Escolar Documentos

Profissional Documentos

Cultura Documentos

Whitepaper - Design Considerations When Integrating Smoke and Fire Curtains

Enviado por

Hellen MartinssonDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Whitepaper - Design Considerations When Integrating Smoke and Fire Curtains

Enviado por

Hellen MartinssonDireitos autorais:

Formatos disponíveis

Design considerations when

integrating smoke and fire

curtains into a building

Your next steps:

Call us: +44(0)23 9245 1111

Email us: info@coltgroup.com

Visit our website: www.coltinfo.co.uk

Whitepaper

(c) 2015 Colt International Licensing Ltd.

Colt whitepaper - Design considerations when integrating smoke and fire curtains into a building

Summary

Fire curtains and smoke curtains are very commonly mixed up and the terminology around them is often interchangeably and wrongly used. This white paper examines what a smoke curtain is and what a

fire curtain is, explaining how they are designed, the standards and test regimes that apply to each, and

how they are each expected to be applied.

This whitepaper covers:

What are smoke curtains and

fire curtains and what are the

key differences between them

The standards which each type

of system has to comply with

The design aspects to consider

when integrating these systems

into a building

Installation, use, testing and

maintenance.

1. The differences between smoke

curtains and fire curtains

2. The differences between smoke

curtains and smoke barriers

A smoke curtain is basically used as part of

a smoke control system. It is there to either

stop smoke reaching another zone or to

channel smoke through a particular route that

we want it to take. As such it will normally be

up at high level, well above head height, and

in most cases smoke curtains dont descend

down to ground level.

The terms smoke curtains and also smoke

barriers are very often used interchangeably.

However in practice a smoke barrier is

anything which will prevent the transmission

of smoke, whereas a smoke curtain is generally

used to describe a fabric curtain, whether

it is fixed or movable. As stated above, the

purpose of smoke barriers is generally to

withstand temperatures of up to about 600oC

and really any material which will withstand

that temperature would be suitable as a fixed

barrier. So a fixed barrier will look something

like this:

A fire curtain, on the other hand, is used to

provide fire separation between two spaces. It

may well provide smoke control at the same

time, but that is not its primary purpose, which

is to prevent the spread of fire, and typically

it may be used to protect a lift door or an

escape route through an open plan dwelling.

In terms of its performance, a smoke curtain is

only expected to be exposed to smoke, so it

is rated to 600oC. A fire curtain, on the other

hand, may well be exposed to the fire itself and

fire temperatures can be a lot higher. So the

fire curtain is fire rated against the normal ISO

fire curve, which exceeds 1000oC, so it is a

much higher rating and the curtain needs to be

more robust in order to achieve that. If you

try to use a smoke curtain in an application

where a fire curtain is needed then the smoke

curtain simply will not be robust enough to

withstand the fire temperatures.

In this case it is a flexible material, permanently

mounted at high level, so that if there is a fire

then we can open the smoke ventilators on

both sides but keep the smoke one side of the

barrier, so the rest of the area is protected.

The reason the curtains are rated to about

600oC is that flashover is expected to occur

in a building once the smoke temperature

reaches around 600oC, so basically once that

temperature is exceeded, the smoke curtain is

not going to do anything anyway, so there is no

point in rating it above 600oC.

Colt whitepaper - Design considerations when integrating smoke and fire curtains into a building

3. Fixed versus movable smoke curtains

4. Smoke versus fire curtains

As an alternative to a fixed curtain, a movable curtain will be held up

above the ceiling level most of the time, and then once a fire occurs

and has been detected, the curtain will drop to its operational position.

This is usually done simply for architectural purposes. Nobody is going

to be concerned about seeing a fixed screen at high level in a large

warehouse. By contrast in a shopping centre or an atrium architects

want to keep any smoke barriers out of sight until they are actually

needed for operational purposes.

Smoke and fire curtains look similar to each other, but they have very

different properties and uses!

A fire curtain is generally installed so as to replace a conventional fixed

element such as a door, shutter or even a wall. A fire curtain is always

movable: the reason it installed is simply because we want to make use

of an opening that is available for everyday use which can also be closed

off in the event of a fire.

Typically an automatic smoke curtain will be a fabric wrapped round

a motorized roller, although there are other designs available, such as

concertina designs.

In terms of their construction, movable fire curtains are fairly similar to

movable smoke curtains but there are two quite important differences.

The first one is that the fabric itself is generally more robust to

withstand the higher temperatures, and to achieve this the glass fibre

woven material generally includes a stainless steel filament which gives

it higher strength at high temperatures. The other difference is that

with a smoke curtain side guides are not normally required, but this is

the opposite for a fire curtain: side guides are always required, because

it is necessary to ensure that there is a complete system with no gaps

for the fire to get through. So smoke and fire curtains are similar in

appearance but a lot of detailed design aspects are different.

A moveable smoke curtain providing escalator containment

Colt whitepaper - Design considerations when integrating smoke and fire curtains into a building

5. Construction of a movable smoke curtain

Most of the rollers are limited to fairly short lengths, typically around

4.5 to 5.0m, and around 80100mm in diameter. The roller diameters

are kept relatively small so that the headboxes can be kept small; if

the roller was larger in diameter, then longer single curtains could be

manufactured but then the roller would be physically much larger and

much more difficult to fit into the building.

A movable smoke curtain comprises a roller which normally has an

integrated motor and bearings. The roller will have fabric fixed onto

it. This fabric is rolled around it and as the roller turns the fabric will

rise or drop. At the bottom of the fabric there is a weighted bottom

bar and normally at the top of the curtain there is a headbox which

contains the mechanism.

So to make curtains above that 4.5 to 5.0m length, then multiple rollers

and overlapping curtains are installed; the rollers may be either side by

side or one above the other, and this simply depends upon what is most

convenient in terms of the space available.

1

Headbox assembly containing a

single roller

1 - Non-flammable glass fibre cloth

2 - Extruded aluminium bottom bar

3 - Weight profile

2

Series of rollers

mounted next

to one another

in a horizontal

configuration to form

a continuous run of

curtains set within a

headbox

The bottom bar has two principal functions. Firstly, it provides a weight

at the bottom of the fabric so that when the power is removed from

the roller motor then gravity acting on the bottom bar weight makes

the curtain drop. This assumes that the curtain is a gravity drop type,

which most curtains are actually are, though some curtains are driven

down to meet some unusual applications. The other function is to limit

the deflection of the curtain if it is subject to high pressure differentials

or air velocities. If the curtain flaps around excessively when it is in use

then it is less effective, so the heavy weight of the bottom bar actually

stops the fabric from deflecting too much.

Series of rollers mounted above one

another in a vertical configuration

to form a continuous run of

curtains set within a headbox

Side guides are available for smoke curtains for some applications but

the vast majority of smoke curtains wont have any, since it is regarded

as acceptable for there to be a bit of smoke leakage around the edges

of the curtains. See page 8 onwards for details on the role of side guides

with fire curtains.

Colt whitepaper - Design considerations when integrating smoke and fire curtains into a building

6. Smoke curtain controls

There normally is a zone control panel and

a local battery back-up (BBU). A BBU is

mainly to prevent nuisance dropping of the

smoke curtain, for example in case of a loss

of mains power. A BBU is not essential in

terms of fire operation because the curtains

will fall automatically under gravity when the

7. Standards and testing for smoke

curtains

In the UK smoke curtains have to comply with

the EN 12101 Part 1 Product Standard. This is

a harmonised Standard to the Construction

Products Regulation and therefore smoke

curtains have to be CE marked.

power is lost. However where a drive-down

curtain is needed, for example in situations

where multiple or intermediate potential drop

positions are required, or where the curtain is

running horizontally rather than vertically, then

of course a BBU is required to be sure the

curtain will deploy in a fire condition.

(a) The product will need to have a heat

exposure test, which exposes the curtain to

600oC for a minimum of 30 minutes, although

most curtains are rated to either 60 or 120

minutes, because a smoke curtain which will

pass the test for 30 minutes will typically also

pass it for 60 to 120 minutes without any

problems.

So the Standard prescribes a minimum speed

of descent of 0.06 m/s and a maximum speed

- depending on where the curtain is located

of either 0.15 m/s or 0.30 m/s. The 0.15 m/s

speed is intended for curtains which descend

below 2.5m, so that there is very little risk of

them clashing or hitting people at this sort of

speed.

(e) The other thing that the Standard covers

is the need to measure gaps and limit gaps

around the edges of the curtain to make sure

that there isnt too wide a gap which could

cause excess smoke leakage past the curtain.

The Standard also applies to static barriers,

so any purpose-designed fabric smoke barrier

should be certified to the Standard as well.

A smoke curtain under fire test

Sample EC Declaration of Conformity

www.coltgroup.com

Ser.No.:

Produkt:

200202 / AFV15012JM

SM5V2_1

Colt International GmbH

Briener Str. 186

47533 Kleve

Germany

Tel. +49(0)2821 990 0

/ 10-2015

Autom. Smoke Curtain ASB (EN 12101-1: 2005+A1: 2006)

SM5/2/DH/N/G/5300/1000/2/25/X/K/X/X/X/D120/PS

Weight

[kg] : 108

Fire Class

: D120

Passage of fabric

[m/h] : 0.3/200C

t amp

: -5C to 60C

Classification report

: 0672-CPD-0144

Response delay

: <60 sec

U

[V AC] : 230

P

[VA] : 140

I

[A] : 1.4

Sample product information label

10-1-1

(b) In addition there is a 1000-cycle reliability

test. This is not because the curtain is

expected to be raised and lowered in normal

day to day usage, but obviously these systems

are expected to be regularly tested and the

1000 cycles equates to 20 years of testing the

curtain once a week.

(c) There is also a response time requirement

to make sure that the curtain does actually

drop immediately once the power is removed.

(d) There is a speed of descent requirement,

because whilst it is important that the curtain

will drop at a reasonably fast rate, it should

drop so quickly that it will either frighten

people or cause significant injury if it actually

drops onto somebody.

Theres a bit of a grey area about whether the

Standard applies to products such as fire rated

glass or fireboard when they are being used

to create a smoke barrier. If a product is being

marketed as a smoke barrier, then it definitely

should comply with the Standard and be CE

marked. On the other hand if as a specifier

you have decided that you want to use fire

rated glass as your smoke barrier, then thats

fine: it probably wont need to be CE marked,

but you certainly would need to be able to

prove to Building Control that whatever

product you are using is at least equivalent to

a smoke curtain tested to the Standard.

Instead of an application Standard, which does

not exist, there is BR 368, which gives a little

bit of guidance on smoke barriers, but it is

quite an old guidance document now and

some of the guidance is out of date. There is

also a limited amount of guidance in BS 7346-4,

which covers the calculation of the deflection

of smoke curtains, smoke reservoirs and

smoke depths.

The Building Regulations of England and Wales

make no direct mention of smoke curtains;

they are referred to in BS 5588, which then

may then refer to BS 7346-4.

Colt whitepaper - Design considerations when integrating smoke and fire curtains into a building

8. Applications for smoke curtains

Typical applications for smoke curtains are as smoke reservoir

boundaries, channelling screens, void edge screens, void sealing screens,

corridor containment, shop unit containment, escalator containment,

stairwell containment and elevator well containment. We illustrate four

more typical applications here:

So, by limiting the width of the spill plume, the size of the smoke

ventilation plant can be reduced with resultant reduction in costs. This

is done by dropping barriers across underneath the balcony; those can

be automatic smoke curtains or they can be fixed screens. It is quite

common for architects to make a virtue out of necessity and put in

fixed screens which are then used as advertising hoardings, and as long

as those are rated to withstand 600oC. Again, any material is perfectly

acceptable.

(a) The most common application is to create a barrier so as to assist in

creating a smoke reservoir. That may be in a warehouse, a shopping

mall, factory, infact in any building where the aims are to provide a

limited smoke reservoir where smoke can be contained before it is

extracted and to prevent smoke spilling through to the rest of the

building. The smoke barrier itself will therefore be at high level and it

needs to descend down to at least the depth to which the smoke itself

is expected to descend.

(c) Another application for smoke curtains is as balcony edge screens.

In this instance, rather than to limit the width of the spill plume, the aim

is to avoid smoke actually from spilling from the balcony into the atrium

or mall above. In this case there would be smoke extraction from

below the balcony and the screens would need to descend to at least

cover the expected depth of the smoke under the balcony. It is not a

common solution, but occasionally it becomes necessary.

There are some differences in the guidance documents in terms of how

large a safety margin is needed below the calculated smoke layer depth.

CIBSE Guide E states that there is no safety margin needed and that the

bottom of the barrier should be at least as low as the bottom of the

smoke layer. BS 7346-4 states that a 100mm safety margin is needed.

The old Smoke Ventilation Association guide recommends a safety

margin of 500mm. So, there are various pieces of guidance and it is

down to the designer and their suppliers as designers to decide which is

applicable. Colt does not recommend that CIBSE guide E guidance (with

its lack of safety margin) is followed, simply because it assumes nice flat

bottom to the smoke layer and it is well established that in practice

the layer is actually going to move about a bit, so some form of safety

margin is very sensible.

(d) The final common application for smoke curtains is for atrium

balcony protection. The image shows smoke curtains descending

right down to floor level, which basically protect people on the balcony

from smoke from within the atrium.

(b) Another application for smoke barriers or smoke curtains is as

channelling screens.

Atrium balcony protection

The illustration here shows barriers mounted underneath a balcony.

In this scenario it is expected that smoke will spill from a shop unit or

an office under that balcony and then up through a mall or atrium. The

wider the spill plume is from the balcony, the more smoke is going to

be generated and the larger the amount of smoke ventilation will be

required.

So in this case smoke is expected to spill so as to fill a large proportion

of the atrium. However because the balcony is used for escape, then

rather than allowing the smoke to spill into the balcony, then we need

smoke curtains across there to separate the balcony from the atrium.

This not an application which is commonly seen in the UK, but is seen

quite a lot in places like South East Asia; it just comes down to different

design methods for different territories, and its a perfectly acceptable

good solution.

6

Colt whitepaper - Design considerations when integrating smoke and fire curtains into a building

9. Installation aspects and potential issues

In order to be sure that a smoke curtain installation remains in good

working order, attention needs to be given to the following installation

aspects at the design stage:

Air movement can also impact on the ability of automatic smoke

curtains to function as designed. When the curtain is deployed, then

excessive deflection and billowing can have two undesirable side

effects. The first is to raise the bottom bar to above the smoke layer

level - which is another good reason for having a good safety factor.

The other potentially undesirable side effect is that a significant edge

gap can appear, thereby allowing significant amounts of smoke to pass

the barrier. Obviously if the curtain is located at 90o to a wall then

edge gaps are not going to be a problem if the curtain billows, but if the

curtain is located say at an angle to another or next to a column, then

those edge gaps can become quite significant, and in those applications

side guides may be required.

(a) Access for maintenance and repair. Since smoke curtains are

inevitably mounted at high level and architects normally want them

to be hidden away, they very often actually have all their mechanisms

above the ceiling. The bottom bar is the only component that is visible

in normal use; when the curtain is deployed then the curtain material

itself plus the bottom bar becomes visible, but the roller and headbox

are never visible.

If it is necessary to maintain or repair anything within the headbox,

then access to the headbox is required.Very often a curtain is installed

and then the ceiling installer simply plasters right up to the headbox

leaving no access for maintenance and repair at all, meaning that if there

is a problem in the future the ceiling has to be ripped out in order for

the system to be maintained. So it does make sense to look at where

maintenance access is going to be needed and to provide access panels

at that point.

(d) Another key consideration is the location of the smoke curtain. The

normal purpose of a smoke curtain is to control the smoke and keep it

within a single reservoir, so therefore if the curtain is directly above the

fire source then smoke from that fire source is probably going to move

into two reservoirs and so the smoke curtain is not going to do its job.

So therefore smoke curtains should always be above aisles or walkways

wherever possible, and if they cant actually be above a walkway then

certainly any major fire source (such as high bay racking or large pieces

of machinery) should not be located directly underneath the curtain.

(b) Location of the controls and the battery back-up. Ideally these

components are positioned close to the motor and the headbox, but

they themselves are generally not actually temperature-rated, so they

do need to be positioned somewhere which is protected and they

also, of course, need to be somewhere where they can be accessed for

maintenance in the future.

(c) Air movement can be an issue as well. If a fixed curtain is placed in a

location where there is regular and significant air movement, then that

curtain can flex, perhaps rip and cause a bit of noise and aggravation, so

it is necessary to consider where the curtain is located and whether it

is likely to be susceptible to excess air movement.

A billowing curtain

Location of curtains away from a potential fire source

Colt whitepaper - Design considerations when integrating smoke and fire curtains into a building

10. Use, testing and maintenance of

smoke curtains

Smoke curtains arent designed for daily use:

there is no particular purpose in dropping

them in daily operation, so their lifecycle is

based upon them being tested once a week if

it is part of a life safety system; other than that,

annual maintenance is normally sufficient and

as mentioned earlier if annual maintenance is

required then access is needed for this.

A typical access panel arrangement

Let us now turn to the design and application

of fire curtains.

11. Construction of a fire curtain

A fire curtain looks pretty similar to a smoke

curtain in construction: there is a roller with

an integrated motor and bearings, a piece of

fabric fixed to and rolled round the roller, a

weighted bottom bar fixed to the fabric and a

headbox to contain the mechanism.

The only additional component with a fire

curtain is that side guides are now not an

optional extra for occasional use, they are an

integral part of the system and are required in

every application.

There are also other detailed differences. The

fabric itself has a different performance rating;

the bottom bar will probably also be slightly

different, because in this case it is expected

that the bottom bar will descend right down

to floor level. In addition, within the bar there

is normally some sort of mechanism to ensure

that a reasonable seal is achieved at floor level,

even if there is a rough floor surface. If the

bottom bar bows slightly under the heat, a

connection to the floor rather than a gap has

to be maintained.

12. Controls for fire curtains

Again controls and a battery back-up unit

will be needed. With a fire curtain a battery

back-up is not only required if the curtain is

driven down to its deployed condition, but

also if there are emergency access or egress

controls, allowing the curtain to be raised after

it has been lowered in order to allow people

through the curtain either to enable people to

escape or for fire fighters to go through.

Colt whitepaper - Design considerations when integrating smoke and fire curtains into a building

13. Standards and testing for fire curtains

There is a British Standard for fire curtains:

BS 8524-1 is the product Standard and

BS 8524-2 is the application Standard, and

both were introduced in 2013. The product

Standard requires the curtain to descend by

gravity wherever possible, though obviously

this is not always possible for horizontal or

lightly sloping units, so in those instances they

are allowed to be drive up, drive down.

(b) There are reliability tests involving cycle

testing and in this case the requirements are

for a relatively low number of cycles, similar

to those used with smoke curtains, where the

fire curtain is not expected to be used on a

daily basis. However a fire curtain may well

of course drop down to floor level, may be

used instead of a fire door and there may be

requirements for it to be dropped regularly, so

there are options within the Standard to go up

as far as 200,000 cycles.

(c) There is also an impact test, since because

a fire curtain is expected to drop down to

floor level, there is the risk of people knocking

against them, and so therefore an impact test

is part of the reliability testing.

(d) The speed of descent is similar to a smoke

curtain: there is a requirement of a 0.15 m/s

speed of descent if the curtain is dropping

vertically below 2m, or 0.3 m/s either if it is

moving horizontally or if it is dropping down

to 2m from floor level (which is pretty rare).

(e) Smoke containment testing in this case is

an optional extra in the same way as it would

be for a fire door: you can test it as say E30 or

E30S, and similarly a fire curtain can be tested

with or without smoke containment.

(a) Fire resistance testing is specified by the

above Standard, and in this instance testing is

to much higher temperatures than for a smoke

curtain.

(f) And finally where there is the need for

accessories such as switches for egress and

access or anything else, then those are tested

as part of the testing regime.

It is worth noting that although the EN 16034

Standard for fire curtains has been published

and accepted by the EU, it is only likely to

come into force in the UK in 2016 or later.

If a curtain is being used as a fire door or a fire

shutter, then it should then comply with EN

16034 and it will need to be CE marked to this

Standard. Generally if the fire curtain complies

with BS 8524-1 it shouldnt have any problems

complying with EN 16034 as that actually has

lower requirements than the British Standard.

The BS 8524-2 application Standard gives a lot

of useful guidance for example as to in what

circumstances such a fire curtain would be

used and which controls should be used for

which curtains.

On the other hand the Building Regulations of

England and Wales make no mention at all of

fire curtains and there is no method of linking

from the Regulations to any related standards

or to any particular requirements. This is

because fire curtains are a relatively recent

development and the current version of ADB

is relatively old (2006).

Colt whitepaper - Design considerations when integrating smoke and fire curtains into a building

14. Applications for fire curtains

15. Ratings of fire curtains

There are five typical applications that a fire curtain is used for:

Where a barrier is fire rated, then quite often there is a requirement for

the curtain to be rated for insulation and/or radiation. Insulation would

be the ideal rating for a fire curtain but unfortunately it is quite difficult

to test for insulation on a fire curtain.

(a) The obvious application for a fire curtain is as a direct replacement

for a fire door or a fire shutter. It doesnt mean to say that the curtain

will be used as a door in everyday use, but it would normally be

intended to keep it open most of the time and just to close it in

emergency or under test conditions.

The reason for this is twofold: one is that quite commonly insulation

is provided by the means of an intumescent coating on the curtain

material, and this will tend to grow during the fire and it is not easy to

be sure that the thermocouple which it is mounted on non-fire side

of the curtain will actually stay in place in the test. The other reason is

that even if the curtain does not have an intumescent coating, the fabric

normally has a coating which quite often heats and dissipates in case

of fire, and if the coating is destroyed, then it gets quite likely that the

thermocouple will fall off. Therefore it is technically quite difficult to test

a curtain for insulation.

(b) Fire curtains are also quite often used to protect lift doors. There is

an application where the lift doors themselves are not fire rated but we

need a fire rating at that location, then simply dropping in a fire curtain

in front of the lift doors is a common way of providing this.

(c) Another reasonably common application is where there is a relatively

large void being used as a smoke shaft, perhaps as an alternative to a

BRE Shaft or an ADB Shaft, then that void can be closed off using a fire

curtain. In normal circumstances such a shaft would be closed off using

a damper or ventilator of some type, but a void is being used then that

void would normally have quite a large opening, too big for a ventilator

or damper, and therefore a fire curtain could be employed to close off

the shaft on the levels where there is no fire.

Because of this BS 8524-2 provides ways of using radiation data,

because obviously with radiation data thermocouples are removed

from the curtain and therefore it is much easier to test radiation than

insulation. Within BS 8524-2 there are a number of methods ranging

from very simple basic methods for small dwellings, through to much

more complex fire engineering methods. Essentially the purpose is to

ensure that in the escape route the radiation is sufficiently low to allow

somebody to escape past a curtain without suffering excess heat or any

injury.

(d) Another common application is in an open plan dwelling. In larger,

more expensive architect-type dwellings, there is often quite a

requirement for the ground floor to be open plan, which is

architecturally very nice and very convenient for the occupants, but it

does mean that if in the case of a fire people are trying to escape from

the upper floors, then they might well have to pass by the fire to get to

an exit. In such circumstances it is quite common to have fire curtains

which will drop in case of fire to provide a protected route through

from the upper floors to the final exit. Another common use is just as

small curtains, basically replacing fire shutters across counters, serveries,

service shafts and so on. The main reason that people would use a fire

curtain rather than a fire shutter is simply that it tends to be smaller

and neater and less expensive.

(e) The final application is as follows. As described above, smoke curtains

can be used to allow escape along atrium balconies. If there is a narrow

atrium balcony then it is quite common to be required to use a fire

curtain rather than a smoke curtain for that particular application. This

is actually one of the very few applications where it is very easy to get

confused about whether a fire curtain or a smoke curtain is required.

Radiation table from BS 8524-2

This table from BS 8524-2 shows the length of barrier assembly along

the escape route which people will have to walk past, and the longer

that barrier is, then the lower the permitted radiation is. The data is

for the test radiation under the normal test regime at 15 minutes into

the test, and there is only a 1m long barrier then only 13.7 kilowatts

per m2 up to 5 metres is allowed, at which point we can only allow 3.7

kilowatts per m2. These are very simplified values worked out by a

Fire Engineering Consultant to give safe conditions in the tenable zone.

There are of course other tables in the Standard which could be used

for fire engineering, or it is possible to go to first principles and use

basic calculations.

10

Colt whitepaper - Design considerations when integrating smoke and fire curtains into a building

16. Controls

There are a number of operational modes for

fire curtains and again these are all detailed

within BS 8524. It is quite possible to have

multiple position deployment: this could

involve a curtain which would drop part-way,

perhaps to provide smoke control in the early

stages of the fire, hold at that for a set period

and then dropped to provide fire protection at

a later stage.

There is also an emergency egress switch

for use by people escaping which allows

the occupant to raise the curtain simply by

pressing the switch once, when upon the

curtain will raise to at least 2m; if the switch

is held there for at least 5 seconds, then the

curtain will drop again.

There is also the option for an emergency

access switch which allows the Fire Service to

raise the curtain in order to access the space

on the other side, and thats arranged in such

a way that when you press the switch the

curtain raises, and as soon as you let go of it, it

starts to drop again.

Obstruction warnings are recommended

because obviously it is undesirable that people

will any obstructions which will stop the

curtain from deploying. The two options are

either a beam protection system providing

audible visual alarm, or for applications in

warehouses the floor can simply be marked

with areas where it is not permitted to

provide any storage, even temporarily.

11

Colt whitepaper - Design considerations when integrating smoke and fire curtains into a building

17. Installation aspects and potential issues

In order to be sure that a fire curtain installation remains in good

working order, attention needs to be given to the following installation

aspects at the design stage:

(f) Maintenance regime. Finally in terms of use, testing and maintenance,

in some cases automatic fire curtains maybe designed for daily use,

although most are intended for emergency use only and this will be

reflected in their reliability classes.

(a) Excessive velocities may cause the fire curtain to stick. In some cases

if the smoke extract fans operate before the fire curtain deploys, then

those extract fans can create quite a large pressure differential. Since a

fire curtain has to overcome friction within its side guide rails in order

to drop, it is possible for the curtain to actually stick part way down. So

if the scheme design allows this to be a possibility, it is important that

the curtain is made to close before the smoke extract fans start.

Maintenance should be to the manufacturers instructions: annual

maintenance is normally sufficient but there are requirements in

BS8524-2 for much more regular testing than is normally used for

smoke curtains, and table shown here taken from BS 8524 shows the

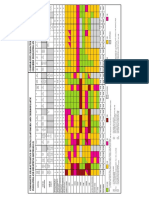

basic testing requirements:

Table 6

This is likely to be less of a problem with smoke curtains, where if the

smoke extract fans start before the smoke curtains deploy, the bottom

bar might just swing about a little bit.

Frequency

Daily

(b) Possible need to calculate the likely deflection. Since a fire curtain

always has side guides, deflection is much less likely to be an issue for

a fire curtain than for a smoke curtain. However where a curtain is

situated adjacent to an escape route, then it is necessary to know what

the deflection is and allow for that in the selection of the width of the

escape route to make sure that there is a suitable available width for

people to escape through.

Weekly

Monthly

(c) Access for maintenance and repair. Again, as for smoke curtains,

access and maintenance repair can be an issue, because the mechanism

is always at high level, and if it is necessary to maintain or repair anything

within the headbox, then access to the headbox is required. However

In general terms it seems much more acceptable for the headboxes to

be on display with fire curtains, but again if the fire curtain headbox is

mounted above ceiling level then consideration needs to be given to

access through the ceiling.

Inspection and testing of barrier assembly

Inspection and testing

Where no sensory equipment

areas, e.g. by alterations to

racking or by furniture or

Operate all barrier assembly

control system protecting

operated in conjunction with

Test the release of self-close

test switch.

Where there is no equipment providing obstruction warnings, that

is to say when some markings are simply made on the floor to show

an area where there should be no obstructions, then daily inspection

is recommended to ensure that nobody has actually stored anything

underneath the curtain.

As with smoke curtains, there is a recommendation for weekly

operation of each unit, basically to check that it is working, a monthly

check of any release mechanism self-closing devices, sensory detection

equipment, etc., basically just making sure that the system is there and

functions properly.

(d) Potential for obstructions. Compared to smoke curtains, obstruction

is quite an important issue. In most cases smoke curtains do not

descend anywhere near floor level, and nothing should be stored

underneath them anyway, so this is probably not an issue. Since fire

curtains descend down to low level, keeping obstructions out of the way

is much more important.

If the system is part of a smoke control system, then also there usually

is a 3 monthly check that it actually works properly in conjunction with

the smoke control system, and then every 6 months there is a check of

any smoke seals: if it is a smoke sealed unit, then just a general structural

check is needed to make sure that it is not damaged or bowed or

deformed.

(e) Timing of descent. The moment when the fire curtain should actually

close needs close consideration. If people are likely to be wanting to

escape through a route where the fire curtain is, then it makes sense to

deploy the fire curtain as late as possible, whereas in other applications

it makes sense to deploy the fire curtain early. So in some cases it will

be deployed from a signal from the general smoke detection system, in

other cases from a local smoke detector, and sometimes from a local

fire detector. BS 8524-2 provides a table which very clearly states which

systems are acceptable and under which circumstances.

So there is quite a lot more testing set out in the Standard for a fire

curtain as opposed to a smoke curtain, but since people never do more

than what is asked for and they quite often do less, it is better to err on

the side of safety rather than anything else.

12

Colt whitepaper - Design considerations when integrating smoke and fire curtains into a building

18. Summary

Smoke curtains and fire curtains have significant differences and are not

interchangeable. It is important to be sure about which one is needed,

and to specify it properly. To make it simple to decide, fire curtains

restrict the spread of fire, and smoke curtains only restrict the

spread of smoke, and this is a very important difference.

At the moment if you are buying a smoke curtain within the UK, it

should be CE marked to the European Standard; if you buy a fire

curtain, there isnt actually a Standard to CE mark it to the moment.

Both products basically are there to enhance architectural flexibility and

they do form important parts of the buildings fire safety strategy, so

it is important that they are applied properly and maintained

properly once they are in place.

See www.coltinfo.co.uk and

http://www.coltinfo.co.uk/fire-and-smoke-curtains-cpd-seminar.html

for further information.

About Colt

Since 1931 Colt has been harnessing the natural elements to provide healthy, comfortable and safe working and living conditions

in buildings. Colt is a specialist in smoke control, climate control and HVAC systems, industrial ventilation and solar shading, with a

presence in more than 50 countries.

Você também pode gostar

- Sound Healing For Health and Well - BeingDocumento36 páginasSound Healing For Health and Well - Beingtormenta7azul6225100% (9)

- R K Konodia Civil Gate Previous Year - by EasyEngineering - Net 1 PDFDocumento214 páginasR K Konodia Civil Gate Previous Year - by EasyEngineering - Net 1 PDFDaante VermaAinda não há avaliações

- Genmega G2500Documento103 páginasGenmega G2500tchindaforentAinda não há avaliações

- Tg-Bec 2015Documento210 páginasTg-Bec 2015Simoncarter LawAinda não há avaliações

- Appendix 7G Rational Fire Design ReportDocumento21 páginasAppendix 7G Rational Fire Design ReportRendani VeleAinda não há avaliações

- PRE - Fire Design and Eurocodes - M.johnson - 2010 - 0365Documento61 páginasPRE - Fire Design and Eurocodes - M.johnson - 2010 - 0365nebojsadj6411Ainda não há avaliações

- Specifications: Louie Jean Mabanag Ar - 3BDocumento8 páginasSpecifications: Louie Jean Mabanag Ar - 3BLouie Jean100% (1)

- Rectification of Beam Stirrub Rebar.: 149B, Selegie Road, Selegie Court Singapore 188314Documento2 páginasRectification of Beam Stirrub Rebar.: 149B, Selegie Road, Selegie Court Singapore 188314jasekan.dcAinda não há avaliações

- Method Statement For Boom Barrier Installation (Rev00) ELV2Documento38 páginasMethod Statement For Boom Barrier Installation (Rev00) ELV2balajiAinda não há avaliações

- 11654Documento8 páginas11654Wildo-aprizaAinda não há avaliações

- CITEL General CatalogDocumento164 páginasCITEL General CatalogHellen MartinssonAinda não há avaliações

- Kingspan Trapezoidal Roof KS1000 RW Installation Guide 012016 NZ enDocumento2 páginasKingspan Trapezoidal Roof KS1000 RW Installation Guide 012016 NZ envincent_devine777dAinda não há avaliações

- Gas AbsorptionDocumento93 páginasGas AbsorptionArgie Adduru73% (11)

- BS 476-7-1971 - Fire Tests On Building Materials & Structures - Part 7 - Surface Spread of Flame Tests For MaterialsDocumento18 páginasBS 476-7-1971 - Fire Tests On Building Materials & Structures - Part 7 - Surface Spread of Flame Tests For MaterialsBiplabAinda não há avaliações

- Nfpa CodesDocumento33 páginasNfpa CodesJarlyAinda não há avaliações

- Bright Ideas 2 Unit 1 Test-Fusionado-Páginas-1-33Documento33 páginasBright Ideas 2 Unit 1 Test-Fusionado-Páginas-1-33Eleonora Graziano100% (1)

- Passive Fire ProtectionDocumento6 páginasPassive Fire ProtectionSonny RamosAinda não há avaliações

- Code of Practice For The Design, Planning, Installation, Testing and Maintenance of Sound SystemsDocumento68 páginasCode of Practice For The Design, Planning, Installation, Testing and Maintenance of Sound Systemsonur313Ainda não há avaliações

- Introduction To Fr-Acp (Fire Retardant Aluminum Composite Panels)Documento12 páginasIntroduction To Fr-Acp (Fire Retardant Aluminum Composite Panels)Syed RaziuddinAinda não há avaliações

- BS5266 Guide Booklet Iss9 Oct18Documento36 páginasBS5266 Guide Booklet Iss9 Oct18FREDAinda não há avaliações

- BS8519 2010 PDFDocumento12 páginasBS8519 2010 PDFwaytobhushan100% (1)

- Cast Your HoroscopeDocumento27 páginasCast Your HoroscopeSunil ShastriAinda não há avaliações

- External Fire SpreadDocumento125 páginasExternal Fire SpreadHellen MartinssonAinda não há avaliações

- ZCH ThermalBridgingGuide Screen 0Documento50 páginasZCH ThermalBridgingGuide Screen 0Atanas StoykovAinda não há avaliações

- Myanmar Fire Safety Code 2020 (Eng Version) PDFDocumento439 páginasMyanmar Fire Safety Code 2020 (Eng Version) PDFThe' Nu AungAinda não há avaliações

- CFPA E Guideline No 19 2009 EVACUATION FROM BUILDINGS PDFDocumento99 páginasCFPA E Guideline No 19 2009 EVACUATION FROM BUILDINGS PDFodemircioglu2Ainda não há avaliações

- Fire BookletDocumento8 páginasFire BookletRichard HollidayAinda não há avaliações

- Fire Safety and Concrete Structures 2007Documento90 páginasFire Safety and Concrete Structures 2007arnoldas.sneiderisAinda não há avaliações

- White Book C06 Floors and Ceilings SectionDocumento94 páginasWhite Book C06 Floors and Ceilings SectionPavaloaie Marian ConstantinAinda não há avaliações

- Understanding Fire Safety Requirements ForDocumento12 páginasUnderstanding Fire Safety Requirements ForRauf HuseynovAinda não há avaliações

- RUSKIN Fire and Smoke Damper Application GuideDocumento16 páginasRUSKIN Fire and Smoke Damper Application Guideiask5275100% (2)

- Enclosure FiresDocumento194 páginasEnclosure FiresHellen MartinssonAinda não há avaliações

- A Guide To BS5839 PDFDocumento10 páginasA Guide To BS5839 PDFvinci101Ainda não há avaliações

- Commissioning Job Book - A Framework For Managing The Commissioning Process - SampleDocumento12 páginasCommissioning Job Book - A Framework For Managing The Commissioning Process - SampleibrahimsirpiAinda não há avaliações

- Fire Test (EN13501-1)Documento8 páginasFire Test (EN13501-1)Vinka PrintAinda não há avaliações

- Olf Guideline For Iec 61508 and 61511Documento157 páginasOlf Guideline For Iec 61508 and 61511Eyoma EtimAinda não há avaliações

- Fire Engineering Guide For Property Protection and Business Resilience 2020Documento19 páginasFire Engineering Guide For Property Protection and Business Resilience 2020Mamoon AlyahAinda não há avaliações

- Scorpius SRT 60 ROW Tracker DatasheetDocumento4 páginasScorpius SRT 60 ROW Tracker DatasheetPhani ArvapalliAinda não há avaliações

- Colt CPD Webinar - The General Principles of Smoke ControlDocumento61 páginasColt CPD Webinar - The General Principles of Smoke ControlArun CherianAinda não há avaliações

- White Book C04 S11 Partitions Non Loadbearing Timber StudDocumento17 páginasWhite Book C04 S11 Partitions Non Loadbearing Timber Studchaval01Ainda não há avaliações

- Kooltherm K18 Insulated PlasterboardDocumento14 páginasKooltherm K18 Insulated PlasterboardEdwin ScallyAinda não há avaliações

- CFPA E Guideline No 19 2009Documento46 páginasCFPA E Guideline No 19 2009Anonymous yh1eFImwG8Ainda não há avaliações

- TCVNS, Qcvns and TCNS: No. Standard Number Standard Name RemarksDocumento3 páginasTCVNS, Qcvns and TCNS: No. Standard Number Standard Name RemarksStudio PuhyAinda não há avaliações

- Novec CalculatorDocumento10 páginasNovec CalculatorIbrahim BenmansourAinda não há avaliações

- CV1 and CV2 Calculations PDFDocumento59 páginasCV1 and CV2 Calculations PDFLennyt0808Ainda não há avaliações

- QCVN 06-2010 - Eng Version - For Fire SafetyDocumento96 páginasQCVN 06-2010 - Eng Version - For Fire Safetyawy02100% (3)

- Smoke Movement: FV 3002 Fire Protection EngineeringDocumento48 páginasSmoke Movement: FV 3002 Fire Protection EngineeringRaccoon Mr.Ainda não há avaliações

- Brochure For Standards Related To Fire PDFDocumento16 páginasBrochure For Standards Related To Fire PDFJohan A. PsailaAinda não há avaliações

- BS 5588-4-1978 Fire Precautions 3Documento46 páginasBS 5588-4-1978 Fire Precautions 3Clifford Juan Correa100% (3)

- Fire Code 2007Documento346 páginasFire Code 2007Liew Kim HoeAinda não há avaliações

- Energy and Buildings - Laboratory01 - Thermal Bridges - 2017 PDFDocumento55 páginasEnergy and Buildings - Laboratory01 - Thermal Bridges - 2017 PDFSamantha GraciAinda não há avaliações

- Method Statement For Concrete Repairing.Documento10 páginasMethod Statement For Concrete Repairing.Smart ShivaAinda não há avaliações

- TCVN 2622-1995 Fire Prevention Standards (En)Documento49 páginasTCVN 2622-1995 Fire Prevention Standards (En)Huan Dinh QuangAinda não há avaliações

- Cable Selection Guide PDFDocumento1 páginaCable Selection Guide PDFkapilAinda não há avaliações

- Snow Load As Weight Per MM Calculation 330Documento1 páginaSnow Load As Weight Per MM Calculation 330Anonymous Iev5ggSRAinda não há avaliações

- BS HvacDocumento70 páginasBS HvacRamiAl-fuqahaAinda não há avaliações

- Challenges For Distributed Generation - Arvind - 11sepDocumento12 páginasChallenges For Distributed Generation - Arvind - 11sepSAEL SOLARAinda não há avaliações

- Afisaj WiebrockDocumento2 páginasAfisaj Wiebrockgheorghecosovan0% (1)

- Astm E779 Jtvo9242Documento11 páginasAstm E779 Jtvo9242Nayth Andres GalazAinda não há avaliações

- Acoustic Testing PDFDocumento25 páginasAcoustic Testing PDFkenwongwmAinda não há avaliações

- MCR SlabDocumento5 páginasMCR SlabAswin KumarAinda não há avaliações

- Celotex BBA - Cavity WallsDocumento12 páginasCelotex BBA - Cavity Wallsfaber1972Ainda não há avaliações

- Fire Door SpecificationsDocumento20 páginasFire Door SpecificationsGopalAinda não há avaliações

- SANS 1128 1 2010 (Ed. 2.01)Documento29 páginasSANS 1128 1 2010 (Ed. 2.01)Olefile Mark MolokoAinda não há avaliações

- Whitepaper - Design Considerations When Integrating Smoke and Fire CurtainsDocumento13 páginasWhitepaper - Design Considerations When Integrating Smoke and Fire CurtainsRoger ChetcutiAinda não há avaliações

- Smoke Curtains and Fire Curtains: Colt Technical SeminarDocumento27 páginasSmoke Curtains and Fire Curtains: Colt Technical SeminarArun CherianAinda não há avaliações

- BLE Catalogue 2013Documento21 páginasBLE Catalogue 2013Shahina Parvin ShaikAinda não há avaliações

- Technical Article The Flame PathsDocumento2 páginasTechnical Article The Flame PathsVijay KumarAinda não há avaliações

- F-SHIELD-STANDARD-MODEL Product Brochure 444Documento7 páginasF-SHIELD-STANDARD-MODEL Product Brochure 444Atamet KilicAinda não há avaliações

- FIRE PROTECTION IN BUILDINGS 20nov2015Documento9 páginasFIRE PROTECTION IN BUILDINGS 20nov2015nada_raadAinda não há avaliações

- GB Prosp Neubauroll 2007Documento8 páginasGB Prosp Neubauroll 2007strozyAinda não há avaliações

- BLE Curtains Catalogue 2010 (Email)Documento16 páginasBLE Curtains Catalogue 2010 (Email)Branza GeorgeAinda não há avaliações

- Automatic Smoke CurtainDocumento7 páginasAutomatic Smoke CurtainHermi DavidAinda não há avaliações

- Fisa Securitate BenzenDocumento17 páginasFisa Securitate BenzenHellen MartinssonAinda não há avaliações

- IC Symposium AntozziDocumento38 páginasIC Symposium AntozziHellen MartinssonAinda não há avaliações

- Animale Din HartieDocumento33 páginasAnimale Din HartieHellen MartinssonAinda não há avaliações

- Water DocumentDocumento11 páginasWater Documentyong6368Ainda não há avaliações

- IC Symposium AntozziDocumento38 páginasIC Symposium AntozziHellen MartinssonAinda não há avaliações

- An TozziDocumento38 páginasAn TozziHellen MartinssonAinda não há avaliações

- Masajul - Ghid PracticDocumento96 páginasMasajul - Ghid PracticHellen MartinssonAinda não há avaliações

- Ghid Ceramic PDFDocumento10 páginasGhid Ceramic PDFHellen MartinssonAinda não há avaliações

- Fire DesignDocumento103 páginasFire DesignHellen MartinssonAinda não há avaliações

- Fire DesignDocumento103 páginasFire DesignHellen MartinssonAinda não há avaliações

- Fire & Blast Technical DirectoryDocumento9 páginasFire & Blast Technical DirectoryHellen MartinssonAinda não há avaliações

- Ghid CeramicDocumento10 páginasGhid CeramicHellen MartinssonAinda não há avaliações

- Explosao em SiloDocumento122 páginasExplosao em SiloRicardo Rigo MacedoAinda não há avaliações

- Police Coloring-Page 60045 Police PatrolDocumento1 páginaPolice Coloring-Page 60045 Police PatrolHellen MartinssonAinda não há avaliações

- MK Ii JetventDocumento16 páginasMK Ii JetventHellen MartinssonAinda não há avaliações

- Fire Safe CampingDocumento6 páginasFire Safe CampingHellen MartinssonAinda não há avaliações

- Fseu Consultation-Response Osh 26-08-2013 PDFDocumento2 páginasFseu Consultation-Response Osh 26-08-2013 PDFHellen MartinssonAinda não há avaliações

- Fseu New-Build Issue-Brief Final 02-04-2013Documento4 páginasFseu New-Build Issue-Brief Final 02-04-2013Hellen MartinssonAinda não há avaliações

- Firesafeeurope-Broch A5 v07 2011Documento12 páginasFiresafeeurope-Broch A5 v07 2011Hellen MartinssonAinda não há avaliações

- Procedura TermosistemDocumento143 páginasProcedura TermosistemMarius Gabriel CraciunAinda não há avaliações

- Fire Safety in Renovation Summary Report VTT R 03472 12 Web Final 07-06-2012Documento12 páginasFire Safety in Renovation Summary Report VTT R 03472 12 Web Final 07-06-2012Hellen MartinssonAinda não há avaliações

- Ep Briefing Hotel Fire Safety 06 2013Documento16 páginasEp Briefing Hotel Fire Safety 06 2013Hellen MartinssonAinda não há avaliações

- BD 2466 PDFDocumento65 páginasBD 2466 PDFHellen MartinssonAinda não há avaliações

- Ficha Tecnica p501Documento4 páginasFicha Tecnica p501LizbethAinda não há avaliações

- Shaped House With Gablehip Roof 2020Documento11 páginasShaped House With Gablehip Roof 2020Marco CamposAinda não há avaliações

- Rebellion - Sagas of Iceland - The History of The Vikings Vol. 1Documento28 páginasRebellion - Sagas of Iceland - The History of The Vikings Vol. 1Manuel Velasco100% (1)

- Surface Chemistry: by General CharacteristicsDocumento8 páginasSurface Chemistry: by General CharacteristicssriAinda não há avaliações

- Design and Modelling of Internal Permanent Magnet Motor (#764846) - 1189475Documento25 páginasDesign and Modelling of Internal Permanent Magnet Motor (#764846) - 1189475Tejas PanchalAinda não há avaliações

- Zbus and Symmetrical Fault AnalysisDocumento20 páginasZbus and Symmetrical Fault Analysishj203800Ainda não há avaliações

- Mat11 PDFDocumento13 páginasMat11 PDFRaquel Martins E SilvaAinda não há avaliações

- Catalyst PreparationDocumento15 páginasCatalyst PreparationVISHAL SHARMAAinda não há avaliações

- 2 2 1 A Productanalysis 2Documento5 páginas2 2 1 A Productanalysis 2api-308131962Ainda não há avaliações

- Coronary Stents: Current StatusDocumento42 páginasCoronary Stents: Current StatusMANSI SALUNKEAinda não há avaliações

- Rama Varma Anagha Research PaperDocumento12 páginasRama Varma Anagha Research Paperapi-308560676Ainda não há avaliações

- Quiz13 130630200754 Phpapp02Documento10 páginasQuiz13 130630200754 Phpapp02anukrititiwaAinda não há avaliações

- 2020 Sustainabilty Report - ENDocumento29 páginas2020 Sustainabilty Report - ENGeraldAinda não há avaliações

- A Ongc HRM Summer ProjectDocumento58 páginasA Ongc HRM Summer ProjectAmit SunsaraAinda não há avaliações

- Ketron 1000 PEEK PDS E 30032019 01Documento1 páginaKetron 1000 PEEK PDS E 30032019 01jorgepradaco1Ainda não há avaliações

- Marlinespike - Rope Breaking StrengthDocumento7 páginasMarlinespike - Rope Breaking StrengthAnonymous ycFeyuLAt100% (1)

- Estimating Crack Widths in Steel Fibre-Reinforced ConcreteDocumento12 páginasEstimating Crack Widths in Steel Fibre-Reinforced ConcreteRm1262Ainda não há avaliações

- Jurnal Praktikum Dasar-Dasar Pemisahan Kimia Pembuatan Membran Polysulfon (PSF)Documento9 páginasJurnal Praktikum Dasar-Dasar Pemisahan Kimia Pembuatan Membran Polysulfon (PSF)Rizki AuAinda não há avaliações

- Read The Following Paragraphs and Answer The Questions That FollowDocumento18 páginasRead The Following Paragraphs and Answer The Questions That FollowMary Ann RanayAinda não há avaliações

- Watch Out For Flying Pumpkins: BOE Member PromotedDocumento16 páginasWatch Out For Flying Pumpkins: BOE Member PromotedelauwitAinda não há avaliações

- The Anaphylactic ShockDocumento8 páginasThe Anaphylactic ShockRooby JeanpierreAinda não há avaliações

- Nokia 6131 NFCDocumento5 páginasNokia 6131 NFCvetvetAinda não há avaliações