Escolar Documentos

Profissional Documentos

Cultura Documentos

RMD Kwikform Superslim Soldiers Product Brochure

Enviado por

John G JoseDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

RMD Kwikform Superslim Soldiers Product Brochure

Enviado por

John G JoseDireitos autorais:

Formatos disponíveis

PRODUCT BROCHURE

RMD Kwikform UAE

Superslim

Soldiers

Superslim Soldiers The definitive formwork primary beam

PRODUCT BROCHURE

Dubai Opera House, UAE

Product Overview

The Superslim Soldier is the definitive formwork primary beam. Robust and

easily assembled into beams of almost any length, the Superslim Soldier can be

used in numerous temporary works applications

Faster

Easier

Standard fixtures and clamps ensure optimum on site

efficiency.

Compatible with all other RMD Kwikform product ranges

make it extremely versatile.

Formwork ties and other components can be fixed almost

anywhere along the Superslim Soldier's length allowing for

best on site productivity and optimum scheme design.

Huge range of standard accessories provide the versatility to

tackle an almost limitless range of applications.

Robust to cope with the demands of frequent reuse

providing easy assembly and consistency for optimum

fabrication on site.

Safer

Manufactured from high yield steel to provide maximum load

capacity.

Proven performance from over 40 years on site.

Arterial Tunnel, KAIA International Airport, Jeddah, KSA

Muharaq STP, Bahrain

Superslim Soldiers The definitive formwork primary beam

PRODUCT BROCHURE

Zublin Tunnel, Qatar

Applications

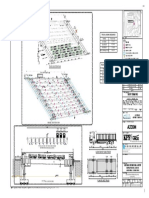

Available in nine lengths, and with a comprehensive range of accessories, the

Superslim Soldier can be assembled into:

Wall formwork panels of virtually any shape and size.

Vertical and raking shores.

Bridge cantilever edge and deck supports.

Spanning beams and trusses.

Composite bridge deck formwork.

Support structures for temporary site buildings.

Travelling gantries.

Facade retention / space frames.

Al La Kuwait Real Estate, Kuwait

Eddstone Avenue Bridge, Australia

Superslim Soldiers The definitive formwork primary beam

PRODUCT BROCHURE

Athabia Flyover, Oman

Manchester Gateway, UK

Features & Benefits

The Superslim Soldier has unrivalled strength-to-weight ratio, versatility and

range of accessories and can be re-used on site after site, in numerous

temporary works applications.

Any length of beam

Nine standard lengths, from 10mm to 3600mm, give almost

unlimited scope for assembling beams of virtually any

length.

Versatile

Versatility to tackle diverse applications demanded by major

projects - gantries, shoring, spanning trusses and frames, as

well as formwork panels.

Compatible

Fully compatible with other RMD Kwikform product ranges

and, in many cases, with customers' own equipment.

Kota Bridge, India

Freedom to create

Complete freedom to create the optimum design, whatever

the application.

Precisely manufactured

Combines maximum durability and load capacity with

reduced unit weight.

Robust

Easy assembly and consistently accurate fabrication on-site

allows Superslim Soldiers to be reused time and again.

Al Kumra Effluent Pumping Station, Jeddah, KSA

Superslim Soldiers The definitive formwork primary beam

PRODUCT BROCHURE

Dubai Mall, UAE

Worli Mixed Use Complex, India

In Detail

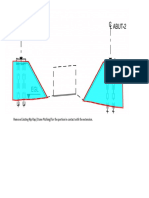

Can be Assembled into

Practically Any Length

Ideal as Primary Beams

Superslim Soldiers are ideal

as primary beams on shoring

or scaffolding to support

reinforced concrete slab

construction.

Because they can be

assembled into practically

any length, Superslim

Soldiers are frequently used

as raking push-pull props, as

well as vertical shoring.

Can be Assembled With

Ease into Frames and

Trusses

Construct Straight,

Curved, Conical or other

Formwork

Configurations

Using system clamps,

scaffold tube and other

accessories, Superslim

Soldiers can be assembled

with ease into frames and

trusses for facade retention,

multi- level supports to

temporary site offices,

cantilever supports,

exhibition stands and film

sets.

When using a plywood form

face together with one of

RMD Kwikform's Aluminium

or GTX secondary beams,

Superslim Soldiers can be

used to construct straight,

curved, conical or other

complex formwork

configurations.

Superslim Soldiers The definitive formwork primary beam

PRODUCT BROCHURE

Shahama Saadiyat Island Freeway, Abu Dhabi, UAE

Projects

PROJECT

PROJECT

Shahama to Saadiyat Island

Freeway

Lusail Tunel, Qatar

REGION

MENA

REGION

MENA

STRUCTURES

STRUCTURES

Tunnels

Bridges, Roads

PROJECT

PROJECT

Phosphate Hangar

Arabian Ranches Interchange

REGION

REGION

Africa

MENA

STRUCTURES

STRUCTURES

Industrial, Mining

Bridges, Roads

PROJECT

PROJECT

Wadi Dayqah Dam

Mafraq Interchange

REGION

REGION

MENA

MENA

STRUCTURES

STRUCTURES

Dams

Bridges, Roads

Superslim Soldiers The definitive formwork primary beam

PRODUCT BROCHURE

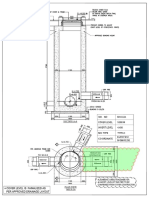

Components

Superslim Soldier

Beams

Code

Description

Weight

SSX10090

Superslim Soldier 90mm

7.32kg

SSX10180

Superslim Soldier 180mm

8.70kg

SSX10360

Superslim Soldier 360mm

11.98kg

SSX10540

Superslim Soldier 540mm

15.24kg

SSX10720

Superslim Soldier 720mm

18.74kg

SSX10900

Superslim Soldier 900mm

22.00kg

SSM11260 Superslim Soldier 1260mm

33.00kg

SSX11800

Superslim Soldier 1800mm

38.80kg

SSX12700

Superslim Soldier 2700mm

55.38kg

SSX13600

Superslim Soldier 3600mm

72.18kg

SSX10040

End Plate 10mm

2.91kg

Note: Superslim Soldiers are also available as galvanised.

Alform to Superslim

Soldier Clamp

Code

Description

AFX20015

Clamp Assembly

0.21kg

AFX20022

M12 Unifix Bolt

0.05kg

BNM00012 Nut - M12 Hex Gr8.8

Weight

0.01kg

Superslim Soldiers The definitive formwork primary beam

PRODUCT BROCHURE

Components

GTX to Soldier Clamp

Code

Description

GTX10001 GTX to Soldier Clamp Mk1A

Timber Waling Clamp

Assembly

Code

Description

Weight

0.6kg

Weight

BNU10054 Bolt Metric Waling 117 x 117

0.3kg

BNU10055 Bolt Metric Waling 176 x 127

0.42kg

SSU10017

Clamp Plate Waling

BNX20014

Washer Plate - 50 x 50 x 6 x 18mm*

BNM00016 M16 Hex Nut Gr8.8

0.4kg

0.12kg

0.03kg

*Note: 2 qty required for assembly.

Universal Clamp

Code

Description

SSM00014 Universal Clamp

Weight

0.14kg

Superslim Soldiers The definitive formwork primary beam

PRODUCT BROCHURE

Components

'B' Clamp

Code

Description

RPX10005 'B' Clamp

Weight

0.7kg

SWL = 3.25kN / pair

Slimshor Tube Clamp

Code

Description

SSU10024 Slimshor Tube Clamp

Weight

1.3kg

SWL = 6.25kNm in slip / each

6-Way Connector

Code

Description

SSU20666 6-Way Connector

Weight

23.0kg

Superslim Soldiers The definitive formwork primary beam

PRODUCT BROCHURE

Components

Anchor Plate

Code

Description

Weight

SSU10036 Anchor Plate

7.40kg

SWL = 70kN Tension / 90kN Shear

90 Degree Corner

Angle

Code

Description

SSU10003 90 Degree Corner

Pivot Cleat Set

Code

Description

SSU10028 Pivot Cleat Set

Range = 55 degrees min, 220 degrees max

Weight

8.66kg

Weight

8.75kg

Superslim Soldiers The definitive formwork primary beam

PRODUCT BROCHURE

Components

Corner Pivot

Code

Description

Weight

SSU10019 Corner Pivot

7.29kg

SWL = 65kN / Pivot

End Plate Adaptor

Code

Description

SSM00020 End Plate Adaptor

Strut Adaptors

Code

Description

Weight

1.0kg

Weight

SSM00006 Strut Adaptor

5.0kg

SSM00069 Strut Adaptor 90 deg

5.0kg

10

Superslim Soldiers The definitive formwork primary beam

PRODUCT BROCHURE

Components

Prop Spade End Link &

Prop Pivot Tube

Code

Description

Weight

SSU10012 Prop Spade End Link

3.09kg

SSU10004 Prop Pivot Tube

1.81kg

SWL = 65kN (SWL can be restricted by the length of the PushPull Prop)

Tilt Plate

Code

Description

SSU10034 Tilt Plate

Weight

4.81kg

SWL = 100kN

Prop Jacks Left & Right

Hand

Code

Description

Weight

SSU10007 Prop Jack - Left Hand

14.48kg

SSU10008 Prop Jack - Right Hand

14.48kg

Adjustable Range = 405 - 635mm. SWL = +/-100kN

11

Superslim Soldiers The definitive formwork primary beam

PRODUCT BROCHURE

Components

Lifting Plate

Code

Description

Weight

SSU10032 Lifting Plate

3.19kg

SSX10046 Superslim 19mm pin & clip

0.22kg

SWL = 30kN / pair

Spreader Beam Plate

Code

Description

SSU10015 Spreader Beam Plate

SSU10004 Prop Pivot Tube

Support Plate

Code

Description

SSX10042

Support Plate

Weight

10.6kg

1.8kg

Weight

5.3kg

BNM00016 Nut - M16 Hex Gr8.8

0.03kg

BSM16040 Set Pin - M16 x 40 Gr8.8

0.08kg

SWL = 10kN

12

Superslim Soldiers The definitive formwork primary beam

PRODUCT BROCHURE

Components

Turnbuckle

Access Bracket

Code

Description

Weight

SSU10016 Turnbuckle. Range = 914 - 1160mm

8.42kg

BBM20090 Bolt - M20 x 90 Gr8.8

0.36kg

Code

Description

SSU10031 Access Bracket

Weight

6.65kg

Supports boards where access is required - SWL = 3.2kN UDL

Plumbing Jack

Code

Description

SSM00019 Plumbing Jack

13

Weight

5.2kg

Superslim Soldiers The definitive formwork primary beam

PRODUCT BROCHURE

Components

Joint Stiffener

Code

Description

SSU10010

Joint Stiffener

BBM16110 Bolt M16 x 110 Gr8.8

BNM00016 M16 Hex Nut

Weight

1.44kg

0.2kg

0.03kg

SWL = 20kNm Bending / 150kN Tension

Slimshor Porthole

Bearing

Code

Description

Weight

SSX10039 Porthole Bearing

2.00kg

BTX10017 50mm Hex Nut

0.16kg

SWL = 65kN Tension

Prop Tube End Link

Code

Description

SSU10013 Prop Tube End Link

14

Weight

2.88kg

Superslim Soldiers The definitive formwork primary beam

PRODUCT BROCHURE

Components

Bolts, Nuts and Pins

Code

Description

Weight

BSX16040 Set Pin - M16 x 40 Gr8.8

0.09kg

BBX20090 Bolt - M20 x 90 Gr8.8

0.28kg

BBX24110 Bolt - M24 x 110 Gr8.8

0.48kg

BNX00016 Nut - M16 Hex Gr8.8

0.03kg

BNX00020 Nut - M20 Hex Gr8.8

0.06kg

BNX00024 Nut - M24 Hex Gr8.8

0.01kg

SSX10046 Superslim 19mm Pin & R Clip

0.29kg

15

Superslim Soldiers The definitive formwork primary beam

PRODUCT BROCHURE

Our Services

Our added value services set us apart...

Consultancy

On Site Assistance

Our technical sales staff will work with you to identify project

requirements, analyse formwork options, planning, design and

safety specifications. Early involvement ensures the best

results.

Trained Site Assistance Technicians can be on hand to provide

practical guidance on how best to utilise our equipment in a

safe and efficient manner, as well as provide solutions for

required design variations due to on site conditions.

Design Expertise

Equipment Availability

Our experienced engineering design staff will translate your

requirements into cost effective formwork and shoring design

solutions, tailored to the exacting needs of the project. By

combining our designers knowledge, flair and experience of

the capabilities of our equipment range, the systems we design

are innovative, practical and cost effective.

With dedicated equipment storage yards throughout the Middle

East, RMD Kwikform can respond quickly and easily to our

customers requirements. With access to the extensive regional

network, our customers are able to benefit from availability,

flexible delivery and improved equipment storage. A high

quality fleet, delivered when its needed, on time, in full.

Technological Advancements

Demonstration & Training Facilities

RMD Kwikform is proud to be leading the way in the

development of technological support. Integrating 3D CAD

design throughout the business, coupled with in house design

programs specifically for RMD Kwikform products, our

customers can now benefit from seeing their vision come to

life. We can translate complicated requirements quickly and

easily.

RMD Kwikform Middle East has dedicated demonstration

facilities throughout the region. We are able to provide our

customers with a more detailed understanding of the benefits

our equipment can provide. We also offer hands-on practical

training in the safe and efficient use of our products,

undertaken either at our demonstration facilities or on our

customers site ensuring they have all the knowledge they need

to work safely with our equipment on site.

Consultancy

RMD Kwikform Demonstration Facility, Dubai

16

PRODUCT BROCHURE

Superslim Soldiers The definitive formwork primary beam

Contacts

RMD KWIKFORM UAE

SHARJAH OFFICE

ABU DHABI OFFICE

DUBAI OFFICE

PO Box 5801, Sharjah, UAE

Tel: +971 6 553 4173

Fax: +971 6 553 4327

Email: rmd.uae@rmdkwikform.com

PO Box 106405, Abu Dhabi, UAE

Tel: +971 2 550 2383

Fax: +971 2 550 2384

Email: rmd.uae@rmdkwikform.com

PO Box 115480, Dubai, UAE

Tel: +971 4 885 0707

Fax: +971 4 885 6141

Email: rmd.uae@rmdkwikform.com

RMD KWIKFORM UNITED KINGDOM

RMD AUSTRALIA

RMD KWIKFORM HONG KONG

Tel: +44 1922 743743

Fax: +44 1922 743400

Email: info@rmdkwikform.com

Tel: +61 (0) 8 8179 8200

Fax: +61 (0) 8 8179 8201

Email: rmd.australia@rmdformwork.com

Tel: +852 2415 4882

Fax: +852 2745 0232

Email: rmd.hongkong@rmdkwikform.com

RMD KWIKFORM SINGAPORE

RMD KWIKFORM PHILIPPINES

RMD KWIKFORM QATAR

Tel: +65 6863 4252

Fax: +65 6863 4275

Email: rmd.singapore@rmdkwikform.com

Tel: +632 696 7635

Fax: +632 661 6456

Email: rmd.manila@rmdkwikform.com

Tel: +974 4465 3034

Fax: +974 4465 3282

Email: rmd.qatar@rmdkwikform.com

RMD KWIKFORM BAHRAIN

RMD KWIKFORM OMAN

RMD KWIKFORM SAUDI ARABIA

Tel: +973 1738 2724

Fax: +973 1738 2624

Email: rmd.bahrain@rmdkwikform.com

Tel: +968 2449 6037

Fax: +968 2449 5836

Email: rmd.oman@rmdkwikform.com

Tel: +966 13 882 5444

Fax: +966 13 882 6460

Email: rmd.ksa@rmdkwikform.com

RMD KWIKFORM INDIA

RMD KWIKFORM USA

RMD KWIKFORM SOUTH AFRICA

Tel: +91 44 4915 3333

Fax: +91 44 4207 9334

Email: rmd.india@rmdkwikform.com

Tel: +1 303 252 7000

Fax: +1 303 252 7319

Email: usa@rmdkwikform.com

Tel: +27 12 004 1000

Fax:

Email: infosa@rmdkwikform.com

RMD KWIKFORM IRELAND

RMD KWIKFORM ESPAA

Tel: +353 (0) 1 830 2500

Fax: +353 (0) 1 830 2741

Email: rmd.dublin@rmdkwikform.com

Tel: +34 91 555 6104

Fax: +34 91 555 4745

Email: rmd.madrid@rmdkwikform.com

WORLDWIDE CONTACTS

www.rmdkwikform.com

Our policy is one of continuous improvement and we reserve the right to change, alter or

modify any detail, design, weight, dimension or code without prior notice beign given.

The arrangements of equipment shown in photographs may have been assembled by

others and therefore not reflect current best working practices or legislation requirements.

A member of Interserve Plc.

Você também pode gostar

- Doka Framed Formwork Panel (Foundation)Documento64 páginasDoka Framed Formwork Panel (Foundation)Mohammed AdnanAinda não há avaliações

- Shorbrace Table Form (ACROW CATALOUG)Documento24 páginasShorbrace Table Form (ACROW CATALOUG)YasserMohsen100% (1)

- Erect and Use Frame SupportsDocumento24 páginasErect and Use Frame SupportsMalik AldmourAinda não há avaliações

- Superslim Technical Datasheets 1Documento117 páginasSuperslim Technical Datasheets 1Fei Fan ChanAinda não há avaliações

- Dokaflex TableDocumento24 páginasDokaflex TableabdullahgentalAinda não há avaliações

- Product CatalogueDocumento72 páginasProduct CatalogueGlenlord Lappay100% (3)

- Business Advantage Pers Study Book Intermediate PDFDocumento98 páginasBusiness Advantage Pers Study Book Intermediate PDFCool Nigga100% (1)

- STS Chapter 5Documento2 páginasSTS Chapter 5Cristine Laluna92% (38)

- Superslim RMD Kwikform Hong Kong 16751 LowDocumento21 páginasSuperslim RMD Kwikform Hong Kong 16751 Lowtmg016Ainda não há avaliações

- Kwikstage RMD-KwikformDocumento14 páginasKwikstage RMD-KwikformMohammed SammanAinda não há avaliações

- RMD Sslim BrochureDocumento16 páginasRMD Sslim Brochurelegionary1Ainda não há avaliações

- MegaShor Technical DataDocumento83 páginasMegaShor Technical Datadcp40322Ainda não há avaliações

- Doka MFDocumento80 páginasDoka MFcrni_mrakoAinda não há avaliações

- Dokascaff: One Scaffold, Multiple ApplicationsDocumento36 páginasDokascaff: One Scaffold, Multiple Applicationscuong voAinda não há avaliações

- Kwikstage Propping RMD Kwikform UAE 8705 Low 5Documento10 páginasKwikstage Propping RMD Kwikform UAE 8705 Low 5vINODAinda não há avaliações

- Medco: Distributor For Agent ForDocumento33 páginasMedco: Distributor For Agent ForMustafa FahmyAinda não há avaliações

- 01 Soldier SystemDocumento26 páginas01 Soldier SystemezzularabAinda não há avaliações

- Rapidshor RMD Kwikform United Kingdom 382 Low PDFDocumento11 páginasRapidshor RMD Kwikform United Kingdom 382 Low PDFAhmed Yousry AbbasyAinda não há avaliações

- Doka Design Calculations-13Documento1 páginaDoka Design Calculations-13Akif0% (1)

- Rapidshor Shoring System Technical Data SheetsDocumento44 páginasRapidshor Shoring System Technical Data Sheetswaquarshai100% (1)

- Climbing Formwork K enDocumento64 páginasClimbing Formwork K enGuudi ConstractionAinda não há avaliações

- Doka Framed Formwork DokaXlightDocumento92 páginasDoka Framed Formwork DokaXlightCông - 62XD6 Đỗ VănAinda não há avaliações

- bALUMcvEMnJWIIl0GnYUGiNDcCw5RhPTIqDktZO6coSKW5Kthy PDFDocumento8 páginasbALUMcvEMnJWIIl0GnYUGiNDcCw5RhPTIqDktZO6coSKW5Kthy PDFSudharsana PrayogaAinda não há avaliações

- Folding Platform KDocumento45 páginasFolding Platform KAhmed MandorAinda não há avaliações

- RMD Shoring PDFDocumento2 páginasRMD Shoring PDFBalaji SubramanianAinda não há avaliações

- Sistema MODEX HunnebeckDocumento7 páginasSistema MODEX HunnebeckDavid Carballo RetanaAinda não há avaliações

- Peri Tillbehör PDFDocumento20 páginasPeri Tillbehör PDFAchmadRiduwanAinda não há avaliações

- Timber H20 BeamDocumento12 páginasTimber H20 BeamKallumRowlands100% (1)

- Steel Ply BrochureDocumento24 páginasSteel Ply BrochureMauricio FuentesAinda não há avaliações

- Doka Top H 20Documento20 páginasDoka Top H 20radem3Ainda não há avaliações

- LIWA Panel FormworkDocumento40 páginasLIWA Panel FormworkAnubhav MukherjeeAinda não há avaliações

- Circular Formwork H20: User InformationDocumento36 páginasCircular Formwork H20: User InformationMMMSLOUHAinda não há avaliações

- RMD Trench Boxes - Issue CDocumento26 páginasRMD Trench Boxes - Issue CMohammed HafizAinda não há avaliações

- ST 100 Stacking Tower: ShoringDocumento32 páginasST 100 Stacking Tower: ShoringPrimelift Safety Resources LimitedAinda não há avaliações

- LC 1600 load chart diagram documentDocumento4 páginasLC 1600 load chart diagram documentJuan P RuizAinda não há avaliações

- Shoring RMD Kwikform UAE 9929 LowDocumento8 páginasShoring RMD Kwikform UAE 9929 LowShima ZamzamiAinda não há avaliações

- Shisham Props Technical Data SheetDocumento1 páginaShisham Props Technical Data SheetCatherine Fatima Mae LeynoAinda não há avaliações

- Doka d3Documento64 páginasDoka d3Aci ManualAinda não há avaliações

- OGUC Febrero 2018 (Disposiciones Transitorias - Vigencia Inmediata)Documento54 páginasOGUC Febrero 2018 (Disposiciones Transitorias - Vigencia Inmediata)PATRICIOAinda não há avaliações

- TEL Derrick Brochure - WebsiteDocumento8 páginasTEL Derrick Brochure - WebsitePete AAinda não há avaliações

- 2009 10 OnlineDocumento8 páginas2009 10 OnlineMirjana VeljkovicAinda não há avaliações

- PERI UP Brochure Rosett Flex 03-2011 (792144) - Shoring DetailsDocumento52 páginasPERI UP Brochure Rosett Flex 03-2011 (792144) - Shoring Detailswawen03Ainda não há avaliações

- Acrow Cup Lock SystemDocumento20 páginasAcrow Cup Lock SystemYasserMohsen100% (1)

- Operation Manual: Temporarily Installed Suspended Access EquipmentDocumento35 páginasOperation Manual: Temporarily Installed Suspended Access EquipmentfuadkhoirulAinda não há avaliações

- CB 240 Assembly Instructions enDocumento96 páginasCB 240 Assembly Instructions enSanja RadovicAinda não há avaliações

- Doka H Frame - Staxo100Documento80 páginasDoka H Frame - Staxo100Ajit Singh RathoreAinda não há avaliações

- DG7 Gass Design Guide Rev G PDFDocumento54 páginasDG7 Gass Design Guide Rev G PDFAnonymous BAYE9xVnLAinda não há avaliações

- Peri Up Easy Brochure PDFDocumento24 páginasPeri Up Easy Brochure PDFSapto SugihartoAinda não há avaliações

- Working platform details and dimensionsDocumento1 páginaWorking platform details and dimensionswaquarshaiAinda não há avaliações

- Acrow Vari Form SystemDocumento20 páginasAcrow Vari Form SystemYasserMohsenAinda não há avaliações

- Acrow Frame System for Construction ProjectsDocumento24 páginasAcrow Frame System for Construction ProjectsYasserMohsenAinda não há avaliações

- Peri HandbookDocumento156 páginasPeri HandbookUmange Ranasinghe100% (1)

- Tower-Cranes Range-Brochure A4 en PDFDocumento24 páginasTower-Cranes Range-Brochure A4 en PDFFejzulla MurtezaniAinda não há avaliações

- Acrow Dam Formwork User Info 2010Documento40 páginasAcrow Dam Formwork User Info 2010Guudi ConstractionAinda não há avaliações

- Doka Formwork EngineeringDocumento148 páginasDoka Formwork EngineeringLim Yew Kwang100% (1)

- Components CatalougeDocumento338 páginasComponents CatalougeTarek AbulailAinda não há avaliações

- The Complete Freedom of VARIOMAX Joist FormworkDocumento6 páginasThe Complete Freedom of VARIOMAX Joist FormworkKartik JanakiramAinda não há avaliações

- CLC - KPR007399 01 37a 101 - REV 01Documento60 páginasCLC - KPR007399 01 37a 101 - REV 01yassir dafallaAinda não há avaliações

- Doka Table FormDocumento80 páginasDoka Table FormShafiullah KhanAinda não há avaliações

- PERI UP Easy PDFDocumento52 páginasPERI UP Easy PDFJwanro HawramyAinda não há avaliações

- Lifting Anchor BrochureDocumento48 páginasLifting Anchor BrochureJacob ChirayilAinda não há avaliações

- Aluminium Beams - RMD Kwikform United Kingdom - 381 - Low PDFDocumento14 páginasAluminium Beams - RMD Kwikform United Kingdom - 381 - Low PDFsherwin veroAinda não há avaliações

- MaqtaDocumento1 páginaMaqtaJohn G JoseAinda não há avaliações

- Fatca Form Individual PDFDocumento2 páginasFatca Form Individual PDFJohn G JoseAinda não há avaliações

- 1243Documento1 página1243John G JoseAinda não há avaliações

- 1 PDFDocumento1 página1 PDFJohn G JoseAinda não há avaliações

- Voidfilters FormersDocumento1 páginaVoidfilters FormersJohn G JoseAinda não há avaliações

- ACAD-D10 & D11 Column Mark at Pier Head Civil 3D ModelDocumento1 páginaACAD-D10 & D11 Column Mark at Pier Head Civil 3D ModelJohn G JoseAinda não há avaliações

- Jafza - Roadworks Logistic PlanDocumento1 páginaJafza - Roadworks Logistic PlanJohn G JoseAinda não há avaliações

- Untitled PDFDocumento1 páginaUntitled PDFJohn G JoseAinda não há avaliações

- 1 XDocumento1 página1 XJohn G JoseAinda não há avaliações

- Rishmawi Thesis 2016Documento242 páginasRishmawi Thesis 2016John G JoseAinda não há avaliações

- Extending an area using satellite imageryDocumento1 páginaExtending an area using satellite imageryJohn G JoseAinda não há avaliações

- Student Visa ChecklistDocumento1 páginaStudent Visa ChecklistJohn G JoseAinda não há avaliações

- D11 ReinforcementDocumento1 páginaD11 ReinforcementJohn G JoseAinda não há avaliações

- Annexure A: Remove Existing Rip Rap (Stone Pitching) For The Portion in Contact With The ExtensionDocumento3 páginasAnnexure A: Remove Existing Rip Rap (Stone Pitching) For The Portion in Contact With The ExtensionJohn G JoseAinda não há avaliações

- Core Vs CubeDocumento10 páginasCore Vs CubeJohn G JoseAinda não há avaliações

- MH Production Schedule Mh-X-2aDocumento1 páginaMH Production Schedule Mh-X-2aJohn G JoseAinda não há avaliações

- Saturday Sunday Monday Tuesday Wednesday Thursday Friday: Holidays and ObservancesDocumento2 páginasSaturday Sunday Monday Tuesday Wednesday Thursday Friday: Holidays and ObservancesJohn G JoseAinda não há avaliações

- Result RET PDFDocumento28 páginasResult RET PDFJohn G JoseAinda não há avaliações

- One Way Traffic Management Plan For Bridge (S1D) D10 D11 Works (DETOUR-02)Documento1 páginaOne Way Traffic Management Plan For Bridge (S1D) D10 D11 Works (DETOUR-02)John G JoseAinda não há avaliações

- AASHTO LRFD Bridge Design Specifications, SI Units, 4th EditionDocumento1 páginaAASHTO LRFD Bridge Design Specifications, SI Units, 4th EditionJohn G JoseAinda não há avaliações

- Interface With Car ParkDocumento1 páginaInterface With Car ParkJohn G JoseAinda não há avaliações

- Comment Compliance SheetDocumento1 páginaComment Compliance SheetJohn G JoseAinda não há avaliações

- Load testing procedures for airport bridgeDocumento1 páginaLoad testing procedures for airport bridgeJohn G JoseAinda não há avaliações

- PT-Anchorage Casting-Test Report: Annexure-6Documento2 páginasPT-Anchorage Casting-Test Report: Annexure-6John G JoseAinda não há avaliações

- OpeningDocumento1 páginaOpeningJohn G JoseAinda não há avaliações

- Annexure 2: VSL Anchorage (Local Zone)Documento1 páginaAnnexure 2: VSL Anchorage (Local Zone)John G JoseAinda não há avaliações

- Route To Site Office From Abu DhabiDocumento1 páginaRoute To Site Office From Abu DhabiJohn G JoseAinda não há avaliações

- Mould PhotoDocumento1 páginaMould PhotoJohn G JoseAinda não há avaliações

- Case 01Documento1 páginaCase 01John G JoseAinda não há avaliações

- Case 01Documento1 páginaCase 01John G JoseAinda não há avaliações

- Air Cycle Refrigeration:-Bell - Coleman CycleDocumento21 páginasAir Cycle Refrigeration:-Bell - Coleman CycleSuraj Kumar100% (1)

- 04 Activity 2Documento2 páginas04 Activity 2Jhon arvie MalipolAinda não há avaliações

- OPIM101 4 UpdatedDocumento61 páginasOPIM101 4 UpdatedJia YiAinda não há avaliações

- Ielts Band 9 Sample Essay NoDocumento5 páginasIelts Band 9 Sample Essay NoNhã NguyễnAinda não há avaliações

- ApudDocumento53 páginasApudlatifahAinda não há avaliações

- 3 0 Visual Weld InspectorDocumento74 páginas3 0 Visual Weld InspectorVincent Sofia RaphaelAinda não há avaliações

- Funded African Tech Startups 2020Documento13 páginasFunded African Tech Startups 2020LoAinda não há avaliações

- DAP FullTextIntroductionByStuartLichtman PDFDocumento21 páginasDAP FullTextIntroductionByStuartLichtman PDFAlejandro CordobaAinda não há avaliações

- PaySlip ProjectDocumento2 páginasPaySlip Projectharishgogula100% (1)

- The Study of Accounting Information SystemsDocumento44 páginasThe Study of Accounting Information SystemsCelso Jr. AleyaAinda não há avaliações

- Laporan Mutasi Inventory GlobalDocumento61 páginasLaporan Mutasi Inventory GlobalEustas D PickAinda não há avaliações

- Cagayan Electric Company v. CIRDocumento2 páginasCagayan Electric Company v. CIRCocoyPangilinanAinda não há avaliações

- Sierra Wireless AirPrimeDocumento2 páginasSierra Wireless AirPrimeAminullah -Ainda não há avaliações

- Successful Organizational Change FactorsDocumento13 páginasSuccessful Organizational Change FactorsKenneth WhitfieldAinda não há avaliações

- Literature Review 5Documento4 páginasLiterature Review 5api-463653994Ainda não há avaliações

- Nuxeo Platform 5.6 UserGuideDocumento255 páginasNuxeo Platform 5.6 UserGuidePatrick McCourtAinda não há avaliações

- I-Parcel User GuideDocumento57 páginasI-Parcel User GuideBrian GrayAinda não há avaliações

- Research Design Elements for ScenariosDocumento25 páginasResearch Design Elements for Scenariosrohizal ibrahimAinda não há avaliações

- Ridge Regression: A Concise GuideDocumento132 páginasRidge Regression: A Concise GuideprinceAinda não há avaliações

- Jodi Ridgeway vs. Horry County Police DepartmentDocumento17 páginasJodi Ridgeway vs. Horry County Police DepartmentWMBF NewsAinda não há avaliações

- HSPA+ Compressed ModeDocumento10 páginasHSPA+ Compressed ModeAkhtar KhanAinda não há avaliações

- Farmers InterviewDocumento5 páginasFarmers Interviewjay jariwalaAinda não há avaliações

- Factors Affecting Employee Turnover and Job Satisfaction A Case Study of Amari Hotels and Resorts Boondarig Ronra and Assoc. Prof. Manat ChaisawatDocumento26 páginasFactors Affecting Employee Turnover and Job Satisfaction A Case Study of Amari Hotels and Resorts Boondarig Ronra and Assoc. Prof. Manat ChaisawathumeragillAinda não há avaliações

- Major Swine BreedsDocumento1 páginaMajor Swine BreedsDana Dunn100% (1)

- Congress Policy Brief - CoCoLevyFundsDocumento10 páginasCongress Policy Brief - CoCoLevyFundsKat DinglasanAinda não há avaliações

- Library Management System (Final)Documento88 páginasLibrary Management System (Final)Ariunbat Togtohjargal90% (30)

- Amended ComplaintDocumento38 páginasAmended ComplaintDeadspinAinda não há avaliações

- S0231689H02-B01-0001 Rev 02 Code 1 General Arrangement Drawing For 44 Kva Diesel Generator PDFDocumento6 páginasS0231689H02-B01-0001 Rev 02 Code 1 General Arrangement Drawing For 44 Kva Diesel Generator PDFAnonymous AfjzJdnAinda não há avaliações