Escolar Documentos

Profissional Documentos

Cultura Documentos

Is 4049 2 1996

Enviado por

م.ذكى فضل ذكىTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Is 4049 2 1996

Enviado por

م.ذكى فضل ذكىDireitos autorais:

Formatos disponíveis

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

1 +, 1 +

01 ' 5

The Right to Information, The Right to Live

Step Out From the Old to the New

Mazdoor Kisan Shakti Sangathan

Jawaharlal Nehru

IS 4049-2 (1996): Formed ends for tanks and pressure

vessels, Part 2: Based on inside diameter basis [MED 17:

Chemical Engineering Plants and Related Equipment]

! $ ' +-

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

! > 0 B

BharthariNtiatakam

Knowledge is such a treasure which cannot be stolen

IS 4049 (Part 2) : 1996

(Reaffirmed 2001 )

REAFFI61MEO

Z006

(Tf&fT~ )

Indian Standard

FORMED ENDS FOR TANKS AND

PRESSURE VESSELS - SPECIFICATION

PART 2 INSIDE DIAMETER BASIS

( First Revision)

First Reprint MAY 2006

res 23.020.10;

23.020.30

BIS 1996

BUREAU

OF INDIAN

STANDARDS

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

October 1996

Price Group 3

AMENDMENT NO.1

JULY 2006

TO

IS 4049 (PART 2) : 1996 FORMED ENDS FOR TANKS

AND PRESSURE VESSELS - SPECIFICATION

PART 2 INSIDE DIAMETER BASIS

( First Revision)

(Page 1, clause 4.3 ) - Substitute following for the existing clause:

'4.3 Length of the Straight Flange - The length of the straight flange shall

not be less than three times the end thickness with a minimum of 38 rom, unless

otherwise agreed to between the manufacturer and the purchaser. '

(ME 17)

Reprography Unit, BIS, New Delhi, India

Chemical Engineering Plants and Related Equipment Sectional Committee, HMD 17

FOREWORD

This Indian Standard (Part 2) (First Revision) was adopted by the Bureau of Indian Standards, after the

draft finalized by the Chemical Engineering Plants and Related Equipment Sectional Committee had been

approved by the Heavy Mechanical Engineering Division Council.

This standard was first published in 1979. This revision of the standard is being brought out to bring

it in line with the latest practices being followed in the country. The important modifications being:

a)

length of the straight flange revised from 20 rom minimum to 38 mm minimum;

b)

tolerance on circularity, that is the difference between the maximum and minimum diameter

increased; and

c)

provision of shallow dished and flanged ends having knuckle radius of 6 percent withdrawn.

Formed ends are used as end closures for pressure vessels, receivers and similar equipments. IS 2825:1969

'Code for unfired pressure vessels' specifies anyone of the following shapes for the ends:

a)

Hemispherical,

b)

Semi-ellipsoidal,

c)

Dished and flanged, and

d)

Conical.

In this specification only semi-ellipsoidal,dished and flanged ends are covered. The code for unfired pressure

vessels (IS 2825:1969) also permits deeper or slightly shallower semi-ellipsoidal ends and dished and flanged

ends deeper than those specified in this standard. But these shapes are considered 'special' and have not,

therefore, been included.

The formed ends are designated either on outside diameter basis or inside diameter basis. The Part 1

of this standard covers formed ends on outside diameter basis while this Part 2 of the standard covers

formed ends on inside diameter basis.

The information to be supplied by the purchaser to the manufacturer along with the enquiry or order is

given in Annex A.

For the purpose of deciding whether a particular requirement of this standard is complied with, the final

value, observed or calculated, expressing the result of a test or analysis, shall be rounded off in accordance

with IS 2:1960 'Rules for rounding off numerical values (revised)'. The number of significant places retained

in the rounded off value should be the same as that of the specified value in this standard.

IS 4049 (part 2)

1996

Indian Standard

FORMED ENDS FOR TANKS AND

PRESSURE VESSELS - SPECIFICATION

PART 2 INSIDE DIAMETER BASIS

(First Revision)

1 SCOPE

where

This standard (Part 2) specifies the profile dimensions

and technical delivery conditions of dished and

flanged, pressed or spun ends designed on the basis

of inside diameter commonly used as end closures

of pressure vessels, receivers, tanks and similar

equipments.

D,

inner diameter of dished end,

Do

outer diameter of dished end.

Ro

outer crown radius.

R,

Inner crown radius.

ro

outer knuckle radius. and

1.1 Where the ends have reinforced or flanged-in

manholes, it is recommended that they are made to

the same geometric shape as the plain ends.

rl

inner knuckle radius.

REFERENCE

4.1 Flange and Dishing Diameter

This standard makes reference to IS 2825:1969 'Code

for unfired pressure vessels' which is a necessary

adjunct to this standard.

3

4 DIMENSIONS

TYPES OF ENDS

The inside diameter, the inside crown radius and

inside knuckle radius shall conform to the requirements

of Tables 1, 2 and 3.

4.2 Thickness

3.1 The ends shall conform to one of the following

shapes.

3.1.1 Deep dished and flanged ends with an internal

height of dishing hi approximately equal to one-quarter

of the inside flange diameter D. for pressure vessels,

either

a) of semi-ellipsoidal shape with the inner

contour of a true ellipse having an axis ratio

of2: I with inside diameter as given in Table 1

or

b) of torispherical shape (see Table 1).

4.2.1 Minimum thickness is the thickness measured

at the thinnest point after manufacture of the dished

ends. Nominal thickness is the thickness of the plate

used in manufacturing of the dished end.

4.2.2 The minimum thickness shall be supplied by

the purchaser based on internal/external pressure and

other design loading inclusive of corrosion/erosion

allowance as per IS 2825: 1969. For non-pressure

vessels and tanks, the minimum thickness shall be as

agreedto between the purchaser and the manufacturer.

4.3 Length of the Straight Flange

3.1.2 Dished and flanged ends with an internal height

of dishing h. slightly less than one-fifth of the inside

flange diameter D, suitable for pressure vessels (see

Table 2).

Minimum length of the straight flange shall be three

times the end thickness but need not exceed 38 mm

except when necessary to provide required length of

taper.

3.1.3 Shallow dished and flanged ends for tanks and

other non-pressure vessels (see Table 3).

4.4 Tolerances

NOlES

1 IS 2825: 1969 specifies that in the case of dished and flanged

ends, the inside radius of dishing (Knuckle radius) shall preferably

be not less than 10 percent of the inside diameter and in no case

less than 6 percent of the inside diameter or three times the thickness

whichever is more.

2 In the case of ends of partial spherical form. the Internal height

of dishIng hi and external height of dishing ho can be determined

as follows:

h,

=R

1 -

(R, - DJ.. x (R, + DI..- 2 r,)

ho = R.- (Ro

2

-

f!) x (Ro + l!..

2

2

.- 2 r)

The ends shall be true to shape within the limits

specified in 4.4.1 to 4.4.4 below, unless more stringent

tolerances are specified by the purchaser.

4.4.1 Circumference

The inside circumference of the straight flange of

the finished end shall not depart from the

circumference calculated from the inside diameter by

more than the values given below:

Inside diameter upto

and including 400 mm

5 mm

Inside diameter over

400 mm

0.25 percent

IS 4049 (Part 2) : 1996

4.4.2

6.2.3 Where depressions exceed the tolerance limits

specified on the plate, such depressions shall be

removed by grinding or by welding with the

permission of the purchaser by an approved welding

procedure. Hammering of surface defects is not

permitted.

Circularity

The difference between the maximum and the

minimum inside diameters of the straight flange shall

not exceed one percent of inside diameter and shall

in no case be greater than D1 + 2500

200

4.4.3

6.2.4 The heat treatment and radiography requirements

shall be in accordance with IS 2825:1969.

Thickness

6.3 Testing of Dished Ends for Material Quality

From the point where the crown radius R. joins the

knuckle radius r. and at the point where the knuckle

radius rj joins the straight portion of the flange end,

a gradual thinning is permissible up to maximum of

10 percent of the nominal thickness or 2 rom whichever

is higher. A similar gradual thinning is permissible

for ends of semi-ellipsoidal shape. Due to gathering

of material, the thickness in the straight portion of

the flange may increase. This shall not exceed 15

percent of the nominal thickness of the plate.

Thickness of the thinnest point of dished end shall

not be less than the minimum thickness specified by

the purchaser.

To ensure that the material properties are not impaired

during the manufacture of dished ends, samples taken

from dished ends after the final heat treatment shall

be subjected to mechanical test for tensile strength,

impact strength where necessary (for low temperature

application) and bend tests as specified in the relevant

specification for the plate material. The location of

test plates is subject to agreement between the

manufacturer and the purchaser and may be one of

the following:

a) Extended portion cut out from the straight

flange.

NOTE - Where dished ends are provided with flanges in

manholes. the thinning is permissible up to a maximum of 40

percent of the nominal thickness on the major axis and 15

percent of the nominal thickness on the minor axis.

4.4.4

b) Opening cut out for nozzles

c) Separate test plates from the same melt and

heat number subjected to simulation similar

to the. dished ends.

J>rollle

The inside depth of dishing h. shall. not be less than

the theoretical depth nor shall this depth exceed by

more than 1.25 percent of the inside diameter D, of

the dished end.

6.4 For high alloy steel (austenitic steels in particular,

dished end subjected to hot forminglheat treatment)

requirement of intergranular corrosion test to check

for carbide precipitation is to be carried out, wherever

specified and agreed upon between the purchaser and

the supplier.

S MATERIAL

The material of construction shall be carbon steel

or low alloy or high alloy steel or non-ferrous metal.

The exact specification shall be specified by the

purchaser in his order.

6.S In case of dished end manufactured by spinning

process, the dished end is to be subjected to dye

penetrant examination on the outside surface of

knuckle region. If desired before by the purchaser

it may be carried out on inside surface knuckle region

also.

6 TECHNICAL DELIVERY CONDITIONS

The following details regarding technical delivery

conditions for dished ends shall be included.

7 MARKING

6.1 Heat-Treated Conditions

7.1 The dished ends shall be marked with the

following:

The dished ends shall be delivered in heat-treated

condition depending upon the process of dishing,

temperature of dishing and the material specification.

Heat treated condition of dished end is a subject of

agreement between the manufacturer and the

purchaser.

a)

b)

c)

d)

e)

6.2 Workmanship

Inside diameter,

Type of dished end,

Minimum thickness,

Material of construction, and

Identification of the source of manufacturer.

6.2.1 Descaling shall be carried out to measure the

dimensions and to carry out visual inspection. Dished

ends shall be free from any injurious defects.

7.2 BIS Certification Marking

6.2.2 Projection, depressions or elongated grooves

usually developed during dishing are permissible so

long as these depressions are not sharp and their

depth is within the tolerance limits specified on the

plate. Sharp grooves, laminations and other surface

cracks shall be completely removed by grinding or

any other suitable method.

7.2.1 The use of the Standard Mark is governed by

the provisions of the Bureau ofIndian Standards Act,

1986 and the Rules and Regulations made thereunder.

The details of conditions under which the licence for

the use of the Standard Mark may be granted to

manufacturers or producers may be obtained {rom

the Bureau of Indian Standards.

The dished ends may also be marked with the Standard

Mark.

IS 4049 (part 2)

1996

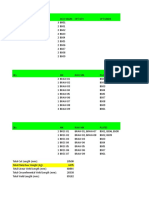

Table 1 Dimensions for Deep Dished and Flanged Ends (Torispherical)

(Clauses 3.1.1 and 4.1)

All dimensions in millimetres.

D;

Inside

Diameter

D,

Crown

Radius

RI

Inside

Knuckle

Radius

r,

N01E -

(I)

(2)

(3)

400

320

40()

60

500

600

480

100

700

560

125

800

640

125

900

'1 000

720

150

800

150

Length of

Straight

Flange

S,

(4)

80

I 100

880

175

I 200

960

200

I 300

1 040

200

I 400

I 120

250

I 500

I 200

250

I 600

1 280

250

I 700

I 360

300

I 800

1 440

300

1 900

I 520

300

2 000

J 600

300

2 100

1 680

350

2 200

1 760

350

2 300

1 840

350

2 400

1 920

400

2 600

2080

400

2800

2240

450

3000

2400

450

3 200

2560

500

3 400

2640

600

3600

2 880

600

3 800

3040

600

4000

3 200

600

4 250

3400

700

4500

3600

700

4 750

3800

800

5000

4 000

800

See 4.3

As sizes below 400 correspond to pipe caps, the dimensions shall conform to the outside diameters of pipes.

3

IS 4049 (part 2) : 1996

Table 2 Dimensions for Dished and Flanged Ends (Torispherical)

(Clauses 3.1.2 and 4.1)

All dimensions in millimetres.

Di

Inside

Diameter

Crown

Radius

D1

R.

Inside

Knuckle

Radius

Length of

Straight

Flange

T1

Sf

(I)

(2)

(3)

(4)

400

500

600

700

800

900

1000

1 100

1 200

1 300

1.400

1 500

1600

1 700

1800

I 900

2000

2 100

2200

2300

2400

2600

2800

3000

3200

3400

3600

3800

4000

4250

4500

4 750

5000

400

500

600

700

800

40

50

60

75

80

100

100

125

125

150

150

150

175

175

200

200

200

250

250

250

250

300

300

300

350

350

400

400

400

450

450

500

500

See 4.3

900

1000

1 100

1200

1300

1400

1 500

1600

1 700

I 800

I 900

2000

2 100

2200

2300

2400

2600

2800

3000

3200

3400

3600

3800

4000

4250

4500

4750

5.000

NOlE- As sizes below 400 correspond to pipe caps, the dimensions shall conform to the outside diameters of pipes.

IS 4049 (Part 2) : 1996

Table 3 Dimensions for Shallow Dished and Flanged Ends for Tanks and Non-pressure Vessels

(Clauses 3.1.3 and 4.1)

All dimensions in millimetres.

Inside

Diameter

Radius

Inside

Knuckle

D.

R.

Radius

(i)

900

CroWD

Length of

Straight

Flange

'1

S,

.(2)

(3)

(4)

950

50

1000

1200

50

I 100

1400

50

I 200

I 500

50

I 300

1700

50

i 400

1700

50

I 500

I 800

50

I 600

2000

50

I 700

2200

50

I 800

2400

50

I 900

2600

50

2000

2800

50

2 100

3000

50

2200

3300

50

2300

3300

50

2400

3300

50

2600

3300

50

2 800

3500

50

3000

3600

50

3200

4000

50

3400

4000

50

3600

5000

SO

3 800

5000

50

4000

5000

50

4 250

5500

50

4500

5500

50

4750

5500

50

5000

5500

60

See 4.3

IS 4049 (Part 2)

1996

ANNEX A

(Foreword)

INFORMATION TO BE SUPPLIED BY THE PURCHASER

AI The purchaser shall supply the following

information to the manufacturer with the enquiry or

order:

a)

b)

c)

d)

e)

f) Radiography and any other non-destructive

g)

h)

Type of dished end required;

Inside diameter in millimetres;

Material of construction of the dished end;

Method of heat treatment;

Minimum and nominal thickness of the dished

end;

j)

k)

m)

testing, if required;

Length of straight flange;

Whether the flange is to be machined and

weld preparation required;

Special requirements for the welded joints

in a dished end made from more than one

plate;

Inspection or survey requirements; and

Manhole or any connection details, if required.

Bureau of Indian Standards

BlS is a statutory institution established under the Bureau of Indian Standards Act, 1986 to promote

harmonious development of the activities of standardization, marking and quality certification of goods

and attending to connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any

form without the prior permission in writing of BIS. This does not preclude the free use, in course of

implementing the standard, of necessary details, such as symbols 'and sizes, type or grade designations.

Enquiries relating to copyright be addressed to the Director (Publications), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also

reviewed periodically; a standard along with amendments is reaffirmed when such review indicates that

no changes are needed; if the review indicates that changes are needed, it is taken up for revision. Users

of Indian Standards should ascertain that they are in possession of the latest amendments or edition by

referring to the latest issue of 'BIS Catalogue' and 'Standards: Monthly Additions'.

This Indian Standard has been developed from Doc: No. HMD 17 (0067).

Amendments Issued Since Publication

Amendment No.

Date-of Issue

Text Affected

BUREAU OF INDIAN STANDARDS

Headquarters:

Manak Bhavan, 9 Bahadur Shall Zafar Marg, New Delhi 110 002

Telephones: 23230131,2323 3375, 2323 9402 Website: www.bis.org.in

Regional Offices:

Telephones

Central:

Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEW DELHI 110 002

23237617

{ 23233841

Eastern:

1/14, C.LT. Scheme VII M, VLP. Road, Kankurgachi

KOLKATA 700 054

Northern: SCO 335-336, Sector 34-A, CHANDIGARH 160022

23378499:2337'8561

{ 23378626,23379120

2603843

{ 260 19285,

Southern: C.I.T. Campus, IV Cross Road, CHENNAI 600 113

2254 1216,2254 1442

{ 22542519,22542315

Western: Manakalaya, E9 MillC, Marol, Andheri (East)

MUMBAI 400 093

28n 9295, 2832 7858

{ 28327891, 28327892

Branches: AHMEDABAD. BANGALORE. BHOPAL. BHUBANESHWAR. COIMBATQRE. FARIDABAD.

GHAZIABAD. GUWAHATL HYDERABAD. JAIPUR. KANPUR. LUCKNOW. NAGPUR.

NALAGARH. PATNA. PUNE. RAJKOT. THIRUVANANTHAPURAM. VISAKHAPATNAM.

Printed at Dee Kay Printers, New Delhi

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- API 650 Tank Design CalculationDocumento8 páginasAPI 650 Tank Design Calculationmail_younes659283% (29)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- API 650 Design TanksDocumento34 páginasAPI 650 Design TanksSyedZainAli100% (13)

- Autocad NotesDocumento53 páginasAutocad Notesadnan100% (7)

- Regulatory AffairsDocumento14 páginasRegulatory AffairsSiddarth Reddy100% (2)

- Guideline Qualification of Equipment Annex 9 PH-meter October 2015Documento4 páginasGuideline Qualification of Equipment Annex 9 PH-meter October 2015Parkhomyuk50% (2)

- Liquid Dye Penetrant Test Inspection Sample ProcedureDocumento8 páginasLiquid Dye Penetrant Test Inspection Sample Procedureم.ذكى فضل ذكىAinda não há avaliações

- Visual Inspection Test ReportDocumento2 páginasVisual Inspection Test Reportم.ذكى فضل ذكىAinda não há avaliações

- Heat Treating The SteelDocumento12 páginasHeat Treating The Steelyasir_anjumAinda não há avaliações

- API 650-Water SS Tank-060914Documento84 páginasAPI 650-Water SS Tank-060914Hamou MelloulAinda não há avaliações

- Supported Cone Roof (CS) Add.4Documento21 páginasSupported Cone Roof (CS) Add.4skhurramq100% (2)

- Sloshing Wave 2 PDFDocumento5 páginasSloshing Wave 2 PDFم.ذكى فضل ذكىAinda não há avaliações

- GRP Installation Procedure PDFDocumento13 páginasGRP Installation Procedure PDFpparreraAinda não há avaliações

- Lifting Lug CalculationDocumento8 páginasLifting Lug CalculationLathesh JanarthananAinda não há avaliações

- Steel Construction and Bridges Allowable Stress DesignDocumento263 páginasSteel Construction and Bridges Allowable Stress DesignSaharAkthamAinda não há avaliações

- API 650 Design TanksDocumento51 páginasAPI 650 Design Tanksم.ذكى فضل ذكى100% (2)

- Chapter 5 98Documento34 páginasChapter 5 98masturaabdulrahimAinda não há avaliações

- Structural SteelDocumento6 páginasStructural SteelYusuf SaputraAinda não há avaliações

- Tank API 650 SI 0001Documento23 páginasTank API 650 SI 0001م.ذكى فضل ذكىAinda não há avaliações

- PR-1002 - Operations Excavation ProcedureDocumento19 páginasPR-1002 - Operations Excavation Procedureم.ذكى فضل ذكىAinda não há avaliações

- GRP Installation Procedure PDFDocumento13 páginasGRP Installation Procedure PDFpparreraAinda não há avaliações

- IS Code 803Documento98 páginasIS Code 803prnpa234Ainda não há avaliações

- F45 CDD 01Documento54 páginasF45 CDD 01paimpillyAinda não há avaliações

- Pad Eye Design Lifting Lug StandartDocumento7 páginasPad Eye Design Lifting Lug Standartstalin_83Ainda não há avaliações

- TANK Design DetailingDocumento17 páginasTANK Design DetailingTiffany Vabiola100% (8)

- Is Code 6512 1984 Criteria For Design of Solid Gravity DamsDocumento28 páginasIs Code 6512 1984 Criteria For Design of Solid Gravity DamsSrinath BonakurthiAinda não há avaliações

- Ldo Storage Tank Calculation 170Documento6 páginasLdo Storage Tank Calculation 170م.ذكى فضل ذكى100% (1)

- Supported Cone Roof CS Add 4 PDFDocumento13 páginasSupported Cone Roof CS Add 4 PDFم.ذكى فضل ذكىAinda não há avaliações

- Samples ITPDocumento4 páginasSamples ITPHassan SajidAinda não há avaliações

- Ziolko J Supernak E Borek P Jedrzejewski M T Kowalski D Tank Construction of 75000 m3 Capacity With A Double Shell and Double ButtomDocumento9 páginasZiolko J Supernak E Borek P Jedrzejewski M T Kowalski D Tank Construction of 75000 m3 Capacity With A Double Shell and Double Buttomم.ذكى فضل ذكىAinda não há avaliações

- Types TanksDocumento17 páginasTypes TanksCarlos Augusto FerreiraAinda não há avaliações

- BTE Dome Brochure Jun 10Documento2 páginasBTE Dome Brochure Jun 10م.ذكى فضل ذكىAinda não há avaliações

- CO2 Absorption by Ionic LiquidsDocumento52 páginasCO2 Absorption by Ionic LiquidsMohd. Belal HaiderAinda não há avaliações

- Comparative Investigation of Organic CompundsDocumento6 páginasComparative Investigation of Organic CompundsKizer Dela Cruz100% (1)

- Que BankDocumento12 páginasQue BankAbhishek VishwakarmaAinda não há avaliações

- Ampho 149Documento18 páginasAmpho 149Luis Andre SilvaAinda não há avaliações

- H.Flyer - SN Housings - Fno3036 - SN - eDocumento4 páginasH.Flyer - SN Housings - Fno3036 - SN - epcesar777Ainda não há avaliações

- Qualitative ChemistryDocumento74 páginasQualitative Chemistryবিশ্বস্ত মিথ্যাবাদীAinda não há avaliações

- Question Bank of ESTDocumento5 páginasQuestion Bank of ESTKishor PatilAinda não há avaliações

- Section 9 Introduction To Welding ProcessesDocumento16 páginasSection 9 Introduction To Welding ProcessesS GoudaAinda não há avaliações

- 3123 PDFDocumento4 páginas3123 PDFTrefina PranaAinda não há avaliações

- HNDBK For Calculation of Nuclear Reaction DataDocumento166 páginasHNDBK For Calculation of Nuclear Reaction DatadelhiprashantAinda não há avaliações

- Metal Precipitation + Solid-Aqueous EquilibriaDocumento26 páginasMetal Precipitation + Solid-Aqueous EquilibriaDotan NutodAinda não há avaliações

- TilesDocumento84 páginasTilesgagan raoAinda não há avaliações

- Agip Eni Alaria-2 - 3 - 7Documento2 páginasAgip Eni Alaria-2 - 3 - 7Andre WantoAinda não há avaliações

- Etheric MelaninDocumento40 páginasEtheric MelaninAsar100% (1)

- Effect of Heat Treatment On Microstructure and Mechanical Behaviours of 18ni-300 Maraging Steel Manufactured by Selective Laser MeltingDocumento11 páginasEffect of Heat Treatment On Microstructure and Mechanical Behaviours of 18ni-300 Maraging Steel Manufactured by Selective Laser MeltingHasan TaşAinda não há avaliações

- (Courseware) ICSE: Mendeleev's Periodic TableDocumento39 páginas(Courseware) ICSE: Mendeleev's Periodic Tableorigami ninjaAinda não há avaliações

- Magnetic SeparatorsDocumento18 páginasMagnetic SeparatorskarthicknlAinda não há avaliações

- CR Architecture + Design Kroger J717 Indianapolis, IN CR# 516361 May 4, 2016Documento5 páginasCR Architecture + Design Kroger J717 Indianapolis, IN CR# 516361 May 4, 2016abdullah amanullahAinda não há avaliações

- Ismael AnabalonDocumento35 páginasIsmael Anabalondnavarrete01Ainda não há avaliações

- IECEE-CTL EQL 62067 - Ed2 - 201404Documento10 páginasIECEE-CTL EQL 62067 - Ed2 - 201404raghavendran raghuAinda não há avaliações

- Inspection and Test Plan No 826 Vendor Qualification For Hardfacing Overlay of Seat Rings and DiscsDocumento3 páginasInspection and Test Plan No 826 Vendor Qualification For Hardfacing Overlay of Seat Rings and DiscsGohilakrishnan ThiagarajanAinda não há avaliações

- Acid Mist Generation in Copper Electrowinning (Hydrometallurgy Publication)Documento6 páginasAcid Mist Generation in Copper Electrowinning (Hydrometallurgy Publication)aweloongaAinda não há avaliações

- Cleaning BallsDocumento11 páginasCleaning BallsG.SWAMIAinda não há avaliações

- Earth Wire FittingsDocumento11 páginasEarth Wire FittingsWeber HahnAinda não há avaliações

- Drilling Fluid Technology: Performances and Environmental ConsiderationsDocumento32 páginasDrilling Fluid Technology: Performances and Environmental ConsiderationsAli EttehadiAinda não há avaliações

- RectalDocumento32 páginasRectalYoga SutrisnoAinda não há avaliações

- Available in Capacities From 35 To 2,637 Ammonia Tons!: Bulletin 153BDocumento32 páginasAvailable in Capacities From 35 To 2,637 Ammonia Tons!: Bulletin 153BHarikrishnanAinda não há avaliações

- Mary Kom Case StudyDocumento24 páginasMary Kom Case StudysahilAinda não há avaliações