indicated by option: 10, 11, 12, 13, 14

INSTALLATION:

Installation condition indicated by option:

C - New construction (cold) or

H - Construction around existing cables (hot).

Example: SET-8X30*14H

ITEM

QTY

DESCRIPTION

GRAMH001

4

VENTILATED GRATE COVER

GRAMH002

4

FILLED GRATE COVER

FRAGR002

4

VENTILATED GRATE FRAME

FRAGR001

2

FILLED GRATE FRAME

SPECIAL ORDER

1

VAULT, PRE CAST CONCRETE

Revised: January 2013

Revised By: SGL

MANHOLES

IV-2 - Page 13 of 20

Approved By: RHS

Underground Electric Distribution Standards

MANHOLE GROUND

GROUNDING PROVISIONS

FINISH GRADE

6"

CODPL005

2'

CODPC007

CODEP024

MANHOLE

ITEM

CODEP024

CODPC007

CODPL005

QTY

1

2 FT

1

DESCRIPTION

ELBOW, 1 PVC SCH 40, 90 DEG., 18RAD.

CONDUIT, 1 PVC DB-120

PLUG, CONDUIT, 1 PVC

NOTES:

1. Please see the grounding Plate G2P-C.

2. This material is issued with all SET-_X_ Manhole plates.

Revised: January 2013

Revised By: SGL

MANHOLES

IV-2 - Page 14 of 20

Approved By: RHS

Underground Electric Distribution Standards

CBL-ARM

CBL-RACK

MANHOLE CABLE ARM & CABLE RACK

*There are four sizes of hooks. Itemize other hooks as required.

CBL-ARM

(CABLE-ARM)

CBL-RACK

(CABLE-RACK)

Revised: January 2013

ITEM

HOKCA003

INSCA001

ANCSD001

BOLMH002

RACUC002

QTY

1

1

2

2

1

Revised By: SGL

MANHOLES

IV-2 - Page 15 of 20

DESCRIPTION

HOOK, CABLE 7-7/8 INCH EXT. LOCK TYPE

INSULATOR, CABLE RACK

ANCHOR, SELF DRILLING 1/2 X 2 INCHES

BOLT, MACHINE HEX HEAD 1/2 X 2 INCHES

RACK, CABLE 42 INCHES

Approved By: RHS

Underground Electric Distribution Standards

BLD-MH-NECK

BUILD MANHOLE NECK

DETAILING ENGINEER:

FOR MORE BRICKS OR

SMALLER EXTENSION RING,

INTEMIZE BUILD OR REMOVE

COVMA001

FRAMC001

XXXZZ015

MANER003

BLD-MH-NECK

ITEM

COVMA001

FRAMC001

MANER003

Revised: January 2013

QTY

1

42

1

1

1

DESCRIPTION

CEMENT, MORTAR 96LB. BAG

BRICK, COMMON 2

COVER, MANHOLE 34 3/4 DIAMETER,

REGULAR

FRAME, MANHOLE COVER 33-1/4 CAST IRON,

4-1/8 HIGH

GRADE EXTENSION RING, CONCRETE, 15

HIGH (JEA STOCK)

Revised By: SGL

MANHOLES

IV-2 - Page 16 of 20

Approved By: RHS

Underground Electric Distribution Standards

FORM-_

CAST IN PLACE MANHOLE

PLATE

DESCRIPTION

FORM-PC

PILE CAPS

FORM-SLAB

FORM-WALL

FORM-WC

FORM TOP-1

FORM TOP-2

FORM-CURB

BOTTOM

REGULAR WALL

WALLS WITH PILASTERED COLUMNS

ELEVATED FLAT PLATE SLAB

ELEVATED TWO-WAY BEAM & SLAB

TRANSFORMER VAULT ACCESS CURB

Revised: January 2013

Revised By: SGL

MANHOLES

IV-2 - Page 17 of 20

UNIT

SQUARE FEET OF CONTACT

AREA (SFCA)

Approved By: RHS

Underground Electric Distribution Standards

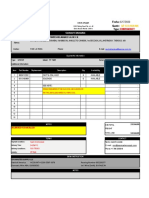

ADJ-MH-T

ADJ-MH-NT

MANHOLE COVER ADJUSTMENTS FOR GRADE CHANGES

MANHOLE ADJUSTMENT NOTES:

1. For non-traffic (NT) bearing applications, 1 - 6 concrete poured-in-place collar not required.

2. ** Call for plate ADD-BRICK if additional courses of brick are required to adjust manhole cover to

grade.

Revised: January 2013

Revised By: SGL

MANHOLES

IV-2 - Page 18 of 20

Approved By: RHS

Underground Electric Distribution Standards

ADJ-MH-MILL-A

ADJ-MH-MILL-B

MANHOLE COVER ADJUSTMENTS FOR PAVT MILLING

ADJ-MH-MILL -A

DESCRIPTION

CEMENT, MORTAR, 96# BAG

BRICK, COMMON, 2

CONCRETE, 4000PS1, CU.FT

Revised: January 2013

QTY

1

42

11

Revised By: SGL

MANHOLES

IV-2 - Page 19 of 20

Approved By: RHS

Underground Electric Distribution Standards

UDBP

LADDER AND SUMP PUMP

6"

12"

M

126"

14"

MANHOLE ACCESSORIES

UDBP

ITEM

CODPC001

B

C

D

E

FUSH0003

FUSUG046

CAIUF001

CODAD009

CODAD010

PUMSU001

PUMSU004

M

Revised: January 2013

QTY

20

1

1

1

1

1

1

15

1

1

1

1

1

DESCRIPTION

PIPE, PVC 2 SCHEDULE 40

ELBOW, 90 PVC

CHECK VALVE, BRASS SWING

NIPPLE, 6 X 2 DIAMETER

UNION, 2

FUSE HOLDER

FUSE, ONE TIME 20 AMP

CABLE, STREET LIGHT

ADAPTER, MALE 2 CONDUIT

ADAPTER, FEMALE 2 CONDUIT

PUMP, SUMP 4/10 HP

DOUBLE FLOAT PUMP SWITCH

LADDER, GALVANIZED STEEL 10 6

Revised By: SGL

MANHOLES

IV-2 - Page 20 of 20

Approved By: RHS

Você também pode gostar

- Concrete BundsDocumento12 páginasConcrete BundsPaul JamesonAinda não há avaliações

- 5628 3 2001 PDFDocumento133 páginas5628 3 2001 PDFhz135874Ainda não há avaliações

- 2.03 Wood Beam Formwork VARIOFIXDocumento23 páginas2.03 Wood Beam Formwork VARIOFIXezzularab100% (1)

- Loffelstein Installation ManualDocumento16 páginasLoffelstein Installation Manuallarushkan100% (2)

- Technical manual sections on lifting systems/TITLEDocumento120 páginasTechnical manual sections on lifting systems/TITLEArnold GarciaAinda não há avaliações

- Muro Wall FormworkDocumento10 páginasMuro Wall FormworkDaliform GroupAinda não há avaliações

- Multiflex: The Flexible Girder Formwork For SlabsDocumento52 páginasMultiflex: The Flexible Girder Formwork For SlabsJack Jeff50% (2)

- RCBC SizesDocumento5 páginasRCBC Sizesenggmohan100% (1)

- CorkelastDocumento12 páginasCorkelastDr. JonesAinda não há avaliações

- Concrete Construction Article PDF - Precast Stairs Speed Concrete Building ConstructionDocumento2 páginasConcrete Construction Article PDF - Precast Stairs Speed Concrete Building ConstructionPhara LuckyAinda não há avaliações

- Steelwork Framing C2Documento26 páginasSteelwork Framing C2Luwalhati TomilasAinda não há avaliações

- Early Thermal Cracking CalculationsDocumento1 páginaEarly Thermal Cracking Calculationsmassive85Ainda não há avaliações

- Density and strength requirements for normal and heavyweight concreteDocumento2 páginasDensity and strength requirements for normal and heavyweight concreteFranklin TwumasiAinda não há avaliações

- Manhole Channel DesignDocumento6 páginasManhole Channel DesignYoke ShuAinda não há avaliações

- Mountain View Community Centre TenderDocumento15 páginasMountain View Community Centre TenderDean KoortzenAinda não há avaliações

- Cisz22 PDFDocumento40 páginasCisz22 PDFLim Yew Kwang100% (2)

- M003-81111 QSPSC11Documento54 páginasM003-81111 QSPSC11harimaumalayaAinda não há avaliações

- BCSA Guide To The Installation of Deep DeckingDocumento0 páginaBCSA Guide To The Installation of Deep DeckingDifa LiuAinda não há avaliações

- Bilag 2b Variation Order RequestDocumento1 páginaBilag 2b Variation Order RequestLegend AnbuAinda não há avaliações

- 07 QUTStudentConnectionDocumento26 páginas07 QUTStudentConnectionThaiNguyenAinda não há avaliações

- Welcome To The Institute For Timber Construction-South Africa Itc-SaDocumento75 páginasWelcome To The Institute For Timber Construction-South Africa Itc-SaMclyb GumbieAinda não há avaliações

- AISC Certification Standard ForDocumento60 páginasAISC Certification Standard ForTry SmallAinda não há avaliações

- National Structural Concrete Specification For Building Construction - Edition 3 PDFDocumento78 páginasNational Structural Concrete Specification For Building Construction - Edition 3 PDFfade2black11100% (2)

- Workmanship On Building SitesDocumento28 páginasWorkmanship On Building SitesSa Reddi100% (1)

- DD20 CircularPrecastConcreteManholesDocumento5 páginasDD20 CircularPrecastConcreteManholesericpardo59Ainda não há avaliações

- Roofing Code of Practice PDFDocumento379 páginasRoofing Code of Practice PDFAlejandro Segura Pereira100% (1)

- Portal Frame Structures ExplainedDocumento2 páginasPortal Frame Structures ExplainedSohanAinda não há avaliações

- Twinson Composite Decking InstallationDocumento17 páginasTwinson Composite Decking InstallationpbrilhanteAinda não há avaliações

- IGS Paper Q 291Documento4 páginasIGS Paper Q 291RoshanRSVAinda não há avaliações

- Methodology For Convreting WorksDocumento7 páginasMethodology For Convreting WorksLokesh SaranAinda não há avaliações

- ManholeDocumento11 páginasManholeNia ZainorinAinda não há avaliações

- U Drain SpecDocumento4 páginasU Drain Speckenji_sanAinda não há avaliações

- TP Water RetainingDocumento22 páginasTP Water RetainingChinthaka SomaratnaAinda não há avaliações

- 0.04 Roof Plumbing Roof and StormwaterDocumento6 páginas0.04 Roof Plumbing Roof and Stormwaterqaisarmehboob82Ainda não há avaliações

- 33 PACS Quick Build PanelsDocumento44 páginas33 PACS Quick Build PanelsOrianAinda não há avaliações

- Sequence of Works For Mezzanine FloorDocumento8 páginasSequence of Works For Mezzanine FloorMyureshwaranAinda não há avaliações

- Concrete and Concrete Structures: Modular Concepts India PVT LTDDocumento24 páginasConcrete and Concrete Structures: Modular Concepts India PVT LTDArunKumar ChandrasekarAinda não há avaliações

- Gir Gai Trading Hot Rolled Steel Sections PDFDocumento4 páginasGir Gai Trading Hot Rolled Steel Sections PDFtpop1707Ainda não há avaliações

- Dilapidation Report ExampleDocumento16 páginasDilapidation Report ExampleJose Israel Barillas SaraviaAinda não há avaliações

- Formwork SpecificationDocumento61 páginasFormwork SpecificationAnonymous ALBuK8vOm100% (1)

- Trench Excavation DiagramDocumento1 páginaTrench Excavation Diagramharry watersAinda não há avaliações

- Tile Works - Terrazzo TilesDocumento5 páginasTile Works - Terrazzo TilesglenAinda não há avaliações

- Retaining Wall With HeelDocumento8 páginasRetaining Wall With HeelKalpanaAinda não há avaliações

- Concrete Formwork and FinishesDocumento15 páginasConcrete Formwork and FinishesIm Chinith100% (1)

- TechNote Manhole Inverts March13Documento5 páginasTechNote Manhole Inverts March13Aruna JayasundaraAinda não há avaliações

- RAFT Foundation FDocumento30 páginasRAFT Foundation F10bcl016100% (3)

- Crack Width - BS 8007Documento1 páginaCrack Width - BS 8007nishchintAinda não há avaliações

- Formworks & ScaffoldingsDocumento56 páginasFormworks & ScaffoldingsGeanno PolinagAinda não há avaliações

- What Is The Column Kicker - Its Formworks, Application and AdvantagesDocumento2 páginasWhat Is The Column Kicker - Its Formworks, Application and AdvantagesNaveen BansalAinda não há avaliações

- Manhole Invert Channels Design and InstallationDocumento5 páginasManhole Invert Channels Design and InstallationJovo BozovicAinda não há avaliações

- PVC Waterstop DatasheetsDocumento2 páginasPVC Waterstop DatasheetssfgfhgfjAinda não há avaliações

- Procedure For Slab To SlabDocumento5 páginasProcedure For Slab To SlabKarthik Chalageri 7100% (1)

- 4 Dygal ST, Mona Vale - Stormwater DrawingDocumento8 páginas4 Dygal ST, Mona Vale - Stormwater DrawingRohan Dutt SharmaAinda não há avaliações

- Unit Weight of Tile With MortarDocumento4 páginasUnit Weight of Tile With MortarzcvzxAinda não há avaliações

- A41 Construction MethodologyDocumento15 páginasA41 Construction MethodologyCasfeta technical official Tayomi100% (1)

- 8M-Digest VOL 6 PDFDocumento52 páginas8M-Digest VOL 6 PDFSamuel AcidriAinda não há avaliações

- TECHNICAL NOTE 011 Lateral Loads On Falsework - Is Cross-Bracing Really Not Required at All PDFDocumento2 páginasTECHNICAL NOTE 011 Lateral Loads On Falsework - Is Cross-Bracing Really Not Required at All PDFmyduyen75Ainda não há avaliações

- CONSTRUCTION STANDARD FOR INSTALLING PRECAST CONCRETE MANHOLESDocumento9 páginasCONSTRUCTION STANDARD FOR INSTALLING PRECAST CONCRETE MANHOLESgemotorresAinda não há avaliações

- Review of Permeable Pavement Systems in Malaysia ConditionsDocumento10 páginasReview of Permeable Pavement Systems in Malaysia ConditionsEkki GustiAinda não há avaliações

- MSI Company Profile FinalDocumento23 páginasMSI Company Profile FinalA.K.A. HajiAinda não há avaliações

- Lscgensets 2Documento6 páginasLscgensets 2Reydel QuimnoAinda não há avaliações

- IEEE 400.2 New Testing Req For Medium Voltage Cables Technical Paper Auth - Craig Goodwin NETA 2005Documento18 páginasIEEE 400.2 New Testing Req For Medium Voltage Cables Technical Paper Auth - Craig Goodwin NETA 2005Giovanni Leras100% (4)

- HindiBook Yogic Sukshma Vyayam Dhirendra Brahmchari Hindi PDFDocumento211 páginasHindiBook Yogic Sukshma Vyayam Dhirendra Brahmchari Hindi PDFRishav Dikshit89% (19)

- Hunter Mach 2Documento9 páginasHunter Mach 2A.K.A. HajiAinda não há avaliações

- Emergency Lighting Discharge Test KitsDocumento2 páginasEmergency Lighting Discharge Test KitsA.K.A. HajiAinda não há avaliações

- Color of Underground Warning TapeDocumento1 páginaColor of Underground Warning TapeA.K.A. HajiAinda não há avaliações

- IEEE 400.2 New Testing Req For Medium Voltage Cables Technical Paper Auth - Craig Goodwin NETA 2005Documento18 páginasIEEE 400.2 New Testing Req For Medium Voltage Cables Technical Paper Auth - Craig Goodwin NETA 2005Giovanni Leras100% (4)

- Megger InsulationtesterDocumento67 páginasMegger InsulationtesterNh Chuminda YapaAinda não há avaliações

- Hanuman CharitraDocumento17 páginasHanuman CharitraA.K.A. HajiAinda não há avaliações

- Curriculum Science Grade 5Documento154 páginasCurriculum Science Grade 5A.K.A. Haji100% (2)

- Digital Lines and The Integrated Service Digital NetworkDocumento9 páginasDigital Lines and The Integrated Service Digital NetworkA.K.A. HajiAinda não há avaliações

- Emergency Lighting Discharge Test KitsDocumento2 páginasEmergency Lighting Discharge Test KitsA.K.A. HajiAinda não há avaliações

- Applying Demand & Diversity FactorDocumento5 páginasApplying Demand & Diversity Factoranchak99100% (1)

- Applying Demand & Diversity FactorDocumento5 páginasApplying Demand & Diversity Factoranchak99100% (1)

- Guide Busbar Issue2 Apr04Documento20 páginasGuide Busbar Issue2 Apr04A.K.A. Haji100% (1)

- Cahier Technique: Discrimination With LV Power Circuit BreakersDocumento30 páginasCahier Technique: Discrimination With LV Power Circuit BreakersDheeraj YadavAinda não há avaliações

- 02 Filipovic DlabacDocumento8 páginas02 Filipovic DlabacA.K.A. HajiAinda não há avaliações

- Electrical - Busbar - Table 3 - Quick Busbar SelectorDocumento3 páginasElectrical - Busbar - Table 3 - Quick Busbar SelectorA.K.A. HajiAinda não há avaliações

- ECT162Documento20 páginasECT162A.K.A. HajiAinda não há avaliações

- Ect166 Enclosures and Degrees of ProtectionDocumento12 páginasEct166 Enclosures and Degrees of ProtectionMarko VujicaAinda não há avaliações

- Earthing 173Documento24 páginasEarthing 173nicus81Ainda não há avaliações

- 1 Cable Size Voltage Drop Calculation1.1.15Documento103 páginas1 Cable Size Voltage Drop Calculation1.1.15mahaprakashAinda não há avaliações

- Selection of Main - Branch CB As Per NEC-210 (1.1.19)Documento9 páginasSelection of Main - Branch CB As Per NEC-210 (1.1.19)jiguparmar1516Ainda não há avaliações

- HV Cable BoxesDocumento5 páginasHV Cable BoxesA.K.A. HajiAinda não há avaliações

- Telecom Equipment RoomDocumento26 páginasTelecom Equipment RoomTimothy LeonardAinda não há avaliações

- Electrical Testing BrochureDocumento20 páginasElectrical Testing BrochureA.K.A. HajiAinda não há avaliações

- Internal Cabling GuidelinesDocumento2 páginasInternal Cabling GuidelinesA.K.A. HajiAinda não há avaliações

- Hassan Al Khalid IDocumento350 páginasHassan Al Khalid IA.K.A. HajiAinda não há avaliações

- Japanese Construction Firms enDocumento4 páginasJapanese Construction Firms enLanang Ardi ParinggaAinda não há avaliações

- Emergency Replacement Parts for Grove RT 760E CraneDocumento1 páginaEmergency Replacement Parts for Grove RT 760E CraneraulAinda não há avaliações

- Igrid SV LV 3kva Split Phase Hybrid Solar Inverter: 110V-120V Grid Tie Solar Inverter With Energy StorageDocumento1 páginaIgrid SV LV 3kva Split Phase Hybrid Solar Inverter: 110V-120V Grid Tie Solar Inverter With Energy Storagejccl2Ainda não há avaliações

- Shandong Lingong Construction Machinery Co., Ltd. Null Product Parts CatalogDocumento353 páginasShandong Lingong Construction Machinery Co., Ltd. Null Product Parts Catalogadelmomoura100% (1)

- This Manual Includes: Repair Procedures Fault Codes Electrical and Hydraulic SchematicsDocumento298 páginasThis Manual Includes: Repair Procedures Fault Codes Electrical and Hydraulic SchematicsJugaro OscarAinda não há avaliações

- Deep Cycle Batteries Solar EbookDocumento27 páginasDeep Cycle Batteries Solar Ebookanakraja11Ainda não há avaliações

- Resistance in The Fluid System PDFDocumento21 páginasResistance in The Fluid System PDFDyo MandeAinda não há avaliações

- AI Guide - What is Artificial Intelligence and How Does it WorkDocumento10 páginasAI Guide - What is Artificial Intelligence and How Does it WorkZeus Kabadayı FanAinda não há avaliações

- H.No:-1148, Sector:-6, Housing Board, Dharuhera (Rewari) Mobile No.: - 9812816143, 8708015205Documento2 páginasH.No:-1148, Sector:-6, Housing Board, Dharuhera (Rewari) Mobile No.: - 9812816143, 8708015205parveen tanwarAinda não há avaliações

- Zroute Training Lab v1 0Documento23 páginasZroute Training Lab v1 0ChetanAinda não há avaliações

- CS Form No. 212 Attachment - Work Experience SheetDocumento2 páginasCS Form No. 212 Attachment - Work Experience Sheetdominic kokoyAinda não há avaliações

- SPE 00 301120 40mah en 1.0verDocumento10 páginasSPE 00 301120 40mah en 1.0verAndreea FilipAinda não há avaliações

- Aer520 LabsDocumento37 páginasAer520 LabsChristopher LauricoAinda não há avaliações

- Production SchedulingDocumento242 páginasProduction SchedulingClint Foster0% (2)

- Gigabyte Sandy Bridge Overclocking GuideDocumento27 páginasGigabyte Sandy Bridge Overclocking GuideGIGABYTE UK100% (2)

- Private Key Addresses and Compressed AddressesDocumento5 páginasPrivate Key Addresses and Compressed AddressesJeffrey Barnes100% (1)

- 0 Delphi Labs DataSnap XE CallbacksDocumento7 páginas0 Delphi Labs DataSnap XE Callbacksduna tarimaAinda não há avaliações

- Zero Escape Virtues Last Reward PDFDocumento33 páginasZero Escape Virtues Last Reward PDFfcaicedo7239Ainda não há avaliações

- Vittore Cossalter Motorcycle Dynamics BDocumento405 páginasVittore Cossalter Motorcycle Dynamics BAsad Ali100% (8)

- Mother Board INTEL D945GNT - TechProdSpecDocumento94 páginasMother Board INTEL D945GNT - TechProdSpecVinoth KumarAinda não há avaliações

- IBPS CLERK 2012 Question Paper DownloadDocumento4 páginasIBPS CLERK 2012 Question Paper DownloadedugeeksAinda não há avaliações

- Instrument TubingDocumento11 páginasInstrument Tubingbab_ooAinda não há avaliações

- 02 CNC Lab Manual NIT APDocumento3 páginas02 CNC Lab Manual NIT APDevesh RehanAinda não há avaliações

- Turbine Heat Rate CalculationDocumento2 páginasTurbine Heat Rate Calculationkaruna34650% (2)

- BUSINESS RESEARCH CHALLENGESDocumento12 páginasBUSINESS RESEARCH CHALLENGESShilpa JadhavAinda não há avaliações

- Advantages of JeepneyDocumento3 páginasAdvantages of JeepneyCarl James L. MatrizAinda não há avaliações

- Company Profile of DAEJU CONTROL CO., LTD.Documento17 páginasCompany Profile of DAEJU CONTROL CO., LTD.Ki Ho ChungAinda não há avaliações

- Pipe Material Specs (MCP)Documento106 páginasPipe Material Specs (MCP)BoulHich BoulHichAinda não há avaliações

- Biogas PlantDocumento37 páginasBiogas PlantMahaManthra100% (1)