Escolar Documentos

Profissional Documentos

Cultura Documentos

Sulphur

Enviado por

bonda_gtvDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sulphur

Enviado por

bonda_gtvDireitos autorais:

Formatos disponíveis

4/21/2015

Sulphur Piping

Sulphuric Acid on the WebTM

Knowledge for the

Sulphuric Acid

Industry

Sulphuric Acid on

the Web

Introduction

General

Equipment Suppliers

Contractor

Instrumentation

Industry News

Maintenance

Acid Traders

Organizations

Fabricators

Conferences

Used Plants

Intellectual Propoerty

Acid Plant Database

Market Information

Library

Technical Manual

Introduction

General

Definitions

Instrumentation

Plant Safety

Metallurgial Processes

Metallurgical

Sulphur Burning

Acid Regeneration

Lead Chamber

Technology

Gas Cleaning

Contact

Strong Acid

Acid Storage

Loading/Unloading

Transportation

Sulphur Systems

Liquid SO2

Boiler Feed Water

Steam Systems

Cooling Water

Effluent Treatment

Utilities

Construction

Maintenance

Inspection

Analytical Procedures

Materials of Construction

Corrosion

Properties

Vendor Data

DKL Engineering, Inc.

Handbook of Sulphuric Acid

Manufacturing

Order Form

Preface

Contents

Feedback

Technical Manual

DKL Engineering, Inc.

Sulphur Systems - Sulphur Piping

September 8, 2010

Introduction

Piping

Valves

Service Conditions

Molten Sulphur

Steam Jacket

Gaskets

Steam Jumpers

Associated Links

Sulphur Properties

Sulphur Safety

Sulphur Melting

Sulphur Filtration

Sulphur Storage

Sulphur Furnace

Procedures

Introduction

It is a design and operating challenge to move molten sulphur around a plant. To

keep the sulphur molten and pumpable at the proper viscosity, all piping and

equipment handling molten sulphur must be heated and insulated. Steam

jacketed piping is by far the most common way of conveying molten sulphur

throughout the plant. Less common methods are steam or electrical tracing.

Piping

Jacketed piping is basically a pipe within a pipe. Molten sulphur flows in the

central or core pipe while steam flows in the annular space formed between the

two pipes. Sulphur piping will generally be carbon steel, seamless pipe supplied

to ASTM A106 Gr. B and/or ASTM A53 Gr. B. Standard sizes of jacketed pipe

for molten sulphur are:

Core Pipe

Pipe Jacket

Flange

1"

2"

6" O.D. x 1" I.D.

1"

2"

7" O.D. x 1" I.D.

2"

3"

7" O.D. x 2" I.D.

3"

4"

9" O.D. x 3" I.D.

4"

6"

11" O.D. x 4" I.D.

6"

8"

13" O.D. x 6" I.D.

8"

10"

16" O.D. x 8" I.D.

Schedule 80 pipe is recommended for pipe sizes 2" and smaller.

Schedule 40 pipe is recommended for pipe sizes larger than 2".

Valves

For on/off service, jacketed plug valves are generally used in molten sulphur

service. Two acceptable plug valves for this service are manufactured by XOMOX

and Durco. Both manufacturers offer partially and fully jacketed valves. Partially

jacketed valves provide uniform heat dissipation and is suitable for most

applications because of the plug valve configuration and a certain amount of

insulating effect of the PTFE sleeve. Fully jacketed valves are for maximum

http://www.sulphuric-acid.com/techmanual/sulphur/piping.htm#Molten Sulphur

1/3

4/21/2015

Sulphur Piping

Sulphuric Acid Decolourization

Order Form

Preface

Table of Contents

heating or cooling duties without regard to uniform heating of surfaces in contact

with the media. For molten sulphur applications, partially jacketed valves are

suitable provided insulation is maintained in good condition.

Process Engineering Data

Sheets - PEDS

Order Form

Table of Contents

Introduction

The valve body is generally cast steel with a ductile cast iron plug. The plug

rotates in a PTFE sleeve that is locked in the body by raised metal lips and

grooves surrounding the body parts.

Bibliography of Sulphuric Acid

Technology

Order Form

Preface

Contents

Sulphuric Acid Plant

Specifications

Google Search

Partially jacketed valves are available in sizes from 25 mm to 300 mm (1" to 12")

in the 150 lb. rating. 300 lb. rated valves are available from 25 mm to 200 mm (1"

to 8") but are generally not required in most acid plant applications.

Valves smaller than 80 or 100 mm (3" or 4") will be wrench operated while larger

valves are equipped with a gear operator.

Tradename

XOMOX

Durco

Tufline

Sleeveline

Model No. (150 lb. rating)

067PJ (partially jacketed) PJG411 (partially jacketed)

067FJ (fully jacketed)

FJG411 (fully jacketed)

Size Range

25 to 300 mm (1" to 12")

(PJ, 150 lb)

25 to 150 mm (1" to 6")

(FJ, 150 lb)

25 to 300 mm (1" to 12")

(PJ, 150 lb)

25 to 150 mm (1" to 6")

(FJ, 150 lb)

Service Conditions

Molten Sulphur

Piping should be designed and rated for the maximum pump

discharge pressure. For plants operating with sulphur guns in the

sulphur furnace, operating pressures can be quite high since a high

spray nozzle pressure drop is required to finely atomize the sulphur.

Piping should be designed for a maximum temperature of 170C

(338F).

A 2 mm corrosion allowance is recommended.

Steam Jacket

The operating pressure of the steam jacket will generally be 3.45 bar

(g) (50 psig). The system will be protected from overpressure by a

relief valve located on the steam header downstream of the pressure

reducing station.

The jacketing pipe should be designed for a maximum temperature

of 170C (338F).

A 2 mm corrosion allowance is recommended.

Gaskets

Early piping system used 3 mm (1/8") compressed asbestos gaskets for flanged

connections. Many companies prohibit the use of asbestos so an alternative

must be used. Spiral wound gaskets to API Standard 601 made of 304 S.S. and

flexible graphite are a good alternative.

Steam Jumpovers

Steam jumpovers can be hard

piped using standard carbon steel

pipe fiittings, stainless steel

tubing with 'Swagelok' type fittings

or flexible hoses. By far the

easiest to install and maintain are

flexible hose jumpovers.

Flexible jumpovers are either

annular or helical flexible metal

hose constructed of 300 series stainless steel for the hose and outer braid.

http://www.sulphuric-acid.com/techmanual/sulphur/piping.htm#Molten Sulphur

2/3

4/21/2015

Sulphur Piping

Flexible jumpovers can also be obtained pre-insulated. Hoses come in standard

lengths of 560, 760 and 1220 mm ( 22", 30" and 48"). Diameters of hose are 13,

19 and 25 mm (1/2", 3/4" and 1") diameter.

Copyright 2005-2011 DKL Engineering, Inc., All Rights Reserved

DKL Engineering, Inc. shall not be held liable for any type of damages resulting from the use of this information. The user assumes all risk and liability in connection with the use of information contained in this and associated web

sites. The data is intended for personal, non-commercial use.

http://www.sulphuric-acid.com/techmanual/sulphur/piping.htm#Molten Sulphur

3/3

Você também pode gostar

- Packed TowersDocumento44 páginasPacked Towersnawazkhan98482Ainda não há avaliações

- Aluminium Window SpecificationDocumento4 páginasAluminium Window SpecificationPraveenSharma100% (1)

- IntercambiadorDocumento2 páginasIntercambiadorIr Go JarAinda não há avaliações

- Symphos-Devco Presentation May 2015 FinalDocumento51 páginasSymphos-Devco Presentation May 2015 FinalIrsan Bin MustaminAinda não há avaliações

- Durco Pressure Leaf Sulfur FiltrationDocumento3 páginasDurco Pressure Leaf Sulfur FiltrationBhusarapu SrinivasAinda não há avaliações

- 2014 Suphur Mag Article S-354-WasteHeatBoilers PMIDocumento4 páginas2014 Suphur Mag Article S-354-WasteHeatBoilers PMIEjaj SiddiquiAinda não há avaliações

- New Sulfur Melting Technology Mark Gilbreath - USADocumento51 páginasNew Sulfur Melting Technology Mark Gilbreath - USARenalyn Torio100% (1)

- WSAC Alternative To CWDocumento47 páginasWSAC Alternative To CWweweqweqwAinda não há avaliações

- Ud He TechnologyDocumento16 páginasUd He TechnologyBejavada Suresh100% (1)

- Implement A Sustainable Steam Trap Management Program AicheDocumento7 páginasImplement A Sustainable Steam Trap Management Program AicheSai Praneethtej SaspretAinda não há avaliações

- Minimum Requirements For The Basic Design of Winterization SystemsDocumento7 páginasMinimum Requirements For The Basic Design of Winterization SystemsAnonymous v5uipHAinda não há avaliações

- Makalah Convection Section Cleaning 4Documento7 páginasMakalah Convection Section Cleaning 4akjayaAinda não há avaliações

- Cara Menentukan Ukuran Steam TrapDocumento5 páginasCara Menentukan Ukuran Steam TraprafiradityaAinda não há avaliações

- Granulation of MAPDocumento3 páginasGranulation of MAPIrvan Key RizkyAinda não há avaliações

- Nickel Alloys For Sulfuric Acid ProductionDocumento5 páginasNickel Alloys For Sulfuric Acid ProductionHeanjiaAlloysAinda não há avaliações

- Stainless Steels For H2SO4Documento4 páginasStainless Steels For H2SO4Marshel LeninAinda não há avaliações

- Strategies For Reducing Start-Up Emissions From Sulfuric Acid PlantsDocumento19 páginasStrategies For Reducing Start-Up Emissions From Sulfuric Acid PlantsAbu Izzan Al BunyAinda não há avaliações

- Tank Heating CoilDocumento2 páginasTank Heating CoilchongchoifattAinda não há avaliações

- OTE Outotec LURO2 Sulfur Burner Eng WebDocumento4 páginasOTE Outotec LURO2 Sulfur Burner Eng WebI. Murali KrishnaAinda não há avaliações

- Sulphuric AcidDocumento2 páginasSulphuric Acidapi-239546340Ainda não há avaliações

- Process Units: Raw Gas GAS Ethane Propane Butane Condensate Sulfur & Acid GAS DSO Meg + WaterDocumento39 páginasProcess Units: Raw Gas GAS Ethane Propane Butane Condensate Sulfur & Acid GAS DSO Meg + WaterYasser JaviAinda não há avaliações

- Pressure Vessel DesignDocumento8 páginasPressure Vessel DesignSihanu SubasinghaAinda não há avaliações

- Sulfur PipelineDocumento26 páginasSulfur Pipelinerahul_pratapAinda não há avaliações

- Vapour Pressure DataDocumento44 páginasVapour Pressure Dataramsrivatsan50% (2)

- Piping Design Articles by Robert Kern PDFDocumento53 páginasPiping Design Articles by Robert Kern PDFDiego IQ100% (1)

- DS-TI Tower InternalsDocumento10 páginasDS-TI Tower Internalschris100% (1)

- KM 111Documento12 páginasKM 111Jak AshishAinda não há avaliações

- TA29Documento5 páginasTA29abderrahimnAinda não há avaliações

- MOGAS Refining Valve Application GuideDocumento28 páginasMOGAS Refining Valve Application Guidecristi_molinsAinda não há avaliações

- Flue-Gas Desulfurization - Wikipedia, The Free EncyclopediaDocumento8 páginasFlue-Gas Desulfurization - Wikipedia, The Free EncyclopediaPraveen KhatriAinda não há avaliações

- Sulphur Magazine - Mar-Apr 2013 - Preventing Corrosion in Sulphur Storage TanksDocumento6 páginasSulphur Magazine - Mar-Apr 2013 - Preventing Corrosion in Sulphur Storage TanksmarraezAinda não há avaliações

- CASE STUDY On Phosphoric Acid Plant ProcessDocumento3 páginasCASE STUDY On Phosphoric Acid Plant ProcessIsrael NarvastaAinda não há avaliações

- BF-9201 US F-200 DatasheetDocumento3 páginasBF-9201 US F-200 DatasheetNguyễn Kim HùngAinda não há avaliações

- pp57-65 MS06Documento9 páginaspp57-65 MS06vikaskatheriaAinda não há avaliações

- PPTDocumento86 páginasPPTAjeet Sony100% (1)

- US8349170 - Components of Riser and Reactor SectionDocumento25 páginasUS8349170 - Components of Riser and Reactor SectionPraveen KumarAinda não há avaliações

- Exhanger Leakages in VDU - ModifiedDocumento14 páginasExhanger Leakages in VDU - ModifiedJay LawsonAinda não há avaliações

- Molten Sulphur Lining Marts96Documento30 páginasMolten Sulphur Lining Marts96LuisAinda não há avaliações

- Low Cost Reliable Sulfur RecoveryDocumento11 páginasLow Cost Reliable Sulfur RecoveryiboAinda não há avaliações

- Presentation MSDS Sulfuric AcidDocumento24 páginasPresentation MSDS Sulfuric Acidtatoo1Ainda não há avaliações

- AFRC - Improving Performance of Coker HeatersDocumento29 páginasAFRC - Improving Performance of Coker Heatersashutosh_garg_10Ainda não há avaliações

- ZeCor® Sulfuric Acid Plant Towers and PumDocumento4 páginasZeCor® Sulfuric Acid Plant Towers and PumacckypenrynAinda não há avaliações

- 2000 Ifa Neworleans GobbitDocumento14 páginas2000 Ifa Neworleans GobbitFajar ZonaAinda não há avaliações

- EDV G NozzleDocumento47 páginasEDV G NozzlePaul BooneAinda não há avaliações

- Polybed PSADocumento2 páginasPolybed PSAJeEJyZaAinda não há avaliações

- Sulfur Magazine Ideas For Better Clean Up Jan 09Documento0 páginaSulfur Magazine Ideas For Better Clean Up Jan 09Bharat VaajAinda não há avaliações

- Ote Outotec Edmeston SX Sulphuric Acid Steel Eng WDocumento2 páginasOte Outotec Edmeston SX Sulphuric Acid Steel Eng WacckypenrynAinda não há avaliações

- S-000-1360-0903J - A - 010 Technical Specification For Sulfur Steam Heating SystemsDocumento10 páginasS-000-1360-0903J - A - 010 Technical Specification For Sulfur Steam Heating Systemsphan hoang diepAinda não há avaliações

- High Emissivity CoatingDocumento12 páginasHigh Emissivity CoatingĐoàn TrangAinda não há avaliações

- Energy Consumption of Tanks & VatsDocumento12 páginasEnergy Consumption of Tanks & Vatsamechmar5935Ainda não há avaliações

- Whrs ManualDocumento41 páginasWhrs ManualAKHLESH JHALLAREAinda não há avaliações

- Acid DewpointDocumento4 páginasAcid DewpointCowdrey IlanAinda não há avaliações

- Topsoe Sec Ref Cat RKS 2Documento5 páginasTopsoe Sec Ref Cat RKS 2Vo Duc Minh MinhAinda não há avaliações

- Catacarb Section, Dawood Hercules Fertilizers LimitedDocumento16 páginasCatacarb Section, Dawood Hercules Fertilizers LimitedMuddassar Sultan100% (1)

- KVTBrochure 19122012 PDFDocumento12 páginasKVTBrochure 19122012 PDFvb_pol@yahooAinda não há avaliações

- Synloop Waste Heat Boiler in Ammonia Plants: Borsig Process Heat Exchanger GMBHDocumento20 páginasSynloop Waste Heat Boiler in Ammonia Plants: Borsig Process Heat Exchanger GMBHArif AhmedAinda não há avaliações

- Choosing Trays and Packings For Distillation: Back To BasicsDocumento7 páginasChoosing Trays and Packings For Distillation: Back To Basicsmsn1981Ainda não há avaliações

- Refinery Sour Water StrippingDocumento2 páginasRefinery Sour Water StrippingramaAinda não há avaliações

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988No EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockAinda não há avaliações

- JacketDocumento1 páginaJacketNirmal SubudhiAinda não há avaliações

- Pipeline in Nutshell (Presentation For Structural Engineering Students)Documento31 páginasPipeline in Nutshell (Presentation For Structural Engineering Students)bonda_gtv0% (1)

- Nominal Pipe Size Chart in MMDocumento1 páginaNominal Pipe Size Chart in MMbonda_gtvAinda não há avaliações

- Mega Job Mela: Saturday, 24 March 2018: 830hrs-1400hrs: DR Sivanthi Aditanar College of Engineering, TiruchendurDocumento2 páginasMega Job Mela: Saturday, 24 March 2018: 830hrs-1400hrs: DR Sivanthi Aditanar College of Engineering, Tiruchendurbonda_gtvAinda não há avaliações

- Piping Code ASME B31 PDFDocumento1 páginaPiping Code ASME B31 PDFbonda_gtvAinda não há avaliações

- Chennai Shivir-List of HotelsDocumento26 páginasChennai Shivir-List of Hotelsbonda_gtvAinda não há avaliações

- RAB Kanopi MoewardiDocumento24 páginasRAB Kanopi Moewardiemail kerjaAinda não há avaliações

- G30-97 (Reapproved 2015) PDFDocumento7 páginasG30-97 (Reapproved 2015) PDFHadi HowaidaAinda não há avaliações

- Capral Industrial Products QLDDocumento41 páginasCapral Industrial Products QLDKevin YewAinda não há avaliações

- Lecture 4Documento18 páginasLecture 4Awwal EdrisAinda não há avaliações

- RRLDocumento5 páginasRRLErick Sumicad0% (1)

- Martensitic Stainless Steel EN 1.4021-QT 700Documento2 páginasMartensitic Stainless Steel EN 1.4021-QT 700LebasAinda não há avaliações

- One 74 SpecificationsDocumento1 páginaOne 74 SpecificationsNidz ReddyAinda não há avaliações

- Com Apps Preliminary SizingDocumento8 páginasCom Apps Preliminary SizingTom SawyerAinda não há avaliações

- WFT101353 Weatherford Valves - CatalogoDocumento13 páginasWFT101353 Weatherford Valves - Catalogoandres peraltaAinda não há avaliações

- Fameg Pricelist2020 EURDocumento99 páginasFameg Pricelist2020 EURjganso0% (1)

- Polyester ValsparDocumento2 páginasPolyester ValsparsuksesAinda não há avaliações

- (AWS A5.20 E71T-1) : Technical ReportDocumento2 páginas(AWS A5.20 E71T-1) : Technical ReportRyu RyuAinda não há avaliações

- 1 Sand Casting ProcessDocumento50 páginas1 Sand Casting ProcessMuhammad Ishaq100% (1)

- 20181210T102654 Silver Bridge DisasterDocumento9 páginas20181210T102654 Silver Bridge Disastergerard correaAinda não há avaliações

- Combined Test Piece For X-Ray ScreenerDocumento2 páginasCombined Test Piece For X-Ray Screenersanjeev kumar verma88% (8)

- Weld DistortionDocumento5 páginasWeld DistortionNSunAinda não há avaliações

- Media Lab BOQ BlankDocumento215 páginasMedia Lab BOQ BlankSomesh ChandolaAinda não há avaliações

- 1.1 Definitions and Classifications Building MaterialsDocumento7 páginas1.1 Definitions and Classifications Building Materialsjack.simpson.changAinda não há avaliações

- Advisory Guidelines For Design and Construction of Roads DT 01 May 2019Documento11 páginasAdvisory Guidelines For Design and Construction of Roads DT 01 May 2019Piyush SoniAinda não há avaliações

- YtDocumento4 páginasYtDinesh TaragiAinda não há avaliações

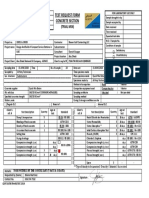

- Test Request Form Concrete Section: (Trial Mix)Documento1 páginaTest Request Form Concrete Section: (Trial Mix)Nimish MadananAinda não há avaliações

- Admixture Technical Sheet - ATS 12 Pumping Admixtures: 1 FunctionDocumento2 páginasAdmixture Technical Sheet - ATS 12 Pumping Admixtures: 1 FunctionDileepa DissanayakeAinda não há avaliações

- Ch-21 Sand CastingDocumento156 páginasCh-21 Sand CastingDivya SoniAinda não há avaliações

- ASTM D3183 10 - Standard Practice For Rubber-Preparation of Pieces For Test Purposes From ProductsDocumento2 páginasASTM D3183 10 - Standard Practice For Rubber-Preparation of Pieces For Test Purposes From ProductsAndre SpirimAinda não há avaliações

- B. Importance of Preheat, Interpass, DHT, Isr, PWHTDocumento19 páginasB. Importance of Preheat, Interpass, DHT, Isr, PWHTJay ShahAinda não há avaliações

- C.0738.PP9.05P - Bulk Piping & Fittings BOQ For Process Water SupplyDocumento4 páginasC.0738.PP9.05P - Bulk Piping & Fittings BOQ For Process Water Supplyfakir mohammadAinda não há avaliações

- ZubehoerDocumento15 páginasZubehoerimtiyazAinda não há avaliações

- CS2500Documento528 páginasCS2500David Muñoz CastroAinda não há avaliações

- Galvanic Corrosion - Fact Sheet #10Documento3 páginasGalvanic Corrosion - Fact Sheet #10onayasAinda não há avaliações