Escolar Documentos

Profissional Documentos

Cultura Documentos

Coating Handout PDF

Enviado por

Victoria MirkoDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Coating Handout PDF

Enviado por

Victoria MirkoDireitos autorais:

Formatos disponíveis

Performance enhancing filler.

Advances in GLASS FLAKE production offer high quality barrier additive coupled

with reinforcement benefits and superior coating performance

Glass flakes are classed as having a lamella structure, similar to broken pieces of

windowpane, characterised by their high aspect ratio (low elevation to plan aspect or low

thickness to surface area).

Glass flakes have been utilised by the coating industry for many years, imparting exceptional

barrier properties reducing moisture and vapour diffusion through coating and paint films.

Glass flakes form a tortuous path of platelets within the coating film, which is totally

impervious to moisture vapour, and are highly chemical resistant.

Granular fillers offer limited resistance,

The path length for moisture vapour

Transmission and ionic transfer remains

virtually unaltered.

With GLASS FLAKE the path length to

substrate is dramatically increased, thus,

MVT potential is substantially reduced.

Glassflake limited manufacture in the UK producing consistently thinner high quality flake

from extra corrosion resistant glass composition, ranging in nominal thickness from 1.0 to 5.5

microns and with particle size ranges to suit applications.

GLASSFLAKE LIMITED

FORSTER STREET LEEDS LS10 1PW

TEL: +44 (0) 113 270 3615

FAX: +44 (0) 113 271 8750

Performance enhancing filler.

Utilising a flake with a lower nominal thickness results in better leafing of flake, and a more

homogenous and stable film preventing cracking and significantly increasing tortuous path

length and in turn further enhancing reduction in moisture vapour permeation.

0.25 mm

Glass flake 3.0 to 18.0 m thick

0.25 mm

Glass flake 1.5 to 3.0 m thick

GLASSFLAKE has pioneered a unique manufacturing process to manufacture consistent

thickness, high quality flake glass as a barrier additive for anti corrosion coatings..

Glass flake coatings have a similar thermal expansion to mild steel, which means that they

can withstand thermal shock and offer low stress and lateral shrinkage.

The multiple layers of flake reinforcement also offer enhance resistance to mechanical abuse

and abrasion and gives excellent resistance to undercutting.

Glass flakes are also available pre-treated with a range of silane coupling agents improving

flake to resin adhesion, our range are compatible with most systems including vinyl ester and

epoxy base resins.

Glass flakes are used in a diverse range of applications, not just within the anti-corrosive

coating s industry. From fire retardant coatings to protect steel structure to a substrate for

pigments.

In thermoplastics Glass flakes have been used for their reinforcement, increasing dimensional

stability and isotropic mechanical properties in the plane of orientation. As well as improving

flexural modulus, heat distortion temperature, tribological properties, thermal and UV

stability.

If you require further information or samples, please call +44 (0)113 2703615, or by e-mail

info@glassflake.com

GLASSFLAKE LIMITED

FORSTER STREET LEEDS LS10 1PW

TEL: +44 (0) 113 270 3615

FAX: +44 (0) 113 271 8750

Você também pode gostar

- Spreader Beam CalculationDocumento2 páginasSpreader Beam Calculationhombre.muerto595977% (13)

- Clock Spring Pipe Repair System PDFDocumento2 páginasClock Spring Pipe Repair System PDFNeo_1982Ainda não há avaliações

- 80 3689 01 Threaded ConnectionsDocumento12 páginas80 3689 01 Threaded ConnectionsMiguel Alfonso Ruiz MendezAinda não há avaliações

- Kirloskar Corrocoat GFC CaseStudyDocumento35 páginasKirloskar Corrocoat GFC CaseStudyAbhishek SharmaAinda não há avaliações

- Epoxy Injection Welds Cracks Back TogetherDocumento4 páginasEpoxy Injection Welds Cracks Back Togethergonzalez_m_aAinda não há avaliações

- High Performance Lubricants: Molykote Molykote MolykoteDocumento4 páginasHigh Performance Lubricants: Molykote Molykote Molykoteestebang956Ainda não há avaliações

- Water PropertiesDocumento4 páginasWater Propertiesaw_aeAinda não há avaliações

- Floorex Concrete Floor Preparation GuideDocumento1 páginaFloorex Concrete Floor Preparation GuideAlekxAinda não há avaliações

- Tabela de Similaridade de Lubrificantes Industriais: Sistema Hidráulico & CirculaçãoDocumento2 páginasTabela de Similaridade de Lubrificantes Industriais: Sistema Hidráulico & CirculaçãoAdilson Tiago da SilvaAinda não há avaliações

- Flat Ends With A Relief GrooveDocumento11 páginasFlat Ends With A Relief GrooveEng-CalculationsAinda não há avaliações

- BucklingDocumento24 páginasBucklingmyusuf_engineerAinda não há avaliações

- Frick Oil No 3 MSDS PDFDocumento8 páginasFrick Oil No 3 MSDS PDFMahmoud Mohamed50% (2)

- 5 Polysiloxane Coatings PublicDocumento24 páginas5 Polysiloxane Coatings PublicChaitanya M MundheAinda não há avaliações

- BelzonaDocumento4 páginasBelzonaSara BrownAinda não há avaliações

- 1 BelzonaDocumento41 páginas1 BelzonashakeelahmadjsrAinda não há avaliações

- Grease Stock Date:30-06-2020: SR.# Code Grease Name Remaing QTY Required QTY RemarksDocumento1 páginaGrease Stock Date:30-06-2020: SR.# Code Grease Name Remaing QTY Required QTY RemarksMuhammad Waqar AhsanAinda não há avaliações

- Belzona - Cold Curing WrapsDocumento4 páginasBelzona - Cold Curing WrapsNay ThihaAinda não há avaliações

- Module 4a - Line Sizing CalculationDocumento9 páginasModule 4a - Line Sizing CalculationEkundayo JohnAinda não há avaliações

- Speciality Lubricants For The Railway Industry B090000102 PDFDocumento11 páginasSpeciality Lubricants For The Railway Industry B090000102 PDFJavier Alejandro Muralles ReyesAinda não há avaliações

- EnDOtec Welding Cored WireDocumento12 páginasEnDOtec Welding Cored WirecriuvosAinda não há avaliações

- FAQ - What Is The Procedure For Welding En24 (Subsequently Known As 817M40 and 1.6582 34CrNiMo6), A 0.4% C, 1.25% CR, 0.3% Mo LowDocumento2 páginasFAQ - What Is The Procedure For Welding En24 (Subsequently Known As 817M40 and 1.6582 34CrNiMo6), A 0.4% C, 1.25% CR, 0.3% Mo LowSubhra S SanyalAinda não há avaliações

- Group 1: Dexter Alicaway Kevin ArriesgadoDocumento19 páginasGroup 1: Dexter Alicaway Kevin ArriesgadoBenz Andrew RegisAinda não há avaliações

- Heavy-Duty, Reinforced Range Heavy-Duty, Reinforced Range Heavy-Duty, Reinforced RangeDocumento8 páginasHeavy-Duty, Reinforced Range Heavy-Duty, Reinforced Range Heavy-Duty, Reinforced RangeengindmecAinda não há avaliações

- Mobilgrease XHP 460Documento3 páginasMobilgrease XHP 460Jaime Miloz Masle JaksicAinda não há avaliações

- Belzona 3111Documento2 páginasBelzona 3111Bobby SatheesanAinda não há avaliações

- 26 Core SolutionsDocumento32 páginas26 Core SolutionsSunil SinghAinda não há avaliações

- BELZONA 1111 Product Specification SheetDocumento2 páginasBELZONA 1111 Product Specification Sheetsibi_s_rajAinda não há avaliações

- Klueberquiet BQH 72 102-EnDocumento2 páginasKlueberquiet BQH 72 102-Enвлад камрAinda não há avaliações

- Aditivi Materiale PlasticeDocumento4 páginasAditivi Materiale PlasticeLavinia CalinAinda não há avaliações

- Training Report FINAL0000 RajatDocumento50 páginasTraining Report FINAL0000 Rajatrajat sharmaAinda não há avaliações

- Conformal Coating Curing and Drying Technical Bulletin Apr 09Documento2 páginasConformal Coating Curing and Drying Technical Bulletin Apr 09Lee HitchensAinda não há avaliações

- of NE Railway Summer TrainingDocumento18 páginasof NE Railway Summer TrainingAkhilesh Singh80% (5)

- Krytox Typical Properties GPL 227Documento2 páginasKrytox Typical Properties GPL 227Ramu NallathambiAinda não há avaliações

- High Temperature Solid LubricantDocumento19 páginasHigh Temperature Solid Lubricantgcytd65e756c56e765rAinda não há avaliações

- Workshop All AnnexuresDocumento18 páginasWorkshop All AnnexuresLavee ChandrakarAinda não há avaliações

- Viscosidades KluberDocumento23 páginasViscosidades KluberRCMAinda não há avaliações

- Mechanical Workshop Name Addresses 170118Documento3 páginasMechanical Workshop Name Addresses 170118vk mishraAinda não há avaliações

- Firex EC-43 DemoDocumento10 páginasFirex EC-43 DemoBanani SahuAinda não há avaliações

- Belzona 4111Documento2 páginasBelzona 4111Bobby SatheesanAinda não há avaliações

- Bechem Lubricants For High Load and High TemperatureDocumento3 páginasBechem Lubricants For High Load and High TemperatureShukor AzAinda não há avaliações

- Belzona 5892 - BrochureDocumento2 páginasBelzona 5892 - BrochureANIBALLOPEZVEGAAinda não há avaliações

- Why Superon SteelDocumento83 páginasWhy Superon SteelArdh0072Ainda não há avaliações

- Final Draft 1 Abhishek VermaDocumento60 páginasFinal Draft 1 Abhishek VermaMasir SinghAinda não há avaliações

- Sealing Compounds From Project Sales CorpDocumento34 páginasSealing Compounds From Project Sales CorpProject Sales CorpAinda não há avaliações

- Mohamed Mansy-QC EngineerDocumento3 páginasMohamed Mansy-QC EngineerMohamed Anwer Abd ElhamedAinda não há avaliações

- Belzona 1391 T (Flyer)Documento2 páginasBelzona 1391 T (Flyer)Bobby SatheesanAinda não há avaliações

- Belzona 1391Documento2 páginasBelzona 1391AsadAliAinda não há avaliações

- Itw Catalog PDFDocumento180 páginasItw Catalog PDFGilbertoAinda não há avaliações

- Belzona Index FolderDocumento3 páginasBelzona Index Foldersrikrish24Ainda não há avaliações

- High Performance Lining Selection Chart For 90C Immersion - Belzona GuidesDocumento2 páginasHigh Performance Lining Selection Chart For 90C Immersion - Belzona GuidesBobby SatheesanAinda não há avaliações

- MBDAF and OZONE Data Sheet For Wastewater TreatmentDocumento1 páginaMBDAF and OZONE Data Sheet For Wastewater TreatmentjayAinda não há avaliações

- Magna Cement 2016Documento2 páginasMagna Cement 2016Amine Ait ElaasriAinda não há avaliações

- Pipeline Coatings The Petrobrás Experience: Joaquim P. Quintela Jorge TavesDocumento51 páginasPipeline Coatings The Petrobrás Experience: Joaquim P. Quintela Jorge Tavesnathgsurendra100% (2)

- Loctite Solutions For Power PlantsDocumento14 páginasLoctite Solutions For Power PlantsHusen TaufiqAinda não há avaliações

- Storage TanksDocumento1 páginaStorage TanksfraemddAinda não há avaliações

- Concrete Repair Q & A: by Bill Scannell and Ali SohanghpurwalaDocumento2 páginasConcrete Repair Q & A: by Bill Scannell and Ali SohanghpurwalaSiva Jothi100% (1)

- Intergard 343 - Marine CoatingsDocumento9 páginasIntergard 343 - Marine CoatingsSerggie TabanaoAinda não há avaliações

- Belzona 3211Documento2 páginasBelzona 3211Bobby SatheesanAinda não há avaliações

- Industrial Maintenance Loctite® Wastewater Treatment GuideDocumento6 páginasIndustrial Maintenance Loctite® Wastewater Treatment GuideDragoslav DzolicAinda não há avaliações

- Bechem Berutox M 21 KN 9007601 (GB)Documento1 páginaBechem Berutox M 21 KN 9007601 (GB)Luciano de Carvalho100% (2)

- M C PCN 102 2009Documento11 páginasM C PCN 102 2009anon_872387960Ainda não há avaliações

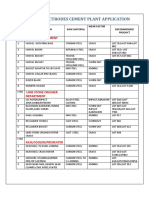

- Lotherme Electrodes Cement Plant Application: Mining DepartmentDocumento2 páginasLotherme Electrodes Cement Plant Application: Mining DepartmentGyanaranjan2011Ainda não há avaliações

- Insulating Coating PDFDocumento55 páginasInsulating Coating PDFBaSant KohliAinda não há avaliações

- Glasse FlakeDocumento18 páginasGlasse FlakeBoris CardenasAinda não há avaliações

- Products: Waterproofing Construction ChemicalsDocumento9 páginasProducts: Waterproofing Construction ChemicalsSwapnil AlandAinda não há avaliações

- Construction MaterialsDocumento3 páginasConstruction MaterialsR. Praveen KumarAinda não há avaliações

- Chemical ThermodynamicsDocumento27 páginasChemical ThermodynamicsPankaj JindamAinda não há avaliações

- F7az Em12kDocumento1 páginaF7az Em12kKara WhiteAinda não há avaliações

- TSM Ch0 ContentsDocumento10 páginasTSM Ch0 ContentsddyzleeAinda não há avaliações

- IJEDR1401101 Comparison of Raft Foundation and Beam & SlabDocumento5 páginasIJEDR1401101 Comparison of Raft Foundation and Beam & SlabSergio Ito SunleyAinda não há avaliações

- GO-PANI Conductive MembraneDocumento13 páginasGO-PANI Conductive MembraneMadalinaAinda não há avaliações

- Interpreting Strain Measurements From Load Tests in Bored PilesDocumento7 páginasInterpreting Strain Measurements From Load Tests in Bored PilesMustafa SütcüoğluAinda não há avaliações

- VESTA2Documento7 páginasVESTA2R. ValenciaAinda não há avaliações

- GTS NX 2015 (v1.1) - Release NoteDocumento15 páginasGTS NX 2015 (v1.1) - Release NoteJeorge Esrom ChambiAinda não há avaliações

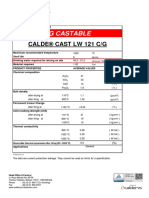

- Tds Calde Cast LW 121 CGDocumento1 páginaTds Calde Cast LW 121 CGAfronie Cepoz D'nextAinda não há avaliações

- Hetro JunctionDocumento30 páginasHetro JunctionKamalesh DebnathAinda não há avaliações

- Flake Graphite Lab ManualDocumento35 páginasFlake Graphite Lab ManualJohn TesfamariamAinda não há avaliações

- Determinari Xps EtaDocumento15 páginasDeterminari Xps EtaAlin StancuAinda não há avaliações

- Materials and Processes For Agricultural and Biosystems EngineeringDocumento19 páginasMaterials and Processes For Agricultural and Biosystems EngineeringMelanie D. Aquino BaguioAinda não há avaliações

- AISI 5160 Steel, Oil Quenched From 830°C (1525°F), 540°C (1000°F) Temper, 13 MM (0.5 In.) RoundDocumento1 páginaAISI 5160 Steel, Oil Quenched From 830°C (1525°F), 540°C (1000°F) Temper, 13 MM (0.5 In.) RoundLizbeth HuertaAinda não há avaliações

- 2020-21 Series Test 1 QPDocumento1 página2020-21 Series Test 1 QPred18ggmuAinda não há avaliações

- CHE617M Schoenfiles, Hermann-Mauguin, Miller Planes, SupercellsDocumento46 páginasCHE617M Schoenfiles, Hermann-Mauguin, Miller Planes, SupercellsIthan Jessemar Dollente100% (2)

- ECOFOR For Cement Mill - Cement Grinding Technology and ECOFORDocumento5 páginasECOFOR For Cement Mill - Cement Grinding Technology and ECOFORAntonAinda não há avaliações

- Percdc Cns Geas 1Documento9 páginasPercdc Cns Geas 1Charles Adrian CAinda não há avaliações

- Basic Conservation Laws-CurrieDocumento12 páginasBasic Conservation Laws-Currieing_tytyAinda não há avaliações

- INTERMOLECULAR VS Intramolecular ForcesDocumento4 páginasINTERMOLECULAR VS Intramolecular ForcesReeb BukhariAinda não há avaliações

- FRP Dam PDFDocumento14 páginasFRP Dam PDFmeldi suhatrilAinda não há avaliações

- Precision Grouting of TurbomachineryDocumento21 páginasPrecision Grouting of TurbomachineryRicardo Barros100% (1)

- A Simplified Deformation Gradient Theory and Its eDocumento23 páginasA Simplified Deformation Gradient Theory and Its eSam GeraghtyAinda não há avaliações

- Mod 1 Smart Mat Lec 4Documento55 páginasMod 1 Smart Mat Lec 4Akshat RastogiAinda não há avaliações