Escolar Documentos

Profissional Documentos

Cultura Documentos

Vertical Roller Mills 01

Enviado por

Kariem R NoweerDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Vertical Roller Mills 01

Enviado por

Kariem R NoweerDireitos autorais:

Formatos disponíveis

w w w . c e m t e c .

a t

VERTICAL

ROLLER MILLS

CEMTEC your partner for success.

CEMTEC operates on the basis of individual responsibility. Every member of our team

has the right to make high-level decisions. The entire responsibility for a project from

planning to commissioning rests with a single person. This means that you have the

same, competent contact partner for all your queries, wishes and suggestions, without

exception. In addition to standard orders, your individual requirements are also fulfilled

rapidly and without complications.

CEMTEC HEADQUARTERS IN ENNS AUSTRIA

CEMTEC manages projects throughout the world

for the cement and processing industry.

CEMTEC manages every project from start to finish. From planning

to commissioning. Our product spectrum includes tube mills for

grinding a wide range of bulk materials and minerals, as well as

rotating drums for thermal treatment (calcination, drying, cooling)

and mechanical processing (mixing, washing, conditioning, etc.)

of different bulk materials. We also offer erection supervision,

commissioning and technical support. Successful projects all

over the world attest to the competence of CEMTEC.

w w w. c e m t e c . a t

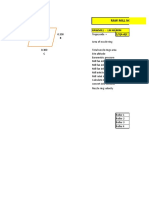

STANDARD SIZES AND DIMENSIONS

DIMENSIONS [mm]

VRM-M FOR FINENESS RANGES FROM d50 = 2-20 m

MILL TYPE TABLE

DIAMETER

[mm]

VRM 6-M

670

VRM 8-M

800

VRM 10-M 1,000

VRM 12-M 1,200

VRM 14-M 1,400

VRM 16-M 1,600

VRM 20-M 2,000

ROLLER

DIAMETER

[mm]

450

570

710

850

1,080

1,150

1,300

NUMBER

INSTALLED

OF ROLLERS MOTOR POWER

[kW]

3

37 - 55

3

55 - 110

3

110

3

132

3

200

3

315

3

355

SEPARATOR AIR FLOW

WEIGHT

[m/h]

4,200 6,600

6,600 10,800

10,800 15,000

15,000 24,000

24,000 32,400

32,400 40,800

40,800 54,000

[to]

7.6

10.2

19.4

27.5

35.0

49.6

88.9

A

2,500

2,900

3,600

4,800

5,050

5,750

7,200

B

2,300

2,700

3,400

4,500

4,700

5,400

6,700

C

1,000

1,200

1,500

1,800

2,100

2,400

3,000

D

1,850

2,150

2,700

3,200

3,800

4,300

5,400

E

2,000

2,380

3,000

3,600

4,200

4,800

5,950

F

3,400

4,000

5,000

6,800

7,000

8,000

10,000

TYPE M

(*dimensions may vary slightly)

50.0

45.0

Specific Power Consumption [kWh/to]

40.0

Specific power consumption - avg [kWh/to] [kW/to]

Specific power consumption - min [kWh/to] [kW/to]

Specific power consumption - max [kWh/to] [kW/to]

Diameter d98 [m]

250.0

200.0

35.0

30.0

150.0

25.0

20.0

100.0

15.0

10.0

50.0

5.0

0.0

10.0

Particle Size Diameter d50 [m]

20.0

0.0

Particle Size Diameter d98 [m]

VERTICAL ROLLER MILL TYPE M

STANDARD SIZES AND DIMENSIONS

VRM-C FOR FINENESS RANGES STARTING FROM d50 = 10 m

MILL TYPE TABLE

DIAMETER

[mm]

VRM 10-C 1,000

VRM 12-C 1,200

VRM 14-C 1,400

VRM 16-C 1,600

VRM 20-C 2,000

VRM 22-C 2,200

VRM 26-C 2,600

ROLLER

DIAMETER

[mm]

710

850

1,080

1,150

1,300

1,450

1,680

NUMBER

INSTALLED

OF ROLLERS MOTOR POWER

[kW]

3

150

3

250

3

315

3

400

3

630

3

700

3

1,000

DIMENSIONS [mm]

SEPARATOR AIR FLOW

WEIGHT

[m/h]

19,000 30,000

30,000 45,000

45,000 75,000

45,000 75,000 90,000

75,000 90,000 110,000

90,000 110,000 140,000

110,000 140,000 185,000

[to]

20.2

28.6

36.5

51.7

92.6

131.4

206.3

A

3,600

4,300

5,050

6,000

7,200

7,900

9,350

B

3,400

4,100

4,700

5,200

6,700

7,400

8,750

C

1,500

1,800

2,100

3,300

3,000

3,250

3,830

D

2,700

3,300

3,800

5,200

5,400

6,000

7,000

E

4,700

5,650

6,600

8,600

9,400

10,300

12,200

F

5,600

6,700

7,800

9,400

11,200

12,200

14,400

TYPE C

(*dimensions may vary slightly)

VERTICAL ROLLER MILL TYPE C

45.0

Specific Power Consumption [kWh/to]

40.0

250.0

Specific power consumption - avg [kWh/to] [kW/to]

Specific power consumption - min [kWh/to] [kW/to]

Specific power consumption - max [kWh/to] [kW/to]

Diameter d98 [m]

200.0

35.0

30.0

150.0

25.0

20.0

100.0

15.0

10.0

50.0

5.0

0.0

10.0

20.0

30.0

Particle Size Diameter d50 [m]

40.0

0.0

Particle Size Diameter d98 [m]

50.0

VERTICAL ROLLER MILLS

CEMTEC vertical roller mills for every requirement.

The CEMTEC vertical roller mill is a completely new and innovative design and a further

step to more efficient grinding of soft and medium-hard products. The basic concept is

based on a combination of the lower section of the mill featuring the roller and its supports,

the grinding table and drive system, together with a series of highly efficient classifiers.

Depending on the different product requirements the mill can be equipped with different

types of separators. For fine grinding the separator type CTM is used, for coarse grinding

the separator type CTC.

The mill combines established technical features with a new innovative support and drive

system. This innovative support and drive system incorporates a bearing cartridge with slide

shoe bearings and a standard bevel gear box with an electric motor. As a result of this

system the forces generated by the grinding action are retained within the vertical roller

mill structure and not conducted to the foundations. This makes civil engineering works

less expensive.

In order to design its vertical roller mills to product specifications, CEMTEC performs inhouse laboratory tests to ensure proper process design of its equipment.

CEMENT & MINING

TECHNOLOGY WORLDWIDE

w w w . c e m t e c . a t

EACH PROJECT STARTS

IN OUR PILOT PLANT!

HEADQUARTERS

CEMTEC Cement and Mining Technology GmbH

Ennshafenstrae 40

4470 Enns

Austria

( +43/7223/83620-0

+43/7223/83620-333

- info@cemtec.at

2013, CEMTEC Cement and Mining Technology GmbH

Você também pode gostar

- Active Redundancy ConceptDocumento9 páginasActive Redundancy ConceptRollerJonnyAinda não há avaliações

- One Kiln - 13,000 TPD: Cement & MineralsDocumento52 páginasOne Kiln - 13,000 TPD: Cement & MineralsKristínaAinda não há avaliações

- Vertical Roller MillDocumento3 páginasVertical Roller MillChaitanya Chinta0% (1)

- Vertical Roller Mill IntroductionDocumento2 páginasVertical Roller Mill Introductionemad sabriAinda não há avaliações

- SikaGrind For Vertical Roller Mills PDFDocumento8 páginasSikaGrind For Vertical Roller Mills PDFEduardo RojasAinda não há avaliações

- Quest - Vertical Roller Mill - KM (Rough)Documento6 páginasQuest - Vertical Roller Mill - KM (Rough)Raji SuriAinda não há avaliações

- Bucket ElevatorsDocumento30 páginasBucket ElevatorsarhescobarAinda não há avaliações

- PFC - The Great CoolerDocumento47 páginasPFC - The Great CoolerM.IBRAHEEM100% (1)

- For Cement and Minerals: Complete SolutionsDocumento36 páginasFor Cement and Minerals: Complete SolutionsHamed MostafaAinda não há avaliações

- MARCH 17, 2017: India's Biggest OK™ Mill - A Story of Reliable Operations and Smoother PerformanceDocumento2 páginasMARCH 17, 2017: India's Biggest OK™ Mill - A Story of Reliable Operations and Smoother PerformanceRahul RoyAinda não há avaliações

- Ball Mill For Cement GrindingDocumento5 páginasBall Mill For Cement GrindingNkosilozwelo Sibanda100% (1)

- SinomaDocumento52 páginasSinomansprasad88Ainda não há avaliações

- Vertical Roller Mills KTM enDocumento6 páginasVertical Roller Mills KTM enJoko Dewoto100% (1)

- OK MillDocumento52 páginasOK MillHazem Hasan100% (2)

- Grinding Mills Optimisation: Magotteaux / Slegten / Sturtevant SolutionsDocumento44 páginasGrinding Mills Optimisation: Magotteaux / Slegten / Sturtevant Solutionsshani5573100% (1)

- Cement Vertical Mill Vs Ball MillDocumento17 páginasCement Vertical Mill Vs Ball Millanrulo50% (2)

- Vertical Roller Pre Grinding Mill by AMCLMachinery Limited@ Mangalam CementsDocumento16 páginasVertical Roller Pre Grinding Mill by AMCLMachinery Limited@ Mangalam CementsRahul RoyAinda não há avaliações

- Rotary Kiln Reconditioning Tyre and Roller GrindingDocumento8 páginasRotary Kiln Reconditioning Tyre and Roller GrindingTiago CamposAinda não há avaliações

- Raw MealDocumento48 páginasRaw Mealrashmiranjan1110Ainda não há avaliações

- Machines and Processes For The Cement IndustryDocumento19 páginasMachines and Processes For The Cement IndustryAli Alshaqah100% (1)

- 04 Vertical Roller MillsDocumento12 páginas04 Vertical Roller MillsaktaserdincAinda não há avaliações

- Ok Vertical Roller Mill V 3Documento8 páginasOk Vertical Roller Mill V 3Andra EneAinda não há avaliações

- Cement Chapter 4Documento11 páginasCement Chapter 4shani5573100% (2)

- Ball MillDocumento23 páginasBall MillSajjad Rasool ChaudhryAinda não há avaliações

- 01-01-PODFA-Equipment OverviewDocumento31 páginas01-01-PODFA-Equipment OverviewДен СтаднікAinda não há avaliações

- A Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BDocumento4 páginasA Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BYhaneAinda não há avaliações

- Phi-Fer MillDocumento20 páginasPhi-Fer MillRahul Roy100% (1)

- Scenario - Hot Spot On Kiln - Questions - Jan12 FINAL-TABLESSEDocumento11 páginasScenario - Hot Spot On Kiln - Questions - Jan12 FINAL-TABLESSEAnonymous 3ESYcrKPAinda não há avaliações

- Co Processing Cement KilnsDocumento10 páginasCo Processing Cement Kilnshanhccid0% (1)

- Training For Tensioning Hydraulic System MPS MillsDocumento69 páginasTraining For Tensioning Hydraulic System MPS MillsImam SampoernoAinda não há avaliações

- Cement Mill - Ball Mill DynamicsDocumento36 páginasCement Mill - Ball Mill DynamicsRohit Manglik100% (1)

- PCCL Cement CourseDocumento3 páginasPCCL Cement CourseAmr A. NaderAinda não há avaliações

- Proceedings Rev A English - Print ResDocumento130 páginasProceedings Rev A English - Print ResRaúl Marcelo Veloz100% (1)

- Ac-Dc KilnsDocumento10 páginasAc-Dc KilnsPrateek SinghAinda não há avaliações

- OK MillDocumento52 páginasOK MillYhaneAinda não há avaliações

- Gebr. Pfeiffer Brochure Passion For Grinding enDocumento28 páginasGebr. Pfeiffer Brochure Passion For Grinding enRollerJonnyAinda não há avaliações

- 13-IMS 2021 Roller PressDocumento63 páginas13-IMS 2021 Roller Presshmaza shakeelAinda não há avaliações

- Preblending of Raw Materia1Documento26 páginasPreblending of Raw Materia1Mohammed Abdo100% (1)

- Cement Mill ReportDocumento13 páginasCement Mill ReportYhaneAinda não há avaliações

- Manual For Visual Inspection of HPGR Rollers: Top PictureDocumento1 páginaManual For Visual Inspection of HPGR Rollers: Top PictureRAVIAinda não há avaliações

- Vertical Roller Mill SummaryDocumento20 páginasVertical Roller Mill SummaryPhyo Thura Htay100% (6)

- 04 Ravishankar Madras Cement Journey of Loesche Mills in Ramco GroupDocumento38 páginas04 Ravishankar Madras Cement Journey of Loesche Mills in Ramco GroupFauzan HamdaniAinda não há avaliações

- Cement Mill Ball Mill TestingDocumento30 páginasCement Mill Ball Mill Testingzementhead100% (2)

- Condition Monitoring Benefits For Cement ManufacturingDocumento12 páginasCondition Monitoring Benefits For Cement ManufacturingEhab SabryAinda não há avaliações

- Cement Mill Shell LinerDocumento7 páginasCement Mill Shell LinerMahaveer SinghAinda não há avaliações

- Loesche-Mills: For Cement Raw MaterialDocumento28 páginasLoesche-Mills: For Cement Raw Materialboyka yuriAinda não há avaliações

- 03 RP - Maintenance Practices For RPDocumento50 páginas03 RP - Maintenance Practices For RPaff bearAinda não há avaliações

- VRM 227Documento43 páginasVRM 227Hazem Hasan100% (2)

- 01.0 - 22146.002E - Hydraulic SystemDocumento126 páginas01.0 - 22146.002E - Hydraulic SystemShariq Khan100% (1)

- 15th NCB Technical PaperDocumento10 páginas15th NCB Technical PaperSalah RomdaniAinda não há avaliações

- Powerpoint VRMDocumento14 páginasPowerpoint VRMAlisa Azizah100% (2)

- Docslide - Net - Optimization of Vertical Raw Mill Operation PDFDocumento32 páginasDocslide - Net - Optimization of Vertical Raw Mill Operation PDFAnonymous PEstm2c9dzAinda não há avaliações

- Foundation For Roller PressDocumento3 páginasFoundation For Roller PressRollerJonny0% (1)

- Vertical Roller MillDocumento2 páginasVertical Roller MillAhmed Younis0% (2)

- Ball Main Motor Rated Power Calculation With Gear Box DetailsDocumento1 páginaBall Main Motor Rated Power Calculation With Gear Box DetailsVijay BhanAinda não há avaliações

- 2010 10 SMP - Grinding of Kiln Tyre and Roller Surface - Final - V1Documento19 páginas2010 10 SMP - Grinding of Kiln Tyre and Roller Surface - Final - V1Wisnu IndriyantoAinda não há avaliações

- LoescheDocumento35 páginasLoescheayaskant751001Ainda não há avaliações

- Slegten Opticontrol PDFDocumento4 páginasSlegten Opticontrol PDFjorge1947100% (1)

- Windsichter CTC 4Documento12 páginasWindsichter CTC 4LuisFernándezAinda não há avaliações

- Standing Up To Any Challenge. Famup MC and MCP: E M Conomy MeansDocumento8 páginasStanding Up To Any Challenge. Famup MC and MCP: E M Conomy MeansskidamdnevnoAinda não há avaliações

- BAGS Purchase Request (Items) PDFDocumento1 páginaBAGS Purchase Request (Items) PDFKariem R NoweerAinda não há avaliações

- Description: هدحولا consumption sales required in tons required material unit 5-Feb-19 STOCK IN 1 APRDocumento24 páginasDescription: هدحولا consumption sales required in tons required material unit 5-Feb-19 STOCK IN 1 APRKariem R NoweerAinda não há avaliações

- Estimation Cost: Al Watania Gypsum Co. LTDDocumento2 páginasEstimation Cost: Al Watania Gypsum Co. LTDKariem R NoweerAinda não há avaliações

- Elec Invo PDFDocumento1 páginaElec Invo PDFKariem R NoweerAinda não há avaliações

- 558Documento1 página558Kariem R NoweerAinda não há avaliações

- Hotoil PumpDocumento2 páginasHotoil PumpKariem R Noweer100% (1)

- Al Watinya Gyp c32 DecDocumento4 páginasAl Watinya Gyp c32 DecKariem R NoweerAinda não há avaliações

- Tyre Coupling CatalogDocumento9 páginasTyre Coupling CatalogKariem R NoweerAinda não há avaliações

- Perkins® 4012-46TWG2ADocumento1 páginaPerkins® 4012-46TWG2AKariem R Noweer50% (2)

- Common RailDocumento3 páginasCommon RailKariem R Noweer100% (1)

- 1491911172gypsemna Product Catalogue 2017Documento64 páginas1491911172gypsemna Product Catalogue 2017Kariem R NoweerAinda não há avaliações

- High Calcium Aluminate Cements and Chemical BindersDocumento16 páginasHigh Calcium Aluminate Cements and Chemical BindersKariem R NoweerAinda não há avaliações

- Cat - Dcs.sis - Controller 3412 XDocumento2 páginasCat - Dcs.sis - Controller 3412 XKariem R Noweer67% (3)

- Fall Gypsum Applications White Paper 11.15.13Documento3 páginasFall Gypsum Applications White Paper 11.15.13Kariem R NoweerAinda não há avaliações

- Chapter 8 - Nervous ReviewerDocumento18 páginasChapter 8 - Nervous Reviewerchristian anchetaAinda não há avaliações

- Detailed Lesson Plan in Science Grade 10Documento9 páginasDetailed Lesson Plan in Science Grade 10christian josh magtarayoAinda não há avaliações

- 3rd Quarter PHYSICAL SCIENCE ExamDocumento19 páginas3rd Quarter PHYSICAL SCIENCE ExamZhering RodulfoAinda não há avaliações

- Automatic Door Opener With PIC12C508 CircuitDocumento3 páginasAutomatic Door Opener With PIC12C508 CircuitLingaraj BeharaAinda não há avaliações

- Comprensión Lectora en Inglés Clecv Plus 3: Unit 11: The Natural World Unit 12: Music: Influence and InnovationDocumento66 páginasComprensión Lectora en Inglés Clecv Plus 3: Unit 11: The Natural World Unit 12: Music: Influence and InnovationJorge Talavera AnayaAinda não há avaliações

- 02-779 Requirements For 90-10 Copper - Nickel - Alloy Part-3 TubingDocumento47 páginas02-779 Requirements For 90-10 Copper - Nickel - Alloy Part-3 TubingHattar MAinda não há avaliações

- Deep Carbon ObservatoryDocumento90 páginasDeep Carbon ObservatorygoblinAinda não há avaliações

- Massage Intake FormDocumento2 páginasMassage Intake Formapi-253959832Ainda não há avaliações

- Poems by Cawein, Madison Julius, 1865-1914Documento126 páginasPoems by Cawein, Madison Julius, 1865-1914Gutenberg.orgAinda não há avaliações

- Post Graduate Diploma in Psychological CounselingDocumento1 páginaPost Graduate Diploma in Psychological CounselingAvalokiteswari KurupAinda não há avaliações

- HOconsDocumento14 páginasHOconsMax PradoAinda não há avaliações

- Designing New Vanillin Schiff Bases and Their Antibacterial StudiesDocumento4 páginasDesigning New Vanillin Schiff Bases and Their Antibacterial StudiesAvinash PurohitAinda não há avaliações

- Properties of Equality PDFDocumento1 páginaProperties of Equality PDFR. I. P.Ainda não há avaliações

- Broadway CafeDocumento13 páginasBroadway CafeIoana Taon100% (1)

- TDC Calculation For The Determination of Drill Bit PerformanceDocumento3 páginasTDC Calculation For The Determination of Drill Bit Performancejanuar baharuliAinda não há avaliações

- British Vs American English - CrosswordDocumento3 páginasBritish Vs American English - Crosswordlkham enkhsaikhanAinda não há avaliações

- High Voltage Fast-Switching NPN Power Transistor: FeaturesDocumento11 páginasHigh Voltage Fast-Switching NPN Power Transistor: FeaturesVESVOCAinda não há avaliações

- CH 7. Pneumatic and HydroulicDocumento20 páginasCH 7. Pneumatic and HydroulicAbenezer Tasew100% (1)

- Module 1 - AE4 - Review of Basic Mathematical Concepts (For Discussion)Documento36 páginasModule 1 - AE4 - Review of Basic Mathematical Concepts (For Discussion)Kimberly Jean LautrizoAinda não há avaliações

- Scorpio PDFDocumento3 páginasScorpio PDFnimi2364010Ainda não há avaliações

- Fluids Mechanics HomeworkDocumento92 páginasFluids Mechanics Homeworkm3994794% (31)

- List Lagu EnglishDocumento7 páginasList Lagu EnglishRyn ZulfanAinda não há avaliações

- Carbohydrate-Related Diseases Term PaperDocumento5 páginasCarbohydrate-Related Diseases Term Paperheiress comiaAinda não há avaliações

- Essential Oil ExtractionDocumento159 páginasEssential Oil ExtractionAubrey Hernandez100% (4)

- Research Article: International Research Journal of PharmacyDocumento5 páginasResearch Article: International Research Journal of PharmacyAlfrets Marade SianiparAinda não há avaliações

- My 6-Step Plan For Diagnosing & Managing The Pruritic DogDocumento6 páginasMy 6-Step Plan For Diagnosing & Managing The Pruritic DogAnonymous TDI8qdYAinda não há avaliações

- Dark Elves WarbandDocumento9 páginasDark Elves Warbanddueydueck100% (1)

- THESISDocumento44 páginasTHESISRowena Shaira AbellarAinda não há avaliações

- Sea Shanty PrintDocumento3 páginasSea Shanty PrintDiego DracvsAinda não há avaliações