Escolar Documentos

Profissional Documentos

Cultura Documentos

Generator in India, Delhi Gensets, India Generator, Gensets Delhi 4

Enviado por

gbaludb0 notas0% acharam este documento útil (0 voto)

24 visualizações3 páginasdre

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentodre

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

24 visualizações3 páginasGenerator in India, Delhi Gensets, India Generator, Gensets Delhi 4

Enviado por

gbaludbdre

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 3

For more detail of installation, commissioning and trouble shooting, please click here..

SELECTION OF SITE

FOUNDATION DETAILS AND GUIDELINES

EARTHING SYSTEM

EXHAUST PIPING

FUEL PIPING

CABLING

BATTERY CHARGING PROCEDURE

SUMP CAPACITY (LITRES)

CHECK UP BEFORE STARTING THE DG SET

PRE-COMMISSIONING CHECK

ROUTINE CHECK POINTS

DO'S & DON'T'S

TROUBLE SHOOTING - ENGINE

TROUBLE SHOOTING CHART : ALTERNATOR

TROUBLE SHOOTING GUIDE FOR MANUAL PANEL

TROUBLE SHOOTING GUIDE FOR AMF PANEL

TROUBLE SHOOTING - ENGINE

Trouble

Cause Cause

Redress

Engine dose not start

No fuel in tank./ Air in fuel

system./In sufficient speed of

starter

Fill in fuel, vent fuel system. / Vent fuel system. / Charge

batteries.

Engine does not start at temperatures

below 0 C

See above or the ready to start /

signal lamp does not light

Of above , or change lamp.

Defect of series resistor solenoid /

valve, or flame heater plug /

Paraffin precipitation of fuel

Heat up fuel Pipings, change / Filter

Fuel tank cock closed. / Dirt in

primary fuel cleaner or in fuel

filter. / No fuel in tank, no

conveyance of fuel.

Open cock / Clean or change filter cartridge respectively /

Fill in fuel , vent fuel system. of fuel. inspect correct operation

pump, replace if necessary, and check safe venting of tank.

Engine starts up but stops after brief time

No power and misfiring of engine

Water or dirt in fuel system. /

Clean fuel tank, fill in clean fuel replace filter, and vent fuel

Interruption of air supply or heavy system.

jamming of air filter. / Air in fuel

/ Inspect, replace if necessary or clean. / Vent fuel system /

system / Fuel filter jammed.

Change filter

Starts of fuel supply missed /

Defect of exhaust brake.

Reset start of fuel supply. / Inspect and repair

Engine emits white or bluish fumes,

Retorted and start of fuel supply

Set correct start of fuel supply

Trouble

Cause

Redress

Engine is still cold. / Mis setting of Permit engine to heat up in operation / Check start of fuel supply

fuel injection system.

inspect injectors.

Engine emits black fumes.

Engine is overloaded.

Reset fuel injection system / consult workshop.

Air filter jammed. / Fuel injection

piping loose or broken.

Change air filter element. / Tighten fuel injection piping or

replace it, respectively.

Heavy knocking of engine.

Engine grows excessively hot.

Starts of fuel supply too early /

Mis-setting of valve air gaps /

Mechanical defects of engine

Set correct start of fuel Supply / Adjust & correct valve air gaps. /

Consult authorised workshop

Slipping of V-Belts. / V-belts

broken. / Defect of temperature

governor. / Defect of temperature

Tighten or Replace V-belts. / Replace V-belts. / Emergency

Controller / Lack of coolant. /

operation; forced opening of valve plate./ Perform electrical

Radiator is dirty. / Mis-setting of check of temperature controller./ Fill in coolant. / Clean radiator. /

fuel supply. / Intake or exhaust

Set correct engine in fuel supply / Redress cause of trouble. /

system jammed / Heavy dirt

Consult workshop.

accumulation on sylinder

elements

Trouble

Cause

Redress

Irregular speed of engine.

Defect of speed governor.

Inspect fuel injection pump and governor

Excessively high fuel consumption

Mis-setting of fuel injection system

Check, fuel injection system

Injection of excessively great fuel

quantity engine emits black fumes

Have fuel injection pump adjusted by specialised workshop. /

/ Leakage of solenoid valve of

Replace solenoid valve. /

cold starting device. / Jammed air Replace air filter. / Consult authorised workshop / Consult

filter. / Engine is worn. / Defective workshop.

exhaust brake.

Very low oil Pressure.

Jammed paper filter cartridge.

Replace paper filter cartridge.

Deficient oil level. / Pressure

gauge or pressure gauge tube

loose or defective / Leakage in oil

Check and add oil. / Inspect and replace ortighten. / Check. /

system. / Improper lube oil

Check brand of oil. / Replace valve. / Consult authorised workshop

(viscosity). / Defect of control valve

for cooling of pistons. / Heavy

wears of bearings.

Increase in lube oil consumption

Leakage in oil system. /

Excessively high oil level.

Inspect pipings, filters, and ducts for tightness. / Defect of air filter

system, and cooling of pistons, consult authorised workshop.

Trouble

Cause

Redress

No dirt deposits centrifugal filter

Rotor jams.

Inspect rotor bearings, inspect oil supply to rotor.

Heavy blowing from venting hose of

engine.

Excessively high oil level,

damages of cylinder elements.

No air supply from piston or compressor.

Defect of cylinder element or of

valve plate.

Consult authorised workshop.

Battery charging signal lamp alight while

ignition is switched off.

Defective insulation in fanned

cable

Consult authorised workshop

Battery charging signal lamp does not

light up when ignition is switched on

Defect of signal lamp. /

Interruption of D* governor and

generator / Battery discharged

Replace signal lamp. / Plug in connector./ Change battery.

Battery charging signal lamp alight

during normal operation

Broken V-belt. / Defective

alternator.

Replace V-belt. / Inspect or consult workshop.

Heavy boiling of battery.

Defective governor, excessive

contact resistance of negative

polarity across brush holder and

end shield bearing of generator.

Consult authorised workshop.

Starter does not run.

Battery discharged.

Charge battery.

Deficient speed of starter

Starter terminal voltage too low.

Check battery cells,recharge battery.

Oxidized or loose terminal

connections

Clean and fasten terminals.

Carbon brushes jam or are worn.

Clean or replace brushes.

Adjust oil level, consult

authorised workshop.

Você também pode gostar

- Troubleshoot engine issues with this comprehensive guideDocumento20 páginasTroubleshoot engine issues with this comprehensive guideAbdallah MansourAinda não há avaliações

- Tips For Troubleshooting EngineDocumento22 páginasTips For Troubleshooting EngineSandeep NikhilAinda não há avaliações

- 02-Engine Mechanical SystemDocumento96 páginas02-Engine Mechanical Systemsalvador341100% (1)

- Maintenance and Trouble Shooting of Hydraulic SystemsDocumento11 páginasMaintenance and Trouble Shooting of Hydraulic SystemsKannan Devadass100% (1)

- Common Maintenance: Finding and Solving ProblemsDocumento3 páginasCommon Maintenance: Finding and Solving Problemsibrahim dimalnaAinda não há avaliações

- Ajax Cause & EffectDocumento3 páginasAjax Cause & EffectgustavoespinosamAinda não há avaliações

- INDICATED MALFUNCTION: Engine Has Low RPM, Exhaust Gas Temperature, andDocumento6 páginasINDICATED MALFUNCTION: Engine Has Low RPM, Exhaust Gas Temperature, andRaul DeonarainAinda não há avaliações

- 06 - Tfheo We 0431Documento486 páginas06 - Tfheo We 0431jrrodrigueza2100% (1)

- Malfunction and Troubleshooting For Diesel EngineDocumento10 páginasMalfunction and Troubleshooting For Diesel Engineعبدالله عمر0% (1)

- Hydraulics Trouble ShootingDocumento3 páginasHydraulics Trouble ShootingGodfrey OdieroAinda não há avaliações

- Defects Reading From Indicator DiagramDocumento7 páginasDefects Reading From Indicator Diagramkum512Ainda não há avaliações

- Boiler Starting Failure - Troubleshooting: 2) Line Filter at The Inlet of The Fuel Line For Burner Is ChokedDocumento36 páginasBoiler Starting Failure - Troubleshooting: 2) Line Filter at The Inlet of The Fuel Line For Burner Is ChokedJhay SustiguerAinda não há avaliações

- Troubleshooting Small Engines: This Presentation Has Not Been Edited by The Georgia Curriculum OfficeDocumento32 páginasTroubleshooting Small Engines: This Presentation Has Not Been Edited by The Georgia Curriculum Officechaudharialpesh50% (4)

- Marine Engine Troubleshooting BasicsDocumento66 páginasMarine Engine Troubleshooting BasicsagvassAinda não há avaliações

- Hydraulic System Troubleshooting GuideDocumento27 páginasHydraulic System Troubleshooting Guidekhumiso100% (1)

- Irregularities During Operation: 0820-1/A1 Operating TroublesDocumento6 páginasIrregularities During Operation: 0820-1/A1 Operating TroubleschrisAinda não há avaliações

- PSP-00088EAF 2023/1 1/04 19:19:18-06:00 SENR2132 © 2023 Caterpillar IncDocumento86 páginasPSP-00088EAF 2023/1 1/04 19:19:18-06:00 SENR2132 © 2023 Caterpillar IncMario Núñez ObandoAinda não há avaliações

- Perkins Fault Finding GuideDocumento13 páginasPerkins Fault Finding GuideMksreekanthMk100% (2)

- WS Manual 1999 F-Super Duty S3 2, G3 - Eng - Powert Con & Emiss Diag-S4 - On BRD Diag II DSL P2Documento309 páginasWS Manual 1999 F-Super Duty S3 2, G3 - Eng - Powert Con & Emiss Diag-S4 - On BRD Diag II DSL P2Osterman NicolasAinda não há avaliações

- 01 Hydraulic GroupDocumento81 páginas01 Hydraulic Groupgica100% (1)

- Evaluacion Motor 3306 Generator Set 85Z03764-UP (SEBP2007 - 39) - Sistemas y ComponentesDocumento101 páginasEvaluacion Motor 3306 Generator Set 85Z03764-UP (SEBP2007 - 39) - Sistemas y ComponentesJuan Carlos100% (3)

- Symboles HydrauliquesDocumento20 páginasSymboles HydrauliquesMooeez BellaamineAinda não há avaliações

- BRIGGS & STRATTON Trouble Shooting Flow ChartDocumento16 páginasBRIGGS & STRATTON Trouble Shooting Flow ChartBerlib75% (4)

- PT6A-27 Engine - Troubleshooting Quick ReferenceDocumento6 páginasPT6A-27 Engine - Troubleshooting Quick ReferenceDade Sobarna100% (1)

- 3412 Fuel Pump Testing and AdjustingDocumento127 páginas3412 Fuel Pump Testing and Adjustingharikrishnanpd332794% (16)

- Cat - Pruebas y Ajustes 3406B S - N 2WBDocumento138 páginasCat - Pruebas y Ajustes 3406B S - N 2WBErika DiazAinda não há avaliações

- CAT Care Seminar On Trouble Shooting For Gas Engine: Presented by Md. Kamal Pervez, Manager Trouble Shooting AshuliaDocumento30 páginasCAT Care Seminar On Trouble Shooting For Gas Engine: Presented by Md. Kamal Pervez, Manager Trouble Shooting Ashuliashakibur rahmanAinda não há avaliações

- Engine Systems SpecificationDocumento10 páginasEngine Systems SpecificationAroonBhagwandinAinda não há avaliações

- 31 Series Trouble ShootingDocumento4 páginas31 Series Trouble ShootingrburtonshawAinda não há avaliações

- Troubleshooting flow chartsDocumento16 páginasTroubleshooting flow chartsigrekqaAinda não há avaliações

- Pump Troubleshooting GuideDocumento2 páginasPump Troubleshooting GuideFallo SusiloAinda não há avaliações

- Wingle Engine ServicemanualDocumento196 páginasWingle Engine ServicemanualJoch Caso Alvariño85% (13)

- Testing and Adjusting: Troubleshooting Problem ListDocumento101 páginasTesting and Adjusting: Troubleshooting Problem ListJose DarioAinda não há avaliações

- Brainerd ManualDocumento76 páginasBrainerd ManualNestor TermairAinda não há avaliações

- C 13Documento5 páginasC 13مصطفي الغنيمى0% (1)

- 3306 TroubleshootDocumento86 páginas3306 Troubleshootferdyak194% (16)

- Diesel Generator TroubleshootingDocumento7 páginasDiesel Generator TroubleshootingChandra Vinoth Senthilnathan100% (4)

- Table Z Troubleshooting Chart For Air ConditionersDocumento7 páginasTable Z Troubleshooting Chart For Air Conditionersvalentinlupascu33Ainda não há avaliações

- Problems With K-Jetronic SystemDocumento4 páginasProblems With K-Jetronic SystemVladimir Lalošević100% (1)

- Pruebas y Ajustes.Documento79 páginasPruebas y Ajustes.Francisco Wilson Bezerra FranciscoAinda não há avaliações

- Sisweb Sisweb Techdoc Techdoc Print Pag - pdf1Documento91 páginasSisweb Sisweb Techdoc Techdoc Print Pag - pdf1MatiussChesteerAinda não há avaliações

- Hydraulic Trouble-ShootingDocumento9 páginasHydraulic Trouble-ShootingTrường NguyenAinda não há avaliações

- Troubleshooting GuideDocumento3 páginasTroubleshooting GuidewsutomoAinda não há avaliações

- 3306 Industrial Engine - Troubleshooting - Testing and AdjustingDocumento93 páginas3306 Industrial Engine - Troubleshooting - Testing and AdjustingJordy Zavaleta100% (7)

- 10 Reasons for High Exhaust Gas TemperatureDocumento34 páginas10 Reasons for High Exhaust Gas Temperatureadesina bensonAinda não há avaliações

- Pruebas y Ajustes 3406CDocumento79 páginasPruebas y Ajustes 3406CJosue Ernesto Santos Rodriguez100% (3)

- Aveo Sivi Ve Ariza Fabri̇ka Bi̇lgi̇leri̇Documento8 páginasAveo Sivi Ve Ariza Fabri̇ka Bi̇lgi̇leri̇Çağrı SivrikayaAinda não há avaliações

- 3066testing & AdjustingDocumento129 páginas3066testing & AdjustingjamcaAinda não há avaliações

- TroubleshootingDocumento7 páginasTroubleshootingg665013Ainda não há avaliações

- Shriram Pistons & Rings: Engine Troubleshooting ChecklistDocumento1 páginaShriram Pistons & Rings: Engine Troubleshooting Checklistdeepak sharmaAinda não há avaliações

- Hyundai D6GA Fuel SystemDocumento53 páginasHyundai D6GA Fuel SystemBigfair HD78100% (11)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitAinda não há avaliações

- Diesel Engine Care and Repair: A Captain's Quick GuideNo EverandDiesel Engine Care and Repair: A Captain's Quick GuideNota: 5 de 5 estrelas5/5 (1)

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SAinda não há avaliações

- Process Engineering: Facts, Fiction and FablesNo EverandProcess Engineering: Facts, Fiction and FablesNota: 3 de 5 estrelas3/5 (2)

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsNo EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsAinda não há avaliações

- Outboard Engines 2E (PB): Maintenance, Troubleshooting, and RepairNo EverandOutboard Engines 2E (PB): Maintenance, Troubleshooting, and RepairNota: 3 de 5 estrelas3/5 (1)

- Tender 755Documento30 páginasTender 755gbaludbAinda não há avaliações

- Govt. of National Capital Territory Delhi Delhi Subordinate Services Selection Board Fc-18, Institutional Area, Karkardooma, Delhi-110092Documento7 páginasGovt. of National Capital Territory Delhi Delhi Subordinate Services Selection Board Fc-18, Institutional Area, Karkardooma, Delhi-110092gbaludbAinda não há avaliações

- Fire Tender 2014Documento37 páginasFire Tender 2014gbaludbAinda não há avaliações

- Tender 13 Dec 2013Documento5 páginasTender 13 Dec 2013gbaludbAinda não há avaliações

- CCTV and PA System TenderDocumento12 páginasCCTV and PA System TendergbaludbAinda não há avaliações

- National Institute of Fashion Technology, KolkataDocumento9 páginasNational Institute of Fashion Technology, KolkatagbaludbAinda não há avaliações

- NITFORPASYSTEMDocumento5 páginasNITFORPASYSTEMgbaludbAinda não há avaliações

- Tender 760Documento4 páginasTender 760gbaludbAinda não há avaliações

- Laboratory Table Installation BARC MumbaiDocumento2 páginasLaboratory Table Installation BARC MumbaigbaludbAinda não há avaliações

- Tender For Sitc of Pa Systems - Nabard MproDocumento30 páginasTender For Sitc of Pa Systems - Nabard MprogbaludbAinda não há avaliações

- For The Works of Near: Unit QTY Rate AmountDocumento3 páginasFor The Works of Near: Unit QTY Rate AmountgbaludbAinda não há avaliações

- Supply, Installation & Testing and Commissioning of P.A. System, Tower AC & Water Cooler Cum Purifier For IHM & Different Panthanivas of OTDC LTDDocumento9 páginasSupply, Installation & Testing and Commissioning of P.A. System, Tower AC & Water Cooler Cum Purifier For IHM & Different Panthanivas of OTDC LTDgbaludbAinda não há avaliações

- AMCPASDocumento3 páginasAMCPASgbaludbAinda não há avaliações

- URANIUM EXTRACTION DIVISION TENDER FOR PA SYSTEMDocumento5 páginasURANIUM EXTRACTION DIVISION TENDER FOR PA SYSTEMgbaludbAinda não há avaliações

- Tender 13 Dec 2013Documento5 páginasTender 13 Dec 2013gbaludbAinda não há avaliações

- Govt. of National Capital Territory Delhi Delhi Subordinate Services Selection Board Fc-18, Institutional Area, Karkardooma, Delhi-110092Documento7 páginasGovt. of National Capital Territory Delhi Delhi Subordinate Services Selection Board Fc-18, Institutional Area, Karkardooma, Delhi-110092gbaludbAinda não há avaliações

- NITFORPASYSTEMDocumento5 páginasNITFORPASYSTEMgbaludbAinda não há avaliações

- Tender 162 Fire TenderDocumento67 páginasTender 162 Fire Tenderrakeshrana1974Ainda não há avaliações

- AMCPASDocumento3 páginasAMCPASgbaludbAinda não há avaliações

- For The Works of Near: Unit QTY Rate AmountDocumento3 páginasFor The Works of Near: Unit QTY Rate AmountgbaludbAinda não há avaliações

- Tender Form Pa SystemsDocumento3 páginasTender Form Pa SystemsgbaludbAinda não há avaliações

- Sunday December 02 20123 11 06 PMNDWBF 2013Documento18 páginasSunday December 02 20123 11 06 PMNDWBF 2013gbaludbAinda não há avaliações

- Pa System Analogue SpecificationDocumento2 páginasPa System Analogue SpecificationgbaludbAinda não há avaliações

- Tender PASystems 08may2013Documento12 páginasTender PASystems 08may2013gbaludbAinda não há avaliações

- Chennai Port Trust: TENDER No. MEE/15/2013/ DCME (EC/OS)Documento56 páginasChennai Port Trust: TENDER No. MEE/15/2013/ DCME (EC/OS)gbaludbAinda não há avaliações

- Tender For Sound System For Class RoomsDocumento5 páginasTender For Sound System For Class RoomsgbaludbAinda não há avaliações

- PAS TenderDocumento8 páginasPAS TendergbaludbAinda não há avaliações

- Cissca v2 Catalog en W o MarkDocumento2 páginasCissca v2 Catalog en W o MarkgbaludbAinda não há avaliações

- WP155002EN Optimizing Rack LRDocumento4 páginasWP155002EN Optimizing Rack LRgbaludbAinda não há avaliações

- WVP 25118 - 218 - 126 - 226 NSDocumento1 páginaWVP 25118 - 218 - 126 - 226 NSgbaludbAinda não há avaliações

- Cercado VsDocumento1 páginaCercado VsAnn MarieAinda não há avaliações

- Planning For Network Deployment in Oracle Solaris 11.4: Part No: E60987Documento30 páginasPlanning For Network Deployment in Oracle Solaris 11.4: Part No: E60987errr33Ainda não há avaliações

- Customer Satisfaction and Brand Loyalty in Big BasketDocumento73 páginasCustomer Satisfaction and Brand Loyalty in Big BasketUpadhayayAnkurAinda não há avaliações

- Welding MapDocumento5 páginasWelding MapDjuangAinda não há avaliações

- ABBBADocumento151 páginasABBBAJeremy MaraveAinda não há avaliações

- Green Management: Nestlé's Approach To Green Management 1. Research and DevelopmentDocumento6 páginasGreen Management: Nestlé's Approach To Green Management 1. Research and DevelopmentAbaidullah TanveerAinda não há avaliações

- 2JA5K2 FullDocumento22 páginas2JA5K2 FullLina LacorazzaAinda não há avaliações

- Iitk Syllabus PDFDocumento520 páginasIitk Syllabus PDFcombatps1Ainda não há avaliações

- 04 Dasmarinas Vs Reyes GR No 108229Documento2 páginas04 Dasmarinas Vs Reyes GR No 108229Victoria Melissa Cortejos PulidoAinda não há avaliações

- Philippine Architecture, Film Industry EvolutionDocumento4 páginasPhilippine Architecture, Film Industry EvolutionCharly Mint Atamosa IsraelAinda não há avaliações

- ASCE - Art Competition RulesDocumento3 páginasASCE - Art Competition Rulesswarup babalsureAinda não há avaliações

- Palmetto Bay's Ordinance On Bird RefugeDocumento4 páginasPalmetto Bay's Ordinance On Bird RefugeAndreaTorresAinda não há avaliações

- Spouses Mariano Z. Velarde and Avelina D. VELARDE, Petitioners, vs. COURT OF Appeals, David A. RAYMUNDO and GEORGE RAYMUNDO, RespondentsDocumento11 páginasSpouses Mariano Z. Velarde and Avelina D. VELARDE, Petitioners, vs. COURT OF Appeals, David A. RAYMUNDO and GEORGE RAYMUNDO, RespondentsRobyn JonesAinda não há avaliações

- KSRTC BokingDocumento2 páginasKSRTC BokingyogeshAinda não há avaliações

- Qatar Airways E-ticket Receipt for Travel from Baghdad to AthensDocumento1 páginaQatar Airways E-ticket Receipt for Travel from Baghdad to Athensمحمد الشريفي mohammed alshareefiAinda não há avaliações

- Excavator Loading To Truck TrailerDocumento12 páginasExcavator Loading To Truck TrailerThy RonAinda não há avaliações

- 01-Azeotropic Distillation (IL Chien)Documento35 páginas01-Azeotropic Distillation (IL Chien)Shivam Vinoth100% (1)

- Engine Controls (Powertrain Management) - ALLDATA RepairDocumento4 páginasEngine Controls (Powertrain Management) - ALLDATA Repairmemo velascoAinda não há avaliações

- Wind EnergyDocumento6 páginasWind Energyshadan ameenAinda não há avaliações

- Marketing ManagementDocumento14 páginasMarketing ManagementShaurya RathourAinda não há avaliações

- 28 Government Service Insurance System (GSIS) vs. Velasco, 834 SCRA 409, G.R. No. 196564 August 7, 2017Documento26 páginas28 Government Service Insurance System (GSIS) vs. Velasco, 834 SCRA 409, G.R. No. 196564 August 7, 2017ekangAinda não há avaliações

- Micromaster 430: 7.5 KW - 250 KWDocumento118 páginasMicromaster 430: 7.5 KW - 250 KWAyman ElotaifyAinda não há avaliações

- Credentials List with Multiple Usernames, Passwords and Expiration DatesDocumento1 páginaCredentials List with Multiple Usernames, Passwords and Expiration DatesJOHN VEGAAinda não há avaliações

- Material Properties L2 Slides and NotesDocumento41 páginasMaterial Properties L2 Slides and NotesjohnAinda não há avaliações

- Ayushman BharatDocumento20 páginasAyushman BharatPRAGATI RAIAinda não há avaliações

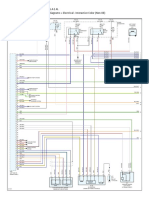

- 1990-1994 Electrical Wiring - DiagramsDocumento13 páginas1990-1994 Electrical Wiring - Diagramsal exAinda não há avaliações

- Taxation of interest income paid to foreign corporationsDocumento1 páginaTaxation of interest income paid to foreign corporationsCass CataloAinda não há avaliações

- C.C++ - Assignment - Problem ListDocumento7 páginasC.C++ - Assignment - Problem ListKaushik ChauhanAinda não há avaliações

- Tyron Butson (Order #37627400)Documento74 páginasTyron Butson (Order #37627400)tyron100% (2)

- Gary Mole and Glacial Energy FraudDocumento18 páginasGary Mole and Glacial Energy Fraudskyy22990% (1)