Escolar Documentos

Profissional Documentos

Cultura Documentos

Hypervelocity Impact Damage in Composites PDF

Enviado por

bedo39Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Hypervelocity Impact Damage in Composites PDF

Enviado por

bedo39Direitos autorais:

Formatos disponíveis

R. A.

Clegg et al / International Journal of Impact Engineering

Hypervelocity Impact Damage Prediction in Composites

Part I - Material Model and Characterisation

*

R. A. Clegg**, D. M. White*, W. Riedel+, W. Harwick+

Century Dynamics Ltd, Dynamics House, Hurst Road, Horsham, West Sussex, RH12 2DT, England

+

FhG - Ernst-Mach-Institut, Eckerstrae 4, D-79104, Freiburg, Germany

Abstract

This paper reports on the development of an extended orthotropic continuum material model and associated

material characterisation techniques for the simulation and validation of impacts onto fibre reinforced composite

materials. This Part I of the paper focuses on the details of the numerical model and the material characterisation

experiments. Part II Experimental Investigation and Simulations [1] provides details of hypervelocity impact

damage experiments and simulations performed to assess the capabilities of the developed model. Here a detailed

description of the material model [2], as implemented in AUTODYN [3], is provided. The model is an extension

of that presented in [4], which allowed the correct thermodynamic response of orthotropic materials to be

simulated under shock wave loading. Improved capabilities to allow prediction of the extent of damage and

residual strength of fibre composite materials after impact are described along with set of quasi-static and

dynamic experiments used to characterise the directional non-linear strength and extent of damage. Application of

the model and derived material data is demonstrated through the simulation of a hypervelocity impact event of an

aluminium sphere impacting the Columbus module shielding system of the International Space Station (ISS).

Keywords: Hypervelocity, Impact, Material Model, Material Characterisation, Kevlar, CFRP

1. Introduction

The study of impacts on composite materials is a requirement for both manned and unmanned

spacecraft structures. On manned spacecraft, such as the ISS, fibre reinforced composite materials are

used in the primary shielding system used to mitigate the effects of orbital space debris impacts. On

unmanned spacecraft carbon fibre reinforced composite materials are commonly employed for major

structural components. Although such components are not designed to mitigate the effects of

hypervelocity impact, the consequences in terms of secondary debris after such impacts is of concern in

relation to the survivability of on-board equipment. This paper describes an advanced material model,

and set of material characterisation experiments, for orthotropic materials that has been developed to

*

Corresponding author. Tel.: +44 1403 270066; fax:+44 1403 270099

E-mail address: richard.clegg@centurydynamics.co.uk

R. A. Clegg et al / International Journal of Impact Engineering

improve the predictive capabilities of numerical simulations of hypervelocity impacts on a range of

composite spacecraft structures/materials [2].

The foundation for the material modelling and characterisation work presented here is described in

detail in [4]. This work led to the identification of the following phenomena, which we believe are of

primary interest for composite and textile materials subject to high/hypervelocity impact:

material anisotropy

shock response

anisotropic strength degradation (damage).

The material model [2] developed to address these aspects of composite material simulation under

impact loading is now described. The material model development was carried out hand-in-hand with

material characterisation experiments which are also described alongside the model features.

2. Basic Orthotropic Stiffness and Shock Response

In anisotropic materials, the traditional independent approach for the solution of the equation of

state and constitutive relations in a hydrocode is complicated because these two sub-models are

strongly coupled; volumetric strain leads to deviatoric stress, and similarly deviatoric strain leads to

spherical stress. A methodology [5] was implemented and further developed in AUTODYN as reported

in [4]. Consider a linear elastic orthotropic material for which the total incremental stress, ij, can be

related to the total incremental strain, ij, through the orthotropic stiffness matrix, Cij. The coefficients

of Cij being functions of the orthotropic elastic material constants, Eii, ij and Gij.

ij = C ij ijd + v

3

(1)

To facilitate the coupling of the deviatoric and volumetric material response the total strain has

been decomposed into volumetric, v, and deviatoric, ijd, components. Since the pressure is the average

of the three direct stresses, from (1) we can obtain:

P =

1

(C11 + C22 + C33 + 2C12 + 2C23 + 2C31 ) v

9

1

1

1

d

d

d

(C11 + C21 + C31 )11

(C12 + C22 + C32 ) 22

(C13 + C23 + C33 ) 33

3

3

3

(2)

For an isotropic Hookean material the first term on the right-hand side of (2) is equivalent to a

linear equation of state, whilst the remaining deviatoric strain terms would be zero. Thus for an

orthotropic material we can replace the first term with a non-linear Mie-Gruneisen equation of state and

the remaining terms act as a correction due to deviatoric strains.

A model based on the above was implemented in AUTODYN [3] and has subsequently been used

for simulating high to hypervelocity impacts on a wide range of applications and materials [6], [7], [8],

[9], [10]. This experience identified potential weaknesses of the model especially with respect to

anisotropic strength degradation. Characterising and modelling these aspects is the main focus of the

R. A. Clegg et al / International Journal of Impact Engineering

current work.

The phases of anisotropic strength degradation in a composite material can be categorised into

Nonlinear hardening (maximum stress increases with strain)

Nonlinear softening (maximum stress decreases with strain)

The observed material characteristics, and tests to derive them, are now outlined along with the

macro-mechanical material modelling features developed to represent the behaviour.

2.1 Non-linear Hardening

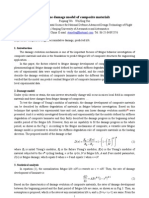

Many composite materials exhibit non-linear stress strain behaviour when subject to tensile uniaxial

stress loading. The most common example of such behaviour is found when loading a unidirectional

fibre reinforced laminate at 45 degrees to the fibre direction (Fig. 1). The observed non-linear response

results in a reduction in the tangent material stiffness with strain.

200

H ydraulic piston

Stepwise Loading

Monotonic Loading

150

Stress [MPa]

100

h

Specimen

l0

h

w

l

l0

t

50

Load cell

= 60 mm

= 10 mm

= 230 mm

= 165 mm

= 20 mm

0

0

0.02

0.04

0.06

0.08

0.1

0.12

Strain [-]

Fig. 1. Uniaxial tension test, cyclic stress strain curve for Kevlar-epoxy (0/90) loaded at 45 to the fibre direction [2].

The envelope to the stress strain curves (Fig. 1) clearly shows non-linear hardening behaviour.

Cyclic unloading and re-loading also reveals that the non-linear hardening results in irreversible

deformation. This terminology is consistent with that used for dislocation plasticity. However, in this

case the underlying micro/meso mechanical behaviour may include a number of different mechanisms

such as matrix plasticity, fibre re-orientation and matrix/fibre damage. The baseline material model [4]

employs a linear elastic orthotropic stiffness matrix under small tensile strains hence is not capable of

capturing this type of behaviour.

To enable phenomenological representation of this hardening behaviour, a generalised limit surface

[11] has been adopted. This surface is quadratic in stress space and is generally applicable to composite

materials. For example, no a priori assumptions are made in respect of the influence of hydrostatic

stress on inelastic deformation as in Hills orthotropic yield criteria [12].

2

2

2

f = a11 11

+ a22 22

+ a33 33

+ 2a12 11 22 + 2a23 22 33 + 2a13 11 33

(3)

+2a44 + 2a55 +

2

23

2

31

k 0

2

2a66 12

where the stresses ij refer to the principal material directions, and k is a state variable defining the

instantaneous value of the limit surface. The nine coefficients, aij define the extent of anisotropy in the

R. A. Clegg et al / International Journal of Impact Engineering

material response and are constants, implying isotropic hardening. It can be shown [11] that these

constants are related to the Plastic Poisson Ratio (PPR) in the material via

a11 = a22

P

21

12P

, a33 = a22

P

23

P

32

, a11 = a33

P

P

a12 = a22 21

, a23 = a22 23

31P

13P

(4)

P

, a13 = a33 31

The values of the coefficients can thus be obtained from a series of well-instrumented tension and

shear experiments. Fig. 2 shows the results of a typical in-plane and through thickness instrumented

tension test on an aramid-fibre-epoxy specimen [2]. Note the non-linear characteristics of both the inplane and out-of-plane Poisson ratio. For the purpose of the numerical model, this data must be

linearised into an elastic and inelastic Poisson ratio.

Applied strain gauges on sample side

and front surface

= 0.08

In-plane PPR

= 0.70

m

m

Out-of-plane-plane PPR

Fig. 2. Uniaxial tension test, measurement of elastic and plastic Poissons ratio [2].

In terms of numerical implementation, an iterative backward-Euler procedure [13] is used to return

trial elastic stresses, which lie outside the limit surface, normally back to the limit surface. The

associated incremental inelastic strains are defined using the Prandtl-Reuss equations, often called an

associated flow rule, and state that the plastic strain increments are proportional to the stress gradient of

the yield function. The proportionality constant, d, is known as the plastic strain-rate multiplier.

Written out explicitly the inelastic strain increments are given by

d 11p 2a11 11 +

p

d 22 2a12 11 +

d 33p 2a13 11 +

p=

d 23

d 31p

p

d12

2a12 22

2a22 22

+

+

2a23 22 +

4a44 23

4a55 31

4a66 12

2a13 33

2a23 33

2a33 33

d

From which an equivalent inelastic strain measure can be derived [2]

(5)

R. A. Clegg et al / International Journal of Impact Engineering

(d )

P 2

8

f d2

3

(6)

This in turn feeds back into the hardening function, k, of the limit surface.

The developed non-linear hardening option, in combination with the baseline model, allows for

much improved simulation of the non-linear in-plane hardening behaviour of fibre composite materials

as shown in Fig. 3.

Fig. 3. Aramid-fibre-epoxy uniaxial stress tension tests - experiment and simulation. (a) Loading at 0 to fibre direction;

(b) Loading at 45 to fibre direction.

2.2 Non-linear Softening (Damage)

Considering failure in fibre composite materials, delamination caused by through thickness strain,

shear strain causing matrix cracking, and fibre failure are the dominant modes of damage for impact

loading. These modes of failure lead to a reduction in load carrying capacity in one or more material

directions we shall term this phase of deformation as softening (reduction in capability to hold stress

with strain). A key characteristic here is the anisotropic nature of the effects of failure on the residual

strength of the material. For example delamination leaves the material with zero tensile strength across

the fibres, but significant tensile strength remains in the plane of the fibres.

To understand and quantify this type of phenomena a range of material characterisation tests must

be performed to establish; the point at which softening starts to occur, the rate at which the material

softens to zero strength in a particular material direction. These features determine the energy absorbed

during the damage process.

The modelling approach taken here introduces additional failure initiation criteria and associated

limit surfaces in material stress space, to represent specific modes of failure. Modified forms of the

well-known Hashin failure criteria [14] have been adopted for both the failure initiation criteria and

additional limit surfaces.

2

ii-plane::

eiif2

ij

ii

ik

1

+

+

=

ii , fail (1 Dii ) ij , fail (1 Dij ) ik , fail (1 Dik )

(7)

R. A. Clegg et al / International Journal of Impact Engineering

The above failure initiation criteria are checked at each material integration point each cycle. If one

of the failure criteria is exceeded (eiif>1), the orthotropic damage model is activated for that integration

point. The damage model has several aspects:

2.2.1

An Updated Elastic Material Stiffness Matrix

C11

C12 (1 Max( D11 , D22 ) ) C13 (1 Max( D11 , D33 ) ) 0

C (1 Max( D , D ) )

C 22

C 23 (1 Max( D22 , D33 ) ) 0

11

22

12

C13 (1 Max( D11 , D33 ) ) C 23 (1 Max( D22 , D33 ) )

0

C33

Cij =

0

0

0

C

44

0

0

0

0

0

0

0

0

2.2.2

0

0

0

0

C55

0

0

0

0

0

C66

(8)

Limit Surfaces in Material Stress Space and Damage Law

Additional limit surfaces are defined in material stress space through the failure initiation criteria in

each material plane. If a stress point lies outside a limit surface, it is associatively returned to the limit

surface using an iterative backward-Euler procedure [13]. Returning a stress point to a softening limit

surface results in inelastic crack strain.

The resulting inelastic strain ijcr is then used as input to an orthotropic damage evolution law

Lij Fij2 ijcr

Dij =

2Gijf Fij

(9)

where Fij represents the initial failure stress in the three material directions and shear, Gijf is the

fracture energy for each mode of failure and Lij is a local characteristic dimension of the numerical

integration point in each direction. This damage equation is formulated such that the work required to

extend a crack by a unit length is relatively insensitive to the local element size in each direction and is

an extension of the model developed for isotropic materials [15].

2.2.3

Damage Characterisation

The material data requirement for the orthotropic softening model was purposely limited to the

direct and shear failure initiation stress (Fij) in each of the material planes, and the associated fracture

energy release rates (Gfij) for mode I and II crack growth. A variety of material characterisation

experiments were developed and used to populate the parameters of the failure surfaces.

Static Damage Characterisation Tests

For the cross woven aramid-fibre-epoxy laminate under consideration (Kevlar/129-epoxy),

transverse isotropy was assumed. In this case the parameters for the failure surfaces in the two material

planes perpendicular to the fibres could be derived from the in-plane uniaxial tension tests, as detailed

above: The tensile failure initiation stress could be obtained directly from the experiment; the in-plane

shear failure stress was derived through numerical simulation and calibration to match the experimental

R. A. Clegg et al / International Journal of Impact Engineering

results for in-plane tension at 45 to the fibres (Fig. 3).

The transverse shear failure stress (mode II) was assumed to be equal to the inter-laminar shear

failure stress and derived from a Double Notched Shear test as descried in Fig. 4(a) (performed

according to standard proposal ASTM D 3846-79 and optimised according to [16] to compensate for

normal stresses). The mode II delamination energy was derived using an End Notch Flexure test as

described in Fig. 4(b) (performed in accordance with standard proposal EN 6034). A predefined crack

propagates as a result of the specimen bending and associated shear forces at the crack tip in the Mode

II loading. The total fracture energy GIIc is calculated from the initial crack length, the critical load to

start the crack and the associated piston displacement at onset of crack propagation.

The through thickness (mode I) delamination energy was obtained using a Double Cantilever Beam

test arrangement as described in Fig. 4(c) (performed in accordance with the standard proposal

EN6033). An initial delamination or pre-crack is introduced at the tip of the specimen with a diamond

saw. The pre-cracked specimen is loaded continuously by the loading device until a total propagated

crack length of 100 mm is achieved. The mode I fracture energy can be derived from the resulting load

displacement curves.

A major challenge for the characterisation and modelling of fibre reinforced composites subject to

impact is the through thickness (transverse shear) mode of deformation. Little attention is paid in the

literature to this mode of deformation, most composite research being focussed on in-plane and bending

response (structural behaviour). In this work a Short Beam Bending test [2] was used to try to

characterise the through thickness behaviour (Fig. 4(d)).

(a)

(b)

hydraulic piston

h

specimen

h

w

l

l0

t

load cell

= 100 mm

= 25 mm

= 35 mm

= 40 mm

= 5.7 mm

Piston

Specimen

Initial crack

l0 l

l

w

a

b

t

= 10 mm

= 8 mm

= 40 mm

=

= 5.7 mm

(c)

a

t

Load cell

Force

(d)

specimen dimensions:

5.7 mm

l=3.35 mm

fixed support

l=3.35 mm

- length: 140 mm

- width: b=20.24 mm

- thickness: t=5.7 mm

50 mm

wt

specimen

a

w

L

w

h

a

= 200 mm

= 25 mm

= 5.7 mm

= 50 mm

loading fork

Fig. 4. (a) Double notched shear test; (b) end notched flexure test; (c) double cantilever beam test; (d) short beam bending test.

Dynamic Damage Characterisation Tests

Planar Plate Impact tests were used here to estimate the spall strength (through thickness tensile

strength) of the material. The tests consisted of a 3mm thick aluminium alloy flyer impacting 5.65mm

thick aramid-fibre-epoxy laminate at velocities between 100m/s and 255m/s. A laser interferometer was

R. A. Clegg et al / International Journal of Impact Engineering

used to measure the particle velocity on the rear surface of the target.

To derive the through thickness tensile strength at high strain rates a superposition of release waves

is generated in the target plate. Therefore the ratios of plate thicknesses and shock velocities are adapted

to superimpose release waves from the target free surface and from the projectile rear side in the sample

(target) material. Fig. 6 shows the velocity signals recorded at the target free surface of the aramidfibre-epoxy composite. Note that in comparing experiment with numerical simulations of the

configurations using accurate shock data for the material [4], mismatches are observed with respect to

rise time and the shock plateau level. So far, shock dispersion in the composite sample is assumed to be

the reason for this unexpected experimental behaviour. Although spallation measurements with the

aramid-fibre-epoxy composite are not as successful as for metals, estimates for input to the material

model could be obtained.

2.3 Final Material Model, Data and Required Material Characterisation

The full set of capabilities of the developed model for fibre composite materials can be summarised

Orthotropic elastic stiffness

Non-linear and energy dependent volumetric response for high compressions

Non-linear orthotropic strength with isotropic hardening

Stress based failure initiation on each material plane

Orthotropic damage based on fracture energy

The required input parameters and the matrix of material characterisation tests used to derive each

parameter is presented in Table 1. Data derived for the aramid-fibre-epoxy laminate considered here is

also provided.

Table 1. Model input data and derived material constants for Kevlar-epoxy

EQUATION OF STATE : Orthotropic

Parameter

= 1.65000E+00 g/cm3

E11 = 1.94800E+06 kPa

E22 = 1.79898E+07 kPa

E33 = 1.79898E+07 kPa

12 = 7.56000E-02

23 = 7.56000E-02

31 = 6.98000E-01

G12 = 2.23500E+05 kPa

G23 = 1.85701E+06 kPa

G31 = 2.23500E +05 kPa

Tref = 3.00000E+02 K

Cv = 1.42000E+03 J/kgK)

Source

Direct Measurement

Uniaxial tension tests*

0o tension test

0o tension test

0o tension test

0o tension test

Confined compression test [4]

45o tension test

Short beam shear test

Short beam shear test

Literature

Sub Equation of State:: Polynomial

A1 = 5.89499E+06 kPa

A2 = 5.00000E+07 kPa

T1 = 5.89500E+06 kPa

Planar plate impact tests

Planar plate impact tests

Assumed equal to A1

STRENGTH MODEL : Orthotropic Yield (non-linear hardening)

Parameter

a11 = 1.50000E+00

a22 = 1.00000E+00

a33 = 1.00000E+00

a12 = -6.80000E-01

a13 = -6.80000E-01

a23 = -2.60000E-01

a44= a55=a66 = 4.00000E+00

Plastic Strain = 0.0, 9.0e-6, 6.2e-4,

1.9e-3, 2.5e-3, 5.0e-3, 8.8e-3, 1.2e-2,

2.6e-2

Effective stress = 1.55e5, 1.55e5,

1.67e5, 1.78e5, 1.87e5, 1.93e5,

2.10e5, 2.35e5, 2.52e5, 3.16e5 kPa

Source

0o tension test

o

0 tension test

0o tension test

0o tension test

0o tension test

0o tension test

45o tension test

0o tension test

0o tension test

FAILURE MODEL : Orthotropic Damage (non-linear softening)

Parameter

fail 11 = 4.50000E+04 kPa

fail 33 = 2.45000E+05 kPa

fail 12 = 1.40000E+04 kPa

fail 23 = 2.00000E+04 kPa

fail 31 = 1.40000E+04 kPa

Gf11 = 5.44710E+02 J/m2

Gf 22 = 3.00000E+01 J/m2

Gf12=Gf23=Gf31=1.46130E+03 J/m2

Source

Calibration to match PPI Spall and DCB tests

fail 22 = 2.45000E+05 kPa

0o tension test

Interlamina shear test

Calibration to match 45o tension test

Interlamina shear test

Double cantilever beam test

Calibrated to 0o tension test

End notched flexure test

R. A. Clegg et al / International Journal of Impact Engineering

3. Validation

Initial validation and assessment of the developed material model and derived input was performed

using dynamic planar plate impact experiments [2]. Here we shall discuss two examples of this type of

test. Further examples are described in Part II of the paper [1] along with hypervelocity impact

validation.

3.1 Inverse Plate Impact

During development of the baseline model [4] inverse plate impact experiments were reported from

which the uniaxial compression behaviour at strain rates up to 104 /s was studied for aramid-fibre-epoxy

composites. In these sets of experiments a 50mm diameter projectile composed of aramid-fibre-epoxy

with a C45-steel backing plate impacts a stationary witness plate also made of C45-steel. A VISAR

laser interferometer system recorded the velocity trace of the witness plate during the impact.

Simulations of these experiments are repeated here using the enhanced material model and data to

ensure that the addition of the non-linear strength and damage aspects of the model did not prejudice

the models ability to reproduce the transient shock wave propagation phenomena. The simulations were

performed using the Lagrange solver of AUTODYN [3] in a uniaxial strain configuration with element

size 0.1mm. Fig. 5 demonstrates the ability of the model to reproduce experimental VISAR signals at

three velocities.

Projectile

KevlarEpoxy

C45 Steel

Stationary witness

plate

C45 Steel

2.0mm 5.7mm 2.0mm

Fig. 5. Aramid-fibre-epoxy inverse flyer plate experiments and simulation comparisons (572m/s, 788m/s, 1055m/s).

3.2 Plate Impact Damage

Both direct and symmetric planar plate impact tests were performed at different velocities to

provide a basis for validating the ability of the numerical model to predict damage levels for given

impact conditions [2]. 2D axisymmetric simulations of these tests were conducted using the Lagrange

solver of AUTODYN [3] and the material model and data as described in [2]. Elements of side 0.1mm

were used throughout. The results are presented and compared with the experiment, and results using

the baseline material model and data [4] (Fig. 6).

R. A. Clegg et al / International Journal of Impact Engineering

(Expt.)

117m/s

(Simulation)

(Expt.)

150m/s

(Simulation)

Fig. 6. Planar plate impact test. (a) target rear surface velocity; (b) recovered samples and simulated delamination.

The key item to correlate between simulation and experiment is the magnitude of the pull-back

spall signal observed in the tests. For the higher velocity, the experiment shows a pull-back spall signal

of 62 m/s. The simulation with the original baseline model and data does not show any velocity

reduction after the peak velocity. The new extended model and data gives a reduction of 58m/s by

release waves, which is similar to the observed signal.

The samples recovered from the experimental tests all showed extensive delamination, illustrating

that the spall strength was exceeded in all tests. Contours of simulated through thickness damage are

consistent with experimental observations (Fig. 6).

The results of simulations of a symmetric planar plate impact test with the enhanced model and data

show a more marked improvement in the prediction levels of damage levels over the original base

model. This configuration is further discussed in detail in Part II [1].

4. HVI Simulation Columbus module shielding

Hypervelocity impact simulations on the Columbus shielding configuration using the baseline

material model have previously been conducted and reported in [4]. These 2D axisymmetric

simulations have been repeated here using the enhanced material model and data. Comparisons with the

previous simulation work and experiments [2] are discussed. The case of a 15mm diameter Al2007

sphere impacting the shielding configuration at 6500m/s (Test case A8611, [4]), is described here.

The projectile, first bumper (aluminium) and the second bumper (Nextel and Kevlar-epoxy) are

represented using the SPH solver with smoothing length of 0.25mm. The rear wall is represented using

the Lagrange solver with element edge size of 0.25mm out to a radius of 60mm. Gradual transition to

larger elements is then made to a final radius of 200mm for efficiency purposes.

Fig. 7 highlights the through thickness damage (delamination) predicted. It can be seen that during

the impact extensive delamination/damage occurs in the immediate vicinity of the impact (Light grey

regions Fig. 7). However the lateral growth in delamination is significantly less for the latest model and

data. This correlates better with experimental observations compared with previous simulations [4]. As

observed in experiment, the new simulation predicts cratering of the backwall with no. This represents a

R. A. Clegg et al / International Journal of Impact Engineering

refined prediction of rear-wall damage over equivalent simulations performed using the baseline

material model and data [4], as quantified in Table 2.

No

perforation

of backwall

(a) Final damage, old model and data[4]

(b) Final damage, new model and data[4]

Fig. 7. 2D Axisymmetric simulation of Alenia/EMI test A8611 [2].

Table 2. Columbus shield HVI simulations, quantitative damage comparison

Test / Ident

Experiment

Original

Simulation [4]

New Simulation [2]

Kevlar/Epoxy

Back wall

Bumper

Hole

Nextel

Hole

Front

Back

Hole

Crater

Pl. Def.

26.55

29

95

96

68

94

52

46

N/A

6

1.2

N/A

227.5

174

30

88

77

75

N/A

1.5

180

5. Conclusions

An improved continuum material model suitable for modelling impact on composite materials

under low to hypervelocity impact conditions has been developed and implemented in AUTODYN [3].

The model is now capable of representing: orthotropic elastic stiffness, non-linear shock effects,

orthotropic non-linear hardening, orthotropic non-linear damage. The features of the model can be

turned on/off as required for the material being simulated and the available input data. The model is

designed to be applicable to a wide range of orthotropic materials under low to hypervelocity impact

conditions.

An extensive experimental programme covering a wide range of static and dynamic tests was

conducted hand-in-hand with the numerical modelling work. This included both material

characterisation experiments for; directional strength and failure, delamination energy, equation of state

measurement. Additionally new impact experiment configurations were developed to allow quantitative

assessment of the extent of damage development in composite materials under different loading

R. A. Clegg et al / International Journal of Impact Engineering

conditions.

Throughout the model development and experimental programme, an extensive simulation

programme was used to support the model development and assess and validate the improved

composite material model. This included; simulation of material characterisation tests to verify that the

model could reproduce the underlying material response observed in experiments, simulation of impact

damage experiments to assess the evolving material model and supplied input data, simulation of

hypervelocity impact events on simplified and representative shielding configurations to assess the

performance of the new model and data on the target application.

Further application and validation of the final model and input data is described in Part II of this

paper [1].

Acknowledgements

This work was funded by ESA/ESTEC under contract No.12400/97/NL/PA(SC), CCN No. 2. The

authors gratefully acknowledge the direction and advice provided by Michel Lambert of ESTEC.

References

[1] Riedel W, Nahme H, White DM, Clegg RA, Hypervelocity Impact Damage Prediction in Composites, Part

II Experimental Investigation and Simulations, paper submitted to Int. J. Impact. Engng. 2005.

[2] Riedel W, Harwick W, White DM, Clegg RA, Advanced Material Damage Models for Numerical

Simulation Codes, Fhg-EMI report no. I 75/03, ESA CR(P) 4397, 2003.

[3] Century Dynamics, AUTODYN Theory Manual, 2005.

[4] Hiermaier SJ, Riedel W, Hayhurst CJ, Clegg RA, Wentzel CM, Advanced Material Models for

Hypervelocity Impact Simulations, EMI report no. E43/99, ESA CR(P) 4305, 1999.

[5] Anderson CE, Cox PA, Johnson GR, Maudlin PJ, A Constitutive Formulation for Anisotropic Materials

Suitable for Wave Propagation Computer program-II, Comp. Mech. 1994; 15: 201-223.

[6] Hayhurst CJ, Livingstone IH, Clegg RA, Destefanis R, Faraud M, Ballistic Limit Evaluation of Advanced

Shielding using Numerical Simulations, Int. J. Impact Engng. 2001; 26: 309-320.

[7] Clegg RA, Hayhurst CJ, Nahme H, Validation of an Advanced Material Model for Simulating the Impact

and Shock response of Composite Materials, APS SCCM 2001.

[8] White DM, Taylor EA, Clegg RA, Numerical Simulation and Experimental Characterisation of Direct

Hypervelocity Impact on a Spacecraft Hybrid Carbon Fibre/Kevlar Composite Structure, Int. J. Impact

Engng., 2003; 29 : 779-790.

[9] Silva MAG, Cismasiu C, Chiorean CG, Numerical Simulation of Ballistic Impact on Composite Laminates,

Int. J. Impact Engng. 2004.

[10] Riedel W, Thoma K et al, Vulnerability of composite aircraft components to fragmenting warheads

experimental analysis, material modeling, numerical studies, 20th Int. Symp. Ballistics, 2002.

[11] Chen JK, Allahdadi FA, Sun CT, J. Comp. Mat., 19997; 31: 788-811.

[12] Hill R., Proc. Royal Society, London A, 1948; 193: 281-297.

[13] Crisfield MA, Non-linear Finite Element Analysis of Solids and Structures, John Wiley, 1997.

[14] Hou JP, Petrinic N, Ruiz C, Prediction of impact damage in composite plates, Comp. In Sc. and Tech., 2000;

60: 273-281.

[15] Clegg RA, Hayhurst CJ, Numerical modelling of the compressive and tensile response of brittle materials

under high pressure dynamic loading, Shock Compression of Condensed Matter, AIP press, 1999.

[16] Thielicke B, Mechanical properties of C/C composites, Key Engineering Materials, 164-165: 145-160.

W. Riedel et al. / International Journal of Impact Engineering

Hypervelocity Impact Damage Prediction in Composites

Part II - Experimental Investigations and Simulations

Werner Riedel*+, Hartwig Nahme+, Darren M. White**, Richard A. Clegg**

+

FhG - Ernst-Mach-Institut, Eckerstrae 4, D-79104, Freiburg, Germany

Century Dynamics Ltd., Dynamics House, Hurst Road, Horsham, West Sussex, RH12 2DT, England

**

Abstract

The extension of damage in composites during hypervelocity impact (HVI) of space debris is controlled by

failure thresholds and subsequent energy consumption during damage growth. Characterisation and modelling of

the material under partially and fully damaged states is essential for the prediction of HVI effects on fibrecomposite structures. Improved experimental and numerical analysis techniques have been developed [5] and are

summarised in paper part I [1]. The present part II deals with the establishment of two precise damage

experiments under hypervelocity impact conditions as a validation basis for numerical simulations: The first type

consists of space debris impact configurations optimised for damage evaluation, the second experiments

reproduce HVI strain rates and compressions in plate impact. Coupling of experimental damage analysis

techniques (visual, ultrasonic, residual strength) to quantify different aspects of failure has been achieved.

Numerical simulations using the commercial hydrocode AUTODYN [4] in mesh-based and SPH formulations are

presented using the material model and data described in part I [1]

Keywords: Delamination, Composite, Damage Modelling, Residual Strength, Plate Impact, ISS

1. Introduction

Model approaches for dynamic behaviour and damage in composite structures caused by

hypervelocity transverse shock loading need to replicate several key aspects of mechanical behaviour:

Non-linear equation of state properties must describe the shock impedances for accurate prediction of

compression and release states with phase changes and spallation [1]. Orthotropic strength is a key

aspect of composite in-plane behaviour to be coupled to equation of state properties. Characterisation

and modelling methods coupling these aspects of directional non-linear mechanical properties have

been developed recently [5] and are described in paper part I Material Model and Characterisation [1].

In part I, application of the numerical technique is demonstrated on the examples of the space

debris protection shield of the International Space Station (ISS) Columbus module involving aramid*Corresponding author. Tel.: +49 761 2714 335; fax: +49 761 2714 316.

E-mail address: riedel@emi.fhg.de

W. Riedel et al. / International Journal of Impact Engineering

fibre reinforced plastics (AFRP) as an intermediate bumper. The aim of the present study was to enlarge

the validation basis by adding controlled damage experiments and loading conditions relevant for

hypervelocity impact applications. Combinations of non-destructive and destructive testing of the

damaged samples should enable in-depth analysis of the aspects of damage and couple different

evaluation techniques. Two types of HVI damage experiments have been developed and used for

validation of the new model approach:

Table 1. Overview and damage experiment types

Damage generated by

HVI debris cloud

Plate impact

Discussion (+ advantages, - limitations)

+ very close to applications

+ damage gradient adapted for validation

- locally statistical impact conditions

+ precise and recorded impact conditions

+ relevant strain rates and pressures

- mainly plane compression and release waves

All tested composite material consisted of 18 layers of 0/90 woven Kevlar 129/812 fabric

(aramid) with 38% mass content of epoxy resin Ciba 914 (Hexcel prepreg: 914/38%/812). The

slightly cylindrical panels, curved to an external radius of 2163.2 mm correspond to the intermediate

composite bumper configuration of the European Columbus module of ISS.

2. Debris Cloud Damage

2.1 Impact Conditions

Whipple shield configurations consisting of an aluminium bumper layer and a composite plate

impacted by an aluminium projectile have been optimised in view of validation of computational

damage models. Experimental knowledge in hypervelocity impact testing and predictive simulations

were used (see Fig. 1) for pre-test optimisation of the design with respect to:

Ballistic limit: Only a small central perforation should occur.

Shatter region: Smooth transition of hit densities from the central impact region to the

outer damage area should be reached by avoiding a large central fragment.

Cloud extension: By maximising this parameter a large damage transition area should be

produced but fully contained in intact surroundings of the sample plate.

Table 2. Impact conditions for debris cloud damage experiments

Experiment No.

Projectile

- material

- density

- diameter

- mass (weighed)

- impact velocity

- impact angle

4354

Al 99.98%

2.70 g/cm3

7.00 mm

474.44 mg

4.75 km/s

0

4355

AlMg3 (Al5754

H34/ hard)

2.70 g/cm3

8.20 mm

770.88 mg

4.68 km/s

0

4356

AlMg3 (Al5754

H34/ hard)

2.70 g/cm3

7.0 mm

474.86 mg

4.81 km/s

0

W. Riedel et al. / International Journal of Impact Engineering

The resulting three configurations consisted of an aluminium sphere (diameter 7.0 to 8.2 mm)

fragmented during perforation of a 2 mm aluminium plate at 4.7 km/s (Table 2). A clear distance of

150 mm to the 5.7 mm composite plate permitted the fragment cloud to expand to a lateral extension of

about 360 mm diameter. High speed shadowgraphs (exposure time 100ns) are shown in Fig. 1, right. It

can be seen that only a small central area is fully perforated, the rest of the plate is impacted and

damaged by a wide range of fragment densities.

Fig. 1. Left: Predictive simulation using base line model [3].

Right: High speed shadowgraphs (28 s, 55s; exposure 100ns) of fragment cloud impact onto composite plate (exp. 4355).

2.2 Visual Damage Inspection

Visual inspection of the samples proved good pre-test prediction: all three fragment clouds loaded

the composite plates slightly above the ballistic limit in the very centre of the impact cloud. The

impacted faces of the plates are shown in Fig. 6. Fig. 2 gives additional views of plate 4355.

Table 3. Visible composite damage after debris cloud impact; damage measure defined in Fig. 2 (right)

No.

4354

4355

4356

Front

Primary damage

d1,f

d2,f

[mm]

[mm]

110

110

110

135

110

105

Rear

Secondary damage

D1,f

D2,f

[mm]

[mm]

360

345

130

390

365

360

d1,r

[mm]

75

390

125

d2,r

[mm]

125

110

75

D1,PS,r

[mm]

100

230

132

D2,r

[mm]

130

10

130

Perforation in Composite / Effect on Witness Plate

4354

4355

4356

some composite layers completely destroyed, no clear hole / few scratches on witness panel

clear perforation hole visible / two bulges; distance from centre and several small bulges in the middle;

cratered area about 100 x 90 mm.

some composite layers completely destroyed, no clear hole / few scratches on witness panel

Notation: di,PS diameter of damaged composite layers; Index: f front, r rear, 1 vertical, 2 horizontal

In experiments 4354 and 4356 with 7 mm spheres no clear hole was noticed but scratches on

witness plates behind the composite indicated composite fibres ejected from the rear surface. Loading

with an 8.2 mm sphere produced a small but clear hole in the composite.

W. Riedel et al. / International Journal of Impact Engineering

In all cases, damage can be categorised into two zones:

Primary damage in the central area with high hit densities and clearly visible surface

delaminations on the front face.

The adjacent area of secondary damage shows isolated, local impacts without obvious

coalescence of damage or delamination on the surface. The observed damage patterns are

summarised in Table 3.

D1,PS

front:d1,PS,f

rear:d1,PS,r

front:d2,PS,f D2,PS

rear:d2,PS,r

Fig. 2. Visible damage on impact and rear face. Definition of damage measures.

2.3 Non-destructive Damage Characterisation

Through thickness failure was analysed by ultrasonic measurements before sectioning of the target

for further evaluations described below. The composite panels and the ultrasonic detector were placed

in water for transmission of longitudinal waves from the source into the test object and back. The pulse

travels through the water and is partially reflected at every impedance boundary such as the front side,

discontinuities in the material or the rear surface of the sample.

0%

0 mm

d3

d1

d2

d1=1,568mm; d2=5,91mm

100 mm

100%

d1=1,86mm; d2=5,91mm

d3=19%

100 mm

d3=16%

Fig. 3. Left pair: Depth of delamination measured from impact and rear side: cone shaped delamination shape.

Right pair: Intensity of reflection from impact and rear side.

The scanning area captured 320 x 320 mm with a scanning step of 0.2 mm. An analysis gate

defined the range d1 to d2 through thickness between the front side and back wall echo in order to

avoid misinterpretation of the plate free surfaces. The values refer to front side, the position of which is

following the curvature of the composite panels. The location of the intermediate echo, caused by

W. Riedel et al. / International Journal of Impact Engineering

delamination, correlates with the depth of the defect. A lower sensitivity threshold value d3 of 16-19%

intensity was used to suppress background noise (see Fig. 3).

Fig. 6 shows scan results of the three panels from the impact side. Fig. 3 gives additionally the rear

view, as only the depth of the first delamination detected in the analysis gate can be displayed in any

scan. The gray scaling of the plate refers to the delamination depth measured between the specified

limits d1 and d2. The following observations could be stated:

Large areas of delamination are shown also in the outer zones where only isolated impacts

occurred. The delaminated areas clearly exceed the visible ranges of heavy damage di,f.

Beginning from a central region of delamination through the complete thickness, the

damage in the secondary region is cone shaped toward the rear surface.

The damage patterns are mostly circular, slightly flattened normal to the laminate axis.

The large sphere (8.2 mm, No. 4355) creates a bigger central damage zone especially on

the rear surface compared to the smaller projectile of equal strength (7.0 mm, no. 4354).

But the total area around the outer zones of damage is of the same size.

Comparing effects created by the small spheres (No. 4354, 4356), the harder alloy (No.

4356) provides a smaller extent of damage with a sharper transition zone. The delamination

cone is steeper through thickness.

2.4 Destructive Testing: Visible Inspections and Residual Strength

Sectioning in strips of 20 mm width, visual inspection and residual strength testing provided

deepened insight to the amount of damage. Hydrocutting was used to minimise additional damage.

Visual inspection of all sections, as exemplarily shown in Fig. 4 showed very fine delaminations in the

zone of secondary damage, proving high sensitivity of ultrasonic scanning.

0

delamination

12

15

18

21

total failure

24

27

30

delamination

Fig. 4. Visual inspection of in-depth damage after sectioning: example central section 4355_8 (out of 16).

Positions of transverse shear testing 0, 3, 6, , 30 of each section.

Advanced damage measures in constitutive models not only describe the areal extension but also

the quantitative effects in terms of strength or stiffness loss. In order to establish the link between

observed damage and its strength effects, local shearing was applied to every section as shown in

Fig. 5. Testing every 30 mm (see scale above Fig. 4) provided a strength analysis grid with 20 mm x

30 mm resolution in the central area of 300 x 300 mm of each composite panel. A surface plot of

damage in terms of shear strength degradation is shown in Fig. 5, right.

W. Riedel et al. / International Journal of Impact Engineering

0

3

2000

Force [N]

30

27

1500

1000

9

24

0.8-1

0.6-0.8

0.4-0.6

0.2-0.4

0-0.2

0.8

0.6

500

12

0.4

0.2

21

15

18

4

5

distance [mm]

30

27

24

21

18

15

12

Damage [-]

1

cm

]

2500

4355_8_0

4355_8_3

4355_8_6

4355_8_9

4355_8_12

4355_8_15

4355_8_18

4355_8_21

4355_8_24

4355_8_27

4355_8_30

strength

th [

stiffness

9

6

3

len

g

3000

0

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30

width [cm] (sections)

Fig. 5. Left: shear test curves of section 4355_8. Right: Damage distribution (shear strength ratio) in plate 4355.

30

24

3000-3500

2500-3000

2000-2500

1500-2000

1000-1500

500-1000

0-500

18

12

6

0

10

14

18

22

26

30

24

18

12

26

22

18

14

10

2500-3000

2000-2500

1500-2000

1000-1500

500-1000

0-500

30

24

2000-2500

1500-2000

1000-1500

500-1000

0-500

18

12

30

26

22

18

6

0

Fig. 6. Coupling evaluation techniques: left: visible damage, centre: ultrasonic scan of depth of defects, right: shear strength.

W. Riedel et al. / International Journal of Impact Engineering

Fig. 6 correlates visual surface damage, depth of delaminations and strength reduction for all three

plates. Quantitative comparison of all three techniques provides:

Secondary damage by isolated cloud fragments causes substantial delamination around the

primary damage zone.

Although hardy visible in sections, delamination in the secondary damage zone reduces the

shear strength by 10% to 30%.

Ultrasonic scanning can detect secondary damage with high resolution.

Primary damage results in strength and stiffness losses from 60% to 100%.

2.5 Simulation of HVI Damage Experiments

The axisymmetric simulation model of test 4355 was established using Smooth Particle

Hydrodynamics discretisation (AUTODYN [4], Fig. 7). A smoothing length of 0.2 mm throughout

allowed to resolve the composite panel with 29 particles through thickness. The Al2017A bumper

shield of thickness 2.0 mm was modelled to a radial extent of 75 mm (3750 particles), the nominally

5.7 mm thick Kevlar-epoxy target to 200 mm (29725 particles).

0%

0

0

0

1

10%

0.5

1

0.5

1

15%

20%

b) new model [1],[5]

c) sample

d) details damage, plastic strain

a) impacting fragment cloud

Fig. 7. (a) Simulated debris cloud impact , (b) delamination extension and central hole after HVI impact damage; (c)

comparison to experiment; (d) details of damage (D=0-1) and plastic hoop strain (0-20%).

More realistic simulations of the outer area with loading by isolated fragment impacts were

achieved by additional 3D models. However, meshing with 0.6 mm diameters or only three particles

through composite thickness already resulted in a total of 590 000 particles. Details on composite

material model and data for both approaches are given in part I [1]. Analysis of the simulation allows

the following conclusions:

The central perforation hole is very accurately predicted by the modelling approach. Earlier

W. Riedel et al. / International Journal of Impact Engineering

model approaches [6] with shock and orthotropic strength descriptions but simpler failure

models provided too large perforation holes (Fig. 1, left).

Extents of surface damage on front and rear face are well captured.

In-depth delamination is correctly modelled in the primary damage zone. Coalescence in

the secondary zone is partly replicated as damage and plastic strain in the fine

axisymmetric model with tendency to underpredict the extent.

The implementation of the model in 3D SPH discretisation provides in the coarse model

qualitatively good results. Higher mesh refinement with the associated computational effort

would be required to validate in detail the extent of delamination.

0

0.4

0.5

1

0.8

Fig. 8. Coarse 3D model with three nodes through thickness; left to right: mode I delamination damage (0-1) on front face, at

2.5mm depths and on rear face; representation in plate sections.

3. Plate Impact Damage

Locally varying loading conditions are an inconvenience of the above described debris cloud

damage experiments. Statistics become more important for the smaller damage amounts in the

secondary zone, making validation of limited degradation more difficult.

Therefore, small amounts of damage at relevant stresses and strain rates for hypervelocity impact

applications have been generated in additional experiments of uniaxial strain loading. Two types of

plate impact damage experiments have been performed on the basis of established flyer plate

methods. The first type of axial compression and subsequent axial tension (spallation) is described and

validated in paper I [1]. The following description will focus on the second type of multiple dynamic

compression and later radial extension.

A symmetric configuration of composite and aluminium plates was used to prevent heavy

delamination caused by superposition of release waves. In this way pre-damaged but solid, monolithic

plates could be produced to perform residual strength tests. Properties of plates and impact velocities

for all tests are summarised in Table 4.

Table 4. Impact conditions for plate impact damage experiments (plate diameters 50 mm)

Test No.

Projectile thickness

(Al+comp.)

Target thickness

(comp.+Al)

Impact velocity

2606

10.00 mm +

5.63 mm

5.63 mm +

10.00 mm

124.4 m/s

2607

9.96 mm +

5.63 mm

5.56 mm +

9.95 mm

206.6 m/s

2608

10.01 mm +

5.64 mm

5.57 mm +

10.01 mm

276.1 m/s

2609

10.00 mm +

5.56 mm

5.58 mm +

10.00 mm

255.6 m/s

2610

9.96 mm +

5.52 mm

5.52 mm +

10.00 mm

241.7 m/s

W. Riedel et al. / International Journal of Impact Engineering

Due to the symmetric impact conditions half of the projectile momentum is transferred to the target.

Considering the different impedances of composite (AFRP) and aluminium (Al) the up and the X-t

diagram can be derived according to Fig. 9. Pressure in the composite samples increases stepwise up to

the state (3,III) before release waves (5) and (V) from the backing and target free surface arrive inside

the composite plates. Subsequently the compressive stress is iteratively decreased by complex wave

superposition, but no tensile loading in through thickness direction occurs during the whole process.

However, tensile loading and complex stress-strain states occur when lateral release waves arrive from

the circumference. At these late stages, no one-dimensional analysis of stress and strain states is

possible, but the loading history can be numerically simulated in two dimensions, e.g. using

axisymmetric modelling approaches.

6,E

VI,

6

F

D

5

4

V

3

VI

III

IV

II

II,

2,

D,4

IV,

1,I

V2606 124m/s

V2608 276m/s

300

AUTODYN - ADAMMO

276 m/s

AUTODYN - ORIG. AMMHIS DATA

250

200

150

100

50

124 m/s

A

0

350

Free Surface Velocity [m/s]

Projectile (Al) compression

Projectile (Al) release

Projectile (AFRP) compression

Projectile (AFRP) release

Target (Al) compression

Target (Al) release

Target (AFRP) compression

Target (AFRP) release

3,III

stress

time

v0

0

0,

v0

F

0,A

5000

15000

20000

Time [ns]

particle velocity up

location x

10000

Fig. 9. Lagrange and X-t-diagrams of symmetric uniaxial strain damage experiment. Right: Measured and simulated free

surface velocities. Similar stress wave levels occur for baseline model AMMHIS [3] and new ADAMMO approach [1].

The free surface velocity measured with the VISAR during early stages of the plate impact damage

experiments is shown in Fig. 9, right. They were not used to derive directly constitutive data, but to

validate simulated free surface velocities of the early arriving stress waves. For the lowest impact

velocity of 124.4 m/s (No. 2606), almost no damage is apparent on the recovered samples. With

increasing impact velocity more stiffness loss can be assumed from visible inspection. For intermediate

to fast impacts up to 276 m/s delamination of the discs is observed.

3000

2500

2000

1500

124.4 m/sec stiffness

206.6 m/sec stiffness

241.7 m/sec stiffness

255.6 m/sec stiffness

276.1 m/sec stiffness

intact stiffness

average stiffness

124.4 m/sec Fmax

206.6 m/sec Fmax

241.7 m/sec Fmax

255.6 m/sec Fmax

276.1 m/sec Fmax

intact Fmax

average Fmax

1000

500

1500

1000

500

0

0

50

100

150

200

250

300

velocity [m/sec]

Fig. 10. Left: Plate impact damage samples recovered and sectioned after loading with 124.4 m/s and 276 m/s.

Right: Strength degradation in terms of stiffness and maximum shear loading.

Fmax [N]

V2608

visible

delaminations

2500

2000

stiffness [N/mm] .

V2606

no visible

delaminations

W. Riedel et al. / International Journal of Impact Engineering

In the same manner as the debris cloud damage panels, the preloaded plate impact samples were

sectioned to 20 mm strips and shear tested. Fig. 10 shows the measured shear stiffness and strength

decrease. Already 124 m/s impact loading caused strength and stiffness decreases by 25 to 30%. Above

220 m/s, the plates are mostly damaged with a residual strength of about 20%. Again, delaminations

hardly observable in sections have major effects on the residual strength.

The experiments were simulated using the composite model approach [1]. 0.125mm square

Lagrangian cells were used to model the thickness of the composite plates in axial symmetry. Fig. 15

shows the comparison of simulated free surface velocities of the aluminium target plate. Differences

were observed on details of shock amplitudes and deceleration by release waves. But the overall match

of acceleration during the first 20 s proved good replication of the momentum balance between

projectile and target plates. Interestingly, the earlier model approach [3] describing non-linear equation

of state with linear-orthotropic strength and instantaneous failure simulates very similar free surface

velocities. Obviously, the uniaxial strain compression properties are not strongly influenced by

additional dissipation from non-linear inelastic deformations as modelled in the new approach.

Exp.

Model [1] ,[5]: Through

thickness damage D11=0-1

Model [1],[5]: Plastic strain

0-10%

0%

Model [3]: Material status

elastic

1.8%

2.7%

2606

failure 11

124.4 m/s

5%

failure 11

0.25

2608

276.1 m/s

7%

multiple

failure modes

Fig. 11. Simulated plate impact damage tests: negigible damage, permanent strains below 3% for 124 m/s impact; strains up to

10% for 276 m/s impact, no delaminations simulated. Overpredicted failure simulation with earlier model status [3].

W. Riedel et al. / International Journal of Impact Engineering

Detailed consideration of simulated deformation and damage contours (Fig. 11) shows that the new

damage model replicates the intact composite samples. Delamination damage is not directly predicted

(as ORT DAM 11). But the slowest impact velocities cause plastic deformations up to 3% and up to

10% local deformation are reached in the samples impacted at 276 m/s. Compared to the previous

model approach with linear-orthotropic strength up to failure, much improved prediction of material

states is observed. With the earlier model, both loading types caused complete through thickness

delamination, which was not observed experimentally.

4. Summary and Outlook

Delamination damage in the aramid-weave-epoxy composite panels impacted by space debris

clouds extends far beyond the area of primary damage into areas, where only isolated impacts are

visible on the surface. In the secondary zone of the debris cloud damage test ultrasonic testing detected

very fine areal delaminations, which were hardly visible in sections of samples.

However, subsequent destructive shear testing across the samples showed the important mechanical

effects of small delaminations on shear stiffness and strength. The following damage quantities could

be identified:

The zone of primary damage with high densities of impacting debris resulting in obvious

surface delamination correlated with strength and stiffness losses from 100% to 70%.

In the zone of secondary damage with low hit densities and isolated impacts, delaminations

extended almost to the external limit of debris impacts. They caused strength and stiffness

losses from 20% to 60%.

Loading by hypervelocity debris clouds results in strong local variations, especially in the

secondary zone of the debris cloud damage experiments. These variations make validation of numerical

methods in the area of limited degradation more difficult. Therefore, plate impact damage experiments

were designed to create smaller damage amounts under well defined loading conditions at relevant

strain rates. A number of samples ranging from weak damage (<30%) to strong damage (80%) could be

produced and recovered. Sectioning, visible inspection and shear testing again underlined the effect of

hardly visible in-depth delaminations on strength degradation. Free surface velocities were recorded

using VISAR techniques to validate numerical simulations.

Numerical Simulations with the SPH and mesh based hydrocode AUTODYN [4] of both debris

cloud damage and plate impact damage experiments were performed with the new composite model

introduced in [1] and [5]. For both loading types improved damage and directional plasticity patterns

could be described. In contrary to excessive delamination in earlier approaches [3], the new model

provides contained delamination with tendency to slight underprediction in areas of weaker loading.

But summing up, deformations and damage of the aramid-weave-epoxy composite plates (ISS

configuration) could generally be well simulated.

The modelling approach seems generally applicable to high strength composite structures, as they

show similar deformation phenomena, but more brittleness. Predictive simulations of aluminium

honeycomb structures with face sheets of carbon fibre reinforced plastics (CFRP) gave promising

deformation and damage patterns (see Fig. 12 and [5], [7]). These types of structures are currently

applied in numerous satellites and spacecraft.

W. Riedel et al. / International Journal of Impact Engineering

3

1

2

4

5

Fig. 12. Preliminary application of new composite model approach [5] to a CFRP-aluminium honeycomb structure

(ENVISAT). Analysis of hit point influence on debris cloud dispersion [7].

Acknowledgements

The authors gratefully acknowledge the important technical contributions of Frank Schfer, Holger

Voss and Jochen Peter. We would like to express our thanks to Michel Lambert from ESA/ESTEC for

funding and directing the described research.

References

[1] Clegg RA, White DM, Riedel W, Harwick W. Hypervelocity Impact Damage Prediction in Composites,

Part I Material Model and Characterisation, submitted to Jn. Impact Engn. 2005

[2] Clegg RA, White DM, Hayhurst CJ, Riedel W, Harwick W, Hiermaier S, Advanced Material Models and

Material Characterisation Techniques for Composite Materials subjected to Impact and Shock Wave

Loading, Journal de Physique IV 2003, 110: 311-316

[3] Hiermaier SJ, Riedel W, Hayhurst CJ, Clegg RA, Wentzel CM, Advanced Material Models for

Hypervelocity Impact Simulations, EMI report no. E43/99, ESA CR(P) 4305, 1999.

[4] N.N., AUTODYN, Theory Manual, Century Dynamics Ltd. Horsham, UK, 2003

[5] Riedel W, Harwick W, White DM, Clegg RA. ADAMMO Advanced Material Damage Models for

Numerical Simulation, ESA CR(P) 4397, EMI report I 75/03, Freiburg October 31, 2003

[6] Soden P, Hinton M., Kaddour A. Failure criteria in fibre reinforced polymer composites, Composites

Science and Technology 1998, 58, Special Issue.

[7] Ryan S, Riedel W, Schfer F. Numerical Study of Hypervelocity Space Debris Impacts on CFRP/AL

Honeycomb Spacecraft Structures, International Astronautical Congress, Vancouver, 2004

Você também pode gostar

- Modi Ling Dynamic MechanicalDocumento15 páginasModi Ling Dynamic MechanicalsiritapeAinda não há avaliações

- A4272609 157 PDFDocumento10 páginasA4272609 157 PDFSaptarshee MitraAinda não há avaliações

- Effective Determination of Cyclic-Visco-Plasticity Material Properties Using An Optimisation Procedure and Experimental Data Exhibiting ScatterDocumento13 páginasEffective Determination of Cyclic-Visco-Plasticity Material Properties Using An Optimisation Procedure and Experimental Data Exhibiting ScatterOssama RamyAinda não há avaliações

- Low-Cycle Fatigue Properties of Steel 42crmo4: R. Kunc, I. PrebilDocumento8 páginasLow-Cycle Fatigue Properties of Steel 42crmo4: R. Kunc, I. PrebilVijayakumar SamyAinda não há avaliações

- Fluid Pressure Loading of A Hyperelastic MembraneDocumento12 páginasFluid Pressure Loading of A Hyperelastic MembraneAnonymous PufNjgAinda não há avaliações

- Plastic Damage Model For Progressive Failure Analysis of Composite StructuresDocumento6 páginasPlastic Damage Model For Progressive Failure Analysis of Composite StructuresandysarmientoAinda não há avaliações

- Prediction of The Plastic Component Parts Durability With Use of A Drop Test SimulationDocumento7 páginasPrediction of The Plastic Component Parts Durability With Use of A Drop Test Simulationxaaabbb_550464353Ainda não há avaliações

- Damage and Plasticity For Concrete BehaviorDocumento16 páginasDamage and Plasticity For Concrete BehaviorJosé Antonio Cornetero UrpequeAinda não há avaliações

- Artigo 5Documento8 páginasArtigo 5Edmilson LimaAinda não há avaliações

- Nonlinear Analysis of Concrete StructuresDocumento28 páginasNonlinear Analysis of Concrete StructuresMarko ŠimićAinda não há avaliações

- Damage Initiation Mechanism in Rubber Sheet Composites During The Static LoadingDocumento8 páginasDamage Initiation Mechanism in Rubber Sheet Composites During The Static LoadingMa RcoAinda não há avaliações

- Fatigue Damage of Composite Structures Applying A Micromechanical ApproachDocumento10 páginasFatigue Damage of Composite Structures Applying A Micromechanical Approachfahriz fathulilahAinda não há avaliações

- 2321-Article Text-10181-1-10-20110622Documento23 páginas2321-Article Text-10181-1-10-20110622steve rubioAinda não há avaliações

- SAXSIM 2012 Plasticity JakelDocumento75 páginasSAXSIM 2012 Plasticity JakelHarsha KolarAinda não há avaliações

- Constitutive Modeling of Elastomers - Accuracy of Predictions and Numerical EfficiencyDocumento19 páginasConstitutive Modeling of Elastomers - Accuracy of Predictions and Numerical EfficiencyAdamDAinda não há avaliações

- MM207E | Materials Science | Lab2_Tensile Test | Mechanic LabDocumento4 páginasMM207E | Materials Science | Lab2_Tensile Test | Mechanic LabKerem Taha TekinAinda não há avaliações

- Materials 13 02422 v2Documento26 páginasMaterials 13 02422 v2Luca CoralloAinda não há avaliações

- A Plastic Damage Model For Concrete Structure Cracks With Two Damage VariablesDocumento10 páginasA Plastic Damage Model For Concrete Structure Cracks With Two Damage VariablesRitesh KumarAinda não há avaliações

- Low-velocity impact response of laminated composite platesDocumento9 páginasLow-velocity impact response of laminated composite platesShivdayal PatelAinda não há avaliações

- Total Life Approach For Fatigue Life Estimation of Welded StructuresDocumento8 páginasTotal Life Approach For Fatigue Life Estimation of Welded StructuresAishik SahaAinda não há avaliações

- The Estimation of Oil Leakage in Hydraulic Cylinders Using FemDocumento8 páginasThe Estimation of Oil Leakage in Hydraulic Cylinders Using FemsunilAinda não há avaliações

- Transversely Isotropic Plasticity With Application To Fiber - Reinforced PlasticsDocumento20 páginasTransversely Isotropic Plasticity With Application To Fiber - Reinforced Plasticsshossain1987Ainda não há avaliações

- Mazars ModelDocumento14 páginasMazars ModelNasr-eddine OudniAinda não há avaliações

- Ajp jp4199707C3139Documento7 páginasAjp jp4199707C3139burakAinda não há avaliações

- Diametral Compression TestDocumento11 páginasDiametral Compression TestCesar Rodolfo Angulo DelgadoAinda não há avaliações

- A Material Model For Transversely Anisotropic Crushable Foam in Ls-DynaDocumento12 páginasA Material Model For Transversely Anisotropic Crushable Foam in Ls-DynaakuoxaiAinda não há avaliações

- Engineering Materials Lab ManualDocumento69 páginasEngineering Materials Lab ManualyousifAinda não há avaliações

- International Journal of Engineering Research and Development (IJERD)Documento8 páginasInternational Journal of Engineering Research and Development (IJERD)IJERDAinda não há avaliações

- Numerical and Experimental Study of Concrete I-Beam Subjected To Bending Test With Cyclic LoadDocumento20 páginasNumerical and Experimental Study of Concrete I-Beam Subjected To Bending Test With Cyclic LoadTAMANA SHAMSIAinda não há avaliações

- DACHDocumento8 páginasDACHMohammad Reza AzadiAinda não há avaliações

- Fatigue damage model predicts composite material life in 40 charactersDocumento4 páginasFatigue damage model predicts composite material life in 40 charactersPrathamesh BilgundeAinda não há avaliações

- Concrete Damage Assessment For Blast Load Using Pressure-Impulse DiagramsDocumento10 páginasConcrete Damage Assessment For Blast Load Using Pressure-Impulse DiagramsaomareltayebAinda não há avaliações

- Fracture Analysis of Compact Tension SpecimenDocumento7 páginasFracture Analysis of Compact Tension SpecimenIJORAT100% (1)

- 1604 2525 Ijmme IjensDocumento6 páginas1604 2525 Ijmme IjensGarudaOzoAinda não há avaliações

- Stress-Strain Curve 3. Short Term Mechanical PropertiesDocumento183 páginasStress-Strain Curve 3. Short Term Mechanical PropertieskhagendrakryadavAinda não há avaliações

- Bilinear Isotropic Hardening BehaviorDocumento7 páginasBilinear Isotropic Hardening BehaviorricardoborAinda não há avaliações

- Size Effect in Concrete Structures Accurately Predicted Using Nonlocal ModelDocumento28 páginasSize Effect in Concrete Structures Accurately Predicted Using Nonlocal ModellifeadventureAinda não há avaliações

- Santos 2014Documento5 páginasSantos 2014Gordei SilviuAinda não há avaliações

- Artigo 3Documento8 páginasArtigo 3Edmilson LimaAinda não há avaliações

- ConstitutiveModeling 037Documento11 páginasConstitutiveModeling 037antonellodelreAinda não há avaliações

- Simulation of Non-Linear Analysis - 2006 ANSYS Conference-LR's Paper PDFDocumento4 páginasSimulation of Non-Linear Analysis - 2006 ANSYS Conference-LR's Paper PDFlisaAinda não há avaliações

- Cattarinuzzi 2019 J. Micromech. Microeng. 29 034001 PDFDocumento14 páginasCattarinuzzi 2019 J. Micromech. Microeng. 29 034001 PDFTestingAccAinda não há avaliações

- Anisotropic Modelling and Numerical Simulation of Brittle Damage in ConcreteDocumento23 páginasAnisotropic Modelling and Numerical Simulation of Brittle Damage in ConcreteamarAinda não há avaliações

- Carpet PlotDocumento7 páginasCarpet PlotAlex OliveiraAinda não há avaliações

- Mechanical Properties of PolymersDocumento16 páginasMechanical Properties of PolymersMalcolm EmileAinda não há avaliações

- Experimental Evaluation of Geocell Reinforcement Using Transparent SoilDocumento10 páginasExperimental Evaluation of Geocell Reinforcement Using Transparent SoilSophiaAinda não há avaliações

- Materials: Experimental and Numerical Investigations of High-Speed Projectile Impacts On 7075-T651 Aluminum PlatesDocumento15 páginasMaterials: Experimental and Numerical Investigations of High-Speed Projectile Impacts On 7075-T651 Aluminum PlatesYousaf SaidalaviAinda não há avaliações

- Simulation of Low Cycle Fatigue With AbaqusFEA 376-383Documento8 páginasSimulation of Low Cycle Fatigue With AbaqusFEA 376-383Dmitry GrenishenAinda não há avaliações

- Fatigue Life Prediction of Additively Manufactured Metallic Materials Using A Fracture Mechanics ApproachDocumento10 páginasFatigue Life Prediction of Additively Manufactured Metallic Materials Using A Fracture Mechanics ApproachAR HassanAinda não há avaliações

- fatigue จากเทพDocumento11 páginasfatigue จากเทพKongsak AkkharawongwhatthanaAinda não há avaliações

- Hyperelastic Material Model Selection ApproachDocumento7 páginasHyperelastic Material Model Selection ApproachHemant MishraAinda não há avaliações

- 1 s2.0 S1359645401002956 MainDocumento20 páginas1 s2.0 S1359645401002956 MainBiswajit AdhikaryAinda não há avaliações

- Engineering Materials Properties Laboratory Manual: BY: DR - Sabeeha A.J.Beden AhmedDocumento66 páginasEngineering Materials Properties Laboratory Manual: BY: DR - Sabeeha A.J.Beden Ahmedb964 SpeedAinda não há avaliações

- ANsys Modelling Paper SIFDocumento7 páginasANsys Modelling Paper SIFPablo CollAinda não há avaliações

- Evaluation of Mode-I Inter Laminar Fracture Toughness For Fiber Reinforced Composite MaterialsDocumento6 páginasEvaluation of Mode-I Inter Laminar Fracture Toughness For Fiber Reinforced Composite Materialsn_kosmasAinda não há avaliações

- 5 Ijlemr 55554Documento14 páginas5 Ijlemr 55554Maicon ArcineAinda não há avaliações

- Using The Uniaxial Tension Test To Satisfy The Hyperelastic Material Simulation in AbaqusDocumento11 páginasUsing The Uniaxial Tension Test To Satisfy The Hyperelastic Material Simulation in AbaquskjklhkAinda não há avaliações

- Viscoelastic Structures: Mechanics of Growth and AgingNo EverandViscoelastic Structures: Mechanics of Growth and AgingAinda não há avaliações

- Metal Fatigue Analysis Handbook: Practical Problem-solving Techniques for Computer-aided EngineeringNo EverandMetal Fatigue Analysis Handbook: Practical Problem-solving Techniques for Computer-aided EngineeringNota: 3.5 de 5 estrelas3.5/5 (5)

- 127 1Documento4 páginas127 1bedo39Ainda não há avaliações

- FM 7-92, The Infantry Reconnaissance Platoon and Squad (Airborne, Air Assault, Light Infantry)Documento325 páginasFM 7-92, The Infantry Reconnaissance Platoon and Squad (Airborne, Air Assault, Light Infantry)bedo39100% (2)

- Strain Gage Transducer Design and Construction GuideDocumento151 páginasStrain Gage Transducer Design and Construction GuideMarcoshhAinda não há avaliações

- Ohsa GDocumento82 páginasOhsa Gbedo39Ainda não há avaliações

- HT Lecture 3Documento11 páginasHT Lecture 3bedo39Ainda não há avaliações

- IndsafeDocumento3 páginasIndsafebedo39Ainda não há avaliações

- Hydraulic Systems MJHDocumento21 páginasHydraulic Systems MJHbedo39Ainda não há avaliações

- (Ebook) Firearms - AK47 Rifle 7.62MM Service ManualDocumento85 páginas(Ebook) Firearms - AK47 Rifle 7.62MM Service ManualPCMASTER_BSDAinda não há avaliações

- HT Lecture 4Documento7 páginasHT Lecture 4bedo39Ainda não há avaliações

- Hydraulics ManualDocumento316 páginasHydraulics ManualTārick CaēédAinda não há avaliações

- Automation StudioDocumento28 páginasAutomation Studiosilviobarros100% (2)

- Sensors and Methods For Autonomous Mobile Robot PositioningDocumento210 páginasSensors and Methods For Autonomous Mobile Robot PositioningrodrigoibanezAinda não há avaliações

- Industrial Safety SystemsDocumento16 páginasIndustrial Safety Systemsbedo39Ainda não há avaliações

- PDF Safety SERVICES IndustrialSafetyDocumento20 páginasPDF Safety SERVICES IndustrialSafetyhayatmdazharAinda não há avaliações

- Ijaerv2n3 4Documento10 páginasIjaerv2n3 4bedo39Ainda não há avaliações

- Robotic ADocumento8 páginasRobotic Abedo39Ainda não há avaliações

- Mechatronics Laboratory - Introduction PDFDocumento6 páginasMechatronics Laboratory - Introduction PDFbedo39Ainda não há avaliações

- Wheelchair Manual-Final PDFDocumento37 páginasWheelchair Manual-Final PDFMuthuraj ShunmugavelAinda não há avaliações

- Mechatronics 2003Documento6 páginasMechatronics 2003SashankSashankAinda não há avaliações

- Mechatronics DC Motor - Tachometer Closed-Loop Speed Control SystemDocumento29 páginasMechatronics DC Motor - Tachometer Closed-Loop Speed Control SystemskheoAinda não há avaliações

- Matlab - An Introduction To MatlabDocumento36 páginasMatlab - An Introduction To MatlabHarsh100% (2)