Escolar Documentos

Profissional Documentos

Cultura Documentos

Calculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A Pump

Enviado por

thanh_79Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Calculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A Pump

Enviado por

thanh_79Direitos autorais:

Formatos disponíveis

Calculation of friction losses, power, developed head and

available Net Positive Suction Head of a pump

1. On the Tools menu, click Options, then click the Calculation tab and tick on the Iteration

2. In the spreadsheet "Calculations"

a. Insert the parameter values in the cells C21-C40 (yellow cells)

- If the pump is below the liquid level in the suction tank, z 1 (cell C38) is positive. If the pump is abo

- If there are not enlargements or contractions in the system, set enlargement and/or contraction c

b. Turn the "SWITCH" ON (set the value in the cell G1 (red cell) equal to 1 and press ENTER)

c. Iterate (by pressing F9) until the value of " f " in the cell H17 is constant

d. To recalculate for different parameter values turn the "SWITCH" OFF (set the value in the cell G1 eq

Equations that are being used in the calculations

Calculation of the Fanning friction factor " f "

In laminar flow, by using the equation:

f=

16

Re

In turbulent flow, by using the Colebrook equation:

1

/ D 1. 255

=4 log10

+

3 .7 Re f

f

Calculation of the friction losses

In straight pipes

In sudden enlargement

h s=

P

L v2

=4 f

D 2

A1

he = 1

A2

v12

2

In sudden contraction

A 2 2 v 22

hc =0 . 55 1

A1 2

( )

Available Net Positive Suction Head

NPSH a =

P p v

g

+ z1

F s

g

e Iteration box. On Maximum iterations box write 1000.

ive. If the pump is above the liquid level in the suction tank, z 1 is negative

t and/or contraction coefficients in the cells C27 and C28 equal to 0

ress ENTER)

value in the cell G1 equal to 0 and press ENTER). Repeat steps 2a to 2c

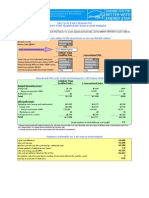

Calculation of friction losses,

required power, developed head and

available NPSH of a pump

Input data

Flow rate

Inside diameter

Pipe length

Suction pipe length

Density

Viscosity

Enlargement-loss coefficient

Contraction-loss coefficient

Q=

Di =

L=

Ls=

den =

visc=

Ke =

Kc =

20

0.042

12

2

1050

0.002

0

0.55

Valves-loss equivalent length

Le/D =

300

Fittings-loss equvalent length

Number of valves

Le/D =

Nv =

32

1

Number of fittings (90o elbows)

Rafness of the pipe

m3/h

m

m

m

kg/m3

Pas

Velocity at point 1

Nf =

raf =

v1=

Pressure at point 1

P1=

101325 Pa

Pressure at point 2

P2=

101325 Pa

Vapor pressure in the suction line

pv =

12349 Pa

Distance of point 1 from reference level

z1*=

-2

Distance of point 2 from reference level

Efficiency of the pump

z2=

8

70%

n=

3

0 m

0 m/s

* If the pump is above the liquid level in the suction tank, z1 is negative

SWITCH=

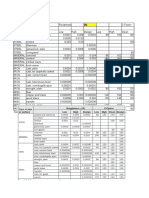

Derived data

Mass flow rate,

Cross sectional area

Mean velocity at point 2

Reynolds number

Relative rafness

Corection factor

m =

A =

vm2 =

Re =

rr =

5.8333 kg/s

0.00139 m2

4.010 m/s

88419

0

f=

0.0047

14.6

14.7

Fe =

Fc =

LeV =

LeF =

Fs =

Ft =

0.00

4.42

12.60

4.03

103.26

107.68

Results

Friction factor

Friction losses

Enlargement losses

Contraction losses

Valve-equivalent length

Fitting-equivalent length

Straight tube losses

Total friction losses

Energy and Power added to the fluid by the pump

-ws =

Required Power (brake power)

-Wsr =

Developed Head

H=

J/kg

J/kg

m

m

J/kg

J/kg

213.8 J/kg

-Ws =

1247.3 W

-Wsr =

1781.8 W

H=

21.8 m

Available NPSH

Friction losses in the suction line

-Contraction losses

-Fitting-equivalent length

-Straight tube losses

Total friction losses in the suction line

Fcs =

4.42 J/kg

LeFs =

Fss =

Fts =

1.34 m

12.06 J/kg

17.83 J/kg

NPSHa =

4.8 m

Você também pode gostar

- Kitchen VentilationDocumento56 páginasKitchen Ventilationwetchkrub100% (3)

- Pressure Loss & Performance Fan Calculation: Input Data Edit Comp & Fitg View Graph View Chart & DRWGDocumento11 páginasPressure Loss & Performance Fan Calculation: Input Data Edit Comp & Fitg View Graph View Chart & DRWGHerawan HeriAinda não há avaliações

- Balancing of Control LoopsDocumento27 páginasBalancing of Control Loopsebru_alpaslanAinda não há avaliações

- Water Calc - IA ClubHouseDocumento8 páginasWater Calc - IA ClubHouseRaxKitAinda não há avaliações

- REDUCTION of The SKI SLOPE EFFECTDocumento8 páginasREDUCTION of The SKI SLOPE EFFECTEnzo MarquesAinda não há avaliações

- Static Pressure Calc.Documento29 páginasStatic Pressure Calc.Allada Trinadh RaoAinda não há avaliações

- Equivalent Length of Pipe PDFDocumento3 páginasEquivalent Length of Pipe PDFSSudhakarAinda não há avaliações

- Static Pressure Calculation SheetDocumento22 páginasStatic Pressure Calculation SheetsafaldAinda não há avaliações

- Duct Leakage TestingDocumento51 páginasDuct Leakage Testingducatti996chAinda não há avaliações

- Pressure Loss - SwitchyardDocumento1 páginaPressure Loss - Switchyardkarthikraja21Ainda não há avaliações

- Engineered Smoke Control System-TraceDocumento156 páginasEngineered Smoke Control System-TraceKevin Chen100% (2)

- Yazd-System Description For Clean Drain System PDFDocumento7 páginasYazd-System Description For Clean Drain System PDFace-winnieAinda não há avaliações

- Louver and Pump SizeDocumento1 páginaLouver and Pump SizeShabeer HamzaAinda não há avaliações

- Construction Quality Assurance Workplan PDFDocumento84 páginasConstruction Quality Assurance Workplan PDFFadi AlabdullahAinda não há avaliações

- GEMI Equations ToolDocumento10 páginasGEMI Equations TooljnmanivannanAinda não há avaliações

- Transfer Pump-2Documento21 páginasTransfer Pump-2sunii19847908100% (1)

- Pump Head and Drive Calculations: General Data Crude OilDocumento1 páginaPump Head and Drive Calculations: General Data Crude OilyusefriAinda não há avaliações

- Tank or Silo - Volume and Level Calculations-D1.9SDocumento24 páginasTank or Silo - Volume and Level Calculations-D1.9SJacques J PienaarAinda não há avaliações

- ParalDocumento9 páginasParalTahirJabbarAinda não há avaliações

- Zero Water DischargeDocumento5 páginasZero Water Dischargehemendra499Ainda não há avaliações

- 6-Door Louver Size CalculationDocumento2 páginas6-Door Louver Size CalculationDang Thai SonAinda não há avaliações

- Psychrometric Chart For H 0 (M.a.s.l.) : X KG/KGDocumento16 páginasPsychrometric Chart For H 0 (M.a.s.l.) : X KG/KGfisplAinda não há avaliações

- Rectangular Duct AtteDocumento4 páginasRectangular Duct AtteShahrukh AnsariAinda não há avaliações

- Reciprocating CompressorsDocumento6 páginasReciprocating CompressorsNicolas LuchmunAinda não há avaliações

- Humidity ChartDocumento18 páginasHumidity ChartShadab AhmadAinda não há avaliações

- Mixer CalcDocumento10 páginasMixer CalchadiAinda não há avaliações

- SECOND QUARTER EXAM - ChemDocumento19 páginasSECOND QUARTER EXAM - ChemJoshua UveroAinda não há avaliações

- Bab Iv Hasil Pengamatan Dan PerhitunganDocumento9 páginasBab Iv Hasil Pengamatan Dan PerhitunganAhmad NurilAinda não há avaliações

- K Value of FittingsDocumento4 páginasK Value of FittingsJoydip Misra100% (6)

- Heat Recovery - EfficiencyDocumento58 páginasHeat Recovery - EfficiencyEshref AlemdarAinda não há avaliações

- System Duct Pressure Loss CalculationDocumento6 páginasSystem Duct Pressure Loss Calculationthanh_79Ainda não há avaliações

- Recommended Equal Friction MethodDocumento2 páginasRecommended Equal Friction MethodPhyu Mar Thein KyawAinda não há avaliações

- A Basic Design Guide For Clean Room ApplicationsDocumento61 páginasA Basic Design Guide For Clean Room ApplicationsAlex Chin67% (3)

- Water Heater Test Report 111413Documento30 páginasWater Heater Test Report 111413thanh_79Ainda não há avaliações

- Process Calculation For FREYLIT CPI Oil SeparatorDocumento4 páginasProcess Calculation For FREYLIT CPI Oil SeparatorRajdeepsinhAinda não há avaliações

- R-Pump Cal Sheet2Documento3 páginasR-Pump Cal Sheet2ggdgdfgdfgdfgdgddddAinda não há avaliações

- LEED Version 4 For Building Design and Construction (IMPORTANTE)Documento154 páginasLEED Version 4 For Building Design and Construction (IMPORTANTE)Carlos L. Oyuela100% (1)

- Boiler ChecklistDocumento2 páginasBoiler ChecklistJoydev GangulyAinda não há avaliações

- 3CCC81 Aeration Tank Design Si UnitsDocumento2 páginas3CCC81 Aeration Tank Design Si Unitsnassif75Ainda não há avaliações

- Ventilation DesignDocumento4 páginasVentilation DesignPhyu Mar Thein KyawAinda não há avaliações

- Kruger - Propeller FanDocumento2 páginasKruger - Propeller FanKok WaiAinda não há avaliações

- Ashp Sav CalcDocumento5 páginasAshp Sav CalcsauroAinda não há avaliações

- DbA CalculationDocumento4 páginasDbA Calculationthanh_79Ainda não há avaliações

- Dual Fuel Genset - Heat Recovery-1-2Documento2 páginasDual Fuel Genset - Heat Recovery-1-2Ab Sami100% (1)

- Density of WaterDocumento5 páginasDensity of WaterJean Pajuelo0% (1)

- Sgps Id01 CalcDocumento48 páginasSgps Id01 Calcsaroat moongwattanaAinda não há avaliações

- Alloy C Shell Thickness CalculationDocumento9 páginasAlloy C Shell Thickness Calculation9913489806Ainda não há avaliações

- Souq Waqif CHW Pump Head - Rev-01a As Per Approved DWGDocumento1 páginaSouq Waqif CHW Pump Head - Rev-01a As Per Approved DWGKarthy GanesanAinda não há avaliações

- Air-Handling Unit Pressure Drop: Unit No. Supply Return External ExternalDocumento6 páginasAir-Handling Unit Pressure Drop: Unit No. Supply Return External ExternalNghiaAinda não há avaliações

- Appendix 1 - Production Separator Sizing - Rev.0Documento5 páginasAppendix 1 - Production Separator Sizing - Rev.0Thái Xuân QuangAinda não há avaliações

- Irrigation Scheduling by Book Keeping MethodDocumento13 páginasIrrigation Scheduling by Book Keeping MethodShekh Muhsen Uddin AhmedAinda não há avaliações

- Static Pressure Calculation in The Air DuctsDocumento2 páginasStatic Pressure Calculation in The Air Ductsmeeng2014Ainda não há avaliações

- Submittal Chiller COP 6.02Documento3 páginasSubmittal Chiller COP 6.02juan yenqueAinda não há avaliações

- Process Specification Heat Exchanger CpeccDocumento2 páginasProcess Specification Heat Exchanger CpeccroyAinda não há avaliações

- Pre-Draft MBR StandardsDocumento14 páginasPre-Draft MBR StandardsAudrius100% (2)

- 1.0) Design Flow: Rectangle R.C.Open DrainDocumento1 página1.0) Design Flow: Rectangle R.C.Open DrainjjdavidAinda não há avaliações

- Calculator GWR Contact Time Calculator v9Documento16 páginasCalculator GWR Contact Time Calculator v9HeruAinda não há avaliações

- Weil Pump Flow and Basin Sizing Calculator (EDocFind - Com)Documento15 páginasWeil Pump Flow and Basin Sizing Calculator (EDocFind - Com)mohdnazirAinda não há avaliações

- Simplified Kachelofen Calculator: InstructionsDocumento8 páginasSimplified Kachelofen Calculator: InstructionscountlessAinda não há avaliações

- All Cooling Load RulesDocumento3 páginasAll Cooling Load RulesEngFaisal AlraiAinda não há avaliações

- Exercises: Che 418-Computer Applications in Chemical EngineeringDocumento12 páginasExercises: Che 418-Computer Applications in Chemical EngineeringeverletteAinda não há avaliações

- FMV Spreadsheets-Master-FMVIDocumento15 páginasFMV Spreadsheets-Master-FMVIadrianaortizv100% (1)

- Final Design Values of PHE C-510 CoolersDocumento4 páginasFinal Design Values of PHE C-510 CoolersRamji MishraAinda não há avaliações

- Copper Pipes (Based On Silver Book) : Purpose AssumptionsDocumento3 páginasCopper Pipes (Based On Silver Book) : Purpose AssumptionscesAinda não há avaliações

- Kaiser Water CalculatorDocumento34 páginasKaiser Water CalculatorPot StillerAinda não há avaliações

- Units ConversionDocumento9 páginasUnits ConversionNoor M KhanAinda não há avaliações

- Vent Dispersion Calc - OptionalDocumento4 páginasVent Dispersion Calc - OptionalPeddy Nesa0% (1)

- Calc-Plum Fire IrtankDocumento6 páginasCalc-Plum Fire IrtankAmro Metwally El HendawyAinda não há avaliações

- Parameter Symbol Value Data Obtained Form Design Intent UnitDocumento8 páginasParameter Symbol Value Data Obtained Form Design Intent Uniteke23Ainda não há avaliações

- Air Duct CalculatorDocumento1 páginaAir Duct Calculatoraravoof84Ainda não há avaliações

- SBD 6479 WaterCalcWorksheet 01 12Documento4 páginasSBD 6479 WaterCalcWorksheet 01 12NghiaAinda não há avaliações

- PumpDocumento31 páginasPumpgrincheu70Ainda não há avaliações

- Level ControlDocumento11 páginasLevel ControlsitinuryanaAinda não há avaliações

- Lab-Instrcution-Wind-Tunnel 2019 FDocumento6 páginasLab-Instrcution-Wind-Tunnel 2019 FDavid100% (1)

- Procedure and Scope: Good Luck, Ravi SankarDocumento27 páginasProcedure and Scope: Good Luck, Ravi SankarRazook MohammedAinda não há avaliações

- Quality Assurance and Quality Control ProceduresDocumento4 páginasQuality Assurance and Quality Control Proceduresthanh_79Ainda não há avaliações

- Stairwell PressurisationDocumento2 páginasStairwell PressurisationsudeeshkumarsAinda não há avaliações

- A7 Guidelines July2013Documento16 páginasA7 Guidelines July2013thanh_79Ainda não há avaliações

- Mica 1-660 PDFDocumento1 páginaMica 1-660 PDFthanh_79Ainda não há avaliações

- ComparingVAVDuctDesigns NCEMBT-070315 PDFDocumento121 páginasComparingVAVDuctDesigns NCEMBT-070315 PDFthanh_79Ainda não há avaliações

- European Standard Norme Européenne Europäische NormDocumento49 páginasEuropean Standard Norme Européenne Europäische Normthanh_79Ainda não há avaliações

- Cash Flow ModelDocumento6 páginasCash Flow ModelniroAinda não há avaliações

- Materials Finer Than 75 - M (No. 200) Sieve in Mineral Aggregates by WashingDocumento4 páginasMaterials Finer Than 75 - M (No. 200) Sieve in Mineral Aggregates by WashingHaftari HarmiAinda não há avaliações

- Materials Finer Than 75 - M (No. 200) Sieve in Mineral Aggregates by WashingDocumento4 páginasMaterials Finer Than 75 - M (No. 200) Sieve in Mineral Aggregates by WashingHaftari HarmiAinda não há avaliações

- Materials Finer Than 75 - M (No. 200) Sieve in Mineral Aggregates by WashingDocumento4 páginasMaterials Finer Than 75 - M (No. 200) Sieve in Mineral Aggregates by WashingHaftari HarmiAinda não há avaliações

- Materials Finer Than 75 - M (No. 200) Sieve in Mineral Aggregates by WashingDocumento4 páginasMaterials Finer Than 75 - M (No. 200) Sieve in Mineral Aggregates by WashingHaftari HarmiAinda não há avaliações

- DW143 Test Summary Sheet July 2015Documento2 páginasDW143 Test Summary Sheet July 2015thanh_79Ainda não há avaliações

- Wap 3 Ventilation WksheetDocumento4 páginasWap 3 Ventilation Wksheetthanh_79Ainda não há avaliações

- DW143 Test Summary Sheet July 2015Documento2 páginasDW143 Test Summary Sheet July 2015thanh_79Ainda não há avaliações

- Hydraulic HandbookDocumento4 páginasHydraulic Handbookthanh_79Ainda não há avaliações

- Vent CalcDocumento5 páginasVent Calcthanh_79Ainda não há avaliações

- DW143 Test Summary Sheet July 2015Documento2 páginasDW143 Test Summary Sheet July 2015thanh_79Ainda não há avaliações

- Mathematical Modelof Freeze Dryingon MangoDocumento14 páginasMathematical Modelof Freeze Dryingon MangoEfraín MagosAinda não há avaliações

- Device Corrosion: Enumerate The Electrical Contact Degradation and The Types of Mechanism Involved in ItDocumento10 páginasDevice Corrosion: Enumerate The Electrical Contact Degradation and The Types of Mechanism Involved in ItSreekanth KrishnamurthyAinda não há avaliações

- Consisting: of The CircuitDocumento25 páginasConsisting: of The Circuitspy shotAinda não há avaliações

- Malaco AdditionalNotes3 MAT70Documento4 páginasMalaco AdditionalNotes3 MAT70I AM DJAinda não há avaliações

- Series Circuits: Prepared By: Alexander T. Montero, Ree, RmeDocumento45 páginasSeries Circuits: Prepared By: Alexander T. Montero, Ree, RmeMarc Jairro GajudoAinda não há avaliações

- TheveDocumento8 páginasTheveET201040 Mohin UddinAinda não há avaliações

- Microsonar: Ultrasonic Proximity TransmitterDocumento4 páginasMicrosonar: Ultrasonic Proximity TransmitterSayed Ibrahim GhanemAinda não há avaliações

- ViscoseDocumento4 páginasViscoseTarique RizwanAinda não há avaliações

- Change of Standard Gibbs Free Energy For The Decomposition of Sodium Hydrogen CarbonaDocumento13 páginasChange of Standard Gibbs Free Energy For The Decomposition of Sodium Hydrogen CarbonaEuphoria V KhosaAinda não há avaliações

- Lecture #2 - Soil Investigation, CENG 401-1-1Documento14 páginasLecture #2 - Soil Investigation, CENG 401-1-1Haphiz JusuAinda não há avaliações

- PTC 25 Manual PTC PDF FreeDocumento8 páginasPTC 25 Manual PTC PDF Freejay javierAinda não há avaliações

- Fx3u 4ad Adp Usermanual Jy997d13901 LDocumento3 páginasFx3u 4ad Adp Usermanual Jy997d13901 LVictor GrassiAinda não há avaliações

- Tuned Liquid DamperDocumento86 páginasTuned Liquid Damperabdulloh_99Ainda não há avaliações

- Stellar SR33 Series Basic Soft Starters: Advantages Standards & ApprovalsDocumento7 páginasStellar SR33 Series Basic Soft Starters: Advantages Standards & ApprovalsJOHAN RICARDO REINA FLORIDOAinda não há avaliações

- Stage 0 183170022 RahulDocumento43 páginasStage 0 183170022 RahulManoj VishwakarmaAinda não há avaliações

- Fin Fan Cooler MotorDocumento1 páginaFin Fan Cooler MotorOm EliasAinda não há avaliações

- Physical Science Week 15Documento11 páginasPhysical Science Week 15Aleli Joy Profugo DalisayAinda não há avaliações

- Compression Testing of Metallic Materials at Room TemperatureDocumento10 páginasCompression Testing of Metallic Materials at Room TemperatureSandipGangurdeAinda não há avaliações

- Controlling The Dispersion of Multi-Wall Carbon Nanotubes in Aqueous Surfactant SolutionDocumento6 páginasControlling The Dispersion of Multi-Wall Carbon Nanotubes in Aqueous Surfactant SolutionDrRoja A RAinda não há avaliações

- AcknowledgementDocumento5 páginasAcknowledgementRonyJoyAinda não há avaliações

- Unesco - Eolss Sample Chapters: Stress Classification in Pressure Vessels and PipingDocumento7 páginasUnesco - Eolss Sample Chapters: Stress Classification in Pressure Vessels and PipingbahmanAinda não há avaliações

- Technical Characteristics Application: Interface C Tee ConnectorDocumento2 páginasTechnical Characteristics Application: Interface C Tee ConnectorJames VidalAinda não há avaliações

- 4.moving Charges and Magnetism 2nd PUC PYQsDocumento2 páginas4.moving Charges and Magnetism 2nd PUC PYQsAjith 007Ainda não há avaliações

- Relativistic DampingDocumento18 páginasRelativistic DampingChrisTselentisAinda não há avaliações

- Cambridge International AS & A Level: Further Mathematics 9231/11Documento16 páginasCambridge International AS & A Level: Further Mathematics 9231/11millieAinda não há avaliações

- (John F. Moulder) PHI Handbook of XRay Photoelectron SpectrosDocumento192 páginas(John F. Moulder) PHI Handbook of XRay Photoelectron SpectrosCamilo CorredorAinda não há avaliações

- Unimac UW125TVDocumento82 páginasUnimac UW125TVCarlos TrybiecAinda não há avaliações

- Mec203 Engineering ThermodynamicsDocumento8 páginasMec203 Engineering ThermodynamicsDeedar SinghAinda não há avaliações