Escolar Documentos

Profissional Documentos

Cultura Documentos

Introduction to API Process Simulation

Enviado por

bayuDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Introduction to API Process Simulation

Enviado por

bayuDireitos autorais:

Formatos disponíveis

Introduction to API Process Simulation, Example 1

Heat Transfer Through Jacket

Objective

The objective of this example is to analyze heat transfer in a pilot plant using

simulation models. The first step is to use pilot plant data to calculate heat transfer

parameters. The second part involves using simulation models to examine the trade-off

between jacket parameters and heating times.

bulk

jacket

Process Description

Assumptions: The stirred tank is assumed to be perfectly mixed. The contributions of

agitator work, heat loss to environment, and evaporation to the energy and mass

balances are assumed to be negligible.

Variables and Parameters: M bulk , Mass of bulk liquid; c p ,bulk , heat capacity; Tbulk ,

Temperature of bulk liquid; F jacket , flow rate of heat transfer fluid in jacket; c p , jacket ,

heat capacity of heat transfer fluid in jacket; T jacket ,in , jacket inlet temperature;

T jacket ,out , jacket outlet temperature, UA , overall heat transfer coefficient times area.

Balance Equations:

F jacket c p , jacket T jacket ,out T jacket ,in (UA) Tlm q

where, Tlm T jacket ,out T jacket ,in ln Tbulk T jacket ,in

M bulk c p ,bulk

bulk

T jacket ,out

d

Tbulk q

dt

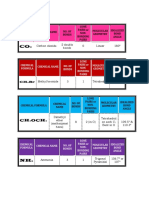

Pilot Plant Data: The following data relating bulk liquid temperatures to the jacket

temperature is available from pilot plant tests.

Introduction to API Process Simulation, Example 1

We want to use this information to determine the UA values for the stirred tank and to

study the impact of jacket parameters on heating times.

Process Parameters

The process parameters and initial conditions for Example 1 are given in the table

below.

Tbulk (initial bulk liquid temperature)

c p ,bulk

(heat capacity)

M bulk (mass of bulk liquid in vessel)

c p , jacket (heat capacity)

UA (initial guess)

27.2

2.516

329

1.65

C

kJ/kg K

kg

kJ/kg K

W/K

257

F jacket Jacket flow rate

kg/s

5

Model Summary

DynoChem provides several utilities for characterizing vessels. These include a

template for fitting heat transfer coefficients to test data. A customized template for this

example is provided in the file TemplateFitUA.xls. The following information is entered

under the Components tab, Process tab and Scenarios tab.

Components. Two components are defined for this example, the solvent in the vessel

and the heat transfer fluid in the jacket.

Process Definition (Statements). The process statements define the bulk liquid phase

and heat transfer with a jacket.

Scenarios (Initial Values and Parameters). The values from the table above are entered

under the scenarios tab for the model. The pilot plant data is specified on the data sheet.

Introduction to API Process Simulation, Example 1

Fitting the UA Value to the Plant Data

The simulation runs below show the calculated temperature profile of the bulk liquid

using various guessed values for the UA parameter. These trial runs show a mismatch

with the experimental data.

DynoChem provides a fitting tool which uses least squares regression to fit simulation

parameters to experimental data. The output from the fitting exercise is shown below.

The UA value from the fitting tool can then be incorporated into the simulation tool and

used for design exercises.

Introduction to API Process Simulation, Example 1

Scenarios

Once the heat transfer parameters have been determined the simulation model can be

used to estimate the heating times for different values of the jacket temperature as

shown by the plots below. Variations in other parameters such as the jacket flow rate

can be studied in a similar manner.

Você também pode gostar

- Final Report v.1-1Documento31 páginasFinal Report v.1-1Damien NaiduAinda não há avaliações

- Name: Section (Day/Time) :: Me139L-Experimental Heat Transfer Prelab For Lab #5Documento2 páginasName: Section (Day/Time) :: Me139L-Experimental Heat Transfer Prelab For Lab #5briant_93478Ainda não há avaliações

- Osmosis Diffusion AP Biology Lab ReportDocumento11 páginasOsmosis Diffusion AP Biology Lab ReportJameson SchultsAinda não há avaliações

- The Heat Transfer Through Jacket: Introduction To API Process Simulation, Example 1Documento4 páginasThe Heat Transfer Through Jacket: Introduction To API Process Simulation, Example 1Tamer Abd ElrasoulAinda não há avaliações

- Aiche Paper Number 291195 Simulating Field Performance Data From An Ethylene Producer For A Cold BoxDocumento10 páginasAiche Paper Number 291195 Simulating Field Performance Data From An Ethylene Producer For A Cold Boxkirandevi1981Ainda não há avaliações

- ME 575: Heat Pump For Pasteurizing Milk: Optimization ProblemDocumento4 páginasME 575: Heat Pump For Pasteurizing Milk: Optimization ProblemAndyAinda não há avaliações

- 2006encit-Simulation and Optimization of Heat Exchangers Cleaning SchedulesDocumento7 páginas2006encit-Simulation and Optimization of Heat Exchangers Cleaning SchedulesMukesh BohraAinda não há avaliações

- Dynamic Simulation and Optimal Matching of A Small-ScaleDocumento7 páginasDynamic Simulation and Optimal Matching of A Small-ScaleEva ViskadourakiAinda não há avaliações

- 2-2 Te-2 GTDocumento10 páginas2-2 Te-2 GTVamsi KrishnaAinda não há avaliações

- HTTPDocumento11 páginasHTTPOswaldo PerezAinda não há avaliações

- Artigo Unifor-Cong NatalDocumento12 páginasArtigo Unifor-Cong NatalJoão PimentaAinda não há avaliações

- Simplified Modeling of Clinker Cooling Based On Long Term Industrial DataDocumento5 páginasSimplified Modeling of Clinker Cooling Based On Long Term Industrial Data1977julAinda não há avaliações

- Unsteady Thermodynamic CFD Simulations of Aircraft Wing Anti-Icing OperationDocumento19 páginasUnsteady Thermodynamic CFD Simulations of Aircraft Wing Anti-Icing OperationnuazzAinda não há avaliações

- Optimization of Diameter Ratio For Alpha-Type Stirling EnginesDocumento6 páginasOptimization of Diameter Ratio For Alpha-Type Stirling EnginesEmiliano VelázquezAinda não há avaliações

- MODEL FOR SIMULATION OF CONVENTIONAL DRYING OF PAPERDocumento6 páginasMODEL FOR SIMULATION OF CONVENTIONAL DRYING OF PAPERAneta HaziAinda não há avaliações

- 10.213 Chemical Engineering Thermodynamics Spring 2002 Problem Set GDocumento2 páginas10.213 Chemical Engineering Thermodynamics Spring 2002 Problem Set GPM SHAinda não há avaliações

- Ijs Mitol Escape18Documento6 páginasIjs Mitol Escape18Lavinia BocănealăAinda não há avaliações

- Guidelines For Ethylene Quench Tower Rev 17Documento17 páginasGuidelines For Ethylene Quench Tower Rev 17totongop0% (1)

- Estimating ballistic parameters of gun propellants using closed vessel experimentsDocumento6 páginasEstimating ballistic parameters of gun propellants using closed vessel experimentssux2beedAinda não há avaliações

- Deliverable 4.2 Control Model Validation 02Documento27 páginasDeliverable 4.2 Control Model Validation 02Nouman YasarAinda não há avaliações

- Welsby 1988Documento15 páginasWelsby 1988Allyson LuizAinda não há avaliações

- First Principles Model For Integrated Cooling SystemsDocumento14 páginasFirst Principles Model For Integrated Cooling SystemsSamir AleixoAinda não há avaliações

- TA125Documento4 páginasTA125WaqasjamAinda não há avaliações

- Dynamic Modeling and Simulation of A #Uidized Catalytic Cracking Process. Part II: Property Estimation and SimulationDocumento18 páginasDynamic Modeling and Simulation of A #Uidized Catalytic Cracking Process. Part II: Property Estimation and SimulationHoang-Vu BuiAinda não há avaliações

- New Methodology For CFD Three-Dimensional Simulation of A Walking Beam Type Reheating Furnace in Steady State-Casal2015Documento29 páginasNew Methodology For CFD Three-Dimensional Simulation of A Walking Beam Type Reheating Furnace in Steady State-Casal2015Beto MurrAinda não há avaliações

- Thermal Modeling and Simulation of Distribution TransformersDocumento4 páginasThermal Modeling and Simulation of Distribution Transformerssujit tiwariAinda não há avaliações

- Unified Propulsion 8Documento9 páginasUnified Propulsion 8lynykerAinda não há avaliações

- Memo 3 - Noviembre 9 2010Documento2 páginasMemo 3 - Noviembre 9 2010andrespunk19Ainda não há avaliações

- Turbocharger Heat FlowsDocumento6 páginasTurbocharger Heat FlowsRichart TPAinda não há avaliações

- Sub ReportDocumento17 páginasSub ReportpachieduAinda não há avaliações

- Experimental Study AND Numerical Simulation OF Preform Infrared Radiative HeatingDocumento8 páginasExperimental Study AND Numerical Simulation OF Preform Infrared Radiative HeatingRafael Calle Napoleon LuisAinda não há avaliações

- Lab 4 Reciprocating CompressorDocumento36 páginasLab 4 Reciprocating CompressorJowesh Avisheik GoundarAinda não há avaliações

- Solar CollectorDocumento9 páginasSolar CollectorMohamed Anas NafirAinda não há avaliações

- Energy Optimization Using Pinch Analysis: Practical ConsiderationsDocumento10 páginasEnergy Optimization Using Pinch Analysis: Practical ConsiderationsconfyAinda não há avaliações

- Mathematical Model of Biomass Boiler for Control PurposesDocumento6 páginasMathematical Model of Biomass Boiler for Control PurposesReda M.SalemAinda não há avaliações

- A First-Principles Simulation Model For The Start-Up andDocumento17 páginasA First-Principles Simulation Model For The Start-Up andEva ViskadourakiAinda não há avaliações

- Settle OutDocumento6 páginasSettle Outamitgoel1989100% (1)

- Chapter 3 - Heat IntegrationDocumento25 páginasChapter 3 - Heat IntegrationAmeerRashidAinda não há avaliações

- Using PHEs in HENsDocumento4 páginasUsing PHEs in HENscymyAinda não há avaliações

- WWW Mathworks inDocumento7 páginasWWW Mathworks inRagini SharmaAinda não há avaliações

- GTCC Inlet Air Cooling Applicability AnalysisDocumento9 páginasGTCC Inlet Air Cooling Applicability AnalysisidigitiAinda não há avaliações

- Steady State Model of Cooling Tower Used in Air ConditioningDocumento4 páginasSteady State Model of Cooling Tower Used in Air ConditioningAKBAR KRISNAAinda não há avaliações

- Modelling SAGD ProcessDocumento7 páginasModelling SAGD ProcessAli ShahAinda não há avaliações

- Tutorial 5 HExDocumento16 páginasTutorial 5 HExishita.brahmbhattAinda não há avaliações

- Applications - Heat Sink With FinsDocumento5 páginasApplications - Heat Sink With FinsSeyfullahYıldızAinda não há avaliações

- Weber Patrick Rep TDocumento14 páginasWeber Patrick Rep TAkindolu DadaAinda não há avaliações

- Fire Relief Rate Calculation-Part 2Documento4 páginasFire Relief Rate Calculation-Part 2zubair195Ainda não há avaliações

- MC15024FU1Documento9 páginasMC15024FU1Bikram RoyAinda não há avaliações

- JCIT3528PPLDocumento8 páginasJCIT3528PPLgajendra2010Ainda não há avaliações

- Dynamics Model of Fire Tube Shell BoilerDocumento10 páginasDynamics Model of Fire Tube Shell BoilerViro AkahanAinda não há avaliações

- Siemens: Procidia™ Control Solutions Heat Transfer CalculationsDocumento3 páginasSiemens: Procidia™ Control Solutions Heat Transfer CalculationsVictor RojasAinda não há avaliações

- Automotive Radiator Sizing and Rating - Simulation Approach: P. S. Amrutkar, S. R. PatilDocumento5 páginasAutomotive Radiator Sizing and Rating - Simulation Approach: P. S. Amrutkar, S. R. PatilPacific NguyenAinda não há avaliações

- Transient Heat TransferDocumento10 páginasTransient Heat TransferRimaz RameezAinda não há avaliações

- Design of a Plug Flow Reactor (PFR) SimulationDocumento10 páginasDesign of a Plug Flow Reactor (PFR) SimulationDee RajanAinda não há avaliações

- Energy and Economic Analysis of Using PCM to Improve Cooling EfficiencyDocumento9 páginasEnergy and Economic Analysis of Using PCM to Improve Cooling Efficiencyhassan aliAinda não há avaliações

- Nasa TM 101475Documento12 páginasNasa TM 101475Eugen IonescuAinda não há avaliações

- Equipment SizingDocumento5 páginasEquipment SizingPandu RockingAinda não há avaliações

- Mathematical ModelDocumento26 páginasMathematical Modeloscop2009Ainda não há avaliações

- Heat Pumps: Solving Energy and Environmental ChallengesNo EverandHeat Pumps: Solving Energy and Environmental ChallengesTakamoto SaitoAinda não há avaliações

- Flow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsNo EverandFlow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsK. H. KhalilAinda não há avaliações

- Test 1 September 2020 SemesterDocumento3 páginasTest 1 September 2020 SemesterAhmed AlwaqediAinda não há avaliações

- F3-ANCQ-2018 (Year 8)Documento9 páginasF3-ANCQ-2018 (Year 8)2G (01) Cho Joshua Chi HoAinda não há avaliações

- APP - The Analysis of A Broad Range of Organic Acids by HPLC With UV Detection 012379 - 01Documento4 páginasAPP - The Analysis of A Broad Range of Organic Acids by HPLC With UV Detection 012379 - 01G_ASantosAinda não há avaliações

- Thermodynamics Chapter 1 ReviewDocumento20 páginasThermodynamics Chapter 1 ReviewReinzo GallegoAinda não há avaliações

- eAuditNet Proficency Testing (PT) Providers 312019Documento2 páginaseAuditNet Proficency Testing (PT) Providers 312019viverefeliceAinda não há avaliações

- Molecular Geometry ChartDocumento3 páginasMolecular Geometry ChartJoyci CauilanAinda não há avaliações

- Coffee-Derived Activated Carbon From Second Biowaste For Supercapacitor Application-CompressedDocumento10 páginasCoffee-Derived Activated Carbon From Second Biowaste For Supercapacitor Application-Compressedsalsa bilaAinda não há avaliações

- Thermochemistry: Practice Questions For H2 Chemistry Remedial ClassesDocumento7 páginasThermochemistry: Practice Questions For H2 Chemistry Remedial ClassesTimAinda não há avaliações

- SAF-FRO - Welding Consumables CatalogueDocumento194 páginasSAF-FRO - Welding Consumables CatalogueLLAinda não há avaliações

- GP208 HW3 SolutionsDocumento4 páginasGP208 HW3 SolutionsSofiaAinda não há avaliações

- Chapter 4: Imperfections in Solids: Issues To Address..Documento34 páginasChapter 4: Imperfections in Solids: Issues To Address..usercmdmcAinda não há avaliações

- Statistical Review of Dry Reforming of Methane Literature Using Decision Tree and Artificial Neural Network AnalysisDocumento14 páginasStatistical Review of Dry Reforming of Methane Literature Using Decision Tree and Artificial Neural Network AnalysisSơn PhanThanhAinda não há avaliações

- G8 Test - Water - MCQDocumento4 páginasG8 Test - Water - MCQSaintm101Ainda não há avaliações

- Homework 1Documento5 páginasHomework 1storres22Ainda não há avaliações

- Quaternion Group Q8 and Yi Jing (I Ching) HexagramsDocumento1 páginaQuaternion Group Q8 and Yi Jing (I Ching) HexagramsGianniAinda não há avaliações

- Clinker Manufacturing ProcessDocumento14 páginasClinker Manufacturing ProcessAnirudh100% (1)

- 2 Vol 12 Issue 11 November 2021 IJPSR RE 4230Documento8 páginas2 Vol 12 Issue 11 November 2021 IJPSR RE 4230Steven M.Farm.,aptAinda não há avaliações

- Howard JohnsonDocumento6 páginasHoward JohnsonDanny DurhamAinda não há avaliações

- General Chemistry Lab ReportDocumento2 páginasGeneral Chemistry Lab Reportzzamaepayot31Ainda não há avaliações

- Engineering Chemistry Module 1: An IntroductionDocumento35 páginasEngineering Chemistry Module 1: An IntroductionAudrey MendozaAinda não há avaliações

- DEFINITIONS FOR PHYSICS UNITSDocumento4 páginasDEFINITIONS FOR PHYSICS UNITSanonlukeAinda não há avaliações

- Part 4 Diffusivity Equation Line Source Radial Flow Radius InvestDocumento34 páginasPart 4 Diffusivity Equation Line Source Radial Flow Radius InvestChai Cws100% (1)

- Nuclear Tech English - PDFDocumento20 páginasNuclear Tech English - PDFShivang BhardwajAinda não há avaliações

- INPhO2018 Solution 20180213 PDFDocumento18 páginasINPhO2018 Solution 20180213 PDFRishit SriwastavaAinda não há avaliações

- Blower Selection and Purge Time ChartsDocumento2 páginasBlower Selection and Purge Time Chartsajengps11Ainda não há avaliações

- Class 5 Unit Test II - ScienceDocumento2 páginasClass 5 Unit Test II - ScienceRakeshAinda não há avaliações

- Artificial Neural Network Based Particle Size Prediction of Polymeric NanoparticlesDocumento18 páginasArtificial Neural Network Based Particle Size Prediction of Polymeric NanoparticlesAMOL RASTOGI 19BCM0012Ainda não há avaliações

- ALCOADocumento8 páginasALCOAsuryaAinda não há avaliações

- Retrowrap Materials Performance FactsDocumento2 páginasRetrowrap Materials Performance FactsMAinda não há avaliações