Escolar Documentos

Profissional Documentos

Cultura Documentos

Bridge Design 4 - Design of Superstructures

Enviado por

gabemzamanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Bridge Design 4 - Design of Superstructures

Enviado por

gabemzamanDireitos autorais:

Formatos disponíveis

Outline

Bridge Design

Components of bridge Superstructure

Bridge Deck

Design of

Slab for

Bridge Deck

Structural Components:

Girder (the big beam)

Roadway Deck (slab)

Floor Beam

Stringer

Diaphragm

Nonstructural Components:

Superstructure

Substructure

Girders

Asphalt Surface

Traffic Barriers

Railings

Signs, Lighting, Drainage etc

Empirical Method

Strip Method

Analysis for Moment

Strip Widths

Slab Design for Primary Reinforcement

Secondary Reinforcement

Temperature and Shrinkage Reinforcement

Bridge Superstructure Girder Bridge

Bridge superstructures consist of

structural and nonstructural

components

Diaphragm

Design of RC Deck Slab

Slab thickness/ Minimum Cover

Analysis and Design Methods

Bridge Superstructure

Types

Materials

For girder bridges, all girders rest

on the pier Thus, they all resist

the load (almost) equally

The slabs rest on the top of the

girder

Diaphragms are used to prevent

girders from bending out of plane

and to transfer lateral loads

Girders

Diaphragm

Superstructure

Pier

Substructure

Bridge Superstructure Girder Bridge

Bridge Superstructure Truss Bridge

Slab

For some types of bridge such as truss bridges, loads are transferred to the

pier through two main structural components locating on the outer sides.

Therefore, we need something in between to carry the slab (slab cannot span

the whole roadway width!!! its too wide)

We need floor beams and stringer

Loads are transferred from Slab Stringer Floor Beam Girder Pier

Diaphragm

Girders

Slab

Steel Plate Girder Bridge

Bridge Superstructure Truss Bridge

Girders

(as a Truss)

Floor Beam

Stringer

Bridge Superstructure

Slab

Stringer

(as a Truss)

Girders

(as a Truss)

Components of Truss

Floor Beam

(as a Truss)

Bridge Superstructure

For some types of bridge (such as segmental construction), the girder and

roadway deck are in one piece We will not consider this type of

construction here.

Bridge Deck

Types

Materials

Outline

Components of bridge Superstructure

Bridge Deck

Types

Materials

Design of RC Deck Slab

Slab thickness/ Minimum Cover

Analysis and Design Methods

Empirical Method

Strip Method

Analysis for Moment

Strip Widths

Slab Design for Primary Reinforcement

Secondary Reinforcement

Temperature and Shrinkage Reinforcement

Types of Deck

Conventional reinforced concrete decks supported on girders

Slab superstructures, cast-in-place, longitudinally reinforced

Stay-in-place formwork decks

Types of Deck

Types of Deck

Slab superstructures, cast-in-place, longitudinally reinforced

Conventional reinforced concrete decks supported on girders

Types of Deck

Types of Slab Reinforcement

The deck slab may be designed as One-Way Slab with main

reinforcement perpendicular or parallel to the traffic direction

Main reinforcement perpendicular

to traffic

Stay-in-place formwork decks

Found in girder bridges

Girder Spacing must not be too

large

Main reinforcement parallel to

traffic

Slab on floor beams

Materials: Concrete

Minimum compressive strength, fc = 28 MPa at 28 days (tested on 150 x

300 mm standard cylinders)

Two classes of concrete specified:

Class A (generally used for all structural elements)

Class AE (air-entrained, suitable for freeze/thaw cycles, exposure to deicing

salts and saltwater)

Water-Cement Ratio (W/C) should not exceed 0.49 for Class A (for both

classes)

Materials: Reinforcing Steel

In general, reinforcing bars shall be deformed

(except wires used for spirals, hoops and wire

fabric).

Modulus of elasticity, Es = 200,000 MPa

Minimum Yield strength 420 MPa (can be less with

approval of the Owner)

Maximum Yield strengths 520 MPa

. 20-2543, 24-2548

Modulus of elasticity, Ec

(for concrete unit weight c between 1440-2500 kg/m3)

Ec = 0.043 c (fc)0.5 ; fc in MPa

Type

Grade

Fy (ksc)

Minimum

Fu (ksc)

Minimum

Ultimate Strain

(%) Minimum

Round Bar

SR 24

2400

3900

21

Deformed Bar

SD 30

3000

4900

17

SD 40

4000

5700

15

SD 50

5000

6300

13

Outline

Design of RC Deck Slab

Slab Thickness/ Minimum Cover

Empirical Design Method

Strip Method

Components of bridge Superstructure

Bridge Deck

Types

Materials

Design of RC Deck Slab

Slab thickness/ Minimum Cover

Analysis and Design Methods

Empirical Method

Strip Method

Analysis for Moment

Strip Widths

Slab Design for Primary Reinforcement

Secondary Reinforcement

Temperature and Shrinkage Reinforcement

Minimum Slab Thickness

Absolute Minimum Thickness = 175 mm (9.7.1.1)

Traditionally, the minimum thickness was specified in AASHTO Standard

Specification for the purpose of deflection control

However, AASHTO LRFD removes all the requirements for maximum

deflection and leaves it to the judgment of the designer. Therefore, the

thickness of slab for deflection control is now optional. (2.5.2.6.3)

Slab Span S

Reinforced

Concrete Slab

Prestressed

Concrete Slab

Minimum Cover of Reinforcement

Slab span (s) is determined from

Face-to-Face distance for slab monolithic with beam (i.e. cast into one

piece)

S = slab span (mm)

L = span length (mm)

The clear cover is the distance

from the top or bottom of the

section to the outer edge of steel

reinforcement (not at the

center!)

Minimum cover is specified so

that there is enough concrete to

cover the steel and prevent the

steel from corrosion

A large covering is required in

corrosive environments

For composite slab on steel or concrete girder, the distance between

the face of the webs

Clear

Cover

s

Corrosion of steel in RC bridge deck

Minimum Cover

Minimum clear cover for reinforcing

steel and prestressing steel (5.12.3)

Analysis and Design Methods

Adjustments for Water-Cement Ratio:

For W/C < 0.4, the concrete tends

to be dense; therefore can use only

80% of the value in the table (i.e.

multiply by 0.8)

For W/C > 0.5, the concrete tends

to be porous; the value in the table

must be increase by 20% (i.e.

multiply by 1.2)

Methods for designing slab

Empirical Method (9.7.2)

Approximate Method (Strip Method) (4.6.2.1)

Refined Method including

Classical force and displacement methods

Yield Line Method

Finite Element Analysis

Etc

If there is no initial overlay of wearing

surface, should add another 10 mm to

the clear cover on the top surface to

allows for some wear and tear

Outline

Empirical Method

Components of bridge Superstructure

Bridge Deck

Types

Materials

Design of RC Deck Slab

Slab thickness/ Minimum Cover

Analysis and Design Methods

Empirical Method

Strip Method

Analysis for Moment

Strip Widths

Slab Design for Primary Reinforcement

Secondary Reinforcement

Temperature and Shrinkage Reinforcement

Empirical Method

Empirical Method

Empirical method is based on the test data (this is why it is called

empirical) that the primary mechanism of the bridge deck under wheel

load is not flexure but rather complex arch-action and punching shear

Empirical method of design can be only used for concrete isotropic decks

(having two identical layers of reinforcement, perpendicular to and in touch

with each other) supported on longitudinal components.

If the required conditions are satisfied, we can get the area of steel directly.

Conditions that must be satisfied in order to use the Empirical Method

cross-frames or diaphragms are used throughout the cross-section at

lines of support

the supporting components (girders) are made of steel and/or concrete

the deck is fully cast-in-place (no precast!) and water cured

the deck has uniform depth

Conditions that must be satisfied in order to use the Empirical Method

(Continued)

core depth of the slab is not less than 100 mm

the effective length (or slab span s) 4.1 m

the ratio of effective length (S) to design depth is between 6 and 18

the minimum depth of the slab is 175 mm, excluding the wearing surface

the specified 28-day fc of the deck concrete is > 28 MPa

the deck is made composite with the supporting structural components.

Empirical Method

Reinforcement Requirement for Empirical Method

This does not

depend on the

slab thickness!

The minimum amount of reinforcement shall be:

0.570 mm2/mm of steel for each bottom layer

0.38 mm2/mm of steel for each top layer

Spacing of steel must be 450 mm

4 layers of isotropic reinforcement (same in all directions) shall be

provided

Strip Method

Analysis for Moment

Strip Widths

Slab Design for Primary Reinforcement

Secondary Reinforcement

Temperature and Shrinkage Reinforcement

Outline

Components of bridge Superstructure

Bridge Deck

Strip Method

Design of RC Deck Slab

Slab thickness/ Minimum Cover

Analysis and Design Methods

Empirical Method

Strip Method

Analysis for Moment

Strip Widths

Slab Design for Primary Reinforcement

Secondary Reinforcement

Temperature and Shrinkage Reinforcement

Strip Method - Procedures

Strip method is an approximate analysis method in which the deck is

subdivided into strips perpendicular to the supporting components (girder)

Types

Materials

Slab

Strip

The slab strip is now a continuous beam and can be analyzed using classical

beam theory and designed as a one-way slab

Strip Method Width of Strip

Slab is modeled as beams and with girders as supports

Wheel loads are placed (transversely) on this slab to produced the

maximum effect

min. 2'

Determine the maximum moment (M+ and M-) based on classical beam

theory

Determine the width of strip for each M+ and M- case

Divide the maximum moment by the width of strip to get the moment per

1 unit width of slab

Design an RC slab for this moment the reinforcement required will be for

1 unit width of slab (this is for the primary direction)

The reinforcement in the secondary direction may be taken as a percentage

of those in the primary direction

S

X

+M

-M

=

=

=

=

spacing of supporting components (FT)

distance from load to point of support (FT)

positive moment

negative moment

Strip Method Width of Strip

We can obtain the width of equivalent interior strips from the table,

which depends on the direction of slab relative to traffic (parallel or

perpendicular)

When deck span is parallel to traffic, strip

width must be less than 3600 mm (thats

the design lane width!) (if it is greater, then

another provision applies, see 4.6.2.3)

When deck span is perpendicular

to traffic, there is no limit on

strip width

Strip Method Analysis for Moments

The strips should be analyzed by classical beam theory. The moment obtained

is divided by the strip width to get moment per unit width

Strip Method Simplified Procedure

The previous procedure is quite complex for routine designs (need to

consider transverse placements of live loads to get the maximum effect).

Therefore, AASHTO offers a simplified procedure to determine maximum

M+ and M- directly!!!

Slab is modeled as beams and with girders as supports

Determine the maximum M+ and M- from table (see next page) based on

the slab span this is the LL+IM moment per mm! (multiply by 1000 to

get per m)

M+ and M- from DL/DW are relatively small and may be approximated as

M=wl2/c where c ~ 10-12

Design an RC slab for this moment the reinforcement required will be

for 1 mm of slab (this is for the primary direction)

The reinforcement in the secondary direction may be taken as a

percentage of those in the primary direction

Deck slab is designed

for maximum positive

and negative bending

moments

These moments are

considered as

representative and may

be used for all panels.

Need to consider LL

placement to get the

maximum effect

Primary reinforcement

is calculated using these

moments

Strip Method Design Aid

Strip Method Design Aid

Slab Design

Recall RC Design

Mn = (C or T)*Moment Arm

For under-reinforced beams

Mn = Asfy(d-a/2)

Mn = (0.85fcba)(d-a/2)

Note that Asfy = 0.85fcba

For over-reinforced beam, the

steel does not yield

Mn = Asfs(d-a/2) ; fs=sEs

Mn = (0.85fcba)(d-a/2)

IM and multiple presence factors are included in this table

Slab Design

Strip Method Secondary Reinf.

In the case of deck design only one of five strength load combinations

needs to be investigated:

STRENGTH I

This limit state is the basic load combination relating to normal vehicular use

of the bridge (without wind)

U = [1.25 DC + 1.75 (LL + IM)]

Resistance factors for strength limit state:

0.90 for flexure and tension of reinforced concrete

1.00 for flexure and tension of prestressed concrete

iQi Rn

Reinforcement in the

secondary direction

may be determined as

a percentage of that

in the primary

direction

Strip Method

Note that the primary and

secondary reinforcement is per

unit width of slab (say 1 m)

There is also a minimum

reinforcement requirement for

temperature and shrinkage

As > 0.75 Ag/fy

We can calculate this for a unit

width; i.e.

Ag = 1.00*slab thickness

Você também pode gostar

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionAinda não há avaliações

- Lecture Notes on Reinforced Concrete DesignNo EverandLecture Notes on Reinforced Concrete DesignAinda não há avaliações

- 2 Way Slab Flat Slab PDFDocumento18 páginas2 Way Slab Flat Slab PDFimaduddin91Ainda não há avaliações

- Chapter 5Documento41 páginasChapter 5tewele brhaneAinda não há avaliações

- Determination of Partical Size Distribution of AggregateDocumento5 páginasDetermination of Partical Size Distribution of AggregateschoffilAinda não há avaliações

- Investigation of The Cause of Failure of The Omo River BridgeDocumento5 páginasInvestigation of The Cause of Failure of The Omo River Bridgeambachew abebeAinda não há avaliações

- Chapter 3-0Documento45 páginasChapter 3-0chaltu TerefeAinda não há avaliações

- FullDocumento20 páginasFullSai GowthamAinda não há avaliações

- ShravaniDocumento14 páginasShravanidussa shravaniAinda não há avaliações

- Geometric Design of HighwaysDocumento75 páginasGeometric Design of Highwayssuman subediAinda não há avaliações

- Course Outline: Amit Kumar Varma Geotechnical Engineer Department of RoadDocumento5 páginasCourse Outline: Amit Kumar Varma Geotechnical Engineer Department of RoadVarma AmitAinda não há avaliações

- Bridges: Prepared By: DIA Baboye Lhmaime Mohamed Ajouaou Farid Yazid HamzaDocumento34 páginasBridges: Prepared By: DIA Baboye Lhmaime Mohamed Ajouaou Farid Yazid HamzaSaid Mrf100% (1)

- Bridges Engineering Assignment: Topic: Long Span BridgesDocumento9 páginasBridges Engineering Assignment: Topic: Long Span Bridgeskheiriya duskiAinda não há avaliações

- CE4070 Structural Modelling Yield Line Analysis of Slab IETDocumento18 páginasCE4070 Structural Modelling Yield Line Analysis of Slab IETkartheepan100% (1)

- Behaviour and Design of Rocker Bearings in Bridge StructuresDocumento7 páginasBehaviour and Design of Rocker Bearings in Bridge StructuresDwijendra ChanumoluAinda não há avaliações

- Chapter 1 - Design of Special BeamsDocumento15 páginasChapter 1 - Design of Special BeamsSine EntertaimentAinda não há avaliações

- Analysis and Design of Hostel Building (G+4) Using EtabsDocumento4 páginasAnalysis and Design of Hostel Building (G+4) Using EtabsSamih S. BarzaniAinda não há avaliações

- Assignment No. 1 On Bridge EngineeringDocumento9 páginasAssignment No. 1 On Bridge EngineeringLawrence IbascoAinda não há avaliações

- Bridge EngineeringDocumento16 páginasBridge EngineeringJoson Anquillano Villegas100% (1)

- Foundation Engineering I CE-325: Chapter 3: Bearing Capacity of Shallow FoundationsDocumento17 páginasFoundation Engineering I CE-325: Chapter 3: Bearing Capacity of Shallow FoundationsRobert Prince100% (1)

- ECE 4215 Pavement Analysis Design Worked ExamplesDocumento8 páginasECE 4215 Pavement Analysis Design Worked ExamplesdantezAinda não há avaliações

- Components of A BridgeDocumento4 páginasComponents of A BridgeBhemalee Tono DimalaluanAinda não há avaliações

- Structural Design-Strip MethodDocumento22 páginasStructural Design-Strip Methodgirma kebedeAinda não há avaliações

- Training Report Rajasthan Housing BoardDocumento13 páginasTraining Report Rajasthan Housing BoardDevendra SharmaAinda não há avaliações

- Finite Element Analysis of Skew Curved RC Box Girder BridgeDocumento8 páginasFinite Element Analysis of Skew Curved RC Box Girder BridgeTran Tien DungAinda não há avaliações

- 3 Truss BridgeDocumento22 páginas3 Truss BridgeVishvanjayAinda não há avaliações

- Structural Analysis Exam PapersDocumento3 páginasStructural Analysis Exam Papersfesada1100% (1)

- Bridge Design PhilosophyDocumento21 páginasBridge Design PhilosophyAddrien Daniel100% (1)

- 2007-S2 Cven9818Documento2 páginas2007-S2 Cven9818Suman SahaAinda não há avaliações

- Bidge Deck AnalysisDocumento36 páginasBidge Deck AnalysisAshish Karki100% (1)

- Deck Slab DesignDocumento27 páginasDeck Slab Designquithanqui100% (1)

- Introduction To Shell TheoryDocumento45 páginasIntroduction To Shell TheorySurendraBhatta100% (1)

- Chapter 1 Deep Beams and Corbels Lecture Notes1Documento49 páginasChapter 1 Deep Beams and Corbels Lecture Notes1Tadesse MegersaAinda não há avaliações

- Fitsum Abebe PDFDocumento87 páginasFitsum Abebe PDFbernice el mazeAinda não há avaliações

- Concrete Technology NOTEDocumento54 páginasConcrete Technology NOTEJanmarc PadilskiAinda não há avaliações

- Highway SurveyDocumento30 páginasHighway SurveyVittal Kumar100% (1)

- Design of Retaining Walls (B&W)Documento29 páginasDesign of Retaining Walls (B&W)Abdul SalamAinda não há avaliações

- Unbraced WallDocumento7 páginasUnbraced WallakanagesAinda não há avaliações

- Lecture On Limit State Design by Manish BhutaniDocumento27 páginasLecture On Limit State Design by Manish BhutaniTarunAinda não há avaliações

- Pile Foundation: Babaria Institute of TechnologyDocumento47 páginasPile Foundation: Babaria Institute of TechnologyKeval ShahAinda não há avaliações

- Two Way Slab DesignDocumento16 páginasTwo Way Slab DesignMandar NadgaundiAinda não há avaliações

- Slab Bridge - Design Example-2 PDFDocumento10 páginasSlab Bridge - Design Example-2 PDFBarklgn BehailuAinda não há avaliações

- Designing of Reinforce Concrete Deck Slab Bridge With Aashto (LRFD) Design SpecificationDocumento54 páginasDesigning of Reinforce Concrete Deck Slab Bridge With Aashto (LRFD) Design SpecificationTharach JanesuapasaereeAinda não há avaliações

- Reinforced Concrete - I DMU Lecture NotesDocumento206 páginasReinforced Concrete - I DMU Lecture NotesAntenehAinda não há avaliações

- Prestress Beam PDFDocumento12 páginasPrestress Beam PDFramapraveengAinda não há avaliações

- Force (Flexibility) Method of Structural AnalysisDocumento48 páginasForce (Flexibility) Method of Structural AnalysisthareendaAinda não há avaliações

- Magazines o o o oDocumento14 páginasMagazines o o o oTemesgenAbiyAinda não há avaliações

- Abutment Design Example To BD 30Documento16 páginasAbutment Design Example To BD 30Muzammil Moosafeer100% (1)

- Analysis and Design of Box CulvertDocumento16 páginasAnalysis and Design of Box CulvertSOUMYA BHATTAinda não há avaliações

- CH-3 Pile FoundationsDocumento85 páginasCH-3 Pile FoundationsDejene Ambese100% (1)

- Evaluating of Rutting in Highways & Providing Its Solution in Terms of Stone Matrix Asphalt.Documento7 páginasEvaluating of Rutting in Highways & Providing Its Solution in Terms of Stone Matrix Asphalt.IJRASETPublications100% (1)

- UNIVERSITY OF GONDAR CH-2 ExamplesDocumento11 páginasUNIVERSITY OF GONDAR CH-2 Examplescherinet bisetegnAinda não há avaliações

- Lec-12 Development LengthDocumento47 páginasLec-12 Development LengthMuhammad UsmanAinda não há avaliações

- Shallow Foundation CalculationDocumento5 páginasShallow Foundation CalculationSanjay BossAinda não há avaliações

- Buttress Dam Le1Documento16 páginasButtress Dam Le1Cj GumiranAinda não há avaliações

- Manual Pavement Condition Survey MethodologyDocumento3 páginasManual Pavement Condition Survey MethodologyS C Jha100% (1)

- Bridge EngineeringDocumento25 páginasBridge EngineeringAnubhav Chaudhary100% (1)

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985No EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Ainda não há avaliações

- Investigation of the Chirajara Bridge CollapseNo EverandInvestigation of the Chirajara Bridge CollapseAinda não há avaliações

- Intro To and Tips For Spreadsheets CHG 13 Jul 2015Documento13 páginasIntro To and Tips For Spreadsheets CHG 13 Jul 2015gabemzamanAinda não há avaliações

- Section 7 Street LightingDocumento18 páginasSection 7 Street Lightinggabemzaman100% (1)

- + Culvert Report-FinalDocumento17 páginas+ Culvert Report-FinalgabemzamanAinda não há avaliações

- Ppr12 322alrDocumento19 páginasPpr12 322alrgabemzamanAinda não há avaliações

- Figures Girder Schedule: Negative Value Indicates Back From MidspanDocumento1 páginaFigures Girder Schedule: Negative Value Indicates Back From MidspangabemzamanAinda não há avaliações

- Fhwa Nhi-06-088 Volume II - Soils and FoundationsDocumento594 páginasFhwa Nhi-06-088 Volume II - Soils and FoundationsKathleen Noonan100% (1)

- Scaffolding PDFDocumento80 páginasScaffolding PDFLeo Richmond75% (4)

- Initial Opening For The Halls of A Humanization Center West of JerusalemDocumento7 páginasInitial Opening For The Halls of A Humanization Center West of JerusalemgabemzamanAinda não há avaliações

- Panorama Tower: Tekla Software in PracticeDocumento8 páginasPanorama Tower: Tekla Software in PracticegabemzamanAinda não há avaliações

- Bridge Design 3 - LoadsDocumento9 páginasBridge Design 3 - LoadsgabemzamanAinda não há avaliações

- Access Scaffolding Structural Design CriteriaDocumento2 páginasAccess Scaffolding Structural Design CriteriagabemzamanAinda não há avaliações

- Terma Rujukan Perunding 2014Documento7 páginasTerma Rujukan Perunding 2014gabemzamanAinda não há avaliações

- Lieh TzuDocumento203 páginasLieh TzuBrent Cullen100% (2)

- Anemia in PregnancyDocumento5 páginasAnemia in PregnancycfgrtwifhAinda não há avaliações

- Pityriasis VersicolorDocumento10 páginasPityriasis Versicolorketty putriAinda não há avaliações

- Physics Education Thesis TopicsDocumento4 páginasPhysics Education Thesis TopicsPaperWriterServicesCanada100% (2)

- Pathology of LiverDocumento15 páginasPathology of Liverערין גבאריןAinda não há avaliações

- Genetics Icar1Documento18 páginasGenetics Icar1elanthamizhmaranAinda não há avaliações

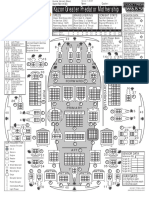

- Kazon Greater Predator MothershipDocumento1 páginaKazon Greater Predator MothershipknavealphaAinda não há avaliações

- Standard Answers For The MSC ProgrammeDocumento17 páginasStandard Answers For The MSC ProgrammeTiwiAinda não há avaliações

- Cable To Metal Surface, Cathodic - CAHAAW3Documento2 páginasCable To Metal Surface, Cathodic - CAHAAW3lhanx2Ainda não há avaliações

- 6GK74435DX040XE0 Datasheet enDocumento3 páginas6GK74435DX040XE0 Datasheet enLuis CortezAinda não há avaliações

- postedcontentadminuploadsFAQs20for20Organization PDFDocumento10 páginaspostedcontentadminuploadsFAQs20for20Organization PDFMohd Adil AliAinda não há avaliações

- Produktkatalog SmitsvonkDocumento20 páginasProduktkatalog Smitsvonkomar alnasserAinda não há avaliações

- Gas Dynamics and Jet Propulsion 2marksDocumento15 páginasGas Dynamics and Jet Propulsion 2marksAbdul rahumanAinda não há avaliações

- Business Plan in BDDocumento48 páginasBusiness Plan in BDNasir Hossen100% (1)

- Mosfet Irfz44Documento8 páginasMosfet Irfz44huynhsang1979Ainda não há avaliações

- Heimbach - Keeping Formingfabrics CleanDocumento4 páginasHeimbach - Keeping Formingfabrics CleanTunç TürkAinda não há avaliações

- Quarter 1 - Module 1Documento31 páginasQuarter 1 - Module 1Roger Santos Peña75% (4)

- Biblical World ViewDocumento15 páginasBiblical World ViewHARI KRISHAN PALAinda não há avaliações

- BrochureDocumento3 páginasBrochureapi-400730798Ainda não há avaliações

- UT Dallas Syllabus For Govt4396.002.08s Taught by Gregory Thielemann (Gregt)Documento2 páginasUT Dallas Syllabus For Govt4396.002.08s Taught by Gregory Thielemann (Gregt)UT Dallas Provost's Technology GroupAinda não há avaliações

- Teaching Profession - Educational PhilosophyDocumento23 páginasTeaching Profession - Educational PhilosophyRon louise PereyraAinda não há avaliações

- In Flight Fuel Management and Declaring MINIMUM MAYDAY FUEL-1.0Documento21 páginasIn Flight Fuel Management and Declaring MINIMUM MAYDAY FUEL-1.0dahiya1988Ainda não há avaliações

- Man As God Created Him, ThemDocumento3 páginasMan As God Created Him, ThemBOEN YATORAinda não há avaliações

- Sept Dec 2018 Darjeeling CoDocumento6 páginasSept Dec 2018 Darjeeling Conajihah zakariaAinda não há avaliações

- Case Study 2Documento5 páginasCase Study 2api-247285537100% (1)

- IMCI Chart BookletDocumento43 páginasIMCI Chart Bookletmysticeyes_17100% (1)

- Aleutia Solar Container ClassroomDocumento67 páginasAleutia Solar Container ClassroomaleutiaAinda não há avaliações

- ReadmeDocumento2 páginasReadmechethan100% (1)

- Module 2 MANA ECON PDFDocumento5 páginasModule 2 MANA ECON PDFMeian De JesusAinda não há avaliações

- Clockwork Dragon's Expanded ArmoryDocumento13 páginasClockwork Dragon's Expanded Armoryabel chabanAinda não há avaliações