Escolar Documentos

Profissional Documentos

Cultura Documentos

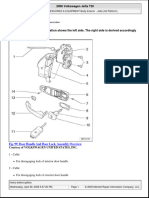

W208 Case Cover Lock and Rear Bow Lock Replacement

Enviado por

Birdy NumnumsDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

W208 Case Cover Lock and Rear Bow Lock Replacement

Enviado por

Birdy NumnumsDireitos autorais:

Formatos disponíveis

MercedesW208(CLK99 03)

CaseCoverLock/RearBowLockReplacement

andHydraulicFluidFlush

Becauseaconvertibleisonlycoolifthetopgoesdown.

Version1.0August9,2012

byjoetwa

Table of Contents

ToolsandParts

H d li Fl id LevelInspection

HydraulicFluid

L lI

ti

LeaksandCylinders

TopandCoverPositoning

FrontCarpeting(Top) Removal

TrunkLuggageScreen Relocation

Front Carpeting (Bottom) Removal

FrontCarpeting(Bottom)

BottomAngledPanel Removal

HydraulicPump

CaseCoverLock PanelRemoval

CaseCoverLock Removal

CaseCoverLock PreparationandInstallation

3

4

5

6

7

8

9

10

11

12

1314

15

RearBowLock CarpetRemoval

RearBowLock TieWrapCut

RearBowLock Removal

Rear Bow Lock PreparationandMounting

RearBowLock

Preparation and Mounting

RearBowLock FinalInstallation

16

17

18

19

20

HydraulicFluid FlushandRefill

SystemTest

21

22

RearBowLock CarpetReassembly

CaseCoverLock PanelReinstall

BottomAngledPanel Reassembly

FrontCarpeting(Bottom) Reassembly

TrunkLuggageScreen Reassembly

TrunkLuggageScreen SpringReTension

FrontCarpeting(Top) Reassembly

23

24

25

26

27

28

29

TheTurtle

30

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Tools and Parts

Whileallthebelowtoolsandpartsarerecommended,threeofthemareoptional.Theseinclude:

1 ElectricDrill forfasterremovalof10mmhexbolts

2 Siphon forrecommendedcompletefluidflush

3 PlasticPanelRemovalTools foreasierremovalofcarpetplasticfasteners(aflathead

screwdriveralsoworks)

ElectricDrillwith

10mmsocket

Mercedes

HydraulicFluid

d l l d

000989910310

Febi Hydraulic

Fluid02615

MercedesManualTopTool

(iftophascompletelystopped)

2088990080

NOTE:Thisisthe

OnlyMercedes

ApprovedSubstitute

SlottedScrew

Driver

DONOTUSEANY

OTHERTYPEOFFLUID

Needle

NosePliers

2 Siphon

RazorKnife

ManualwrenchesWith10mm

socket

RearBowLock

Assembly

Smallfunnel

1Medium

TieWrap

PlasticPanel

CaseCoverLock

Assembly

Adjustable

Wrench

3 removaltools

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Hydraulic Fluid - Level Inspection

Althoughitisnotobvious,thereisasimplewaytoobserveyourconvertibletophydraulic

fluidlevel,directlyfromthetrunk.Thereisactuallyaportalthatyoucanlookthrough

with a flashlight thereiseventhebeginningsofthecutinthecarpet,similartothe

withaflashlight

there is even the beginnings of the cut in the carpet similar to the

openingforthehydraulicpumpreliefscrew(thatyouusetoraisethetopmanually) but

forsomereasonMercedesAutoworkersonlycut2ofthe3sidesneeded.Cutthebottom

withasmallrazorblade,andyouareinbusiness.

HydraulicPump

PressureRelief

Screw under here

Screwunderhere

Cutacrossbottom

Youcannowseethelevelwithaflashlight(lyingdownonyour

stomach).Note: Thispictureshowsthecorrectlevel,notthe

levelyoullprobablyfindifyouarehavingslow/nomovingtop

issues.Ifyourlevellooksfine,yourissueisprobablyNOTwith

thehydraulicfluidsystem,butprobablyarelayoraswitch.

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Leaks and Cylinders

Ifyourhydraulicfluidislow,thereismostdefinitelyaleakinyoursystem somewhere.

Hydraulicfluiddoesevaporate,butataveryminisculerate.Themostcommonelements

that leak are the rear bow lock and/or the case cover lock and the specific instructions to

thatleakaretherearbowlockand/orthecasecoverlock,andthespecificinstructionsto

replacebothofthesepartsfollow.

WhilethepartsareavailabledirectlythroughMercedes,themosteconomicalwayto

procurethemisthroughacoreexchangeviaTopHydraulics.Tosimplifytheoperation

evenfurther,TopHydraulicswillshipyourebuiltcylinders,alreadymountedintheproper

lock assemblies (

lockassemblies(below),andchargeyoua$150refundablecoredepositforeach.

below) and charge you a $150 refundable core deposit for each

Simplyshipyouroldonesbackwhenyouaredone,andyoullgetyourrefund(provided

youdontdamagethemwhenremoving!).Thisisthewaytogoasitwillsaveyouhoursof

installationtime.

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Top and Cover Positioning

Thefirststepnecessaryispreparingyourtopandtopcoversoitsinthecorrectpositionso

youcanworkonit,however,youFIRSTmustdothefollowingfromwithinyourtrunk,as

once you are underway access to your trunk through the boot will not be possible Note:

onceyouareunderway,accesstoyourtrunkthroughthebootwillnotbepossible.Note:

Thebelowinstructionsassumeyourtopisstillfunctioning(albeitslowly) ifyourtopis

notfunctioningatall,youmustfollowtheinstructionsintheMercedeshandbookfor

manualoperationviathespecialwrenchprocess.

1. Removeyourtrunkfloorliner putitinasafeplace.

2. Leavethetrunkluggagescreenfullydeployed/inplace/operationalasifyouwere

going to put the top down (it is easier to relocate from inside the top cover panel)

goingtoputthetopdown(itiseasiertorelocatefrominsidethetopcoverpanel).

3. Closethetrunk.

4. Manipulatesothattheconvertibletopandreartopcoverareinthesamepositions

asthebelowpicturedemonstrates dothisviathedashopen/closecontrol(orvia

themanualprocessoutlinedinthehandbook).

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Front Carpeting (Top) - Removal

Thefrontdecorativecarpetingisfastenedusingamultitudeofplasticfasteners the

smalleronespopup(useaplasticpanelremovaltool),thelargeronesunscrew(thereisa

threaded rod connected to the frame underneath)

threadedrodconnectedtotheframeunderneath).

Smallonespopup

andremove

Besuretoremove

bothparts

NOTE:Whileremoving,secureloop

endwithapapercliponeachsideso

thatitdoesntfullyretractintothe

edgeofthemeshwhileyouare

working.

LargerButtonOnes

Unscrew

Whenallfastenershavebeenremoved,simplypryupcarpet,andremovetoasecureplace

(likethehoodofthecar.)

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Trunk Luggage Screen - Relocation

Removing/relocatingthetrunkluggagescreenisaverysimplematter,andwhendonethis

waywillcontinuetomakecontactwiththeswitchintherailsothatyoucaneasilyperform

testing of the top when done Follow the steps in this order:

testingofthetopwhendone.Followthestepsinthisorder:

1.

1 Whileholdingthescreenbracket,removethesinglescrew peelupthebracketthat

willbealsofastenedtothecarviaasmallfabricpiecethatisgluedon.

2 Whileholdingthemiddleoftheshadesothatitdoesntspin,pulltheentireshade

2.

assemblytowardsyou,whichwillfreethefarsidefromitscorrespondingbracket.

3.

3 Lettheshaderetract(slowly)towardstherearofthecar,holdingthemiddlecylinder

withonehandandthebracketwiththeother

ith

h d d th b k t ith th th

l

leaveasshown

h

shouldjusthang

h ld j t h

thereunderitsowntension.

4 Removethefarsidebracketscrewandsimplyflipupoutofthewayslightly no

4.

needtoreleasethegluedfabriconthisside.

Becarefultonotlet

this end spin

thisend

spin ,releasing

releasing

springtension butifithappens,

dontpanic itseasilyremedied

duringthereinstallprocess.

2

3

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Front Carpeting (Bottom) - Removal

Theremainingbottomcarpetpieceisheldonlyinplaceby4singlepieceplasticpush

1

pins.Thetwosidepiecesconnectinmultipleplaces,butcanbemovedoutoftheway

2

be removing the large button on either side (unscrew) and then by folding the carpet back

beremovingthelargebuttononeitherside(unscrew)andthenbyfoldingthecarpetback

towardstherearofthecar.

2

LargerButtonOnes

Unscrew

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Bottom Angled Panel - Removal

10

Toremovethebottomangledpanel,youmustremoveALLofthegold10mmboltsfrom

theperimeter ofthepanel.Anelectricdrillwithabitadapterisusefulformostofthem,

but some bolts around the perimeter will require a box wrench to get access

butsomeboltsaroundtheperimeterwillrequireaboxwrenchtogetaccess.

Donotremovethe4interiorboltsfromthemid/rightsideofthepanelastheholdthey

Boseamplifierunderneath.Oncealltheboltsareremoved,youcancarefullyshiftthe

panelasshownbelow,exposingthepumpassembly.

Yourbestfriend

DONOTREMOVE

Shiftover

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Hydraulic Pump

11

Nowthatyouhaveaccesstothehydraulicpump,youcanrefillthefluidlevel(togetyour

topworkingintheinterim/helpidentifyyourleak),althoughthisisnotrequiredifyou

already know where your leak is or you are just proactively replacing your lock(s)

alreadyknowwhereyourleakis,oryouarejustproactivelyreplacingyourlock(s).

Beforeyoubeginthenextstepsofreplacingyourcasecoverlockorrearbowlock,its

importanttoreleasepressureinthesystembyturningastandardscrewdrivertwoturnsto

theleft(ifyouhaventalreadydonethisaspartofamanualprocess.)

Removeboltandrefillusingsmall

funnel(ifrequiredtohelpidentify

leaklocation)

Chancesareyourfluid

levellookslikethis:

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Case Cover Lock - Panel Removal

12

First,removethe4boltsholdingtheprotectivepaneloverthecasecoverlock place

panelinasafeplace.Ifyouhaveacasecoverlockleak,youwillnoticeitsomewherein

this area

thisarea.

Remove4bolts

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

13

Case Cover Lock - Removal

Usingtheneedlenosepliers,removethehydrauliclineclipsfrombothlinesandpullthe

linesfreeofthecasecoverlock makesureyoulabelwhichlinegoeswhere,although

they are easy to tell just by their length Separate the electrical connector as well

theyareeasytotelljustbytheirlength.Separatetheelectricalconnectoraswell.

PUTTHECLIPSSOMEWHERESAFEASYOUWILLREUSETHEMLATER.

Removeclips

withneedlenose

pliers

Pullouthydraulic

linesandleave

hanging

Unplug

connectorand

leavehanging

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Case Cover Lock - Removal

14

Unscrewboltsandcompletelyremovecasecoverlock putinasafeplace.

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Case Cover Lock - Preparation & Installation

15

Partiallyslidethehydrauliclinelockingclipsontothebodyofthenewlockasshown its

mucheasiertodothisbeforeyoumountitonthecar.Remountthelockasshownbelow

and then reattach the hydraulic lines (just push in tight) and then use needle nose pliers to

andthenreattachthehydrauliclines(justpushintight)andthenuseneedlenosepliersto

firmlyslidetheclips,securingthehydrauliclinestothenewlock.Reconnectelectrical

connector.

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Rear Bow Lock - Carpet Removal

16

Usingtheplasticpanelremovaltool,removealloftheplasticfasteners.Completely

removethecarpetandplacesomewheresafe.Therearbowlockassemblyisnoweasily

accessible Any leaks will be clearly visible

accessible.Anyleakswillbeclearlyvisible.

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Rear Bow Lock - Tie Wrap Cut

17

Usingyourrazorknifeorwireclips,carefullycutthetiewrapholdingtheelectrical

connectortothebodyofthevalve.Unplugtheconnectorandcarefullyremovethefoam

rubber around the connector as you will reuse

rubberaroundtheconnectorasyouwillre

usethisonthenewassembly.

this on the new assembly

Unplug

connectorand

leavehanging

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Rear Bow Lock - Removal

18

ThehydrauliclineclipsremoveinthesamefashionastheTopCoverLock removethese.

PUTTHECLIPSSOMEWHERESAFEASYOUWILLREUSETHEMLATER.

C

Completelyremovetherearbowlockbyremovingthe4outerbolts.Donotloosenthe

l l

h

b l kb

i

h 4

b l

D

l

h

5th boltthatholdstheassemblyontotheTmount.

DoNotLoosen

Removeclips

withneedlenose

pliers

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Rear Bow Lock - Preparation and Mounting

19

YoumustnowremovethecopperTmountfromtheoldassemblybylooseningthesingle

boltandreattachittothenewassembly keepfairlyloosefornow.

Attach the new Rear Bow Lock on the Top Cover by first tightening the 4 outer screws then

AttachthenewRearBowLockontheTopCoverbyfirsttighteningthe4outerscrews,then

tightenthe5th screwasshownbelow.

NEW

OLD

Tightenlast

Tightenfirst(x4)

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Rear Bow Lock - Final Installation

20

Slidethehydraulicclipspartiallyontothevalvebodyusingneedlenosepliers,andthen

pushinthelinesfirmly.Securetheclips.Slidethefoamonasitwasbefore(Idamaged

mine slightly taking it off) and then reattach

mineslightlytakingitoff)andthenre

attachtheelectricalconnector.Completethe

the electrical connector Complete the

installationwithasingletiewrap(Ionlyhadwhite,butuseblackifyouareasticklerfor

detail.)

FirstPartially

slideclips

2

2

1

Secureclips

withneedle

nosepliers

thenfirmlyseat

Hydrauliclines

TieWrapas

shown

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Hydraulic Fluid - Flush and Refill

21

Unscrewthebrassreservoirscrewusinganadjustablewrench(putscrewsomewheresafe

whereyouwontloseitandwhereitcantfallintothetrunkunderthesparetire!)Using

the siphon (and any convenient small soda bottle) completely remove any remaining

thesiphon(andanyconvenientsmallsodabottle),completelyremoveanyremaining

hydraulicfluidfromthereservoir(andpleasedisposeofproperly.)

Note:Thefluidremovalstepisnotrequired,butitishighlyrecommendedasthefluidin

thesystemwillbeasoldasyourcar!Additionally,youshouldalsocheckthebottomofthe

reservoirforwaterorsmallparticles,astheyshouldalsobothberemoved Waterwill

ruin the OEM seals and small particles will wear out the system

ruintheOEMseals,andsmallparticleswillwearoutthesystem.

ReplacewithnewMercedesorFebi fluidasshowntotheverytopofthetopline.Replace

thebrassreservoirboltandtighten(butnottootightasthereservoirisplastic.)

NOTE:ifyouhaveeverusedStopLeaktypeproductsinyoursysteminthepast,you

shouldrepeatthefill/remove/fillprocedureseveraltimes,cyclingthetopatleast10times

(Seenextpage SystemTest).AllStopLeaktypeproductsarebadforthehydraulictop

system,andtheywilleventuallymakealltheOEMcylindersealsfail.

Removeboltandrefillusingsmall

funnelafterremovingoldfluid.

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

System Test

22

First,tightenthescrewonthehydraulicpump2turnstotherighttoclosethesystem.

Next,makesuretheconvertibletopareaiscompletelyclearoftools,fasteners,etc.Start

the car and cycle through 510

thecarandcyclethrough5

10fullopen/closetopcycles.

full open/close top cycles

NOTE:Duetosomeairremaininginthesysteminitially,thefrontedgeoftheconvertible

topmayBANGdownonthetopofthewindshieldheaderwhenclosing,soyoumaywant

tocatchthetopwithyourlefthandasitcomesdown.Thiswillclearafterapproximately

10cyclesasairisautomaticallybledout(systemisselfbleeding.)

Youmayneedtocontinuetoaddhydraulicfluidduringtheprocess(remembertoturn

screwtothelefttoreleasepressurebeforeyouopenthereservoir)toensurethelevel

staysattheverytopline,asfluidcontinuestobepulledbackintothesystemandairis

returnedtothereservoir.

Tightenscrew 2

turnstotheright

beforeTesting

Removeboltandrefill

usingsmallfunnelas

needed.

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Rear Bow Lock - Carpet Reassembly

23

Reinstalltherearbowlockcover,beingcarefultorefitthetwooutsideedgesofthecarpet

pieceunderneaththerubberedgeofthelid.Securewithalloftheplasticpushpinsyou

removed before

removedbefore.

Refitcarpetpieceunderneath

rubberedge bothsides.

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Case Cover Lock - Panel Reinstall

24

Reinstalltheprotectivepaneloverthecasecoverlockandtightenthe4bolts.

Reinstall4bolts

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Bottom Angled Panel - Reassembly

25

CarefullyrepositionthebottomangledpanelbackinplaceandthenreinstallALLofthe

gold10mmboltsaroundtheperimeter ofthepanel.

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Front Carpeting (Bottom) - Reassembly

26

Foldthetwosidecarpetpiecesbackinplaceoverthethreadedpostsandreinstallthe2

largerbuttonsbyscrewingontobothsidesofcar,andthenreinstallthebottomcarpet

1

piece 2 using the 4 single piece plastic push pins

pieceusingthe4singlepieceplasticpushpins.

1

LargerButtonOnes

S

Screwbackon

b k

threadedposts

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Trunk Luggage Screen - Reassembly

27

Reinstallthetrunkluggagescreenbyfollowingthesesteps(Note:Thisiseasiertodowith

twopeopleoneithersidetoensurethescreendoesntunroll,losingspringtension) If

the screen unravels

thescreen

unravels abitandyoulosespringtension,donotpanic,justfollowthesteps

a bit and you lose spring tension do not panic just follow the steps

onthenextpage.

1.

1 Flipthefarsidebracketbackdownandreinstallthebolt.Besuretohavetheother

sidebracket/boltnearyousoyoucaneasilyreachitlater.

2 Slowlyclosethescreentowardsthefrontofthecar,holdingthebracketandthe

2.

middleofthescreen.

33. Reinsertthefarendofthescreenintothefarbracket,makingsurethespindleis

R i

t th f

d f th

i t th f b k t

ki

th

i dl i

wellseated.

4.

4 Fitthecloseendbracketbackoverthespindle,andreattachthebolt,pressingdown

onthefabrictohelpreglueittotheframerail.

3

2

2

4

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Trunk Luggage Screen - Spring Re-Tension

28

Ifyouhavelostspringtensioninyourluggagescreenduringtherelocation/reinstallation

process,followthesestepstogetitback Note:Thisisatwopersonactivity!

1.

1

2

2.

33.

4.

4

Withsomeoneholdingthefarside,fromthedriversside,pushinonthespindlehub,

thiswillpushouttheoppositeside.

Ifyoupullitoutfartheryouwillseeaspiralspring,butthisisnotrequired,andit

makesslidingitbackindifficult(havetojiggleit),sojustleaveitoutjustfarenough

soyoucanturnitfreely(asshowninstep1.)

Turntheplasticendcounterclockwise ifyourspringisfullyreleased,youwillneed

toturnitabout15fullturns.Becarefulnottoovertightenasyourisksnappingthe

spring.

Whenyouaredonetightening,alignthematchinggrooveintotheslotonthemetal

tubetolockthescreenbackinplace.Completeprocessasshownonpreviouspage.

3

2

4

Alignplasticgroovewith

slotandslidebackin

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Front Carpeting (Top) - Reassembly

29

Refitthetopcarpetinplace,aligningitalongthetopedgeandovereachofthethreaded

rods.Reinstalltheplasticpushpinsandlargerbuttoncaps.Dontforgettorefittheelastic

loops on the side mesh before you insert the last 2 push pins

loopsonthesidemeshbeforeyouinsertthelast2pushpins.

LargerButtonOnes

Screwbackon

threadedposts

NOTE:Remembertorefit

theelasticloops

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

The Turtle

30

Althoughithasabsolutelynothingtodowiththerepair,Iwantedtomentiontheturtle.

O

Ononeofmymultipletripstothelocalhardwarestore(thistimetobuyafunnelthatfit

f

li l i

h l lh d

( hi i

b

f

l h fi

thehydraulicreservoir IactuallytooktheToolsandPartsphotographonpage3AFTERI

wasdone),aturtleactuallycrossedtheroadinfrontofme.Tookabout5minutesforhim

(her?)togetacross.

Iassumeitwasgoodluck!

Use as a guideline only apply common sense, be careful and wear protective gear!

Top Hydraulics, Inc. is not responsible or liable for personal injury or material damage.

Você também pode gostar

- Isuzu Axiom 2002 ManualDocumento2.100 páginasIsuzu Axiom 2002 Manualgasman11195% (19)

- Drilling Rig Inspection Program 5 Year, 2 Year, 1 Year 6 Months, MonthlyDocumento76 páginasDrilling Rig Inspection Program 5 Year, 2 Year, 1 Year 6 Months, MonthlyAhmed Imtiaz Rao100% (5)

- Navigator Suspension Light Off!!! - ForM01161Documento3 páginasNavigator Suspension Light Off!!! - ForM01161J WatsonAinda não há avaliações

- Saab900cv Supplement Owners Manual 87 (Ocr)Documento15 páginasSaab900cv Supplement Owners Manual 87 (Ocr)mnbvqwertAinda não há avaliações

- Grand Scenic: Quick GuideDocumento24 páginasGrand Scenic: Quick GuideSaša RadićAinda não há avaliações

- Mantenimiento Forklift AnchaDocumento106 páginasMantenimiento Forklift AnchaYeisson Agudelo100% (3)

- INDIGODocumento25 páginasINDIGORohitAinda não há avaliações

- Peugeot 406 Owners Manual 2003Documento84 páginasPeugeot 406 Owners Manual 2003husni103180% (15)

- Tiburon 2003Documento882 páginasTiburon 2003Gilberto Sepulveda Motta100% (4)

- Honda XR250 R XR 250 Owners Maintenance ManualDocumento88 páginasHonda XR250 R XR 250 Owners Maintenance Manualcrawdoogie100% (2)

- A183-14 Standard Specification For Carbon Steel Track Bolts and NutsDocumento3 páginasA183-14 Standard Specification For Carbon Steel Track Bolts and NutsDiego Egoávil MéndezAinda não há avaliações

- VW Eos Maintenance PDFDocumento75 páginasVW Eos Maintenance PDFNick P100% (1)

- Ne6 3911gb-MidlumDocumento234 páginasNe6 3911gb-MidlumDinu GabrielAinda não há avaliações

- General Vehicle InformationDocumento20 páginasGeneral Vehicle InformationBloorimAinda não há avaliações

- 1997-99 CR-V PDI and New Model InformationDocumento5 páginas1997-99 CR-V PDI and New Model InformationxenonbulbAinda não há avaliações

- Tou 70-06Documento5 páginasTou 70-06amando manuelAinda não há avaliações

- R129 Bow Extension Cylinder RemovalDocumento15 páginasR129 Bow Extension Cylinder RemovalcannafabritvAinda não há avaliações

- Renault Magnum 400 - 440 - 480 Service ManualDocumento251 páginasRenault Magnum 400 - 440 - 480 Service ManualMihai CostasAinda não há avaliações

- Reparacion Cortina SunroofDocumento20 páginasReparacion Cortina SunroofLuis De la hozAinda não há avaliações

- CatalogeDocumento1.394 páginasCatalogecesarincass100% (1)

- E1Ab0Bf1 - 206 Cabriolet Operation of The Retractable Roof/Boot System (Coupe/Cabriolet) 1 - Description of The SystemDocumento8 páginasE1Ab0Bf1 - 206 Cabriolet Operation of The Retractable Roof/Boot System (Coupe/Cabriolet) 1 - Description of The SystemSalvador MurenaAinda não há avaliações

- 2010-01-19 234417 Cold Air PassengerDocumento4 páginas2010-01-19 234417 Cold Air PassengerAlice LeeAinda não há avaliações

- Peugeot Partner Owners Manual 2004Documento78 páginasPeugeot Partner Owners Manual 2004JoaoAlbertoMaioralAinda não há avaliações

- Carga de Acumulador 950fDocumento5 páginasCarga de Acumulador 950fjaimeAinda não há avaliações

- Volvo C70 Modelyear 1997 Instruction Book US CanadaDocumento228 páginasVolvo C70 Modelyear 1997 Instruction Book US CanadaEero AhoAinda não há avaliações

- A Few Tips: Don't... yDocumento55 páginasA Few Tips: Don't... yArizona RonnAinda não há avaliações

- Verna WorkshopDocumento1.230 páginasVerna WorkshopYasser NassarAinda não há avaliações

- Vehicle General Information: Vehicle Bodywork Specifications Lifting Impact Paintwork Bodywork Equipment and ToolingDocumento35 páginasVehicle General Information: Vehicle Bodywork Specifications Lifting Impact Paintwork Bodywork Equipment and ToolingNatasa DurdaAinda não há avaliações

- NSX1991 Service ManualDocumento1.420 páginasNSX1991 Service ManualRobert LaRueAinda não há avaliações

- R129 Front Locking Cylinder RemovalDocumento6 páginasR129 Front Locking Cylinder RemovalcannafabritvAinda não há avaliações

- Renault Magnum 400 - 440 - 480 PDF Service Manual (PDF. ENG, 139 MB) PDFDocumento251 páginasRenault Magnum 400 - 440 - 480 PDF Service Manual (PDF. ENG, 139 MB) PDFVladimir Panuch100% (4)

- Selector Lever Cable and Bracket Removal and Installation PDFDocumento5 páginasSelector Lever Cable and Bracket Removal and Installation PDFMichael HernandezAinda não há avaliações

- 1982 Saab 900 Turbo - Owners Manual + APC Supplement (OCR)Documento109 páginas1982 Saab 900 Turbo - Owners Manual + APC Supplement (OCR)mnbvqwertAinda não há avaliações

- Mechanical Engineering Department: Lab ReportDocumento17 páginasMechanical Engineering Department: Lab ReportLukman Hadi0% (2)

- Peugeot Elyseo 125-150 - Manuale D'uso (English)Documento22 páginasPeugeot Elyseo 125-150 - Manuale D'uso (English)tinobiker100% (1)

- Clutch RepairDocumento3 páginasClutch RepairKari HyvönenAinda não há avaliações

- Sealing and SoundproofingDocumento23 páginasSealing and SoundproofingcadatiAinda não há avaliações

- Manual Peugeot Satelis 125 InglesDocumento83 páginasManual Peugeot Satelis 125 Inglescperez8650% (4)

- VMR 6SPDocumento24 páginasVMR 6SPLeonard ReinaAinda não há avaliações

- 2006 Volkswagen Jetta TDI 2006 Volkswagen Jetta TDI: Door Handle and Door Lock, Assembly OverviewDocumento12 páginas2006 Volkswagen Jetta TDI 2006 Volkswagen Jetta TDI: Door Handle and Door Lock, Assembly OverviewBitcoin 007Ainda não há avaliações

- tb9 2300 426 20Documento20 páginastb9 2300 426 20Rolando DaclanAinda não há avaliações

- Site Reference Card: MBM-2 TC06050M3-EN (-) 2007-04-03Documento22 páginasSite Reference Card: MBM-2 TC06050M3-EN (-) 2007-04-03Ahmed RaafatAinda não há avaliações

- MR393CLIO5-Mechanisms and AccessoriesDocumento184 páginasMR393CLIO5-Mechanisms and AccessoriesanghilaAinda não há avaliações

- Introduction: TowingDocumento7 páginasIntroduction: TowingMarius Ioan BaleaAinda não há avaliações

- A5SportbackRearLidTrim 2Documento10 páginasA5SportbackRearLidTrim 2Dmitrii PanasiukAinda não há avaliações

- Manually Closing The Vario RoofDocumento7 páginasManually Closing The Vario RoofdavgrovesAinda não há avaliações

- Chapter 06Documento10 páginasChapter 06Kabil RajAinda não há avaliações

- JT QB - 1 (Previous Times Questions)Documento25 páginasJT QB - 1 (Previous Times Questions)RohitAinda não há avaliações

- Cruizin Cooler ManualDocumento8 páginasCruizin Cooler ManualJohan DiscoBiscuit PrinslooAinda não há avaliações

- Peugeot 407 Owners Manual 2007Documento121 páginasPeugeot 407 Owners Manual 2007lsasha110Ainda não há avaliações

- 4x4 Flashing Lights PajeroDocumento12 páginas4x4 Flashing Lights PajeroTawanda NyakupindaAinda não há avaliações

- Installation Instructions: 1520 Hoist W/ SubframeDocumento14 páginasInstallation Instructions: 1520 Hoist W/ SubframeHugo RodriguezAinda não há avaliações

- Pajero - Problemas Com Luzes de TraçãoDocumento11 páginasPajero - Problemas Com Luzes de Traçãodaniel lacerdaAinda não há avaliações

- July 1985 VW T25 Instruction Manual WestfaliaT3WMDocumento132 páginasJuly 1985 VW T25 Instruction Manual WestfaliaT3WMDavid BernalAinda não há avaliações

- Focus Installation InstructionsDocumento6 páginasFocus Installation Instructionsmike chenAinda não há avaliações

- T.C V Driving With Trouble Shooting GuideDocumento23 páginasT.C V Driving With Trouble Shooting Guideraymundorome30Ainda não há avaliações

- SLJ Super Lift Jack ManualDocumento10 páginasSLJ Super Lift Jack Manualaula8045040Ainda não há avaliações

- A Through Zs of Learning to Drive, Accident Free!: Drivers HandbookNo EverandA Through Zs of Learning to Drive, Accident Free!: Drivers HandbookAinda não há avaliações

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)No EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)Ainda não há avaliações

- Berlin Station 1x01 - The Absence of Something Is SomethingDocumento71 páginasBerlin Station 1x01 - The Absence of Something Is SomethingBirdy NumnumsAinda não há avaliações

- Narcos 1x01 - DescensoDocumento53 páginasNarcos 1x01 - DescensoBirdy NumnumsAinda não há avaliações

- Desperate Housewives - The PilotDocumento60 páginasDesperate Housewives - The PilotBirdy NumnumsAinda não há avaliações

- 1998-2002 CLK 430 Diy Oil ChangeDocumento8 páginas1998-2002 CLK 430 Diy Oil ChangeBirdy NumnumsAinda não há avaliações

- Internal/External Permanent Opportunity: P: S: $51,487.97 - $62,766.29 D: F #: TCHC#10LS29 L: # P: 1Documento3 páginasInternal/External Permanent Opportunity: P: S: $51,487.97 - $62,766.29 D: F #: TCHC#10LS29 L: # P: 1a4agarwalAinda não há avaliações

- 88E1240 Technical Product BriefDocumento30 páginas88E1240 Technical Product Briefjschen916Ainda não há avaliações

- 2.7 Safety Features in VehiclesDocumento24 páginas2.7 Safety Features in VehiclesSue Suraya NazaAinda não há avaliações

- TR60 Parts BookDocumento392 páginasTR60 Parts Bookfernandoj100% (1)

- Homologation of Respiratory Protective Devices CMMDocumento42 páginasHomologation of Respiratory Protective Devices CMM胡大威Ainda não há avaliações

- Deutz-Fahr 25.5 Service - English PDFDocumento180 páginasDeutz-Fahr 25.5 Service - English PDFduongpn100% (1)

- ARCHITECTURAL 220512 - Full Set - 88 Romaine Avenue-CompressedDocumento31 páginasARCHITECTURAL 220512 - Full Set - 88 Romaine Avenue-Compressedramon rodriguezAinda não há avaliações

- 9.2.1.11 Packet Tracer - Configuring Named Standard ACLs Instructions IG - Alexis PedrozaDocumento10 páginas9.2.1.11 Packet Tracer - Configuring Named Standard ACLs Instructions IG - Alexis Pedrozaalexis pedrozaAinda não há avaliações

- Safety ShoesDocumento13 páginasSafety ShoesyustimdAinda não há avaliações

- UNIT I 2 MarksDocumento5 páginasUNIT I 2 MarkscourageouscseAinda não há avaliações

- Jura Ena9 Espresso User ManualDocumento27 páginasJura Ena9 Espresso User ManualIoana Felicia Matei0% (1)

- Electrical Calculator EngineeringDocumento16 páginasElectrical Calculator Engineeringfuziadithia188Ainda não há avaliações

- Com Art ManualDocumento125 páginasCom Art Manualcpatel99Ainda não há avaliações

- Trunnion Mounted Ball ValveDocumento17 páginasTrunnion Mounted Ball ValveMohanAinda não há avaliações

- GLOFADocumento60 páginasGLOFArobertoAinda não há avaliações

- BOEHMER Split-Body Ball Valves PDFDocumento24 páginasBOEHMER Split-Body Ball Valves PDFLuka BornaAinda não há avaliações

- 4A SSL SSHDocumento30 páginas4A SSL SSHMauricio SiguenzaAinda não há avaliações

- Baskar-Barsched 8666Documento33 páginasBaskar-Barsched 8666Ganesh Kumar GuptaAinda não há avaliações

- Uniview WholesaleDocumento13 páginasUniview WholesaleDick BaileyAinda não há avaliações

- Mini a-LOK BookletDocumento162 páginasMini a-LOK BookletjcastelohAinda não há avaliações

- H4c81s.a.01 Stu - Part1Documento404 páginasH4c81s.a.01 Stu - Part1ArmandoAinda não há avaliações

- Linux Commands 1Documento8 páginasLinux Commands 1Sathish SaranyaAinda não há avaliações

- SM-Ethernet User Guide Issue 7 (0471-0047-07)Documento132 páginasSM-Ethernet User Guide Issue 7 (0471-0047-07)Duvan TamayoAinda não há avaliações

- 2011 Kia Sorento SpecificationsDocumento2 páginas2011 Kia Sorento Specificationsswift100% (1)

- MS - Excavation & EarthworkDocumento17 páginasMS - Excavation & EarthworkDinesh Priyankara100% (1)

- Philips 190x6 - 170x6 Service ManualDocumento105 páginasPhilips 190x6 - 170x6 Service ManualzeljavalybiAinda não há avaliações

- ABC Cma ProjectDocumento5 páginasABC Cma ProjectAakash BhotikaAinda não há avaliações

- Boat Trim SystemDocumento4 páginasBoat Trim SystemDino MandicAinda não há avaliações