Escolar Documentos

Profissional Documentos

Cultura Documentos

Strengthening of RC Beams With Externally Bonded GFRPs

Enviado por

IOSRjournalTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Strengthening of RC Beams With Externally Bonded GFRPs

Enviado por

IOSRjournalDireitos autorais:

Formatos disponíveis

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684,p-ISSN: 2320-334X, Volume 12, Issue 2 Ver. VI (Mar - Apr. 2015), PP 139-142

www.iosrjournals.org

Strengthening Of RC Beams with Externally Bonded GFRPs

Nikita Jain1, Varun Kumar Sikka2.

Abstract: The rehabilitation of existing reinforced concrete (RC) bridges and building becomes

necessary due to ageing, corrosion of steel reinforcement, defects in construction/design, demand in the

increased service loads, and damage in case of seismic events and improvement in the design

guidelines. Fiber-reinforced polymers (FRP) have emerged as promising material for rehabilitation of

existing reinforced concrete structures. The rehabilitation of structures can be in the form of

strengthening, repairing or retrofitting for seismic deficiencies. Shear failure of RC beams is identified as the

most disastrous failure mode as it does not give any advance warning before failure. The shear strengthening

of RC T-beams using externally bonded (EB) FRP composites has become a popular structural

strengthening technique, due to the well-known advantages of FRP composites such as their high strength-toweight ratio and excellent corrosion resistance. This study assimilates the experimental works of glass fiber

reinforced polymer (GFRP) retrofitted RC beams under symmetrical four-point static loading system.

Keywords: Glass fiber, carbon fiber, epoxy, retrofitting.

I.

Introduction

FRP composites comprise fibers of high tensile strength embedded within a thermosetting matrix

such as epoxy, polymer or vinyl ester. The most widely used matrix is epoxy. FRP was originally

developed for aircraft, helicopters, space-craft, satellites, ships, submarines, high speed trains because of its

light weight. The application of FRP in the civil engineering structures has started in 1980s[1]. Then, the use

of FRP for strengthening of existing or new reinforced concrete (RC) structures against normal and seismic

loads increases at a rapid pace because of numerous advantages enlisted as follows:

1. FRP materials are not vulnerable to the swift electrochemical corrosion that occurs with steel

2. They can be rolled which makes easy to transport.

3. High fatigue resistance

4. High strength to weight ratio

5. Fiber composite materials are available in very long lengths while steel plate is generally limited

to 6m. The availability of long length and the flexibility of the material simplify the installation

process

6. Time required for installation is very less

7. Fiber composite strengthening materials have higher ultimate strength and lower density as

compared to those of steel

8. Low energy consumption during fabrication of raw material and structure, and has the potential for real

time monitoring.

II.

Literature Review

When the RC beam is deficient in shear, or when its shear capacity is less than the flexural capacity

after flexural strengthening, shear strengthening must be considered. It is critically important to examine

the shear capacity of RC beams which are intended to be strengthened in flexure

Many existing RC members are found to be deficient in shear strength and need to be repaired.

Shear failure of RC beams are catastrophic which could occur without any forewarning. Shear

deficiencies in reinforced concrete beams may crop up due to factors such as inadequate shear

reinforcement, reduction in steel area due to corrosion, use of outdated design codes, increased service

load, poor workmanship and design faults. The application of Glass Fiber Reinforced Polymer

(GFRP) composite material, as an external reinforcement is a viable technology recently found to be

worth for improving the structural performance of reinforced concrete structures.[2]

Ghazi et al. (1994) studied the shear repair of reinforced concrete (RC) beams strengthened with

fiber glass plate bonding (FGPB) for structural and non-structural cracking behaviour due to a variety of

reasons. Results from a study on strengthening of RC beams having deficient shear strength and showing

major diagonal tension cracks have been presented. The beams with deficient shear strength were damaged to

a predetermined level (the appearance of the first shear crack) and then repaired by fiber glass plate

bonding (FGPB) techniques.[5]

DOI: 10.9790/1684-1226139142

www.iosrjournals.org

139 | Page

Strengthening Of RC Beams With Externally Bonded GFRPS

Varastehpour and Hamelin (1997) examined the application of composite materials in civil

engineering by strengthening of a reinforced concrete beam in situ by externally-bonded fiber reinforced

polymer (FRP). The study of the mechanical properties of the interface and the rheological behaviour of

composite materials are very important to design.[15]

Khalifa et al. (2000) studied the shear performance and the modes of failure of reinforced concrete

(RC) beams strengthened with externally bonded carbon fiber reinforced polymer (CFRP) wraps

experimentally. The experimental program consisted of testing twenty-seven, full-scale, RC beams. The

variables investigated in this research study included steel stirrups (i.e., beams with and without steel stirrups),

shear span-to depth ratio (i.e., a/d ratio 3 versus 4), CFRP amount and distribution (i.e., Continuous wrap

versus strips), bonded surface (i.e., lateral sides versus U-wrap), fiber orientation (i.e., 90/0 fiber

combination versus 90 direction), and end anchor (i.e., U-wrap with and without anchor)[8]. As part of the

research program, they examined the effectiveness of CFRP reinforcement in enhancing the shear capacity

of RC beams in negative and positive moment regions, and for beams with rectangular and T-cross

section. The experimental results indicated that the contribution of externally bonded CFRP to the shear

capacity is significant and dependent upon the variable investigated. For all beams, results show that an

increase in shear strength of 22 to 145% was achieved.[9]

Hadi (2003) examined the strength and load carrying capacity enhancement of reinforced

concrete (RC) beams, those had been tested and failed in shear. A total of sixteen sheared beam specimens

with a length of 1.2m and cross-sectional area of 100 x 150 mm were retrofitted by using various types

of fiber reinforced polymer (FRP) and then retested. The retrofitted beam specimens wrapped with different

amounts and types of FRP were subjected to four-point static loading. Load, deflection and strain data were

collected during testing the beam specimens to failure. Results of the experimental program indicate that

there were several parameters that affect the strength of the beams[6]. The results also show that the use of

FRP composites for shear strengthening provides significant static capacity increase.

Teng et al. (2004) have studied the shear strengthening of reinforced concrete (RC) beams with

FRP composites. A recent technique for the shear strengthening of RC beams is to provide additional

FRP web reinforcement, commonly in the form of bonded external FRP strips/sheets. Over the last few

years, a large amount of research has been conducted on this new strengthening technique, which has

established its effectiveness and has led to a good understanding of the behaviour and strength of such

shear-strengthened beams. Here, the methods of strengthening were described first, followed by a

summary of experimental observations of failure processes and modes. The accuracy of existing design

provisions was examined next through comparisons with test results. Limitations of existing experimental

and theoretical studies were also highlighted.[14]

Islam et al. (2005) investigated shear strengthening of RC deep beams using externally bonded

FRP systems. In this study, six identical beams were fabricated and tested to failure for this purpose. One of

these beams was tested in its virgin condition to serve as reference, while the remaining five beams were

tested after being strengthened using carbon fiber wrap, strip or grids. The test results have shown that the

use of a bonded FRP system leads to a much slower growth of the critical diagonal cracks and enhances the

load-carrying capacity of the beam to a level quite sufficient to meet most of the practical upgrading

requirements[7]. Although FRP grids placed in normal orientation demonstrated to be the most effective

system as far as the amount of material used in strengthening is concerned, other systems were found to be

almost equally effective. An enhancement of shear strength in the order of about 40%, was achieved in this

study. Saafan (2006) studied the shear strengthening of reinforced concrete (RC) beams using GFRP wraps. The

objective of the experimental work was to investigate the efficiency of GFRP composites in strengthening

simply supported reinforced concrete beams designed with insufficient shear capacity. Using the hand

lay-up technique, successive layers of a woven fiber glass fabric were bonded along the shear span to

increase the shear capacity and to avoid catastrophic premature failure modes. The strengthened beams were

fabricated with no web reinforcement to explore the efficiency of the proposed strengthening technique

using the results of control beams with closed stirrups as web reinforcement. The test results of 18 number of

beams were reported, addressing the influence of different shear strengthening schemes and variable

longitudinal reinforcement ratios on the structural behaviour. The results indicated that significant

increase in the shear strength and improvements in the overall structural behaviour of beams with

insufficient shear capacity could be achieved by proper application of GFRP wraps. It was observed that the

layers can easily slip down under self weight[13].

Mosallam and Banerjee (2007) studied experimentally on shear strength enhancement of

reinforced concrete beams externally reinforced with fiber-reinforced polymer (FRP) composites. A

total of nine full-scale beam specimens of three different classes, as-built (unstrengthened), repaired and

retrofitted were tested. Three composite systems namely carbon/epoxy wet layup, E-glass/epoxy wet

layup and carbon/epoxy procured strips were used for retrofit and repair evaluation. Experimental results

DOI: 10.9790/1684-1226139142

www.iosrjournals.org

140 | Page

Strengthening Of RC Beams With Externally Bonded GFRPS

indicated that the composite systems provided substantial increase in ultimate strength of repaired and

strengthened beams as compared to the pre-cracked and as-built beam specimens.[11]

Kim et al. (2008) studied the shear strength of RC beams strengthened by fiber material. It consists

of a plasticity model for web crushing, a truss model for diagonal tension, and a simple flexural theory

based on the ultimate strength method. To analyze the shear strengthening effect of the fiber, the

model considers the interfacial shear-bonding stress between base concrete and the fiber. This reflects that

the primary cause of shear failure in strengthened RC beams is rapid loss of load capacity due to separation

of the strengthening fibers from the base material. The predictive model can estimate load capacities of

each failure mode, and is compared to tested specimen data including extreme load failure. The analysis

matches well with the experiments concerning load capacity and failure mode. Also, the experimental results

of other published data are compared to the predictive model to evaluate its application. The results show

that the predictive model has good adaptability and high accuracy.[10]

Balamuralikrishnan (2009) has studied the flexural behaviour of RC beams strengthened with carbon

fiber reinforced polymer (CFRP) fabrics. For flexural strengthening of RC beams, total ten number of

beams were cast and tested over an effective span of 3000 mm up to failure under monotonic and cyclic

loads. The beams were designed as under-reinforced concrete beams. Eight number of beams were

strengthened with bonded CFRP fabric in single layer and two layers which are parallel to beam axis

at the bottom under virgin condition and tested until failure; the remaining two beams were used as control

specimens. Static and cyclic responses of all the beams were evaluated in terms of strength, stiffness,

ductility ratio, energy absorption capacity factor, compositeness between CFRP fabric and concrete, and

the associated failure modes. The theoretical moment-curvature relationship and the load-displacement

response of the strengthened beams and control beams were predicted by using software ANSYS.

Comparison has been made between the numerical (ANSYS) and the experimental results. The results show

that the strengthened beams exhibit increased flexural strength, enhanced flexural stiffness, and composite

action until failure.[3] Ceroni (2010) experimentally studied on RC beams externally strengthened with carbon

fiber reinforced plastic (FRP) laminates and Near Surface Mounted (NSM) bars under monotonic and cyclic

loads, the latter ones characterized by a low number of cycles in the elastic and post-elastic range.

Comparisons between experimental and theoretical failure loads were discussed in detail.[4]

More recently, Obaidat et al. (2011) investigated experimentally, the behaviour of the

structurally damaged full-scale reinforced concrete beams retrofitted with CFRP laminates in shear or in

flexure. The main variables considered were the internal reinforcement ratio, position of retrofitting and

the length of CFRP. The experimental results, generally, indicate that beams retrofitted in shear and flexure

by using CFRP laminates are structurally efficient and are restored to stiffness and strength values nearly

equal to or greater than those of the control beams. Employing externally bonded CFRP plates resulted

in an increase in maximum load. The increase in maximum load of the retrofitted specimens reached values

of about 23% for retrofitting in shear and between 7% and 33% for retrofitting in flexure. Moreover,

retrofitting shifts the mode of failure to be brittle. It was found that the efficiency of the strengthening

technique by CFRP in flexure varied depending on the length. The main failure mode in the experimental

work was plate debonding which reduces the efficiency of retrofitting. Based on the conclusion deeper

studies should be performed to investigate the behaviour of the interface layer between the CFRP and

concrete. Also numerical work should be done to predict the behaviour of retrofitted beams and to evaluate the

influence of different parameters on the overall behaviour of the beams.[12]

Mix Design:

The mix design strength of concrete is 25 Mpa in 28 days. The specific gravity of Coarse and Fine

Aggregates are 2.88 and 2.64. The standard deviation is taken as 4Mpa. Portland slag cement is being used of

specific gravity 2.96.

Table 1: Mix Proportions

Water

0.45

Cement

1

Fine Aggregates

1.49

Coarse Aggregates

2.89

Table 2: Quantity of materials for casting

Materials

Cement

Fine Aggregate

Coarse Aggregate

Fly Ash

Water

DOI: 10.9790/1684-1226139142

One Mould (in Kg)

2.816

5.376

7.460

0.256

1.3

www.iosrjournals.org

Three Mould (in Kg)

8.448

17.208

22.380

0.768

3.9

141 | Page

Strengthening Of RC Beams With Externally Bonded GFRPS

Table 3: Curing Specimens

Cured

7 Days

28 Days

Plain concrete beam

3 nos

3 nos

U Wrapped beam

3 nos

3 nos

Two side Wrapped beam

3 nos

3 nos

Experimental Study:

Analysis of beam for 7 days:

The beams B1, B2 and B3 cured for 7 days and 28 days were tested on Flexural Testing Machine. One

sided GFRP Wrapped concrete beams, Two sided GFRP Wrapped concrete beams , Details are illustrated in the

table below:

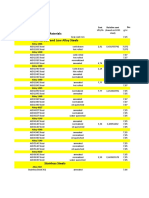

Table 4: Load in KN for 7 Dyas & 28 Days

Beam

B1

B2

B3

Avg Load (KN)

Plain cement concrete

Load in KN

7 days

28days

26

31

25

30

26.5

31

25.84

30.67

III.

U GFRP wrapped

Load in KN

7 days

28 days

31

40

32

39

33

42

32

40.34

Two sided GFRP wrapped

Load in KN

7 days

28 days

28

33

30

32

31

39

20.34

34.67

Results

Conclusion drawn from above results

Sr No

1

2

Beam

GFRP Wrapped U

GFRP Wrapped Two sides

Increase in strength compared to PCC in %

32

11

The strength of beam wrapped by GFRP on beam in U shape is 32% more than that of Plain cement

concrete and the strength of beam wrapped on two parallel sides is comparatively more than the strength of Plain

cement concrete but lesser than the wrapped in one side.

IV.

Conclusion

From theabove research and results we can conclude that GFRP wrapped in U shape gives better

strength as compared to GFRP wrapped on two parallel sides. The strengthening of beam in U shape is more

effective than in sides of beam. And finally we can conclude that the GFRP can increase the shear capacity of

beams.The use of GFRP sheets as an external reinforcement is recommended to enhance the shear capacity of

RC Beams with anchorage system.

References

[1].

[2].

[3].

[4].

[5].

[6].

[7].

[8].

[9].

[10].

[11].

[12].

[13].

[14].

[15].

ACI 440.2R-02, Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete

Structures, Reported by ACI Committee 440.

Archana kumari panigrahi (2013), Strengthening Of Shear Deficient RC T beams with externally bonded FRPs, Composite

structures.

Balamuralikrishnan R., and Jeyasehar C. A. (2009), Flexural behaviour of RC beams strengthened with Carbon Fiber Reinforced

Polymer (CFRP) fabrics, The Open Civil Engineering Journal.

Ceroni F. (2010), Experimental performances of RC beams strengthened with FRP materials, Construction and Building

materials.

Ghazi J. Al-Sulaimani, Alfarabi Sharif, Istem A. Basunbul, Mohhamed H. Baluch, and Bader N. Ghaleb (1994), Shear

Repair for Reinforced Concrete by Fiberglass Plate Bonding, ACI Structural Journal, Vol. 91, Issue No. 4.

Hadi M. N. S. (2003), Retrofitting of shear failed reinforced concrete beams, Composite Structures.

Islam M. R., Mansur M. A., and Maalej M. (2005), Shear strengthening of RC deep beams using externally bonded FRP

systems, Cement & Concrete Composites.

Khalifa A., Lorenzis L. D., and Nanni A. (2000), FRP composites for shear strengthening of RC beams,

Proceedings, 3rd International Conference on Advanced Composite Materials in Bridges and Structures, 15-18 Aug.

. Khalifa A., and Nanni A. (2000), Improving shear capacity of existing RC T-section beams using CFRP composites, Cement &

Concrete Composites.

Kim G., Sim J., and Oh H. (2008), Shear strength of strengthened RC beams with FRPs in shear, Construction and Building

Materials.

Mosallam A. S., and Banerjee S. (2007), Shear enhancement of reinforced concrete beams strengthened with FRP composite

laminates, Composites: Part B.

Obaidat Y. T., Heyden S., Dahlblom O., Farsakh G. A. and Jawad Y. A. (2011), Retrofitting of reinforced concrete

beams using composite laminates, Construction and Building Materials.

Saafan M. A. A. (2006), Shear strengthening of Reinforced Concrete beams using GFRP wraps, Czech Technical University

in Prague Acta Polytechnica, Vol. 46 No. 1.

. Teng J. G., Lam L., and Chen J.F. (2004), Shear strengthening of RC beams with FRP composites, Programm Structural.

Engineering Material.

. Varastehpour H., and Hamelin P. (1997), Strengthening of concrete beams using fiber reinforced plastics, Materials and

Structures.

DOI: 10.9790/1684-1226139142

www.iosrjournals.org

142 | Page

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Boeing 787 AirplaneDocumento45 páginasThe Boeing 787 AirplaneRomeoTango80% (5)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Kinesics, Haptics and Proxemics: Aspects of Non - Verbal CommunicationDocumento6 páginasKinesics, Haptics and Proxemics: Aspects of Non - Verbal CommunicationInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Human Rights and Dalits: Different Strands in The DiscourseDocumento5 páginasHuman Rights and Dalits: Different Strands in The DiscourseInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Externally Post-Tensioned Carbon FRP Bar System For Deflection ControlDocumento20 páginasExternally Post-Tensioned Carbon FRP Bar System For Deflection ControlTamizhan_K100% (1)

- Aircraft Materials, Structures, Damages, Repair and AgeingDocumento18 páginasAircraft Materials, Structures, Damages, Repair and AgeingFrancisco Zurisaddai MenesesAinda não há avaliações

- Structural Analysis of Spar Madeup of Carbon Fibre Composite MaterialDocumento6 páginasStructural Analysis of Spar Madeup of Carbon Fibre Composite MaterialVarunAinda não há avaliações

- The Impact of Technologies On Society: A ReviewDocumento5 páginasThe Impact of Technologies On Society: A ReviewInternational Organization of Scientific Research (IOSR)100% (1)

- Carbon FiberDocumento30 páginasCarbon FiberAarizMalik100% (1)

- A Rehabilitation of RCC - PSC BridgesDocumento77 páginasA Rehabilitation of RCC - PSC BridgesOneTech ManAinda não há avaliações

- Attitude and Perceptions of University Students in Zimbabwe Towards HomosexualityDocumento5 páginasAttitude and Perceptions of University Students in Zimbabwe Towards HomosexualityInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- "I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweDocumento5 páginas"I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- The Role of Extrovert and Introvert Personality in Second Language AcquisitionDocumento6 páginasThe Role of Extrovert and Introvert Personality in Second Language AcquisitionInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Socio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanDocumento7 páginasSocio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- A Proposed Framework On Working With Parents of Children With Special Needs in SingaporeDocumento7 páginasA Proposed Framework On Working With Parents of Children With Special Needs in SingaporeInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- An Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyDocumento14 páginasAn Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Assessment of The Implementation of Federal Character in Nigeria.Documento5 páginasAssessment of The Implementation of Federal Character in Nigeria.International Organization of Scientific Research (IOSR)Ainda não há avaliações

- Edward Albee and His Mother Characters: An Analysis of Selected PlaysDocumento5 páginasEdward Albee and His Mother Characters: An Analysis of Selected PlaysInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- A Review of Rural Local Government System in Zimbabwe From 1980 To 2014Documento15 páginasA Review of Rural Local Government System in Zimbabwe From 1980 To 2014International Organization of Scientific Research (IOSR)Ainda não há avaliações

- Comparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesDocumento7 páginasComparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Investigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehDocumento4 páginasInvestigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Relationship Between Social Support and Self-Esteem of Adolescent GirlsDocumento5 páginasRelationship Between Social Support and Self-Esteem of Adolescent GirlsInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Topic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshDocumento7 páginasTopic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- The Lute Against Doping in SportDocumento5 páginasThe Lute Against Doping in SportInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Designing of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesDocumento5 páginasDesigning of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesIOSRjournalAinda não há avaliações

- Importance of Mass Media in Communicating Health Messages: An AnalysisDocumento6 páginasImportance of Mass Media in Communicating Health Messages: An AnalysisInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Transforming People's Livelihoods Through Land Reform in A1 Resettlement Areas in Goromonzi District in ZimbabweDocumento9 páginasTransforming People's Livelihoods Through Land Reform in A1 Resettlement Areas in Goromonzi District in ZimbabweInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Role of Madarsa Education in Empowerment of Muslims in IndiaDocumento6 páginasRole of Madarsa Education in Empowerment of Muslims in IndiaInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Beowulf: A Folktale and History of Anglo-Saxon Life and CivilizationDocumento3 páginasBeowulf: A Folktale and History of Anglo-Saxon Life and CivilizationInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Motivational Factors Influencing Littering in Harare's Central Business District (CBD), ZimbabweDocumento8 páginasMotivational Factors Influencing Littering in Harare's Central Business District (CBD), ZimbabweInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Classical Malay's Anthropomorphemic Metaphors in Essay of Hikajat AbdullahDocumento9 páginasClassical Malay's Anthropomorphemic Metaphors in Essay of Hikajat AbdullahInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Women Empowerment Through Open and Distance Learning in ZimbabweDocumento8 páginasWomen Empowerment Through Open and Distance Learning in ZimbabweInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- An Exploration On The Relationship Among Learners' Autonomy, Language Learning Strategies and Big-Five Personality TraitsDocumento6 páginasAn Exploration On The Relationship Among Learners' Autonomy, Language Learning Strategies and Big-Five Personality TraitsInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Substance Use and Abuse Among Offenders Under Probation Supervision in Limuru Probation Station, KenyaDocumento11 páginasSubstance Use and Abuse Among Offenders Under Probation Supervision in Limuru Probation Station, KenyaInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Micro Finance and Women - A Case Study of Villages Around Alibaug, District-Raigad, Maharashtra, IndiaDocumento3 páginasMicro Finance and Women - A Case Study of Villages Around Alibaug, District-Raigad, Maharashtra, IndiaInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Design Management, A Business Tools' Package of Corporate Organizations: Bangladesh ContextDocumento6 páginasDesign Management, A Business Tools' Package of Corporate Organizations: Bangladesh ContextInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- A Study On The Television Programmes Popularity Among Chennai Urban WomenDocumento7 páginasA Study On The Television Programmes Popularity Among Chennai Urban WomenInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Analysis of Drive Shaft: Bhirud Pankaj Prakash, Bimlesh Kumar SinhaDocumento6 páginasAnalysis of Drive Shaft: Bhirud Pankaj Prakash, Bimlesh Kumar SinhakumarAinda não há avaliações

- Measuring CFRP Composite Impedance Using Electrical SpectroscopyDocumento12 páginasMeasuring CFRP Composite Impedance Using Electrical SpectroscopyDavid AcostaAinda não há avaliações

- Apc-2 Peek 031912-01Documento6 páginasApc-2 Peek 031912-01Angel LagrañaAinda não há avaliações

- Features and Benefits: Technical Data SheetDocumento7 páginasFeatures and Benefits: Technical Data SheetNavshinder SinghAinda não há avaliações

- CM Seminar Topics PDFDocumento2 páginasCM Seminar Topics PDFraviAinda não há avaliações

- Simplified Micromechanics of Plain Weave CompositesDocumento15 páginasSimplified Micromechanics of Plain Weave Compositess_padu3003@yahoo.comAinda não há avaliações

- BMECME 305 - MSM - Unit 3 - For SharingDocumento40 páginasBMECME 305 - MSM - Unit 3 - For SharingMohamed SohaibAinda não há avaliações

- Defining Composite Materials and Their ClassificationDocumento23 páginasDefining Composite Materials and Their ClassificationIrudhayaraj DavidAinda não há avaliações

- Advanced Materials, Robotics and NanotechnologyDocumento43 páginasAdvanced Materials, Robotics and NanotechnologyIsabella MagallanesAinda não há avaliações

- Materials Properties DatabaseDocumento34 páginasMaterials Properties DatabaseffontanaAinda não há avaliações

- Masterbrace® Lam (Formerly Known As Mbrace® Laminate)Documento2 páginasMasterbrace® Lam (Formerly Known As Mbrace® Laminate)KY PengAinda não há avaliações

- TestDocumento104 páginasTestkasvikrajAinda não há avaliações

- Applied SciencesDocumento15 páginasApplied Sciencessushil deshmukhAinda não há avaliações

- Italian Technical Committee Defines Bridge Reinforcement GuidelinesDocumento53 páginasItalian Technical Committee Defines Bridge Reinforcement Guidelinessanusi69Ainda não há avaliações

- Canusa CATalogo CommunicationsDocumento17 páginasCanusa CATalogo CommunicationschangoelAinda não há avaliações

- FEModels of GFRP and CFRP StrengtheningDocumento14 páginasFEModels of GFRP and CFRP StrengtheningCrystal SuriyaAinda não há avaliações

- Analysis of tool wear after machining FRPDocumento102 páginasAnalysis of tool wear after machining FRPJosefa PencarralAinda não há avaliações

- STC 2015 CatalogDocumento88 páginasSTC 2015 CatalogOscar SpinningaliciaAinda não há avaliações

- Polymers: Some Properties of Composite Drone Blades Made From Nanosilica Added Epoxidized Natural RubberDocumento11 páginasPolymers: Some Properties of Composite Drone Blades Made From Nanosilica Added Epoxidized Natural RubberseetharamanAinda não há avaliações

- Seminar ReportDocumento35 páginasSeminar ReportSRUTHI FRANCIS M.Tech Environmental Engineering 2020-2022Ainda não há avaliações

- Composite Materials, Structure, General Properties and Applications (2006)Documento14 páginasComposite Materials, Structure, General Properties and Applications (2006)RobbyMuliadiAinda não há avaliações

- Rick Wianeckis Leaning Trike Project PDFDocumento16 páginasRick Wianeckis Leaning Trike Project PDFJoshua Phillip Austero FederisAinda não há avaliações

- WP3.3 033051 095Documento93 páginasWP3.3 033051 095prasadmehtaAinda não há avaliações

- Optistruct CompositesDocumento36 páginasOptistruct CompositesJitendra ItankarAinda não há avaliações