Escolar Documentos

Profissional Documentos

Cultura Documentos

Measurement Assurance 10-16-2013

Enviado por

imran shaukatDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Measurement Assurance 10-16-2013

Enviado por

imran shaukatDireitos autorais:

Formatos disponíveis

Procedure for Measurement Assurance

Drug Chemistry Section

Issued by Drug Chemistry Forensic Scientist Manager

Version 4

Effective Date: 10/16/2013

Procedure for Measurement Assurance

1.0

Purpose - This procedure specifies the required elements for measurement assurance in the Drug

Chemistry Sections of the State Crime Laboratory.

2.0

Scope This procedure applies to Drug Chemistry at the Raleigh, Triad, and Western locations of the

State Crime Laboratory.

3.0

Definitions

4.0

Measurement a process of experimentally obtaining one or more quantity values, typically of

physical, chemical, or biological nature. Implies comparison of quantities.

Metrology the science of measurement.

Measurand the (unknown) quantity subject to measurement.

Reference standard measurement standard designated for the calibration of other measurement

standards (reference standards or equipment)

Reference material material sufficiently homogeneous and stable, with reference to specified

properties, which has been established to be fit for its intended use in measurement or in examination

of nominal properties.

Measurement Traceability an unbroken chain of comparisons (using acceptable and documented

methods) to national or international standards (SI) with each comparison having stated

uncertainties.

Equipment, Materials and Reagents

4.1

Equipment

4.2

Materials and Reagents

5.0

Section balances (individual, analytical, and bulk)

Liquid Handling System

Headspace GC

Toxicology GC-MS

HPLC

Class A Reference Standard Weights

Primary Reference materials

Volumetric flasks

Class A Pipettes

Glassware

Procedure

5.1

Standards and Control

5.1.1

Class A Reference Standard weights shall be used for QC checks and to determine the

Uncertainty of Measurement for section balances.

Page 1 of 12

All copies of this document are uncontrolled when printed.

Procedure for Measurement Assurance

Drug Chemistry Section

Issued by Drug Chemistry Forensic Scientist Manager

5.2

Version 4

Effective Date: 10/16/2013

5.1.2

Primary reference standards, primary reference materials, Class A pipettes and Class A

volumetric flasks shall be used for Section Blood Alcohol Quantitations, Cannabinoid

Quantitations, and GHB Quantitations.

5.1.3

Primary reference materials, Class A pipettes, Class A volumetric flasks and graduated

cylinders shall be used for Section Methamphetamine Quantitations via HPLC.

Section Balances

5.2.1

The process to determine the Uncertainty of Measurement for Section balances shall be

conducted on a yearly basis for ten consecutive business days according to the

procedure outlined below.

5.2.2

In order to determine uncertainty for balances, several factors must be taken into

consideration. These factors include but are not limited to:

5.2.2.1

The uncertainty of the measuring instrument (expressed as C1) shall be

obtained from the statement of uncertainty from the approved vendors

current Calibration Report.

If the expanded uncertainty was reported on the certificate provided

by the vendor, divide the expanded uncertainty value by the coverage

factor K.

5.2.2.2

The uncertainty of the item being measured (expressed as C2) shall be

obtained from the approved vendors current Calibration Report for the

Class A Reference Standard Weights.

5.2.2.3

The uncertainty of human/environmental influences (expressed as C3)

shall be obtained from the data collection performed by the Forensic

Scientists in the Drug Chemistry Sections of the North Carolina State

Crime Laboratory on an annual basis.

5.2.2.3.1

These factors include, but are not limited to:

Position and leveling of the balance

Position of weight on the balance pan

Draft

Ambient temperature changes

Vibration

5.2.3

All common use balances (analytical and bulk) as well as all individual top loading

balances currently being used for case analysis shall be included in the data collection.

5.2.4

A rotation list of Forensic Scientists shall ensure that multiple users contribute to the

data collection of common use balances.

5.2.5

If a Forensic Scientist is out of the office for a partial day or partial week during the

data collection period, a substitute Forensic Scientist shall collect data on that

individuals balance.

Page 2 of 12

All copies of this document are uncontrolled when printed.

Procedure for Measurement Assurance

Drug Chemistry Section

Issued by Drug Chemistry Forensic Scientist Manager

Version 4

Effective Date: 10/16/2013

5.2.6

The monthly QC check shall be performed at the start of each work day in accordance

with the Drug Chemistry Technical Procedure for Balances, but shall be documented

with the replicate weight determinations.

5.2.7

In addition to the monthly QC check, each morning and afternoon three replicate weight

determinations shall be obtained for two reference standard weights. The Forensic

Scientist performing the determination shall record these values on a data collection

sheet along with the identifier for each weight used.

5.2.7.1

The specific weights used for each type of balance will depend on certified

reference weights at the respective laboratories.

5.2.8

The standard deviation of all occurrences for each weight on each balance shall be used.

5.2.9

Calculations

5.2.9.1

Data collection and data manipulation may be done in an Excel

spreadsheet (Determination of Uncertainty) due to the volume of data

collected.

5.2.9.2

After completion of the data collection, the uncertainty of

human/environmental influences (C3) shall be determined. The

following equation shall be used to determine C3:

C3 =

5.2.9.3

s

n

Where s = standard deviation

Where n = number of measurements

Combined Uncertainties (u)

5.2.9.3.1

In order to accurately reflect the total uncertainty from all of

the contributing factors, the following equation shall be used to

determine the combined uncertainty (u):

u = [(C1)2+(C2)2+(C3)2]

Where

5.2.9.4

C1 = uncertainty of measuring device

C2 = uncertainty of items being measured

C3 = uncertainty of human/environmental

influences

Expanded Uncertainties at 99.7 % Confidence Level (U)

5.2.9.4.1

In order to determine the expanded uncertainty (U), the

combined uncertainty (u) shall be multiplied by a coverage

factor (k) of 3, which states the uncertainty at a 99.7 % level of

confidence.

U=ku

Where

k = a coverage factor of 3 for a 99.7 %

confidence level

Page 3 of 12

All copies of this document are uncontrolled when printed.

Procedure for Measurement Assurance

Drug Chemistry Section

Issued by Drug Chemistry Forensic Scientist Manager

Version 4

Effective Date: 10/16/2013

u = the combined uncertainty for each type of

measurement

5.2.10

The expanded uncertainties for each type of measurement on each type of balance (top

loading/analytical/bulk) included in the uncertainty study shall be evaluated. The

highest value for each type of balance (top loading/analytical/bulk) shall be used as the

section value. These values shall be updated annually and used as directed in the Drug

Chemistry technical procedure for each type of measurement.

5.2.10.1

5.2.11

Calculations shall be verified by a second Forensic Scientist and

documented on the yearly summary chart for each type of uncertainty.

Reporting of Final Expanded Uncertainty for the Weighing Process

5.2.11.1

The Expanded Uncertainty for each type of balance (see 5.2.10.4.1) shall be

used to calculate the Final Expanded Uncertainty for the weighing process.

This process is repeated when multiple units are weighed for a combined net

weight. The following equation shall be used:

Ufinal = (Ubalance)2 x N) which can be simplified to

Ufinal = N x Ubalance

Where:

Ufinal = Final expanded uncertainty for the weighing process

Ubalance = Expanded Uncertainty of the Balance

N = Number of weighings

99.7 % Confidence Level using k=3 coverage factor and normal distribution

5.2.11.2

The expanded uncertainty for the weighing process for the type of balance

used shall be reported with the results of reported net weights. The

calculations shall be recorded in the case notes.

5.2.11.2.1

Top loading (individual) balances (lower range):

Net weight of material XX.XX (+/- 0.0X) grams

When the upper range of a top loading balance is triggered, the

readout drops to the one tenths place. Yearly uncertainty

calculations are based on the lower range; therefore, any

evidence which triggers the upper range shall be weighed on a

bulk balance.

5.2.11.2.2

Analytical balances:

Net weight of material XX.XXXX (+/- 0.000X) grams

5.2.11.2.3

Bulk balances:

(Raleigh/Triad Regional Laboratories)

Net weight of material XX.XX (+/- 0.0X) kilograms

OR

(Western Regional Laboratory)

Page 4 of 12

All copies of this document are uncontrolled when printed.

Procedure for Measurement Assurance

Drug Chemistry Section

Issued by Drug Chemistry Forensic Scientist Manager

Version 4

Effective Date: 10/16/2013

Net weight of material XX.XXX (+/- 0.XXX) kilograms

5.2.11.2.3.1 A notice shall be posted near the bulk balance

stating the range for which the balance has been

calibrated and certified for use, as needed.

5.2.11.2.4

5.2.12

5.3

Gross weights shall not require a reported uncertainty and shall

be truncated to the 0.1 place or whole number.

Annual Secondary Reference Standard Weight Checks

5.2.12.1

During the month of September, the Section Balances Coordinator shall

record the weights of the Section Primary and Secondary Reference

Standard Weights. Identifiers for the weights and balances used shall also be

documented.

5.2.12.2

The balances used shall be checked with the primary standard reference

weights according to the monthly QC Check criteria listed in the Technical

Procedure for Balances before the secondary weights are checked.

5.2.12.3

A successful recheck will require the weights recorded for the secondary

reference standard weights agree with expected values within the expanded

uncertainty measurement as stated on the annual balance calibration

certificate of the balance used.

Alcohol/Acetone Concentration Determinations

5.3.1

The method to determine alcohol and/or acetone concentration is Headspace Gas

Chromatography (HS-GC). This method is documented in the Technical Procedure for

Headspace Gas Chromatography to Quantitate and Identify Volatiles in Liquids. The

uncertainty budget for this procedure was prepared to establish the uncertainty

associated with the determination of the concentration of ethanol, methanol,

isopropanol, and acetone in blood, serum, urine, and liquor samples. While other

volatiles (i.e., 1,1-difluoroethane) are identified by this process, they are identified

qualitatively; therefore, they are outside the scope of this method.

5.3.2

The analyte concentration is calculated, through least squares regression of calibrator

solutions, using the manufacturers software. The software calculates both the slope

and the intercept used to generate the equation of the line that will determine analyte

concentration. The equations used are:

Analyte Conc. = (Area Ratio * slope + intercept)/ISTD conc.

Area Ratio = Sample peak area/ ISTD peak area

The calibration curve is a historical curve that is valid for up to three months. If a new

lot of internal standard is prepared, a new calibration shall be performed. If

maintenance is performed on the HS-GC that may significantly affect the calibration

(e.g., new column, detector maintenance), a new calibration shall be performed.

Page 5 of 12

All copies of this document are uncontrolled when printed.

Procedure for Measurement Assurance

Drug Chemistry Section

Issued by Drug Chemistry Forensic Scientist Manager

Version 4

Effective Date: 10/16/2013

5.3.3

The analytes are analyzed via HS-GC using an internal standard calibration method

employing a 0.05 gram per 100 mL n-propanol internal standard solution. The

calibration curve for all analytes consists of a 5 point curve with calibrators spaced

between 0.010 gram per 100 mL and 0.500 gram per 100 mL. The correlation

coefficient of the curve defined as R must be greater than 0.995. Any concentration

beyond this range is not within the scope of the current validated method. The

Technical Procedure for Headspace Gas Chromatography to Quantitate and Identify

Volatiles in Liquids also requires that four quality controls (0.015, 0.050, 0.100, and

0.400 gram per 100 mL) be analyzed with the calibration. The 0.050, 0.100, and 0.400

gram per 100 mL quality controls are certified reference material solutions. The 0.015

gram per 100 mL solution is prepared in-house. The calibration is valid if all quality

control samples are within 0.004 for controls less than 0.080 and within 5 % of the

expected concentration for controls greater than 0.080. Each run shall contain two of

the certified reference material solutions to serve as positive controls. These shall meet

the same acceptance criteria as the controls used to verify the calibration curve.

5.3.4

Analyte and Sampling

5.3.4.1

5.3.5

Instrumental

5.3.5.1

5.3.6

The instrumental related factors that contribute to the overall process

uncertainty considered in this evaluation were peak broadening, peak

tailing, resolution, and flame ionization detector (FID).

Calibration

5.3.6.1

5.3.7

The analyte and sampling related factors that contribute to the overall

process uncertainty considered in this evaluation were homogeneity,

temperature, liquid handling system, matrix effects, reactivity, and

partitioning.

The calibration factors that contribute to the overall process uncertainty

considered in this evaluation were peak area, calibration solutions, and

linear regression.

Internal Standard

5.3.7.1

The internal standard concentration is a unique source of uncertainty.

The n-propanol used in the preparation of the internal standard is greater

than 99.5 % pure. The internal standard solution is prepared using Class

A volumetric glassware and a calibrated analytical balance. Because the

calibration is tied to the internal standard lot, all case samples will be

analyzed using the same lot of internal standard that was used to

calibrate the instrument.

5.3.7.2

The internal standard is subject to the same sources of uncertainty as the

analytes. These sources of uncertainty are uniformly applied to both

internal standard and analyte. As such, the use of an internal standard

normalizes and minimizes these effects on uncertainty.

Page 6 of 12

All copies of this document are uncontrolled when printed.

Procedure for Measurement Assurance

Drug Chemistry Section

Issued by Drug Chemistry Forensic Scientist Manager

5.3.8

All factors considered were reflected in the overall variance of replicate sample analysis

(repeatability-Ethanol only) and quality control data (repeatability-Methanol, Acetone,

Isopropanol and reproducibility-all analytes). These are the two major components of

the overall process uncertainty.

5.3.9

Repeatability

5.3.10

5.3.9.1

Quadruplicate sample data for cases worked from September 2012 thru

May 2013 were evaluated for mean and standard deviation. Only mean

sample results between 0.01 and 0.50 were considered for analysis of

variance. Based on the mean of the results, sample data was separated

into incremental pools of 0.010 g/100 mL. The overall mean, standard

deviation, relative standard deviation, and % CV of the pool was

obtained. Mean relative standard deviation was obtained by linear

regression analysis. The mean relative standard deviation was assumed

to approximate the population mean relative standard deviation, and thus

a coverage factor (k) of 3.0 was assumed to approximate the 99.73 %

confidence interval. Analysis of quadruplicate sample data was assumed

to be reflective of the total process repeatability. Sample regression was

performed in Microsoft Excel.

5.3.9.2

For analytes other than ethanol, sample repeatability was estimated from

analysis of certified reference material control data. Control results from

the same period were analyzed for mean, standard deviation, and % CV

using Microsoft Access and Microsoft Excel.

Control Chart Data

5.3.10.1

5.3.11

5.3.12

5.3.13

5.3.11.1

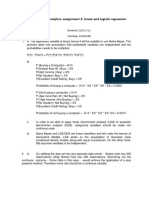

Ethanol process uncertainty = (((repeatability)2/4) + (Rm)2)

5.3.11.2

Other analytes process uncertainty = (((repeatability)2) + (Rm)2)

The expanded uncertainty was calculated by:

Expanded uncertainty (99.73 % CI) = 3 * process uncertainty

These values shall be updated annually by the Drug Chemistry Forensic Scientist

Manager or his/her designee and used as directed in the Drug Chemistry SectionToxicology Unit Technical Procedure for Headspace Gas Chromatography to

Quantitate and Identify Volatiles in Liquids.

Cannabinoid Quantitations

5.4.1

5.5

Certified reference material control data was also evaluated for mean

recovery/accuracy (Rm) versus the expected value.

Overall process uncertainty was calculated by:

5.3.12.1

5.4

Version 4

Effective Date: 10/16/2013

Currently being established.

Methamphetamine Quantitations via HPLC

Page 7 of 12

All copies of this document are uncontrolled when printed.

Procedure for Measurement Assurance

Drug Chemistry Section

Issued by Drug Chemistry Forensic Scientist Manager

Version 4

Effective Date: 10/16/2013

5.5.1

This method is used to determine the purity of methamphetamine as requested for

certain solid drug cases undergoing federal prosecution. Quantitation of other target

analytes is not within the scope of the current validated method. The method has been

analyzed and tested to acquire data on the following sources of uncertainty: instrument

uncertainty, uncertainty due to scientist technique, volumetric glassware uncertainty,

balance uncertainty, and sample homogeneity.

5.5.2

Instrument Uncertainty

5.5.3

5.5.2.1

The HPLC is calibrated using an external calibration method on a five

point calibration curve utilizing calibrators of methamphetamine. The

correlation coefficient of the curve defined as R must be better than

0.995. Policy requires that a new calibration curve be created with every

run. Policy also requires that two quality controls (0.50 and 1.0 mg/mL)

be analyzed with every run. The calibration is valid if both quality

control samples are within +/-5 % of the expected concentration.

5.5.2.2

The linearity of the technique used for methamphetamine quantitation

encompasses a range of 0.05-1.0 mg/mL. Any range beyond this is not

within the scope of the current validated method.

5.5.2.3

The calibration standards used to make the calibrators are purchased

through an approved vendor. The calibration requirements, as well as inhouse standard verification requirements, would reveal any deviations.

Homogeneity of the sample

5.5.3.1

5.5.4

Scientist Technique

5.5.4.1

5.5.5

This element is monitored by homogenizing all samples prior to analysis

and by the use of quadruplicate measurements. The procedure for

homogenizing a sample is outlined in the Technical Procedure for High

Performance Liquid Chromatography. The Relative Percent Difference of

the measurements must be below 3 % to ensure homogeneity. If the RPD is

found to be greater than 3 %, the scientist shall prepare new sample

solutions from the original homogenized powder.

Only scientists who have completed HPLC training shall perform HPLC

quantitation to minimize the measurement uncertainty of the process.

Control samples are analyzed in the same manner as the case samples

with every run. The controls monitor the uncertainty contributions of the

scientist, and include the uncertainty contributions from both balances

and volumetric glassware.

Additional sources of uncertainty

5.5.5.1

Additional sources of uncertainty include lab locations, environmental

conditions, and calibration standards. Each lab independently performed its

own method validation. Environmental conditions did not prove to be a

Page 8 of 12

All copies of this document are uncontrolled when printed.

Procedure for Measurement Assurance

Drug Chemistry Section

Issued by Drug Chemistry Forensic Scientist Manager

Version 4

Effective Date: 10/16/2013

significant source of uncertainty and the method was validated to be

performed under typical laboratory environmental conditions.

5.5.6

Overall process uncertainty

5.5.6.1

Fifty-five control samples were analyzed in the Western and Raleigh

laboratories. The analysis of theses samples resulted in an average recovery

of 101.11 % and a standard deviation of 1.76 %. At a 99.7 % confidence

interval, z=3.0. The measurement uncertainty of the process is calculated

by:

MU (process meth) = (Std dev (process)*(z-value @99.7%CI))/4

= (1.76*3.00) /4

= 2.65%

The overall process uncertainty of 2.65 % was rounded up to 3.0 % to

provide a more conservative estimate of uncertainty.

5.5.7

Uncertainty re-evaluation

5.5.7.1

6.0

Limitations N/A

7.0

Safety N/A

8.0

References

The overall process uncertainty shall be evaluated annually from control

chart data and updated as needed. If the process uncertainty changes, the

percentage shall be rounded up to the nearest whole number.

ASCLD/LAB Level 100A Traceability presentation. Copyright 2011; Heusser Neweigh, LLC &

ASCLD/LAB.

ASCLD/LAB Level 100B Measurement Assurance presentation. Copyright 2011; Heusser Neweigh,

LLC & ASCLD/LAB.

ASCLD/LAB Level 100C Measurement Uncertainty Concepts presentation. Copyright 2011; Heusser

Neweigh, LLC & ASCLD/LAB.

ASCLD/LAB Level 200 Measurement Confidence for the Forensic Laboratory: Measurement

Uncertainty in Drug Chemistry presentation. Copyright 2011; Heusser Neweigh, LLC & ASCLD/LAB

Clark, J.P. and Shull, A.H. Evaluation of Methods for Estimating the Uncertainty of Electronic Balance

Measurements. Westinghouse Savannah River Company, 2002.

EURACHEM/CITAC Guide CG 4: Quantifying Uncertainty in Analytical Measurement,

Third Edition 2012.

Gariott, James C. Medicolegal Aspects of Alcohol. 5th ed. Lawyers and Judges Publishing Co. 2008.

Page 9 of 12

All copies of this document are uncontrolled when printed.

Procedure for Measurement Assurance

Drug Chemistry Section

Issued by Drug Chemistry Forensic Scientist Manager

Version 4

Effective Date: 10/16/2013

Gullberg, Rod. Estimating the Measurement Uncertainty in Forensic Blood Alcohol Analysis. Journal

of Analytical Toxicology. 2012. 36: 153-161.

JCGM 100:2008 Evaluation of measurement data - Guide to the Expression of Uncertainty in

Measurement, First Edition September 2008.

Jones, Alan. Determination of Liquid/Air Partition Coefficients for Dilute Solutions of Ethanol in Water,

Whole Blood, and Plasma. Journal of Analytical Toxicology. 1983. 7: 193-197.

Kristiansen, Jesper and Petersen, Henning. An Uncertainty Budget for the Measurement of Ethanol in

Blood by Headspace Gas Chromatography. Journal of Analytical Toxicology. 2004. 28: 456-463.

LeBeau, Marc. Introduction to Measurement Uncertainty. RTI International. 2009.

Measurement Uncertainty for Weight Determinations in Seized Drug Analysis Supplemental Document

SD-3 Revision 2. Copyright 2011; SWGDRUG.

Sklerov, Jason and Couper, Fiona. Calculation and Verification of Blood Ethanol Measurement

Uncertainty for Headspace Gas Chromatography. Journal of Analytical Toxicology. 2011. 35: 402-410.

Taylor, B.N, and Kuyatt, C.E. NIST Technical Note 1297 Guidelines for Evaluating and Expressing the

Uncertainty of NIST Measurement Results, September 1994 Edition.

Tilson, Chris. Analysis of Biological Specimens. FTCB. 2010.

Virginia Department of Forensic Sciences. Controlled Substances Procedure Manual. Document 221D100 Revision 7, February 6, 2012.

9.0

Records

10.0

Determination of Uncertainty - Yearly Report for Balances

Calibration Reports for section balances

Calibration Reports for section Class A pipettes

Reference Standard Weight Calibration Certificates

Uncertainty Budget for the HPLC Quantitation of Methamphetamine

HPLC Control charts

Uncertainty Budget for the Quantitation of Ethanol, Methanol, Isopropanol, and Acetone using

Headspace Gas Chromatography

Toxicology Control Charts

Attachments N/A

Page 10 of 12

All copies of this document are uncontrolled when printed.

Procedure for Measurement Assurance

Drug Chemistry Section

Issued by Drug Chemistry Forensic Scientist Manager

Version 4

Effective Date: 10/16/2013

Revision History

Effective Date

Version

Number

Reason

09/17/2012

05/10/2013

1

2

06/14/2013

Original Document

Original 5.1- Moved first statement to apply to Section

Balances only. References to traceability maps removed, since

this data covered by calibration certificates

Original 5.2, 5.3 N/A sections removed

5.2 Section renamed and edited to cover Section Balances only

5.2.2.1 Removed normalization calculation that is not needed

5.2.2.2 Added reference to Class A Reference Standard

Weights

5.2.2.3.1 Section moved from below

5.2.3 5.2.9 Sections moved from below; Weights used will

depend on availability at laboratories

5.2.9.1 Added name of Excel spreadsheet used to calculate

data

5.2.11 Added clarification on types of balances

5.2.11.1 Corrected reference line number

5.3, 5.4 - Revised to Currently being established

5.5 Added explanation for Methamphetamine Quantitations

via HPLC

Original 5.7 Removed section for GHB Quantitations

5.5.7.1 - Added process evaluated annually

References Added EURACHEM/CITAC Taylor, and

JCGMreferences

Records Removed Measurement Assurance Cause & Effect

Diagram, added Uncertainty Budget for the HPLC Quantitation

of Methamphetamine and HPLC Control Charts

Removed Technical in title

5.2.10 - Removed last sentence

5.3 - Inserted explanation of measurement uncertainty as it

relates to Alcohol/Acetone Concentration Determinations

References - Added Garriott, Gullberg, Jones, Kristiansen,

LeBeau, Sklerov, and Tilson

Records Added Uncertainty Budget for the Quantitation of

Ethanol, Methanol, Isopropanol, and Acetone using Headspace

Gas Chromatography and Toxicology Control Charts

10/16/2013

5.2.11.2.1 Reworded to remove use of upper range on table

top balances

5.2.11.2.3 Clarified nonuse of upper ranges on bulk balances

5.2.11.2.4 Deleted unneeded reference to range of balance

Page 11 of 12

All copies of this document are uncontrolled when printed.

Procedure for Measurement Assurance

Drug Chemistry Section

Issued by Drug Chemistry Forensic Scientist Manager

Version 4

Effective Date: 10/16/2013

5.2.12 Added section to clarify successful annual Secondary

Reference Weight check; added issuing authority to header

Page 12 of 12

All copies of this document are uncontrolled when printed.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Oil & Gas UK Guidelines On Risk Related Decision Making - Issue 2 July 2014Documento25 páginasOil & Gas UK Guidelines On Risk Related Decision Making - Issue 2 July 2014Ella Agbettor100% (2)

- Heavy Metals Removal by Apricot ShellsDocumento43 páginasHeavy Metals Removal by Apricot Shellsimran shaukatAinda não há avaliações

- Al Qahtani2015 PDFDocumento24 páginasAl Qahtani2015 PDFimran shaukatAinda não há avaliações

- Suganya Ea2019Documento9 páginasSuganya Ea2019imran shaukatAinda não há avaliações

- Performance Studies Removal of Chromium (CR) and Lead (PB) by Oil Palm Frond (OPF) Adsorbent in Aqueous SolutionDocumento8 páginasPerformance Studies Removal of Chromium (CR) and Lead (PB) by Oil Palm Frond (OPF) Adsorbent in Aqueous Solutionimran shaukatAinda não há avaliações

- Journal Pre-Proof: Surfaces and InterfacesDocumento33 páginasJournal Pre-Proof: Surfaces and Interfacesimran shaukatAinda não há avaliações

- Ultrasonics Sonochemistry: Harsh Gupta, Parag R. GogateDocumento10 páginasUltrasonics Sonochemistry: Harsh Gupta, Parag R. Gogateimran shaukatAinda não há avaliações

- Materials Chemistry and PhysicsDocumento11 páginasMaterials Chemistry and Physicsimran shaukatAinda não há avaliações

- Environmental Technology & Innovation: Lucy SemerjianDocumento13 páginasEnvironmental Technology & Innovation: Lucy Semerjianimran shaukatAinda não há avaliações

- Ecological Engineering: Manal Fawzy, Mahmoud Nasr, Samar Adel, Heba Nagy, Shacker HelmiDocumento10 páginasEcological Engineering: Manal Fawzy, Mahmoud Nasr, Samar Adel, Heba Nagy, Shacker Helmiimran shaukatAinda não há avaliações

- Chemosphere: Wachiraphorn Cherdchoo, Srisuda Nithettham, Jittima CharoenpanichDocumento10 páginasChemosphere: Wachiraphorn Cherdchoo, Srisuda Nithettham, Jittima Charoenpanichimran shaukatAinda não há avaliações

- Journal of Cleaner Production: R. Fern Andez-Gonzalez, M.A. Martín-Lara, J.A. Moreno, G. BL Azquez, M. CaleroDocumento11 páginasJournal of Cleaner Production: R. Fern Andez-Gonzalez, M.A. Martín-Lara, J.A. Moreno, G. BL Azquez, M. Caleroimran shaukatAinda não há avaliações

- Ecological Engineering: Rehab M. Ali, Hesham A. Hamad, Mohamed M. Hussein, Gihan F. MalashDocumento16 páginasEcological Engineering: Rehab M. Ali, Hesham A. Hamad, Mohamed M. Hussein, Gihan F. Malashimran shaukatAinda não há avaliações

- Ferreira 2019Documento10 páginasFerreira 2019imran shaukatAinda não há avaliações

- Moringa bark removes metals from industrial wasteDocumento50 páginasMoringa bark removes metals from industrial wasteimran shaukatAinda não há avaliações

- Accepted Manuscript: Process Safety and Environment ProtectionDocumento51 páginasAccepted Manuscript: Process Safety and Environment Protectionimran shaukatAinda não há avaliações

- Materials Chemistry and PhysicsDocumento11 páginasMaterials Chemistry and Physicsimran shaukatAinda não há avaliações

- Sustainable Chemistry and Pharmacy: ArticleinfoDocumento5 páginasSustainable Chemistry and Pharmacy: Articleinfoimran shaukatAinda não há avaliações

- Adsorption of Heavy Metals Using Wild HerbsDocumento8 páginasAdsorption of Heavy Metals Using Wild Herbsimran shaukatAinda não há avaliações

- Heavy Metals Removal Using Activated Carbon SilicaDocumento9 páginasHeavy Metals Removal Using Activated Carbon Silicaimran shaukatAinda não há avaliações

- Environmental Nanotechnology, Monitoring & ManagementDocumento8 páginasEnvironmental Nanotechnology, Monitoring & Managementimran shaukatAinda não há avaliações

- Accepted Manuscript: Process Safety and Environment ProtectionDocumento69 páginasAccepted Manuscript: Process Safety and Environment Protectionimran shaukatAinda não há avaliações

- Sustainable Chemistry and Pharmacy: ArticleinfoDocumento5 páginasSustainable Chemistry and Pharmacy: Articleinfoimran shaukatAinda não há avaliações

- Environmental Nanotechnology, Monitoring & ManagementDocumento8 páginasEnvironmental Nanotechnology, Monitoring & Managementimran shaukatAinda não há avaliações

- Farhan 2013-Ficus Carcia Leaves-LeadDocumento8 páginasFarhan 2013-Ficus Carcia Leaves-Leadimran shaukatAinda não há avaliações

- Materials 12 02020Documento16 páginasMaterials 12 02020imran shaukatAinda não há avaliações

- ADSORPTIONDESORPTIONCrVI NA PDFDocumento7 páginasADSORPTIONDESORPTIONCrVI NA PDFimran shaukatAinda não há avaliações

- Brochure ChemicalManagementSafetyDocumento2 páginasBrochure ChemicalManagementSafetyimran shaukatAinda não há avaliações

- UCM092149Documento6 páginasUCM092149rpbpaAinda não há avaliações

- Adsorption ProcessDocumento12 páginasAdsorption Processimran shaukatAinda não há avaliações

- I So ComparisonDocumento2 páginasI So Comparisonimran shaukatAinda não há avaliações

- La Carlota City College Module in ProEl 12Documento14 páginasLa Carlota City College Module in ProEl 12Maria Lesty BustaleñoAinda não há avaliações

- Geometrodynamics of Gauge Fields - On The Geometry of Yang-Mills and Gravitational Gauge Theories PDFDocumento377 páginasGeometrodynamics of Gauge Fields - On The Geometry of Yang-Mills and Gravitational Gauge Theories PDFDennis Gerken100% (3)

- Test 09iouujjkkllDocumento11 páginasTest 09iouujjkkllzola_getAinda não há avaliações

- Brenda J. Dunne and Robert G. Jahn - Consciousness and Anomalous Physical PhenomenaDocumento31 páginasBrenda J. Dunne and Robert G. Jahn - Consciousness and Anomalous Physical PhenomenaCanola_OliveAinda não há avaliações

- Iceman Worksheet PDFDocumento8 páginasIceman Worksheet PDFGreg KennedyAinda não há avaliações

- Marketing ResearchDocumento38 páginasMarketing ResearchJerry MataiAinda não há avaliações

- CSM Book 2018 PDFDocumento210 páginasCSM Book 2018 PDFDeval SrivastavaAinda não há avaliações

- Cdi1 LQDocumento4 páginasCdi1 LQLoise SalasAinda não há avaliações

- General Const: Aj'I Litlll'i 'Documento3 páginasGeneral Const: Aj'I Litlll'i 'Kawser HossainAinda não há avaliações

- METROLOGY: THE SCIENCE OF MEASUREMENTDocumento41 páginasMETROLOGY: THE SCIENCE OF MEASUREMENTTed Mana-ayAinda não há avaliações

- Daily Test I Core Subject Mathematics Grade 12th Santa Laurensia Senior High School 2022-2023 (A)Documento1 páginaDaily Test I Core Subject Mathematics Grade 12th Santa Laurensia Senior High School 2022-2023 (A)Paulo Bastan Kitta BangunAinda não há avaliações

- Clare Math 111Documento2 páginasClare Math 111Gerrenin Clare GumandoyAinda não há avaliações

- Methodology - Statement April 2019Documento2 páginasMethodology - Statement April 2019Anonymous QPo1yt3twqAinda não há avaliações

- Teaching English One To OneDocumento65 páginasTeaching English One To OneAlba Casado100% (2)

- Econometrics & Business StatisticsDocumento4 páginasEconometrics & Business Statisticsyida chenAinda não há avaliações

- Analysis of Square Lattice Designs Using R and SASDocumento43 páginasAnalysis of Square Lattice Designs Using R and SASNimona FufaAinda não há avaliações

- OOT Investigation FormDocumento7 páginasOOT Investigation FormAnkur Choudhary100% (2)

- Sampling 1Documento3 páginasSampling 1Tanmoy ChakrabortyAinda não há avaliações

- Appendix - A Academic Tools To Write Research Proposal For M.Phil. /Ph.D. / UG & PG ProjectDocumento8 páginasAppendix - A Academic Tools To Write Research Proposal For M.Phil. /Ph.D. / UG & PG ProjectROHIT RANEAinda não há avaliações

- GROUP 8 - Regression SW-1Documento42 páginasGROUP 8 - Regression SW-1John Christopher Gozun100% (1)

- Template Manuscript AdUSHSDocumento16 páginasTemplate Manuscript AdUSHSRad JulongbayanAinda não há avaliações

- Methods of Research Week 3-FDocumento30 páginasMethods of Research Week 3-FShailah Leilene Arce BrionesAinda não há avaliações

- Scientific Method and Variables Power PointDocumento21 páginasScientific Method and Variables Power PointMendoza, Aleksy Marie A.Ainda não há avaliações

- Data analytics: Linear and logistic regressionDocumento3 páginasData analytics: Linear and logistic regressionDevansh RaiAinda não há avaliações

- Which TESTDocumento9 páginasWhich TESTfasilistheoAinda não há avaliações

- 758 3021 4 PBDocumento26 páginas758 3021 4 PBAakashAinda não há avaliações

- 10 Pillars of KnowledgeDocumento14 páginas10 Pillars of Knowledgebrettlee20030% (1)

- 2D Viewing: CGVR - Korea.ac - KRDocumento61 páginas2D Viewing: CGVR - Korea.ac - KRSangeetha BajanthriAinda não há avaliações

- Tipus Mikropipet 1 PDFDocumento10 páginasTipus Mikropipet 1 PDFAnnisa Amalia0% (1)