Escolar Documentos

Profissional Documentos

Cultura Documentos

15-2-Insulation of Buildings

Enviado por

linamohdzhor4815Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

15-2-Insulation of Buildings

Enviado por

linamohdzhor4815Direitos autorais:

Formatos disponíveis

QCS 2014

Section 15: Insulation of Buildings

Part

02: Building Insulation

BUILDING INSULATION ......................................................................................... 2

2.1

2.1.1

2.1.2

GENERAL ............................................................................................................... 2

Scope

2

References

2

2.2

2.2.1

THERMAL INSULATION ......................................................................................... 4

Minimum Envelope Performance Requirements

4

2.3

2.3.1

ACOUSTICAL CONTROL ....................................................................................... 5

References

5

2.4

2.4.1

2.4.2

2.4.3

2.4.4

2.4.5

2.4.6

2.4.7

2.4.8

2.4.9

INSULATION MATERIAL TYPES ............................................................................ 6

General

6

External Thermal Insulation Composite System (ETICS)

6

Cavity Wall Insulation

6

Perimeter Insulation

6

Exterior Framing or Furring Insulation

7

Rigid Insulation

7

Masonry Fill Insulation

7

Adhesive

7

Tape

7

2.5

2.5.1

2.5.2

2.5.3

2.5.4

2.5.5

2.5.6

2.5.7

INSTALLATION ....................................................................................................... 7

Execution and Workmanship

7

Masonry Cavity Walls

8

Perimeter Insulation

8

Exterior Framing or Furring Blanket Insulation

8

Rigid Insulation

9

Masonry Fill Insulation

9

Insulation Behind Marble Cladding

9

2.6

2.6.1

2.6.2

PREFABRICATED WALL INSULATION................................................................ 10

General

10

Quality and Requirements

10

ed

En

gi

ne

er

in

on

st

ru

ct

io

o.

-Q

at

ar

on

so

lid

at

Page 1

Section 15: Insulation of Buildings

Part

02: Building Insulation

Page 2

BUILDING INSULATION

2.1

GENERAL

2.1.1

Scope

This Part specifies the type, quality and application of exterior wall insulation.

Related Sections are as follows:

o.

-Q

at

ar

QCS 2014

This Section

Part 1 ............... General

ct

io

Section 5 ......... Concrete

Section 13 ....... Masonry

Section 18 ....... Carpentry, Joinery and Ironmongery

References

The following standards are referred to in this Section:

st

ru

2.1.2

on

BS 874........................Methods for determining thermal insulating properties

BS 1142......................Fibre building boards

BS 1202......................Nails

BS 1210......................Wood screws

in

BS 3692......................Isometric precision hexagon bolts, screws, nuts

er

BS 3837......................Expanded polystyrene boards

ne

BS 3958......................Thermal insulation materials

BS 4841......................Rigid urethane foam

En

gi

BS 5250......................Code of practice for control of condensation in buildings

BS 5617......................Urea-formaldehyde (UF) foam systems suitable for thermal insulation

of cavity walls with masonry or concrete outer leaves

ed

BS 5618......................Thermal insulation of cavity walls (with masonry or concrete outer

leaves)

by filling with urea-formaldehyde (UF) foam systems

on

so

lid

at

BS 5803......................Thermal insulation for use for use in pitched roof spaces in dwellings

BS 6203......................Guide to fire characteristics and fire performance of expanded

polystyrene materials (EPS and XPS) used in building applications

BS 6676......................Thermal insulation of cavity walls using man-made mineral fibre batts

(slabs)

BS 7021......................Code of practice for thermal insulation of roofs externally by means of

sprayed rigid polyurethane (PUR) or polyisocyanurate (PIR) foam

BS 7456 .....................Code of practice for stabilization and thermal insulation of cavity walls

(with masonry or concrete inner and outer leaves) by filling with

polyurethane (PUR) foam systems

BS 8208......................Assessment of stability of external cavity walls for filling with thermal

insulants

QCS 2014

Section 15: Insulation of Buildings

Part

02: Building Insulation

Page 3

BS 8216......................Code of practice for use of sprayed lightweight mineral coatings used

for

thermal insulation and sound absorption in buildings

-Q

at

ar

BS 8233......................Sound insulation and noise reduction for buildings. Code of practice

BS EN 998-1 .............Specification for mortar for masonry: Part 1: Rendering and plastering

mortar

BS EN 13162:2012.....Thermal insulation products for buildings. Factory made mineral wool

(MW) products. Specification

o.

BS EN 13163..............Thermal insulation products for buildings. Factory made expanded

polystyrene (EPS) products. Specification

BS EN 13164 .............Thermal insulation products for buildings. Factory made extruded

polystyrene foam (XPS) products. Specification

ct

io

BS EN 13165..............Thermal insulation products for buildings. Factory made rigid

polyurethane foam (PU) products. Specification

ru

BS EN 13166..............Thermal insulation products for buildings. Factory made phenolic foam

(PF) products. Specification

on

st

BS EN 13167:2012. ...Thermal insulation products for buildings. Factory made cellular glass

(CG) products. Specification

BS EN 13168:2012.....Thermal insulation products for buildings. Factory made wood wool

(WW) products. Specification

BS EN 13169:2012.....Thermal insulation products for buildings. Factory made expanded

perlite board (EPB) products. Specification

er

in

BS EN 13170:2012.....Thermal insulation products for buildings. Factory made products of

expanded cork (ICB). Specification

ne

BS EN 13171:2012.....Thermal insulation products for buildings. Factory made wood fibre

(WF) products. Specification

BS EN 13172..............Thermal insulation products. Evaluation of conformity

En

gi

BS EN 13467..............Thermal insulating products for building equipment and industrial

installations. Determination of dimensions, squareness and linearity of

preformed pipe insulation

ed

BS EN 14319-1 ..........Thermal insulating products for building equipment and industrial

installations. In-situ formed dispensed rigid polyurethane (PUR) and

polyisocyanurate foam (PIR) products

on

so

lid

at

BS EN 14320-1 ..........Thermal insulating products for building equipment and industrial

installations. In-situ formed sprayed rigid polyurethane (PUR) and

polyisocyanurate foam (PIR) products

BS EN 14496..............Gypsum based adhesives for thermal/acoustic insulation composite

panels and plasterboards. Definitions, requirements and test methods

EN 1745:2002 ............Masonry and masonry products Methods for determining design

thermal values

EN 13501-1 ................Fire classification of construction products and building elements

Part 1: Classification using test data from reaction to fire tests

GSO EN 13950 ..........Gypsum plasterboard thermal/acoustic insulation composite panels Definitions, requirements and test methods

QCS 2014

Section 15: Insulation of Buildings

Part

02: Building Insulation

Page 4

ISO 12575-1 ...............Thermal insulation. Exterior insulating systems for foundations

Material specification

systems

for

-Q

at

ar

ISO 12575-2 ...............Thermal insulation products. Exterior insulating

foundations: Principal responsibilities of installers

ISO 11925-2 ...............Reaction to fire tests -- Ignitability of products subjected to direct

impingement of flame -- Part 2: Single-flame source test

Health Technical Memorandum 08-01: Acoustics

THERMAL INSULATION

2.2.1

Minimum Envelope Performance Requirements

For all new air conditioned buildings, exterior building elements must have average thermal

transmittance (also known as U Value) and Shading Coefficients (SC) that does not exceed

the values specified and Light Transmittance greater than or equal to the values specified.

External Walls, Roofs and Floors:

ru

(a)

ct

io

o.

2.2

on

st

Building elements forming the external walls and floors (where one side of the floor is

exposed to ambient conditions) must have an average thermal transmittance (U

Value) which does not exceed the following values:

Roof

External Wall

U=0.57W/m K

2

U=0.57W/m K

in

Floor

U= 0.44W/m K

ne

er

If the floor is in contact with the ground, the insulations should only be applied to one

meter (1m) in from the perimeter of the building.

(b)

Glazed Elements-Fenestration:

If the total area of external walls that let in light is forty percent (40%) or less of the external

wall area, then the glazing elements must meet the following performance criteria:

on

so

lid

at

ed

En

gi

Glazed elements with back insulated panels must be treated as walls (and therefore

must meet the performance requirement for walls.)

Thermal Transmittance (Summer U Value)

U=2.1W/m K (max)

Shading Coefficient (SC)

0.4 (max)

Light Transmittance

0.25 (min)

If the total area of external walls that let in light is between forty percent (40%) and sixty

percent (60%) of the external wall area, then the glazing elements must meet the following

performance criteria:

2

Thermal Transmittance (Summer U Value)

U=1.9W/m k (max)

Shading Coefficient (SC)

0.32 (max)

Light Transmittance

0.1 (min)

If the total of external walls that let in light is sixty percent (60%) or greater of the external wall

area, then the glazing elements must meet the following performance criteria.

Thermal Transmittance (Summer U Value)

U=1.9W/m K (max)

Shading Coefficient (SC)

0.25 (max)

Light Transmittance

0.1 (min)

For shop fronts and showrooms, other than those at ground floor level, glazing elements

must meet the following performance criteria:

2

U=1.9W/m K (max)

Shading Coefficient (SC)

0.76 (max)

o.

Thermal Transmittance (Summer U Value)

If the glazing portion of a roof is ten percent (10%) or less of the roof area, then the glazing

elements must meet the following performance criteria:

Page 5

Section 15: Insulation of Buildings

Part

02: Building Insulation

-Q

at

ar

QCS 2014

ct

io

Thermal Transmittance (Summer U Value)

U=1.9W/m K (max)

Shading Coefficient (SC)

0.32 (max)

st

If the glazing portion of a roof is greater than ten percent (10%) of the roof area, then the

glazing elements must meet the following performance criteria:

on

0.4 (min)

ru

Light Transmittance

U=1.9W/m K (max)

Shading Coefficient (SC)

0.25 (max)

Thermal Transmittance (Summer U Value)

0.3 (min)

er

in

Light Transmittance

ACOUSTICAL CONTROL

2.3.1

References

En

gi

ne

2.3

Building Type

ed

Villas/Residential Buildings

Healthcare Facilities

Building Regulations Approved Document E (revised 2003)

(UK)

Health Technical Memorandum 08-01 (UK)

Educational facilities

Building Bulletin 93: Acoustic Design of Schools A design

Guide (UK)

Commercial Buildings

BS8233:1999 Sound insulation and noise reduction for

buildings-code of practice. (UK)

Industrial

BS8233:1999 Sound insulation and noise reduction for

buildings-code of practice. (UK)

Public

BS8233:1999 Sound insulation and noise reduction for

buildings-code of practice. (UK)

on

so

lid

at

Document Reference

*Residential buildings

Accommodations.

include

Villas,

Apartments,

Worker

Accommodations

and

Student

**Educational Facilities include Nursery Schools, Primary Schools, Secondary Schools, Colleges and

Universities.

QCS 2014

Section 15: Insulation of Buildings

Part

02: Building Insulation

Page 6

INSULATION MATERIAL TYPES

2.4.1

General

Various types of insulation may be specified for varying conditions or wall construction. The

BS, EN classification system is to be used for insulation material; or to any other reference

mentioned in paragraph 2.1.2 , or approved by Qatar Standards.

The Contractor shall use only one type of insulation in any particular area where more than

one type is optional unless approved other wise by the Engineer.

At least thermal insulation is to be used for exterior roofs and exterior walls of the building

Where insulation is used for exterior walls, roof surfaces, or below grade, the requirements

for condensation control shall be to BS 5250 and BS 5803.

2.4.2

External Thermal Insulation Composite System (ETICS)

If specified the external thermal insulation composite system (ETICS) shall be bonded

system and tested in accordance with ETAG-004 (European organization for technical

approvals):-

The external thermal insulation system shall compose of the following components:-

on

st

ru

ct

io

o.

-Q

at

ar

2.4

Adhesive layer

(b)

Extruded or expanded Polystyrene board

(c)

Insulation boards fasteners (Plastic or metal)

(d)

Cementitious adhesive protective mortar layer

(e)

Fibremesh reinforcement

(f)

Cementitious adhesive protective mortar layer

(g)

Decorative layer of acrylic or polymer modified cementitious mortar

En

gi

ne

er

in

(a)

Cavity Wall Insulation

Mineral Fibre Board shall comply with the relevant provisions of BS 1142 and be faced with a

vapour retarder having a perm rating of not more than 0.5.

Polyurethane or polyisocyanurate board shall comply with the relevant provisions of BS 4841

and be faced with a vapour retarder having a perm rating of not more than 0.5.

on

so

lid

at

ed

2.4.3

Polystyrene board shall comply with the relevant provisions of BS 3837.

Foam system insulation used in cavity walls shall be to BS 5617 and BS 5618.

Unless otherwise stated on the drawings cavity wall insulation shall be extruded polystyrene

3

board of minimum density 25 kg/m to the thickness detailed.

2.4.4

Perimeter Insulation

Polystyrene board where used for exterior perimeter insulation below ground and in contact

with soil shall comply with the relevant provisions of BS 3837 and BS 8216.

Where sprayed lightweight mineral coatings are used, they shall be to BS 8216.

QCS 2014

Section 15: Insulation of Buildings

Part

02: Building Insulation

Page 7

Exterior Framing or Furring Insulation

On approval by the Engineer, batt or blanket type insulation can be used for exterior wall

insulation provided that proper protection, as designated in the Project Documentation, is

present.

Mineral fibre shall comply with the relevant provisions of BS 6676.

2.4.6

Rigid Insulation

Rigid insulation shall be applied to the inside face of exterior walls, spandrel beams, floors

and where indicated in the Project Documentation.

Mineral fibre board shall comply with the relevant provisions of BS 6676 Part 1 and Part 2.

2.4.7

Masonry Fill Insulation

Vermiculite insulation shall comply with the relevant provisions of BS 8208.

Fasteners for masonry fill insulation shall be as follows:

st

ru

ct

io

o.

-Q

at

ar

2.4.5

staples or nails complying with the relevant provisions of BS 1202, zinc-coated, size

and type best suited for purpose.

(b)

screws complying with the relevant provisions of BS 1210 and BS 3692, with washer

not less than 50 mm in diameter.

(c)

steel impaling pins with heads not less than 50 mm in diameter with adhesive for

anchorage to substrata; the impaling pins shall be of sufficient length to extend beyond

the insulation and retail cap washer when a washer is placed on the pin.

er

in

on

(a)

Adhesive

Adhesives shall be as recommended by the manufacturer of the insulation.

2.4.9

Tape

Tape used to seal cuts, tears or unlapped joints of insulation shall have pressure sensitive

adhesive on one face.

En

gi

ed

The perm rating of the tape shall not be more than 0.50.

on

so

lid

at

ne

2.4.8

2.5

INSTALLATION

2.5.1

Execution and Workmanship

Insulation shall be installed with the vapour barrier facing the heated side, unless specified

otherwise.

Rigid insulating units shall be installed with joints close and flush, in regular courses and with

cross-joints broken.

Batt or blanket insulation shall be installed with tight joints and filling framing void completely.

Seal cuts, tears, and unlapped joints with tape.

QCS 2014

Section 15: Insulation of Buildings

Part

02: Building Insulation

Page 8

Insulation shall be fitted tight against adjoining construction and penetrations, unless

specified otherwise.

2.5.2

Masonry Cavity Walls

Insulation shall be mounted on exterior faces of inner leaves of masonry cavity walls and

brick faced concrete walls. Fill joints with the same material used for bonding.

Polystyrene board shall be bonded to surfaces with adhesive or Portland cement mortar

mixed and applied in accordance with recommendations of insulation manufacturer.

Mineral fibreboard and polyurethane shall be bonded to surfaces with adhesive as

recommended by insulation manufacturer.

2.5.3

Perimeter Insulation

When applying vertical perimeter insulation, the contractor shall:

ct

io

o.

-Q

at

ar

fill joints of insulation with the same material as used for bonding

(b)

bond polystyrene board to surfaces with adhesive or Portland cement mortar mixed

and applied in accordance with recommendations of the insulation manufacturer.

When applying horizontal perimeter insulation under concrete floor slabs the Contractor shall:

lay insulation boards and blocks horizontally on level, compacted and drained fill

(b)

extend insulation from foundation walls towards the centre of the building.

(a)

in

on

st

ru

(a)

Exterior Framing or Furring Blanket Insulation

The insulation shall be packed around door frames and windows and in building expansion

joints, door soffits and other voids. Open voids are not permitted. The insulation shall be held

in place with pressure sensitive tape.

Vapour retarder flanges shall be lapped together over the face of the framing for a

continuous surface. Seal all penetrations through the insulation.

The blanket insulation shall be fastened between metal studs or framing and exterior wall

furring by continuous pressure sensitive tape along flanged edges.

ed

The blanket insulation between wood studs or framing shall be fastened with nails or staples

through the flanged edges on the face of the stud. Fastenings shall be spaced the not more

than 150 mm apart.

on

so

lid

at

En

gi

ne

er

2.5.4

For roof rafter insulation or floor joist insulation, mineral fibre blankets shall be placed

between the framing to provide not less than a two 50 mm space between the insulation and

the roof sheathing or sub-floor.

Ceiling insulation and soffit insulation shall be as follows:

(a)

at wood framing, blanket insulation shall be fastened between the wood framing or

joist with nails or staples through flanged edges of insulation.

QCS 2014

Section 15: Insulation of Buildings

Part

02: Building Insulation

Page 9

at metal framing or ceiling suspension systems, blanket insulation shall be installed

above suspended ceilings or metal framing at right angles to the main runners or

framing; the insulation shall be taped tightly together so no gaps occur and metal the

framing members are covered by insulation.

(c)

in areas where suspended ceilings adjoin areas without suspended ceilings, either

blanket, batt, or mineral fibreboard insulation shall be installed; the insulation shall

extend from the suspended ceiling to underside of deck or slab above; the insulation

shall be secured in place to prevent collapse or separation of the insulation and

maintain it in a vertical position; blanket or batt insulation shall be secured to the

structure above with continuous cleats.

o.

-Q

at

ar

(b)

Rigid Insulation

Rigid insulation shall be securely fixed to the interior face of exterior walls of solid masonry,

or to concrete walls, beams, beam soffits, underside of floors, and to the face of studs where

shown on the Project Drawings for interior walls unless otherwise approved by the Engineer.

The insulation shall be bonded to solid vertical surfaces with adhesive as recommended by

insulation manufacturer. Joints shall be filled with adhesive cement.

Impaling pins shall be used for attachment of the insulation to the underside of horizontal

surfaces. Fastenings shall be spaced as necessary to hold insulation in place and prevent

sagging.

Insulation board is to be fastened at walls or underside of ceilings with screws, nails or

staples. Fastenings shall be spaced not more than 25 mm apart and there shall be a

fastening in each corner. The fasteners shall be staggered at the joints between boards.

Floor insulation shall be as follows:

insulation shall be bond to concrete floors in attics by coating surfaces with hot asphalt

applied at rate of not less than 35 kg per 10 m2, and firmly bed the insulation.

(b)

En

gi

ne

(a)

when applied in more than one layer, bed succeeding layers in hot asphalt applied at

the rate to equal a total of not less than 35 kg per 10 m2 when completed.

insulation may be installed with non-flammable adhesive in accordance with the

manufacturer's instructions when a separate vapour barrier is used.

ed

(c)

Masonry Fill Insulation

on

so

lid

at

2.5.6

er

in

on

st

ru

ct

io

2.5.5

Fill insulation shall be poured into cavity voids of masonry units from the tops of walls, or from

a sill where windows or other openings occur.

The fill insulation shall be poured in lifts of not more than 6 metres.

2.5.7

Insulation Behind Marble Cladding

Insulation to external walls is to be 60, 70 or 80 mm thick, as shown on the Project Drawings;

resin bonded glass fibre slabs shall be approximate 600 x 1250 mm size

The wall insulation is to be mounted on the outside face of the external concrete walls,

behind the marble cladding panels. After ensuring that the surface is even and free from dirt,

grease, oil, concrete nibs etc an approved primer is to be applied.

QCS 2014

Section 15: Insulation of Buildings

Part

02: Building Insulation

Page 10

The insulation slabs are to be fixed with an approved adhesive in accordance with the

manufacturers instructions. Both sides of the insulation are to be covered building paper.

The external face of the insulation is to be finished mat black.

2.6

PREFABRICATED WALL INSULATION

2.6.1

General

This Clause addresses the use of insulation in prefabricated wall systems.

2.6.2

Quality and Requirements

Insulation and related vapour barriers or weather proofing are to be as shown on the Project

Drawings and as specified in the manufacturers literature, shop drawings and any other

relevant supporting documentation.

Manufacturers literature, shop drawings, supporting documentation and certification that

necessary thermal requirements will be met shall be submitted to the Engineer for approval

prior to delivery.

Thermal requirements will at minimum meet specifications as stated in this Part 2 of this

Section for standard wall construction unless stated otherwise in the Project Documentation.

Curtain wall or glass clad wall systems are also to meet the thermal requirements of this

Section. Refer to Section 25 for additional requirements.

on

st

ru

ct

io

o.

-Q

at

ar

on

so

lid

at

ed

En

gi

ne

er

in

END OF PART

Você também pode gostar

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989No EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookAinda não há avaliações

- Building Automation A Complete Guide - 2020 EditionNo EverandBuilding Automation A Complete Guide - 2020 EditionAinda não há avaliações

- Computers in Materials Technology: Proceedings of the International Conference Held at the Institute of Technology, Linköping University, Sweden, June 4-5, 1980No EverandComputers in Materials Technology: Proceedings of the International Conference Held at the Institute of Technology, Linköping University, Sweden, June 4-5, 1980T. EricssonNota: 5 de 5 estrelas5/5 (1)

- Composites Evaluation: Proceedings of the Second International Conference on Testing, Evaluation and Quality Control of Composites-TEQC 87No EverandComposites Evaluation: Proceedings of the Second International Conference on Testing, Evaluation and Quality Control of Composites-TEQC 87J. HerriotAinda não há avaliações

- 06.17 Roadworks - Road DrainageDocumento12 páginas06.17 Roadworks - Road DrainageKishanshettyAinda não há avaliações

- Electrical Overstress (EOS): Devices, Circuits and SystemsNo EverandElectrical Overstress (EOS): Devices, Circuits and SystemsAinda não há avaliações

- Green Walls in High-Rise Buildings: September 2014Documento23 páginasGreen Walls in High-Rise Buildings: September 2014Nafis Abrar 1631155610Ainda não há avaliações

- BuildingMaterialsPropertiesPerformanceandApplications 1 PDFDocumento422 páginasBuildingMaterialsPropertiesPerformanceandApplications 1 PDFminkhangAinda não há avaliações

- As 5604-2005 Timber - Natural Durability RatingsDocumento8 páginasAs 5604-2005 Timber - Natural Durability RatingsSAI Global - APACAinda não há avaliações

- Ul-Eu Certificate: Chris MilesDocumento6 páginasUl-Eu Certificate: Chris Milescity chemAinda não há avaliações

- Thermal ConductivityDocumento9 páginasThermal ConductivityKilaru HareeshAinda não há avaliações

- GGF Good Practice Guide Dec 13 PDFDocumento89 páginasGGF Good Practice Guide Dec 13 PDFKhurshed Alam IndiaAinda não há avaliações

- Mrhkli: Beam Pro Training and ExaminationDocumento68 páginasMrhkli: Beam Pro Training and ExaminationSimon LawAinda não há avaliações

- Icc Ibc 2012Documento732 páginasIcc Ibc 2012ChristianFernandoAinda não há avaliações

- IP Protection Degree (IEC 60529) Explained - EEPDocumento3 páginasIP Protection Degree (IEC 60529) Explained - EEPLouie FernandezAinda não há avaliações

- Air and Water Permeability of Sandwich Panel JointsDocumento43 páginasAir and Water Permeability of Sandwich Panel JointsThiên BìnhAinda não há avaliações

- Catalogue Myrra Version 2013Documento84 páginasCatalogue Myrra Version 2013Axone CommunicationAinda não há avaliações

- 1 Sean BalfeDocumento25 páginas1 Sean BalfeShrikant BudholiaAinda não há avaliações

- Windows Specification - Replacement WindowsDocumento13 páginasWindows Specification - Replacement WindowsthaidzungAinda não há avaliações

- Manual FireStopDocumento148 páginasManual FireStopTimothy Hancock100% (1)

- Passive Fire Protection Getting It Right Wilf Butcher PDFDocumento44 páginasPassive Fire Protection Getting It Right Wilf Butcher PDFSonny Ramos100% (1)

- Epoch 4 Operations ManualDocumento164 páginasEpoch 4 Operations ManualpjhollowAinda não há avaliações

- Bs 263Documento12 páginasBs 263AndreyAinda não há avaliações

- EN 54-14 2004 PRDocumento75 páginasEN 54-14 2004 PRerhanAinda não há avaliações

- BS EN 10228-12016 Non-Destructive Testing of Steel Forgings Part 1 Magnetic Particle InspectionDocumento20 páginasBS EN 10228-12016 Non-Destructive Testing of Steel Forgings Part 1 Magnetic Particle InspectionudomAinda não há avaliações

- Wood Inspection by Infrared ThermographyDocumento6 páginasWood Inspection by Infrared ThermographysalekojicAinda não há avaliações

- AEE - Northern Ohio - Stockton Infrared Presentation - SMDocumento257 páginasAEE - Northern Ohio - Stockton Infrared Presentation - SMIuli BaicoianuAinda não há avaliações

- RT Film Classification - C1 To C6Documento31 páginasRT Film Classification - C1 To C6Ravindira C DevAinda não há avaliações

- 18-ASTM E2174-14bDocumento7 páginas18-ASTM E2174-14bAli Adnaan RazaAinda não há avaliações

- 16 10 25 Epd 7 Reynaers Curtain Wall CW 50 r01Documento14 páginas16 10 25 Epd 7 Reynaers Curtain Wall CW 50 r01supadiAinda não há avaliações

- Wallis Earthing & Lightning Protection Systems CatalogueDocumento120 páginasWallis Earthing & Lightning Protection Systems CatalogueRelief_EngineerAinda não há avaliações

- Din 1670Documento10 páginasDin 1670GODREJ LAB THANEAinda não há avaliações

- BS en 1288-3-2000Documento14 páginasBS en 1288-3-2000Ziyad KubbaAinda não há avaliações

- PromatUK Fire Protection Handbook Chapter 1 IntroductionDocumento15 páginasPromatUK Fire Protection Handbook Chapter 1 Introductionsloba68Ainda não há avaliações

- BS en 10177-2019Documento16 páginasBS en 10177-2019Federico De MartiniAinda não há avaliações

- Ecology Report ExampleDocumento59 páginasEcology Report ExampletgavrilovaAinda não há avaliações

- Ultrasonic Testing of ConcreteDocumento4 páginasUltrasonic Testing of ConcreteAshrafAinda não há avaliações

- En60598 2 13Documento14 páginasEn60598 2 13Zhenhua Gao100% (1)

- Eva Film Inter Layer For Laminated GlassDocumento7 páginasEva Film Inter Layer For Laminated GlassPeter LinAinda não há avaliações

- AAMA 2605铝制品喷漆Documento15 páginasAAMA 2605铝制品喷漆秦川Ainda não há avaliações

- Inhoud Handbooks Paints & VarnishesDocumento22 páginasInhoud Handbooks Paints & VarnishesLauraMilenaHernándezTorresAinda não há avaliações

- IK RatingDocumento2 páginasIK RatingViorel CatalinAinda não há avaliações

- V07 (Architectural FOH Lighting)Documento231 páginasV07 (Architectural FOH Lighting)Parth WankhedeAinda não há avaliações

- List of IEC Codes For CableDocumento6 páginasList of IEC Codes For CableGuha Arnab100% (1)

- Astm e 1139Documento6 páginasAstm e 1139KEN KAinda não há avaliações

- Iso 7345:1997Documento10 páginasIso 7345:1997Blaise Roithridh100% (1)

- Cladding To Timber FrameDocumento34 páginasCladding To Timber Framecolinbooth91Ainda não há avaliações

- API5L 45th Edition Specification For Line Pipe For WebsiteDocumento6 páginasAPI5L 45th Edition Specification For Line Pipe For WebsiteRaja Ram yadav0% (1)

- Cable Trunking Test Report BS 4678 IEC61084 G275Documento5 páginasCable Trunking Test Report BS 4678 IEC61084 G275iask5275Ainda não há avaliações

- En 1999 1 5 2007 PDFDocumento67 páginasEn 1999 1 5 2007 PDFNiko NeznanovicAinda não há avaliações

- BS en 12412-2-2003Documento46 páginasBS en 12412-2-2003DoicielAinda não há avaliações

- Glass Standards PDFDocumento4 páginasGlass Standards PDFCristian TofanAinda não há avaliações

- BS en Iso 12567-1-2010 - (2020-04-30 - 03-32-26 PM)Documento64 páginasBS en Iso 12567-1-2010 - (2020-04-30 - 03-32-26 PM)Luca ScarsellaAinda não há avaliações

- Fire Test (EN13501-1)Documento8 páginasFire Test (EN13501-1)Vinka PrintAinda não há avaliações

- My BS 4568Documento1 páginaMy BS 4568khaledaj1977Ainda não há avaliações

- Electrical Wire LabelingDocumento2 páginasElectrical Wire LabelingAlliver SapitulaAinda não há avaliações

- Glass CorrosionDocumento8 páginasGlass CorrosionCan Yigit DincAinda não há avaliações

- 5444r 88Documento18 páginas5444r 88Mohammed IsmailAinda não há avaliações

- White Et Al. 2010 - CAT CFED Phase IVDocumento85 páginasWhite Et Al. 2010 - CAT CFED Phase IVlinamohdzhor4815Ainda não há avaliações

- Mse WallsDocumento105 páginasMse Wallslinamohdzhor4815Ainda não há avaliações

- MCL 9904Documento11 páginasMCL 9904linamohdzhor4815Ainda não há avaliações

- Controlling Temperatures in Mass ConcreteDocumento4 páginasControlling Temperatures in Mass ConcreteBatepola Bac100% (1)

- Mercedes Benz Actros BrochureDocumento19 páginasMercedes Benz Actros Brochurefdpc1987100% (6)

- DR 600 CulvertsDocumento54 páginasDR 600 Culvertslinamohdzhor4815Ainda não há avaliações

- Commentariolus TextDocumento7 páginasCommentariolus Textlinamohdzhor4815Ainda não há avaliações

- Capacity Charts For The Hydraulic Design of Highway CulvertsDocumento95 páginasCapacity Charts For The Hydraulic Design of Highway Culvertslinamohdzhor4815Ainda não há avaliações

- DD 9Documento11 páginasDD 9linamohdzhor4815Ainda não há avaliações

- Historical Eclipses and Earth's RotationDocumento6 páginasHistorical Eclipses and Earth's Rotationlinamohdzhor4815Ainda não há avaliações

- 100mm PU Panels, 100mm PU Panels Direct From Foshan Baoguan Cold Room & Insulation Panel Factory in China (Mainland)Documento3 páginas100mm PU Panels, 100mm PU Panels Direct From Foshan Baoguan Cold Room & Insulation Panel Factory in China (Mainland)linamohdzhor4815Ainda não há avaliações

- Document 3Documento1 páginaDocument 3linamohdzhor4815Ainda não há avaliações

- Laying Block PavingDocumento2 páginasLaying Block Pavingglynis100% (1)

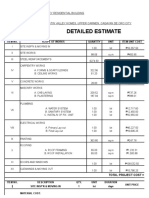

- Sample EstimateDocumento58 páginasSample EstimateMark Kenneth P. OntejoAinda não há avaliações

- Villa Savoye FormDocumento7 páginasVilla Savoye FormAlexis Carlos Rodriguez SalamancaAinda não há avaliações

- Mizutani 2011 KajimaCTD.d4cb8482 D56e 4b4b 92c5 0f1ee77bb35dDocumento9 páginasMizutani 2011 KajimaCTD.d4cb8482 D56e 4b4b 92c5 0f1ee77bb35dciprimihAinda não há avaliações

- The Ultimate Plant and Garden Book PDFDocumento534 páginasThe Ultimate Plant and Garden Book PDFEstee Gee100% (11)

- Construction of Stone Masonry Drain (1700 RFT) : Comparative Statement (Civil Department)Documento2 páginasConstruction of Stone Masonry Drain (1700 RFT) : Comparative Statement (Civil Department)Amir HabibAinda não há avaliações

- TBDY 2018 EnglishDocumento608 páginasTBDY 2018 EnglishaygunbayramAinda não há avaliações

- Yale Nandoms Technical ReportDocumento48 páginasYale Nandoms Technical ReportJy GrilloAinda não há avaliações

- ENDocumento1 páginaENreacharunkAinda não há avaliações

- Shallow Foundation and Deep FoundationDocumento43 páginasShallow Foundation and Deep FoundationWei Siong95% (21)

- GR 5 Term 2 2020 Ns T Resource PackDocumento38 páginasGR 5 Term 2 2020 Ns T Resource PackLorraine NoloAinda não há avaliações

- The Columns Legazpi Village MakatiDocumento32 páginasThe Columns Legazpi Village MakatiSari EspinaAinda não há avaliações

- RSW Design in ArchitectureDocumento6 páginasRSW Design in ArchitectureKathleen Denise Doria MacaraegAinda não há avaliações

- NECB Energy Efficiency Requirements GuideDocumento4 páginasNECB Energy Efficiency Requirements GuideracatalanAinda não há avaliações

- Architecture and FilmDocumento127 páginasArchitecture and FilmMichael GrajeraAinda não há avaliações

- Pit Plan: Detail LDocumento8 páginasPit Plan: Detail LsubagioAinda não há avaliações

- Fire Spread RatingDocumento4 páginasFire Spread RatingSamson Rajan BabuAinda não há avaliações

- Russian Pavilion Expo 2010Documento5 páginasRussian Pavilion Expo 2010Vishnupriya ParthasarathyAinda não há avaliações

- SRM TRP Engineering College, Irungalur, Trichy - 621 105: Co6 L3Ap Co4 L1ReDocumento2 páginasSRM TRP Engineering College, Irungalur, Trichy - 621 105: Co6 L3Ap Co4 L1RemyidmaranAinda não há avaliações

- One World Trade CenterDocumento31 páginasOne World Trade Centersakshi meherAinda não há avaliações

- 1 - Architectural Interiors and The Theories of Architecture Module PDFDocumento35 páginas1 - Architectural Interiors and The Theories of Architecture Module PDFJamie Jordan100% (2)

- Borobudur Is A Buddhist TempleDocumento2 páginasBorobudur Is A Buddhist TempleAndini FatmawatiAinda não há avaliações

- Area StatementDocumento4 páginasArea StatementSwetha GopinathAinda não há avaliações

- Principles of Building PlanningDocumento19 páginasPrinciples of Building PlanningNikhil VishavkramaAinda não há avaliações

- SATIP Summary - Civil Rev1Documento16 páginasSATIP Summary - Civil Rev1راجہ شہزاد انور100% (1)

- Building Construction Technology - Assignment 01 (Semester 01)Documento50 páginasBuilding Construction Technology - Assignment 01 (Semester 01)Anushke Hennayake86% (7)

- Site AnalysisDocumento3 páginasSite AnalysisRahul ChandraAinda não há avaliações

- Chinese: By: Gie Gie Diala and Precious OdnimerDocumento69 páginasChinese: By: Gie Gie Diala and Precious OdnimerAngeline Diala100% (2)

- High Rise Building Data SheetDocumento1 páginaHigh Rise Building Data SheetjajajajAinda não há avaliações

- Architecturetosc 00 GranuoftDocumento240 páginasArchitecturetosc 00 GranuoftGlauco RomeoAinda não há avaliações