Escolar Documentos

Profissional Documentos

Cultura Documentos

Production and Purification of Tannase From Aspergillus Aculeatus Using Plant Derived Raw Tannin

Enviado por

Innovative Research PublicationsTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Production and Purification of Tannase From Aspergillus Aculeatus Using Plant Derived Raw Tannin

Enviado por

Innovative Research PublicationsDireitos autorais:

Formatos disponíveis

International Journal of Scientific Engineering and Technology

Volume No.4 Issue No.2, pp : 50-55

(ISSN : 2277-1581)

01 Feb2015

Production and Purification of Tannase from Aspergillus aculeatus Using Plant

Derived Raw Tannin

Jasbir Bagga1*, Soumya Kanti Pramanik1, Vibha Pandey2

1

G.L.A. College, 2Y.S.N.M. College, Department of Botany, N.P. University, Daltonganj, Jharkhand, India.

Email:baggajasbir@ymail.com

Abstract:Tannase, an enzyme with immense potential has lot of

applications in food, beverage, pharmaceutical and chemical

industries. During the present study, tannin content of

different plant materials was determined. Tannase has been

produced from Aspergillus aculeatus through fermentation of

tannin rich plant materials. Among the plant materials used,

Cassia ciamia gives better result. Maximum oxygen is utilized

by the organism after 24 h of growth. pH of the fermented

broth falls to 4.1 after 28 h of growth. Organism utilizes wheat

bran as a solid substrate to produce maximum tannase.

Maximum enzyme production through solid state fermentation

was achieved after 72 h of growth. Purified enzyme has pH &

temperature optima at 5.0 and 600c respectively.

Key Words: Tannase, Aspergillus aculeatus, plant material,

optimum pH, optimum temperature.

INTRODUCTION

Tannin acyl hydrolase (E.C.3.1.1.20), commonly called tannase

hydrolyses ester and depside bonds of hydrolysable tannins

(tannic acid) & thereby releases glucose, gallic acid and galloyl

esters (Mehta et al., 2013). There are two types of tannin (a)

Hydrolyzable tannin and (b) Condensed tannin. Hydrolyzable

tannin consist of a polyhydric alcohol esterified with gallic acid

or derivatives of gallic acid whereas Condensed tannin is made

up of phenols of flavan type & are often called flavolans because

they are polymers of such flavan 3-ols. According to the product

obtained by its hydrolysis, Hydrolyzable tannins is classified

into i) Gallatannin & ii) Ellagitannin. Tannase cleaves ester &

depside linkage in tannic acid & chebulinic acid, both

Hydrolyzable tannins. The enzyme tannase is extensively used in

different industries such as food, beverage, brewing,

pharmaceutical (Pourrat et al.,1987), chemical, cosmetics etc.

(Mehta et al., 2013). Instant tea preparation is one of the most

promising application of this enzyme. The tea cream contains

polyphenolic complex which are insoluble in cold water.

Tannase make this insoluble tea cream soluble in cold water.

The enzyme hydrolyses the ester linkage between galloyl groups

& various compounds present in unconverted tea leaves. A

continous process for solubilizing tea cream by passing a hot

water extract of black tea through a column containing

immobilized tannase was also described by Coggon et al. (1975).

Besides, tannase has been found to be of immense importance in

Beer chillproofing (Massechelin & Batum, 1981), Wine making

etc. (Koichi & Tokuji, 1972). In animal feed additives, the use

of tannin containing feed may prove beneficial in removal of

antinutritional effects of tannin and improve their digestibility.

Tannase may also find use in cosmetology to eliminate the

IJSET@2015

turbidity of plant extracts and in the leather industry to

homogenize tannin preparation for high-grade leather tannin.

The enzymatic product gallic acid also has various industrial

uses, such as- manufacture of gallic acid ester (propyll gallate),

which in turn is an antioxidant, preparation of trimethoprim (a

broad-spectrum anti-bacterial agent used as photosensitive resin

in semiconductor production) and manufacture of pyrogallol.

In view of the above mentioned immense importance of

the enzyme tannase and its products, various workers (Hadi et

al.,1994; Lekha & Lonsane 1994; Bajpai & Pati 1996; Bradoo et

al., 1997; Bhat et al., 1998; Kar et al., 1999; Mondal& Pati

2000; Aboubakr et al., 2013) have studied the different aspects

of its production. However, tannase is still considered a costly

industrial enzyme owing to its low yield and long fermentation

time of the processes (Kumar et al., 2007; Aboubakr et al., 2013;

Mehta et al., 2013). Therefore, research is still needed to

develop a cost effective protocol for tannase production. In this

paper, we present our study carried on the production of tannase

using raw tannin from different plant materials. Purification and

some properties of tannase have also been studied. Proper

exploitation of these techniques would enable a significant

reduction in the cost of enzyme production.

MATERIALS & METHODS

Chemical: Following chemicals are used for experiment :

Tannic acid (Qualigens, India), Gallic acid (Himedia, India),

BSA [Bovine Serum Albumin, (Loba, India) ] MgSO 4

(Qualigen), (NH4)2HPO4,KH2 Po4, CaCl2,Glucose, (NH4)2So4,

DEAE[diethyl amino ethyl] cellulose, Acetic acid, sodium

acetate, sephadex G-100, NaOH, sodium tungstate,

phosphomolybic acid, phosphoric acid, Na2co3. Otherwise stated

all the chemicals are of analytical grade.

Microorganism: Aspergillus aculeatus .

Inoculum: Organism was grown on tannic a agar media

containing (g/1) (NH4)2HPO4, 3,0; MgSO4, 1.0 KH2 PO4 0.05;

CaCl2, 0.3; tannic acid 10.0 & Agar, 25.0. The pH of the medium

was adjust to 5.5 After growth at 30.0c for 72 hrs spores are

collected & spore suspension (5X107 spores/ m1) was used as

source of inoculum.

Measurement of tannin content of some plants : Tannin content

of different plant specimens were measured by Folin-Denis

method. 10 gm of sample was taken with 50ml of distilled water

& boiled for 30min. Then 0.2 ml of filtrate was taken & 8.3 ml,

0.5ml, 1ml of DH2O, Folin-Denis reagent, 15% Na2 CO3

respectively was added. After retaining the mixture for 30 min.

optical density was measured at 700 nm.

Production of tannase using raw tannin :

Page 50

International Journal of Scientific Engineering and Technology

Volume No.4 Issue No.2, pp : 50-55

Different tannin rich plant materials ware inoculated with

Aspergillus aculeatus I spores to find out their suitability for

tannase production.

Fermentation in EYELA 5-L Fermentation : Organism was

grown in a EYELA 5-L fermentor in 2.5 L of medium 20ml of

spore suspension was used as inoculum. Composition of medium

was same as inoculum medium except agar. Fermentation took

place at 300c with pH 5.5 & the pH of the medium was adjust

using 1 (N) NaOH or 1(N)HCL.

Solid State fermentation: Solid state fermentation (SSF) for

tannase production was carried out in 500ml Erlenmeyer flask

containing 20 gm of wheat bran with 5% (W/V) tannic acid &

50ml distilled water. Medium was inoculated with 5x108

spores/ml & incubated at 300c with 80% humidity for 72hrs.

After fermentation enzyme was extracted from the fermented

solid by addition of 100 ml of 1% (W/V) aqueous solution of

NaCl through agitation for 3hrs. in a rotary shaker (200rpm).

Filtration was done using Whatman No.1 filter paper. Filtrate

was centrifuged at 6000xg for 15min & the supernatant was

assayed for tannase activity.

Preparation of enzyme: Fermented broth was filtered & filtrate

was used as the source of extracellular enzyme. Harvested

mycelium was homogenized & centrifuged & supernatant was

used as the source of intracellular enzyme.

Purification of tannase: Intracellular & extracellular enzyme

suspension was brought to 70% saturation with solid enzyme

grade (NH4)2 So4 & kept overnight at 4 C. The supernatant was

separated by centrifugation (10,000 for 15 min) & the precipitate

was taken & dissolved in 0.02(M) acetate buffer (pH 5.5). The

remaining salt in the protein was removed by dialysis of the

same. In a DEAE- cellulose packed column (2.5 x 30cm.)

dialysis enzyme solution was applied & eluted through the

acetate buffer (pH 5.5) containing linear gradient of NaCl [0.011.0(M)]. After elution, the active fractions containing tannase

activity were collected & concentrated in lyophilizer & stored at

0C for further purification.

The enzyme solution was

now put on sephadex G-100 column (1.5 x100 cm) that is preequilibrated with 0.02 (M) acetate buffer & then eluted with

same buffer (pH 5.5). The collected protein fractions were

assayed for enzyme activity.

Properties of tannase :

(a) Effect of temperature on tannase activity & stability : To

determine optimum temperature, tannase activity was

measured at different temperature (30-80 C) in pH 5.5.

Thermal stability of the enzymes was determined by

incubating it at different temperatures for 60 min & then

residual activity was measured at optimum pH &

temperature.

(b) Effect of pH on tannase activity & stability : To find out

optimum pH, tannase activity was measured at different pH

values (3-8). For pH stability, the enzyme solution was kept

at different pH values at 4C for 24 hrs & then residual

activity was measured at optimum pH temperature.

Assay of tannase: Tannase activity was determined by the

method of MONDAL et al. (2001). Enzyme solution (0.1 ml)

was incubated with 0.3 ml of 1.0% (W/V) tannic acid, in 0.2

M citrate buffer (pH 5.0) at 400C for 30 min and then the

IJSET@2015

(ISSN : 2277-1581)

01 Feb2015

reaction was terminated by the addition of 2 BSA (1 mg/ml),

which precipitates the remaining centrifuged (5,000 x g, 10

min). The precipitate was dissolved in 2 ml of SDS

triethanolamine (1% W/V, SDS in 5% V/V, triethanolamine)

solution and the absorbency was measured at 550 nm after

addition of 1 ml of FeCl3 (0.13 M) (systronics

spectrophotometer 105). One unit of the tannase was defined

as the amount of enzyme, which is able to produce 1 g of

gallic acid from tannic acid in 1 min at specific condition.

RESULTS & DISCUSSION

(A) Determination of tannin content of some plant material:

Tannin content of different plant material was determined (Fig.

I). It has been found that Acacia gives maximum tannin among

the different plants tested. Eucalyptus, Psidium, Anacardium,

Jam , Terminalia , Delonix are the moderate tannin producer.

(B) Production of tannase using raw tannin : Among the

different plant sources tested Cassia ciamia gave better result

(Fig. II a,b), where production of tannase is about 6 unit/ml.

Fermentation was carried out in EYELA 5 L fermentor. This

fermentation process gives maximum tannase and biomass after

30 hrs and 36 hrs respectively.

(C) Fermentation : Enzyme production by the organism was

made in fermentor by using raw tannin.

(i) Fermentation at constant pH :- During submerged

fermentation if pH retains constant, O2 consumption varies with

time (Fig : III a,b,c). During fermentation dissolved oxygen level

decrease from 30% to 5% after 20 hrs of growth and again

increased to 25% after 42 hrs. It has been found that oxygen

consumption increased during active growth of the organism.

(ii) Fermentation at constant dissolved oxygen :- When D.O.

become constant, initial pH 6.2, gradually falls to 4.1 after 28

hrs. of growth and then slowly increases upto 4.7 after 36 hrs. of

growth (Fig : IV a,b,c). Actually gallic acid production takes

place at initial growth phase when pH falls, but when organism

utilizes gallic acid as carbon source, then pH slightly increase.

Product analysis from the fermentation broth at different

fermentation period confirms our prediction.

(D) Solid State fermentation : Solid state fermentation was

carried out in presence of different solid substance & the result is

represented in the table-1.The amount of enzyme production in

relation to the substrates can be arranged in following order:

wheat bran> rice bran> sawdust> rice straw dust> sugar cane

pith. Earlier Chatterjee et al., (1996) showed that bran could

enhance tannase production in Rhizopus oryzae. Enzyme

synthesis was also studied in relation to tannic acid

concentration (Fig :V a,b). It has been observed that higher

concentration is inhibitory to tannase synthesis whereas lower

concentrations are not repressive. Actually, tannic acid at higher

concentration produces complex with membrane protein.

Enzyme as well as gallic acid production were studied

simultaneously in relation to time (Fig : Vi a,b). Organism

produce maximum enzyme and gallic acid with in 72-84 hrs &

in 60hrs respectively. Previously maximum extracellular tannase

and gallic acid production in 96 hrs and 120 hrs has been

Page 51

International Journal of Scientific Engineering and Technology

Volume No.4 Issue No.2, pp : 50-55

recorded in Aspergillus niger (Lekha and Lonsane, 1997) and

Rhizopus oryzae (Chatterjee et al., 1996) respectively.

(E) Purification of extracellular and intracellular tannase :

Various steps of purification of both extracellular and

intracellular tannase was represented in Table-2. In DEAECellulose column about six protein peaks are found of which 3436th tubes posses tannase activity (Fig VII). In Sephadex G-100

Column single protein peak with maximum tannase activity at

tube no 48-49 was found (Fig : VIII). The specific activity of

purified enzyme was 79.7 unit/ mg protein. Earlier Banerjee et

al. (2001) have reported the production and characterization of

extracellular and intracellular tannase from newly isolated

Aspergillus aculeatus. Costa et al. (2012) purified the

extracellular tannase by using two chromatography techniques,

filteration chromatography using G-150 sephadex column

followed by ion exchange chromatography in a DEAE Sephadex

column.

(F) Properties of purified tannase : The optimum pH of the

enzyme was 5.0 and the enzyme retained more than 85% of its

original activity between pH 5.0-6.0. The enzyme is stable in pH

4.0-7.0 (Fig : X a,b). Batra & Saxena (2005) reported that

tannase from A. fumigatus and A. flavus is stable at pH 4.0. &

doesnt show tannase activity at alkaline pH of 8.0. In contrast,

A. versicolor tannase showed less stability at pH 3.0. with a

maximum (100%) activity at pH 6.0.

Optimum temperature of the enzyme is 60C. Enzyme is stable

upto 50 C and looses only 5% activity at 60C (Fig: IX a,b).

Similar optimum temperature of the enzyme has been found in

different spp. of Aspergillus by Batra & Saxena (2005). Banerjee

et al. (2005) reported that maintenance of an optimal

fermentation temperature is important as it affects the fungal

growth, spore formation, germination, microbial physiology, and

thus product formation.

Fig- I

(ISSN : 2277-1581)

01 Feb2015

Carthamus 26. Cyperus 27. Ficus 28. Eucalyptus 29.Polyalthia

30. Calotropis 31. Psidium.)

Fig-II(a)

Fig-II (b)

Fig-II (a,b) : Production of tannase using different plant tannin

(1. Cassia ciamia; 2. Delonix; 3. Anacardium; 4. Bruguiera; 5.

Acacia; 6. Mimosa; 7.Casuarina).

Fig-III(a)

Time

Fig-III(b)

Fig I : Tannin content of some plants (1. Bruguiera 2.

Soneratia 3. Rhizophora 4. Terminalia 5. Jam; 6. Curcuma 7.

Tectona 8. Delonix 9. Shorea 10. Mimosa pudica 11. Zizyphus

12.Cassia 13.Alstonia 14. Casuarina 15. Anacardium 16. Acacia

17. Eupatorium 18. Trewia 19.Mimosa sp 20. Sida

21.Parthenium 22. Azadiracta 23. Crotolaria 24.Lantana 25.

IJSET@2015

Page 52

International Journal of Scientific Engineering and Technology

Volume No.4 Issue No.2, pp : 50-55

(ISSN : 2277-1581)

01 Feb2015

Fig-III(c)

Fig-III(a,b,c) : Fermentation profile of Aspergillus aculeatus

tannase fermentation where pH is fixed.

Fig-IV (a)

Fig-V (a,b) Effect of tannin acid concentration on tannase

Fig-IV(b)

Fig-VI(a,b) Effect of incubation time on tannase activity

Fig IV a-c : Fermentation profile of Aspergillus aculeatus

tannase fermentation when dissolved oxygen is fixed

IJSET@2015

Page 53

International Journal of Scientific Engineering and Technology

Volume No.4 Issue No.2, pp : 50-55

(ISSN : 2277-1581)

01 Feb2015

Fig-VII: Column chromatography of Aspergillus aculeatus

tannase on DEAE-cellulose. The enzyme was applied to the

column (2X25m) of DEAE- cellulose equilibrated with 0.02 M

acetate, pH5.5.

Fig X(a,b) : Effect of pH on tannase activity

Fig VIII: Column chromatography of Aspergillus aculeatus

tannase on Sephadex G-100.

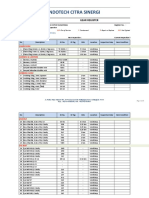

Table -1: Purification of tannase of Aspergillus aculeatus

Fig- IX (a, b) : Effect of temperature on tannase activity

IJSET@2015

Table-2 : Effect of solid substrate on tannase and gallic acid

production by Aspergillus aculeatus grown on 5% tannic acid at

300C for 72 h & pH 5.0.

Page 54

International Journal of Scientific Engineering and Technology

Volume No.4 Issue No.2, pp : 50-55

CONCLUSION

The enzyme tannase has wider application in different

chemical, pharmaceutical and food industries. Thus, it is

important to reduce the cost and scale up tannase production as

well as determine the factors affecting enzyme activity. This

would enable the utilization of enzyme in the most efficient

manner. We have prepared tannase from raw tannin sources,

which is cheaper, so it is industrially useful.

ACKNOWLEDGEMENT

The authors are grateful to SESA (Society for Environment

& Social Awareness) for providing laboratory facility to carry

out the research work.

REFERENCES

i.

Aboubkar HA, El-Sahn MA, El-Banna AA 2013. Some

factors affecting tannase production by Aspergillus niger Van

Tieghem. Braz J Microbiol 44: 559-567

ii.

Bajpai B, Pati S 1996. Tannin acyl hydrose (Ec :

3.1.1.20) activity of Aspergillus, Penicillium, Fusarium and

Trichoderma. World Microbiol Biotechnol 12:217-220

iii.

Banerjee D, Mondal KC, Pati BR 2001. Production

and characterization of extracellular and intracellular tannase

from newly isolated Aspergillus aculeatus DBF 9.J. Basic

Microbiol 41: 313-318

iv.

Banerjee R, Mukherjee G, Patra KC 2005 Microbial

transformation of tannin rich substrate to gallic acid through coculture method. Bioresource Technol 96: 949-953

v.

Batra A, Saxena RK 2005.

Potential tannase

producers from the genera Aspergillus and Penicillium. Process

Biochemistry 40: 1553-1557

vi.

Bhat TK, Singh B, Sharma OP 1998. Microbiol

degradation of tannins - a current perspective. Biodegradation

25: 343-357

vii.

Bradoo S, Gupta R, Saxena RK 1997. Parametric

optimization and biochemical regulation of extracellular

tannase from Aspergillus japonicus. Process Biochem. 32: 135139

viii.

Chatterjee R, Dutta A, Bannerjee R and Bhattacharya

BC 1996. Production of Tannase by Solid state fermentation.

Bioprocess Engg. 14:159

ix.

Coggon P, Sanderson GW 1975. Manufacture of instant

tea. Patent Ger Offen 2.304073 (cl.A.23f) 16August 1975

IJSET@2015

(ISSN : 2277-1581)

01 Feb2015

x.

Costa AM, Kadawaki MK, Minozza MC, De Souza

CGM, Boer CG, Bracht A and Peralta RM 2012. Production,

purification and characterization of Tannase from Aspergillus

tamari. African journal of Biotechnology vol 11(2): 391-398

xi.

Hadi TA, Banerjee R, Bhattacharya BC 1994.

Optimization of tannase biosynthesis by a newly isolated

Rhizopus oryzae. Bioprocess Engg. 11: 239-243

xii.

Kar B, Banerjee R, Bhattacharya BC 1999. Microbiol

production of gallic acid by modified solid state fermentation. J

Ind Microbiol Biotechnol. 23: 173-177

xiii.

Koichi Y, Tokuji T 1972. Wine making using tannase in

fermentation process. Japenese Patent 2224100

xiv.

Kumar R, Sharma J, Singh R 2007. Production of

tannase from Aspergillus ruber under solid-state fermentation

using jamun (Syzygium cumini) leaves. Microbiol Res 162: 384390

xv.

Lekha PK, Lonsane BK 1994. Comparative titers,

location and properties of tannin acyl hydrose produced by

Aspergillus niger PKL 104 in solid state, liquid and submerged

fermentation. Process Biochem 29: 497-503

xvi.

Lekha Pk, Lonsane BK 1997. Production and

application of tannin acyl hydrolase. State of the art advances.

Appl. Microbiol. 44: 215-260

xvii.

Massachelin CA, Batum MS 1981. Enzymatic

degradation and participation of ester linked beer polyphenols

in chill haze formation. Proc Cong Eur Brew Conv 18: 359-370

xviii.

Mehta M, Muddapur UM, Shanmuga Priya VG 2013.

Fungal production of tannase : a review. Int. J. Sci. Engg.

Technol. 2: 752-755

xix.

Mishra SK, Kumar R, Banerjee R, Bhattacharya BC

1997. Production of gallic acid by immobilization of Rhizopus

oryzae. Bioprocess Engg. 16: 257-260

xx. Mondal KC, Pati BR 2000. Studies on the extra cellular

tannase from newly isolated Bacillus licheniformis KBR 6. J

Basic Microbiol 40: 223-232

xxi.

Mondal KC, Banerjee D, Jana M, Pati Br 2001.

Calorimetric assay method for determination of the tannin acyl

hydrose (Ec : 3.1.1.20) activity. Anal. Biochem

295(2): 168171

xxii.

Pourrat H, Regerat F, Morvan P, Pourrat A 1987.

Microbiological production of gallic acid from Rhus coriaria L.

Biotechnol Lett 9: 731-734

Page 55

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- May 2021 Examination Diet School of Mathematics & Statistics ID5059Documento6 páginasMay 2021 Examination Diet School of Mathematics & Statistics ID5059Tev WallaceAinda não há avaliações

- Sample CBAP Elicitation Scenario Based Questions Set 01Documento31 páginasSample CBAP Elicitation Scenario Based Questions Set 01Rubab Javaid100% (1)

- Sex, Law, and Society in Late Imperial China (Law, Society, and Culture in China) by Matthew SommerDocumento444 páginasSex, Law, and Society in Late Imperial China (Law, Society, and Culture in China) by Matthew SommerFer D. MOAinda não há avaliações

- Case Study: Implementation of 5S Methodology in JCB Assembly Business Unit Material StorageDocumento6 páginasCase Study: Implementation of 5S Methodology in JCB Assembly Business Unit Material StorageInnovative Research PublicationsAinda não há avaliações

- The Experimental Study of Eccentric Loadingfor Piled Raft Foundations Settling On Slope CrestDocumento5 páginasThe Experimental Study of Eccentric Loadingfor Piled Raft Foundations Settling On Slope CrestInnovative Research PublicationsAinda não há avaliações

- 3D Modeling of Complex Structure Based On AutoCAD VBADocumento3 páginas3D Modeling of Complex Structure Based On AutoCAD VBAInnovative Research PublicationsAinda não há avaliações

- Power Transformer Protection Using Fuzzy Logic Based ControllerDocumento5 páginasPower Transformer Protection Using Fuzzy Logic Based ControllerInnovative Research PublicationsAinda não há avaliações

- Computational EconomicsDocumento2 páginasComputational EconomicsInnovative Research PublicationsAinda não há avaliações

- Surveillance NetworksDocumento2 páginasSurveillance NetworksInnovative Research PublicationsAinda não há avaliações

- Information EngineeringDocumento2 páginasInformation EngineeringInnovative Research PublicationsAinda não há avaliações

- Role of Coaching Institutes in IndiaDocumento5 páginasRole of Coaching Institutes in IndiaInnovative Research PublicationsAinda não há avaliações

- Computational ElectromagneticsDocumento3 páginasComputational ElectromagneticsInnovative Research PublicationsAinda não há avaliações

- Online Laboratory: Roy G. Perry College of Engineering Prairie View A&M University Prairie View, TX 77446Documento2 páginasOnline Laboratory: Roy G. Perry College of Engineering Prairie View A&M University Prairie View, TX 77446Innovative Research PublicationsAinda não há avaliações

- CFD Analysis of A 210 MW Tangential Fired BoilerDocumento6 páginasCFD Analysis of A 210 MW Tangential Fired BoilerInnovative Research PublicationsAinda não há avaliações

- Wearable ComputingDocumento3 páginasWearable ComputingInnovative Research PublicationsAinda não há avaliações

- Comparative Print Quality Analysis of Screen Printing and Liquid Ink Based Digital Printing MachinesDocumento3 páginasComparative Print Quality Analysis of Screen Printing and Liquid Ink Based Digital Printing MachinesInnovative Research PublicationsAinda não há avaliações

- A Smart Monitoring of Faults in Power Transformers and Maintenance Based On Wi-FiDocumento6 páginasA Smart Monitoring of Faults in Power Transformers and Maintenance Based On Wi-FiInnovative Research PublicationsAinda não há avaliações

- Experimental Study About Soil Improvement With Glass FibersDocumento5 páginasExperimental Study About Soil Improvement With Glass FibersInnovative Research PublicationsAinda não há avaliações

- Information Security in Cloud Computing: A Systematic Literature Review and AnalysisDocumento6 páginasInformation Security in Cloud Computing: A Systematic Literature Review and AnalysisInnovative Research PublicationsAinda não há avaliações

- Load Dwe Eigh Ing D Devi Ice: For R Elev Vators SDocumento28 páginasLoad Dwe Eigh Ing D Devi Ice: For R Elev Vators SNaren AnandAinda não há avaliações

- Differential Association Theory - Criminology Wiki - FANDOM Powered by WikiaDocumento1 páginaDifferential Association Theory - Criminology Wiki - FANDOM Powered by WikiaMorningstarAsifAinda não há avaliações

- Executive Shirt CompanyDocumento6 páginasExecutive Shirt CompanyPramod kAinda não há avaliações

- Metal, Metallurgy, Music, Husserl, Simondon Richard Pinhas: I Have Two Questions To Formulate Regarding The Last Session, Although WhatDocumento13 páginasMetal, Metallurgy, Music, Husserl, Simondon Richard Pinhas: I Have Two Questions To Formulate Regarding The Last Session, Although WhatbluexpectroAinda não há avaliações

- 2022 05 141RBSF351652506386Documento6 páginas2022 05 141RBSF351652506386tathagat jhaAinda não há avaliações

- Analysis and Design of Cantilever Slab Analysis and Design of Cantilever SlabDocumento3 páginasAnalysis and Design of Cantilever Slab Analysis and Design of Cantilever SlabMesfinAinda não há avaliações

- Command Center Processing and Display System ReplacementDocumento2 páginasCommand Center Processing and Display System ReplacementImranAinda não há avaliações

- Getting Started in Steady StateDocumento24 páginasGetting Started in Steady StateamitAinda não há avaliações

- Dossat PrinciplesOfRefrigerationDocumento554 páginasDossat PrinciplesOfRefrigerationHernan CobaAinda não há avaliações

- Unit 3 Approaches To The Study of Medieval Urbanisation : StructureDocumento20 páginasUnit 3 Approaches To The Study of Medieval Urbanisation : StructureSunil SunilAinda não há avaliações

- Strain GaugeDocumento7 páginasStrain GaugefahadarizkiAinda não há avaliações

- SIP Project ProposalDocumento2 páginasSIP Project ProposalDeep SutariaAinda não há avaliações

- Timing Chain InstallationDocumento5 páginasTiming Chain InstallationToriTo LevyAinda não há avaliações

- KIT REQUEST FORM - GradDocumento2 páginasKIT REQUEST FORM - Graddamie aadamsAinda não há avaliações

- Guide For H Nmr-60 MHZ Anasazi Analysis: Preparation of SampleDocumento7 páginasGuide For H Nmr-60 MHZ Anasazi Analysis: Preparation of Sampleconker4Ainda não há avaliações

- 19 - 22187 - Pritchard RD (1969)Documento36 páginas19 - 22187 - Pritchard RD (1969)Isaias MoralesAinda não há avaliações

- Inspection List For Electrical PortableDocumento25 páginasInspection List For Electrical PortableArif FuadiantoAinda não há avaliações

- International Trade SyllabusDocumento3 páginasInternational Trade SyllabusDialee Flor Dael BaladjayAinda não há avaliações

- RH 120eDocumento8 páginasRH 120eSawadogo Gustave NapinguebsonAinda não há avaliações

- 33392-01 Finegayan Water Tank KORANDO PDFDocumento3 páginas33392-01 Finegayan Water Tank KORANDO PDFShady RainAinda não há avaliações

- Addis Ababa University Lecture NoteDocumento65 páginasAddis Ababa University Lecture NoteTADY TUBE OWNER100% (9)

- Grade 8 For Demo Cigarette SmokingDocumento3 páginasGrade 8 For Demo Cigarette SmokingSteven TaperoAinda não há avaliações

- Discussion 2: OOA: Case Study Robot in MazeDocumento17 páginasDiscussion 2: OOA: Case Study Robot in MazeArmmetAinda não há avaliações

- Coding Prony 'S Method in MATLAB and Applying It To Biomedical Signal FilteringDocumento14 páginasCoding Prony 'S Method in MATLAB and Applying It To Biomedical Signal FilteringBahar UğurdoğanAinda não há avaliações

- Student Material CN Version - 2017.11.10Documento25 páginasStudent Material CN Version - 2017.11.10Jagaddeesha BRAinda não há avaliações

- Overview of Risk Based Audit ProcessDocumento17 páginasOverview of Risk Based Audit ProcessAira Nhaira Mecate100% (1)

- Strata Ene 2023Documento8 páginasStrata Ene 2023gabyAinda não há avaliações