Escolar Documentos

Profissional Documentos

Cultura Documentos

Calibration Program

Enviado por

Doan Chi ThienDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Calibration Program

Enviado por

Doan Chi ThienDireitos autorais:

Formatos disponíveis

Pfizer Biotechnology Ireland

A

B

Draft Standard Operating Procedure for Calibration

Pfizer Ireland Pharmaceuticals Maintenance Strategy

Co

ns

en

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

se

ATTACHMENT F.1

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC

ATTACHMENT F.1.DOC

Attachment F.1

Page 1

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

MAINTENANCE SOP

PFIZER SMALL SCALE MONOCLONAL ANTIBODY FACILITY

SHANBALLY IRELAND

CALIBRATION POLICY

Document No:

se

Draft

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

This procedure is intended as an overview of the approach to equipment and instrument calibration at the

Shanbally MABS Small Scale Facility.

Role / Department

Name

Author

Engineering

Vincent Coleman

Reviewed By

Engineering

Declan J Murphy

Approved By

Engineering

Signature

Date

Liam OBrien

Co

ns

en

Approval

Revision History

Document

Revision

Date

Name

Reason for Update

29/07/08

Vincent Coleman

Original

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC

ATTACHMENT F.1.DOC

Attachment F.1

Page 2

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

TABLE OF CONTENTS

1.0

PURPOSE 4

2.0

SCOPE

3.0

APPLICABLE PERSONNEL

4.0

DEFINITIONS ACRONYMS AND SYMBOLS

5.0

RULES AND GUIDELINES 8

.

se

ru

he

ot

Calibrations

8

Instrument Specifications

8

Records

9

Selection and Use of Calibration Standards

11

Calibration Instruction and Instruction Numbers 11

PM Schedule Codes

12

Calibration Labels

12

Instrument Tolerances 12

Calibration Certificates 12

Calibration Intervals

13

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

5.10

SAFETY PRECAUTIONS 14

7.0

CREATING/MODIFYING INSRUMENT/PM/CALIBRATION INSTRUCTION RECORD

14

8.0

DEACTIVATING EQUIPMENT

15

9.0

ACTIVATING EQUIPMENT

16

10.0

REQUEST PM EXTENSION

16

11.0

PERFORMING CALIBRATIONS

17

Co

ns

en

6.0

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 3

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

1.0 PURPOSE

To provide an overview of the approach to instrument calibration at the Shanbally Small Scale

Facility (SSF), which establishes the requirements for calibration of equipment, instruments, and

standards used in production, storage, and testing that may affect the identity, strength, quality,

or purity of product.

2.0 SCOPE

This calibration procedure applies to the SSF, defining the responsibilities, criteria, and

documentation requirements for the calibration of equipment and instruments used on site.

Calibration of all production and facility equipment is included in the scope of the SOP.

Calibration of Laboratory equipment is excluded.

3.0 APPLICABLE PERSONNEL

Co

ns

en

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

se

This procedure applies to all Pfizer colleagues and to contractors who request, perform or

approve calibration activities.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 4

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

4.0 DEFINITIONS ACRONYMS AND SYMBOLS

Calibration

Set of operations that establish, under specified conditions, the relationship between values of

quantities indicated by a measuring instrument or measuring system or values represented by a

material measure or a reference material, and the corresponding values realised by standards.

Calibration Interval

The interval, in days, between successive calibrations.

Calibration Instruction Number

The unique number assigned by the Calibration Co-Coordinator to a new calibration

task.

se

Calibration Standard

This is the designated measuring equipment used routinely to calibrate or check

measuring instruments, or material measures. This is also referred to as Working

Standard, Transfer Standard or Reference Standard.

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

Calibration Range

Specified range over which the instrument is calibrated. This should at least cover the

normal operating range.

cGMP

Current Good Manufacturing Practices.

Co

ns

en

CMMS

Computerised Maintenance Management System. The integrated modular computerised

system used at the SSF to control all maintenance and calibration activities.

Calibration Co-ordinator

Responsible for the overall management of the plant calibration programme.

CMMS Administrator

Responsible for the CMMS administration of all maintenance related activities within the

plant.

Calibration Instructions

A set of instructions which describes the process for calibrating an instrument.

Device Input & Output Range

Range over which instrument is capable of measuring. Provided in manufacturers

specification.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 5

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

Environmental Critical Instruments

An instrument that is used to assure environmental compliance and which have

appreciated environmental implications if it fails on demand.

GMP Critical Instruments

Instruments used directly to manufacture, process, package and/or hold pharmaceutical

products or drug substances and as a result whose failure may directly affect product

quality.

Increment

Smallest difference between indications of a displaying device that can be meaningfully

distinguished.

Instrument/Standard ID Label

The label containing the Instrument/Standard ID Number.

ru

se

Instrument/Standard ID Number

The unique number assigned by the Calibration Co-ordinator to each loop or individual

instrument/standard that is not part of a loop.

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

Loop Calibration

Calibration of a group of instruments connected together to monitor, or control a process

variable.

Non Critical Instruments

Instruments whose function is important to the operation or efficiency of parent

equipment but whose failure are deemed to have no effect on product quality

Co

ns

en

Normal Operating Range (NOR)

Specified range within which the process NORMALLY operates.

Process Control Limit

The maximum allowable error in the measured reading within the process.

QAR Notification Form

A report generated to notify relevant personnel when GMP critical equipment is found

operating outside of design parameters.

Standard Calibration Label

The label containing the calibration information for a calibration standard.

Safety Critical Instruments

An instrument which is used to assure the safety of personnel and equipment and which

has appreciable safety implications if it fails on demand.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 6

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

Traceability

Property of the result of a measurement or the value of a standard whereby it can be

related to stated references, usually national or international standards, through an

unbroken chain of comparisons all having stated uncertainties.

Co

ns

en

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

se

Unit Of Measure (UOM)

Unit Of Measure

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 7

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

5.0 RULES AND GUIDELINES

5.1

Calibrations

5.2

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

se

1. The Engineering Department is responsible for the administration of the Calibration System

and that the Calibration program is reviewed on an annual basis. A work order is generated in

the CMMS and the Engineering Department reviews the Calibration System.

2. All calibrations will be scheduled through the CMMS.

3. Calibrations will be loop calibrations where possible.

4. One record will be generated in the CMMS for each instrument or loop.

5. Where applicable the CMMS record will reference the P&ID tag number of the instrument or

loop and the instrument ID number as assigned by the calibration co-ordinator.

6. The instrument ID number will be assigned to the instrument or loop when the CMMS record

is generated.

7. Calibration shall be conducted at a minimum of three points (e.g. upper optional range, lower

optional range and NOR), if possible. For instruments that cannot be calibrated at three

points, the points to be included in the calibration shall be defined and justified.

8. Calibrations will be scheduled and performed in accordance with best calibration and cGMP

practices and applicable safety and environmental policies

9. Instruments will be calibrated over their device Input & Output range, where practical.

10. Where it is not practical to calibrate the instrument over the full range, the instrument must at

a minimum; be calibrated over the normal operating range.

11. Measurement instruments will be re-calibrated if dropped jarred or damaged.

12. Loop components must be individually calibrated prior to installation in the loop or in the

event of overall loop failure during routine calibration of the loop.

Instrument Specifications

ns

en

13. Instrument specifications shall be established prior to defining the calibration method for the

instrument and shall be based on the requirements of the application and specific

parameter(s) that the instrument is intended to measure.

Co

14. Instrument Specification shall include, and are not limited to:

Definition of required tolerance and precision

Expected process parameter values, including unit of measure

Expected NOR of the process parameter values.

Acceptable Tolerance

Instrument stability requirements

Safety and environmental consideration.

The instrument specification record shall be attached to the Instrument Change

Record Form. Prior to removing an instrument from service, a final calibration shall

be performed, if possible (i.e. instrument still functional), to verify that the

instrument is still within tolerance.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 8

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

Initial As found data shall be recorded prior to removing an instrument

from the calibration schedule, performing and upgrade, or before an

instrument is moved. If the instrument is not calibrated prior to a move, the

justification must be documented and approved by the site Quality Authority.

Co

ns

en

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

se

15. Personnel requesting Corrective Maintenance for GMP instruments are responsible for

completing a QAR form and for releasing a CM work order, as applicable

16. Calibrations shall not be performed unless environmental conditions are suitable for both the

measurement equipment and the calibration standard used.

17. Where a PM is to be extended for greater than 30% of the PM frequency (either single or

cumulative extensions), QA approval must be obtained by opening a planned QAR.

18. Criticality determination for instruments is as per the following: GMP, Safety,

Environmental, GMP and Safety, GMP and Environmental and non-critical are CLS01,

CLS02, CLS03, CLS04, AND CLS09 respectively

19. Instruments will be considered overdue for calibration after the due date if the calibration has

not been completed. A calibration due-date extension may be granted provided that

reasonable assurances can be made based on the instrument calibration history and/or a

statement from the original equipment manufacturer that continued equipment use for a

limited time would not affect performance.

20. A QAR Notification (QAR) form must be completed if a GMP critical instrument is not

calibrated by the due date and the associated equipment is used to manufacturer product.

21. If a GMP critical instrument is found to be out of tolerance, a QAR must be initiated and

must include a product quality impact assessment carried out in conjunction with the

process/manufacturing owner and the person performing the calibration.

22. A full instrument criticality assessment must be made for all new instruments.

23. New equipment will be tagged Do Not Use until the criticality status and calibration

requirements of instruments associated with it are evaluated.

24. Instruments already classified as Non Critical are calibrated at the sole discretion of

engineering.

25. Stationary instruments must be re-calibrated after movement.

26. Any instrument that has been repaired must be re-calibrated before being returned to service.

27. Trained personnel only will carry out calibrations and are detailed on file with HR (Human

Resources) and the Calibration Co-Ordinator.

28. Learning records will be maintained for all personnel engaged in performing and

administering the calibration program.

29. Calibrations performed by vendors or contract services must meet the requirements of this

document.

30. Vendors to be reviewed and audited as deemed necessary by the site quality authority.

31. Vendors/contractors must have procedures that assure the accuracy and traceability of their

reference and test equipment.

32. All efforts should be made to keep instruments as accurate as possible. Thus instruments

should be adjusted even if within tolerance but approaching the limits.

33. Individual calibration tasks must be maintained for each instrument calibrated. These tasks

can be a guideline described in the manufacturers manual or written procedures that may be

contained in CMMS.

5.3

Records

34. An instrument record must be maintained for each loop or instrument. The instrument record

must provide sufficient information to set up a replacement loop and/or instrument, if

necessary.

35. For original loop records, hard copies of the element/transmitter certificates will be attached

and filed with the original loop calibration certificate in the QA DCC (document control

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 9

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

36.

37.

centre). All subsequent loop calibration certificates will be filed with these. This file will be

the record for loops and the loop components.

The calibration files will be organised by Instrument ID number.

A calibration certificate will be completed for each calibration carried out and then filed in

the calibration files.

Calibration intervals will be specified in days.

The next due date for calibration will be calculated from the date done.

All calibration activities must be recorded in the relevant Equipment Logbook.

The instrument or loop record must include the following

Instrument ID number

Instrument or loop description

System number that the instrument or loop is part of (as applicable)

Criticality

P & ID tag number of the instrument or loop

Date last calibrated ( as applicable)

Type

Manufacturer

Model number

Serial number

Location

Device Input/Output range

Calibration Failure Limit

Device

or loop calibration interval

Calibration Instruction reference

Operating range ( where applicable)

Process Control Limit (where applicable)

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

se

38.

39.

40.

41.

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

Nominal Test points

ns

en

Note: Prefixes relating to nominal test points for weigh scales include:

Co

CTR: Centre (Point)

FRT: Front Right (Load cell)

FLT: Front Left (Load cell)

BRT: Back Right (Load cell)

BLT: Back Left (Load cell)

RPT: Repeatability (Test)

The point of reference for the load cell locations being the local indicator.

42. For in-house standards, a calibration certificate shall be prepared based on supporting

raw data. The certificate shall include, and not be limited to:

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 10

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

Description of standard

Date the standard was established

Signature of the person preparing the standard

Date standard must be recertified or replaced

Handling or storage conditions for the standard

Reference to a method or task used to establish the standard

Accuracy and precision of the standard.

5.4

Selection and Use of Calibration Standards

Co

ns

en

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

se

43. Standards used for calibrating measurement equipment will have the capability for accuracy,

stability and range needed for their intended use.

44. The calibration standard must always be more accurate than the instrument under test. Where

possible the uncertainty ratio should be 1:4. Where this is not practical, a less accurate

standard may be used with the approval of site QA.

45. Calibration certificates will support all calibration standards used in the calibration system.

Certificates for Pfizer standards will be filed in Pfizer document control. Certificates for

contractor standards must be available on request.

46. A calibration standard, when not in use, shall be stored in a secure manner which prevents

unauthorised adjustment.

47. Standards must be safe to operate in the specific process area in which the equipment is

being used. Ensure the standards are clean prior to use to prevent Cross Contamination.

48. The storage environment shall meet the standards storage requirement.

49. Calibration Standards used in calibrating measurement equipment will be: Traceable to one

or more of the following; the National Institute of Standards and Technology (NIST), the

National Physical Laboratory U.K. (NPL), the United Kingdom Accreditation Service

(UKAS), the National Standards Authority of Ireland (NSAI) or equivalent institutes.

50. Where applicable all calibration standards must be added to a Portable Appliance Testing

(PAT) schedule.

5.5

Calibration Instruction and Instruction Numbers

51. An instruction for the calibration of each type of Instrument (e.g. pressure gauge,

temperature transmitter, flow meter) shall be reviewed and approved by the system

expert/designee to ensure that the instructions are technically correct and are approved by the

site Quality Authority, Environmental Health and Safety principles shall be consulted if

required.

The format for Calibration Instruction numbers is:

CI-sequential number-revision number

For example, the first revision of the fiftieth calibration instruction would be

numbered: CI-0050-01.

Instructions will be filed in equipment files or calibration task files under calibration

instruction number.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 11

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

5.6

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

PM Schedule Codes

52. A PM schedule code will have the same code as the instruction code to which it is linked to

in CMMS.

5.7

Calibration Labels

53. Calibrate before use: the calibration label used for all calibrated loops or instruments that

must be calibrated before use. It contains the calibration date, signature of the person

performing the calibration, and the required calibration interval.

54. Do not use: the label attached to a loop or instrument that has not been calibrated, is over-due

for calibration, is not operating correctly, or must not be used for other reasons.

55. Instrument ID Labels: for loops, the Instrument ID label will be attached as close as

practicable to the measuring element of the loop.

56. An instruction for the calibration of each type of Instrument (e.g. pressure gauge,

temperature transmitter, flow meter) shall be reviewed and approved by the system

expert/designee to ensure that the instructions are technically correct and are approved by the

site Quality Authority, Environmental Health and Safety principles shall be consulted if

required.

5.8

Instrument Tolerances

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

se

57. Loop and instrument calibration tolerances will be based on manufacturers'

recommendations, process requirements, and stability of the instrument, purpose and

accuracy and/or historical calibration data for similar instruments.

58. Loop tolerances will be based on the cumulative effect of the individual component

accuracies, taking into account the resolution of the display.

For example:

Co

ns

en

Sensor 0.25C,

Transmitter 0.05C,

Input card 0.1C,

Display reads out in 0.5C increments,

Loop tolerance should be 1C.

5.9

Calibration Certificates

59. A calibration certificate must be completed for each calibration carried out.

60. The calibration record must include the following:

Instrument ID number

Instrument or loop description

Manufacturer

Model

Serial Number

Location

Device Input/Output Range

Calibration Failure Limit

Nominal test points

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 12

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

Calibration interval

Calibration Instruction reference

Reference standards used for calibration, identification number and

calibration due date.

As found calibration data

As left calibration data, if applicable

Reference to QAR Form, if applicable

Instrument criticality

Signature of person performing the calibration

Date of calibration

Signature of person approving the calibration

Date of approval

Comments

Calibration Intervals

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

5.10

ot

he

ru

se

Co

ns

en

61. Calibration intervals will be specified in days.

62. The next due date will be calculated, in days, from the date done.

63. Calibration intervals will be based on manufacturers' recommendations, stability of the

instrument, and consequence of calibration failure, purpose and accuracy and/or historical

calibration data for similar instruments.

64. Calibration interval must not exceed 365 days for instrument classified as GMP critical.

65. A calibration interval may be lengthened if the instrument or loop remains within tolerance,

without adjustment, for 3 successive calibrations.

66. A calibration interval may be shortened as a corrective action or part of one if the instrument

or loop is outside tolerance for two successive calibrations.

67. The new interval should be half the previous interval and cannot be less than 1 day, except

where instruments are designated as Calibrate Before Use.

Note: corrective actions to instrument failure are treated on an individual basis based on the

instruments criticality, use within the process, and closeness to the product, current tolerance

and previous calibration history.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 13

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

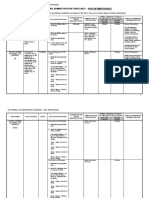

IPPC Licence Application

6.0 SAFETY PRECAUTIONS

Ensure you read the relevant Risk Assessments

7.0 CREATING/MODIFYING

INSRUMENT/PM/CALIBRATION INSTRUCTION

RECORD

Person

Step

Action

Responsible

Project/request

1.

originator

Tag the instrument appropriately to prevent its use until equipment

maintenance and validation/qualification determinations can be

2.

he

ot

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

type changes

ru

se

completed. Note this step is only applicable for Instrument entry

Complete the Entry/Change form and issue to the Engineering

dept.

Engineering

3.

Review information and issue to relevant approvers.

Relevant

4.

Review and, if acceptable, approve request and return to CMMS

5.

Administrator

Project/request

originator

Enter relevant data from Record Entry/Change form into CMMS

Co

CMMS

administrator.

ns

en

Approver

and return paperwork to originator.

6.

Verify that equipment is appropriately tagged with correct

equipment code (only applicable for Instrument entry/changes) and

file paperwork in DCC.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 14

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

8.0 DEACTIVATING EQUIPMENT

Person

Step

Action

Responsible

Request

1.

Originator

Identify the equipment to be de-activated and tag it Deactivated

If

Then

Scrapping Equipment

Raise a calibration work

order in order to calibrate the

instrument prior to removal.

Dispose of it

appropriately and inform the

finance department.

Taking out of service

temporarily

order in order to calibrate the

Raise a calibration work

Calibration Coordinator

2.

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

se

instrument prior to removal.

Prepare the equipment as

necessary, for inactive period.

Deactivate the equipment and associated PM schedules in CMMS as

appropriate.

Co

ns

en

/Designee

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 15

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

9.0 ACTIVATING EQUIPMENT

Request

1.

Originator

Calibration Co-

Raise a Calibration work order in order to calibrate the instrument prior to

installation.

2.

Activate the equipment and associated PM schedules in CMMS.

ordinator

/Designee

10.0 REQUEST PM EXTENSION

Person

Step

Action

Responsible

1.

Contact engineering with request for extension

Engineering

2.

Make determination on validity of request and amend target date as

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

se

Requestor

appropriate.

3.

Record justification in comments section of work order and where

Co

ns

en

appropriate seek approval by QA.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 16

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

11.0 PERFORMING CALIBRATIONS

Person

Step

Action

Responsible

Calibration Co-

1.

Release a work-order for the scheduled calibration.

ordinator /

2.

Distribute the work-order to the colleague responsible for the calibration.

designee

3.

Apply for an extension to the work order, if the calibration cannot be

completed by the due date.

If

Then

Extension is granted

The calibration must be completed by

the revised due date & the calibration

label must be replaced.

Tag equipment DO NOT USE on the

.

Extension is rejected

he

ru

se

calibration due date and until calibration

Technician

4.

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

is completed.

Follow the calibration instruction attached to or referenced by the workorder.

5.

Complete the calibration record and ensure that each person involved in

the work signs the form. Attach a calibration label showing the instrument

Notify an area rep which instrument was worked on and where possible

Co

6.

ns

en

ID number, calibration date, next due date and initials.

request an equipment dry run prior to returning equipment to normal

operation. (only applicable when calibrating a critical parameter)

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 17

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Person

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

Step

Action

Responsible

Technician

7.

Enter the calibration data into CMMS.

If

Then

As-found data is

un-acceptable and the

accordance with SOP DEV-1002

instrument is GMP critical

Event and Deviation System.

Complete a QAR form in

When entering data into the

CMMS, enter the QAR number in

Co

ns

en

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

se

the work order Comments field.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 18

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

Technician

As-left data is un-

acceptable

and seek a replacement.

Tag equipment DO NOT USE

If replacement is like for like

follow the procedure,

Creating/Modifying Instrument records

in the Calibration Program outlined in

this SOP. Record the calibration results

for the replacement instrument in the

left results section of the certificate.

Enter the serial number of the original

and replacement instrument on the

work order. Clearly identify that the

replacement was carried out in the

se

ru

If the replacement is not a like for

he

comments section of the work order.

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

like change, complete a change

request form (CRF) and enter the CRF

number in the comments section on the

work order. Request the calibration coordinator / designee to remove the

ns

en

existing instrument, and setup the

Co

replacement as per Creating/Modifying

instrument records in the calibration

program

8.

Record calibration work in appropriate Equipment logbook.

9.

Forward the completed Calibration Record to the Calibration Coordinator/ Designee for approval.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 19

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Calibration Co-

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

10. Review the Calibration record and ensure the calibration was carried out

ordinator /

in accordance with the task associated with the instrument. Confirm that

Designee

the data on the record is accurate and corresponds to the data entered into

the CMMS.

11. Approve the calibration work order.

12. Forward the completed calibration records to the QA Document Control

Centre (DCC). Scheduled calibrations are filed by Instrument ID number.

13. Monitor the completion of calibrations throughout the scheduled period to

notify relevant colleagues if calibrations are overdue.

Generate the following report.

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

15.

Facilitate the execution of calibrations throughout the facility.

se

14.

A weekly Calibration due report to review all overdue

Co

ns

en

and due calibrations for the coming month.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 20

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

Pfizer Ireland Pharmaceuticals

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

se

PIP Maintenance Strategy

Co

ns

en

Revision 1

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 21

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

Table of Contents

Section

Description

Page

1.0

Vision

2.0

Purpose

3.0

Scope

4.0

Regulatory Compliance & Environmental, Health and

Safety

Organisation and Administration

6.0

Responsibilities

7.0

Partnerships

8.0

Asset Management

9.0

Work Control Systems

10.0

Work Planning and Scheduling

11.0

Reliability Plans

12.0

Predictive and Preventive Maintenance

13.0

Maintenance Metrics

10

14.0

Materials Management

11

15.0

Cost Management

11

16.0

Maintenance Interface

12

17.0

Maintenance Evaluation and Continuous Improvement

12

18.0

Training and Development

12

19.0

Maintenance Teams and Knowledge Sharing

13

20.0

Communication

13

21.0

Abbreviations

14

22.0

Approvals

15

Co

ns

en

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

se

5.0

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 22

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

1.0 Vision

The Global Maintenance Initiative is outline as follows:

Program to implement Reliability Based Maintenance practices consisting of assessments, master

planning, training, tool implementation, and continuous improvement.

The PIP Maintenance Team will ensure alignment with the global GMI vision by means of the following:

he

ru

se

Develop processes to enable Continuous Improvement of all aspects of Maintenance as a

Business; through the use of both RFT and GMI tools.

Utilise a data driven approach to enhance the quality and compliance of maintenance operations.

Ensure safety of colleagues and facilities through effective and compliant operation of

maintenance activities.

Promote leadership in maintenance departments and increase job satisfaction

Engage with other functions across product Value Streams to ensure Maintenance continues to

deliver value and ensure strong customer service.

Maintenance functions will deliver cost savings to the overall business in PIP.

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

2.0 Purpose

This strategy document outlines the elements for performing maintenance at all Pfizer Ireland

Pharmaceutical Facilities.

ns

en

This document is intended to put the processes in place to allow Pfizer Ireland Pharmaceuticals to strive

towards maintenance excellence for the purpose of supporting operational excellence through equipment

reliability, compliance and safety whilst utilising resources in an effective and efficient manner.

Co

The expected outcomes of this strategy include:

Optimised asset life cycle costing and overall equipment effectiveness. (OEE)

Reliability plans based on reliability practices and techniques.

Reduced risk in areas including regulatory compliance, environmental, health and safety.

Improved organisational effectiveness and engagement of maintenance colleagues.

Managing maintenance as a business based on metrics, monitoring and reporting.

Effective cost management

Effective partnering between maintenance and operations.

Increased sharing of knowledge and expertise across Pfizer Ireland Pharmaceuticals

Alignment with Right First Time (RFT)

Continuous improvement

3.0 Scope

This document applies to the following at all Pfizer Ireland Pharmaceuticals Facilities

Site Engineering/Maintenance Teams

Equipment Owners

Operations

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 23

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

Site Leadership Teams

Right First Time

Quality Operations

EHS

4.0 Regulatory Compliance & Environmental, Health and Safety

Maintenance activities performed by internal and external parties must be developed, planned and

executed in compliance with all regulatory guidelines, standards and policies.

Maintenance teams should promote a safe, compliant and clean working environment. Quality and

compliance should be addressed in the execution of all maintenance activities. Furthermore, contingency

plans must be in place to deal with unexpected adverse events.

Co

ns

en

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

se

These plans shall be developed in partnership with operations and communicated to all stakeholders.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 24

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

5.0 Organisation and Administration

All maintenance roles should be clearly defined and documented.

Resource plans should be developed from metrics to determine staffing levels and shift allocations.

Insourcing/outsourcing decisions should be based upon customer requirements, core competencies,

associated risks, local market conditions and other relevant factors.

6.0 Responsibilities

Leadership:

Leadership should promote reliability based maintenance concepts to Operations and across site

partnerships

Engineering

he

ru

se

and maintenance leaders are responsible for communicating the maintenance

strategy to their maintenance teams, applying the strategy and setting maintenance performance

objectives.

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

Site Maintenance Teams:

The site maintenance teams shall be responsible for the following:

Co

ns

en

Ensure that planned equipment maintenance and calibrations are performed in a timely manner to

prevent unplanned failure of critical equipment and ensure compliance with regulatory

requirements.

Perform corrective actions to correct equipment failures, prevent potential equipment failures and

ensure equipment safety.

Perform root cause failure analysis on equipment failures.

Continuous improvement in maintenance activities through equipment modification, PM

optimisation, introduction of reliability techniques and implementation of RFT techniques.

Maintaining the CMMS system to ensure that equipment, instruments, maintenance schedules,

personnel and spare parts are correctly set up and maintained.

Development of asset care plans for new equipment.

Ensure that colleague training, development and performance management systems are in place

and effectively delivered.

Ensure that training plans are based on an overall training program that is developed in

conjunction with the needs of the business and maintenance colleagues.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 25

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

Project Engineering:

Project Engineering shall be responsible for

Providing relevant details for set up of equipment on the CMMS system.

Engaging with maintenance colleagues for design and selection of new equipment.

Providing necessary handover documents for equipment.

Engaging in the development of asset care plans for new equipment.

Equipment Owners:

Equipment owners shall be responsible for

Notification to maintenance of equipment issues that may affect the reliability of that

equipment.

Engage in RCM, FMEA and RCFA activities in relation to the equipment.

Operations:

ru

se

The operations team are responsible for

Co

7.0 Partnerships

ns

en

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

Operating equipment in a manner that supports reliability

Monitoring equipment operation and highlighting potential issues that may impact on

equipment performance

Liaising with the maintenance planner and scheduler to ensure that the production schedule

aligns with the maintenance schedule so that planned maintenance and calibrations can be

performed within their required target dates

Engaging in RCM, FMEA & RCFA activities in relation to equipment

Equipment reliability and maintenance excellence is dependant on the partnerships between site

maintenance teams, equipments owners and equipment operators. Partnership agreements will ensure that

all stakeholders understand their role in the maintenance excellence process.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 26

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

Partnership agreements shall contain the following:

Operations expectations of maintenance

Response times to emergency situations

Production Support requirements

Use of RCFA to eliminate recurring issues

Measures of reliability

Optimisation of planned maintenance activities to reduce impact of maintenance on equipment

availability

Prioritisation of work

Maintenance expectations of operations

Methods of reporting equipment issues

Agreements for equipment downtime to perform maintenance

Identification of potential equipment issues

ru

se

Engagement in RCFA for recurring issues

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

8.0 Asset Management

Assets shall be uniquely identified using an identification scheme structured into asset classes based on

equipment characteristics.

ns

en

All maintenance activities performed on an asset whether performed internally or externally, planned or

unplanned shall be recorded in the CMMS to ensure a complete and accurate asset history.

Co

9.0 Work Control Systems

A computerised maintenance management system (CMMS) shall be deployed to ensure proper work

control, regardless of who actually executes the work. The CMMS is essential for scheduling work and

resources, gathering equipment history reports for improvement purposes and managing maintenance

costs.

The work orders generated from the CMMS will contain sufficient information to enable a standardised

workflow that moves through eight phases: Request, Confirm, Plan, Schedule, Execute, Completion,

Review and Close out.

Approvals at the appropriate stages in the process shall ensure the quality and cost effectiveness of the

process.

Work Order Types:

Work order types are categorised as follows

Planned preventive work: This is work that is placed on a work schedule based on timed intervals or

equipment usage. This work is performed so that potential issues can be addressed prior to those issues

causing an unplanned equipment failure.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 27

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

Planned corrective work: This is corrective work that has been identified that could cause a potential

unplanned equipment failure but the potential failure is not imminent and this corrective work can be

placed on the work backlog and planned and scheduled.

Emergency Work: This is work that is required to be performed immediately to prevent failure or

restore operation of critical equipment.

Production Support Work: This is non repair work that is required to support the production operation

such as line set up, equipment operation assistance, scheduling assistance, etc.

Calibration: Periodic instrument calibrations.

Administration: Non repair work such as data retrieval, training, meeting attendance, etc.

CBM / Predictive: Work carried out utilising technologies that will monitor equipment performance and

identify potential failures based on results.

se

10.0 Work Planning and Scheduling

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

Maintenance work planning and scheduling is essential for maintenance excellence and brings benefits in

terms of efficiencies through having work available for maintenance resources.

The role of the maintenance planner and scheduler is to develop job plans for planned work to include

task lists, spare parts requirements, special tools required, work prioritisation and resource requirements.

Co

ns

en

The planner and scheduler shall also be responsible for liaising with maintenance supervisors and

operations to ensure that equipment and resources are made available for routine maintenance to be

performed, ensuring that equipment is reliable and regulatory and statutory are met.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 28

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

11.0 Reliability Plans

Reliability plans shall be developed in accordance with the Pfizer Ireland Pharmaceutical reliability

strategy (*TO BE DEVELOPED)

The reliability plans shall incorporate reliability based maintenance principles, namely:

Asset identification

Criticality assessment

Asset performance standards and requirements

Determination of failure modes and effects

Periodic evaluation and continuous improvement.

Reliability plans are the specific tasks performed on an asset. These plans shall address all elements of

asset utilisation and performance including quality, safety, environmental protection, uptime

requirements and throughput.

he

ru

se

Criticality assessment tools shall be utilised for assets, this provides the basis for the reliability plan of an

asset.

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

Periodic reviews of criticality assessments and reliability plans shall be performed and any modification

or usage change of an asset shall also trigger a review of the criticality assessment and reliability plan.

12.0 Predictive (PdM) and Preventive (PM) Maintenance

Co

ns

en

Proactive maintenance activity shall be promoted by maintenance teams. Inspections based on actual

measurements and data are preferred because they are typically more effective than those based on a

technicians senses.

Predictive maintenance techniques are most effective and shall be utilised where possible. These

techniques are intended to identify the onset of a specific failure mode objectively through the

monitoring, measuring and trending of changes in equipment condition.

Vibration analysis, ultrasonics, thermography and electrical circuit evaluation are among the most

common PdM tools that can be applied by maintenance teams.

In addition, preventive maintenance practices such as inspection, adjustment, cleaning and lubrication

shall be utilised in the reliability plan.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 29

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

13.0 Maintenance Metrics

Metrics will allow the maintenance team and partners to evaluate performance and target areas of

opportunity for continuous improvement in equipment reliability and maintenance processes.

Maintenance metrics are essential in the approach of managing maintenance as a business in order to

provide the best value to our partners and customers.

Maintenance Metrics can be divided into three categories:

1: PGE Core Metrics These are metrics that have been pre-defined by the Global Maintenance Team as

base metrics for a maintenance organization. The purpose of these metrics is to assist in strategical

decision making at a global, PIP and local level. These metrics are reported monthly to ILT, PGE,

Engineering Team Leaders and Maintenance Team Leaders. These metrics are also generally shared with

maintenance organisations elsewhere in the globe for knowledge sharing purposes. (*METRICS TO BE

DEFINED)

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

se

2: PIP Additional Metrics These metrics are defined by the PIP maintenance team leaders as metrics

that would provide benefit for the operating environment of the PIP Sites. The purpose of these metrics is

to assist in strategic decision making at a PIP and local level. These metrics are reported monthly to ILT,

PGE, Engineering Team Leaders and Maintenance Team Leaders. (*METRICS TO BE AGREED BY

MTLs)

3: Site Specific Metrics These are metrics that may be defined at a site level and are relevant to the site

maintenance teams specific needs. These metrics are recorded at the discretion of the site and are utilised

to assist in tactical decision making in relation to equipment reliability and maintenance processes.

Site specific metrics may include but should not be limited to the following:

ns

en

OEE Measurement

Maintenance Cost Reports (By site, department and asset)

Past Due Work

Backlog Measurement

Percent Production Support

Stock outs of critical spares

Environmental releases attributable to maintenance

Co

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 30

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

14.0 Materials Management

An effective materials management program is necessary to ensure the availability and delivery of parts,

tools, equipment and materials for the execution of the reliability plans.

This program balances inventory levels and the cost of inventory. It also ensures suppliers are managed

to provide Pfizer Ireland Pharmaceuticals with the best possible supply agreements.

Where possible, the Ireland sites should regionalise stockrooms and/or leverage availability of parts and

suppliers.

The materials management program shall address items including:

Material identification and storage

Inventory management

Controls

Replenishment systems

Stock codes linked to assets

ot

he

ru

se

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

15.0 Cost Management

Budgets shall be developed based upon predetermined maintenance activities including preventive

maintenance, historical levels of unplanned maintenance, customer support requirements, materials, tools

and equipment needs etc.

ns

en

The EMU cost template shall be used as a tool to capture and trend costs. Cost tracking and reporting

shall be performed on a monthly basis and compared against targets and benchmarks.

Co

Cost data collected as the asset level is preferred as it can be used to aid decisions to repair, refurbish or

replace the asset.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 31

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

16.0 Maintenance Interfaces

Maintenance organisations are partners in the operations that they support, it is expected that

maintenance teams will have regular communications and meetings with their partners.

Reliability plans shall be reviewed with the asset owners to establish appropriate service levels and user

requirements.

17.0 Maintenance Evaluation and Continuous Improvement

Continuous improvement is enabled by measuring performance, setting improvement goals, tracking and

reporting progress towards those goals.

Pfizer Ireland Pharmaceutical maintenance teams will measure, track and report key performance metrics

as recommended by the Global Maintenance Team.

ru

se

Metrics must be made visible to operations and be well understood by all maintenance colleagues.

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

Regular assessments of maintenance operations shall be conducted to identify progress against each sites

maintenance master plans, good practices and external benchmarks.

18.0 Training & Development

Co

ns

en

All maintenance colleagues will be competent and qualified to perform their duties through a

combination of their education, training and experience. There will be documented evidence available

for each individuals training status. Required training for the job will be identified through a job function

curricula which will be available for each job position. Colleagues will be responsible for ensuring they

are adequately trained prior to undertaking any task.

Every colleague will be encouraged to identify developmental opportunities to enhance their skills and

qualifications; this will be done with the support of maintenance leadership.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 32

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

19.0 Maintenance Teams and Knowledge Sharing

To leverage the depth and breath of maintenance knowledge at Pfizer Ireland Pharmaceuticals,

maintenance teams shall be established and will regularly meet to share experiences and knowledge.

Leveraging items such as criticality assessments, toolkit applications such as PM optimisation, planning

and scheduling, supply and service agreements etc, is essential to strive towards a maintenance

excellence organisation.

The PIP maintenance leaders team shall work together on tactical implementation of their goals and

objectives and stay closely linked to the Global Maintenance Team.

Individual maintenance team leaders are expected to support the Ireland Maintenance Team by:

Participating in meetings

Staying abreast of activities

Providing input in the form of good practices, learnings etc

Utilising communications vehicles such as E-room/Sharepoint.

ru

se

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

20.0 Communications

Co

ns

en

Communications vehicles shall be used to keep all stakeholders informed and to seek feedback on all

maintenance activities at each Ireland site. Communications processes between maintenance teams will

be essential to promote knowledge sharing, good practices and successes. Communications at site,

regional, area and global levels should be utilised.

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 33

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

21.0 Abbreviations

CBM

CONDITIONED BASED MONITORING

CMMS

EHS

COMPUTERISED MAINTENANCE

MANAGEMENT SYSTEM

ENGINEERING MAINTENANCE AND

UTILITIES

ENVIRONMENTAL, HEALTH AND SAFETY

FMEA

FAILURE MODE AND EFFECTS ANALYSIS

OEE

OVERALL EQUIPMENT EFFECTIVENESS

PdM

PREDICTIVE MAINTENANCE

PIP

PFIZER IRELAND PHARMACEUTICALS

PM

PLANNED MAINTENANCE

RCFA

ROOT CAUSE FAILURE ANALYSIS

RCM

RELIABILITY CENTRED MAINTENANCE

RFT

RIGHT FIRST TIME

Co

ns

en

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

se

EMU

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 34

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Pfizer Biotechnology Ireland

Pfizer Monoclonal Antibodies Small Scale Facility

IPPC Licence Application

22.0 Approvals

Approved By/Date:

_________________________________

Eugene O Callaghan, GMI Facilitator

_________________________________

Michael Cohalan, MTL Ringaskiddy

Approved By/Date:

Approved By/Date:

_________________________________

Michael Cleere, ETL LIAPI

_________________________________

Ryan Cleary, ESM Dublin

Approved By/Date:

Approved By/Date:

ns

en

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

se

Author/Date:

_________________________________

Jim Conway, MTL LOAPI

Approved By/Date:

Approved By/Date:

_________________________________

Michael Boyle, ETL Sponsor

_________________________________

Jim Brinkman, PGE Sponsor

Co

_________________________________

Tom Dineen, FCO LODP

J:\C2000-C2099\C2054\3) DOCUMENTS\40\REPORTS\IPPC LICENCE

APPLICATION\IPPC ISSUE\PFIZER BIOTECHNOLOGY IPPC ATTACHMENT

F.1.DOC

Attachment F.1

Page 35

Arup Consulting Engineers

24 September 2008

EPA Export 26-07-2013:01:46:19

Você também pode gostar

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1No EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Nota: 4.5 de 5 estrelas4.5/5 (2)

- Calibration Master PlanDocumento18 páginasCalibration Master PlanDoan Chi Thien100% (3)

- Implementing Calibration ProgramDocumento10 páginasImplementing Calibration ProgramcleitonmoyaAinda não há avaliações

- Software Validation A Complete Guide - 2020 EditionNo EverandSoftware Validation A Complete Guide - 2020 EditionAinda não há avaliações

- Temperature Mapping and Monitoring - A SummaryDocumento3 páginasTemperature Mapping and Monitoring - A SummaryEduardAinda não há avaliações

- G 63 Quality Risk Management (QRM) Application For Critical Instrument CalibrationDocumento7 páginasG 63 Quality Risk Management (QRM) Application For Critical Instrument CalibrationDoan Chi Thien100% (1)

- Best Practice Paper Visual Inspection Vs 3 2Documento16 páginasBest Practice Paper Visual Inspection Vs 3 2Dimitris PlotasAinda não há avaliações

- Validation Master Plan A Complete Guide - 2020 EditionNo EverandValidation Master Plan A Complete Guide - 2020 EditionAinda não há avaliações

- Cleanroom Technology: Fundamentals of Design, Testing and OperationNo EverandCleanroom Technology: Fundamentals of Design, Testing and OperationAinda não há avaliações

- 2015 VMP TemplateDocumento10 páginas2015 VMP Templatekulbhushan singh100% (2)

- Validation VialWasher OQ NIHDocumento30 páginasValidation VialWasher OQ NIHcongacon3aAinda não há avaliações

- Cross Contamination Prevention in HVACDocumento8 páginasCross Contamination Prevention in HVAChuynhhaichauchauAinda não há avaliações

- Validation Master Plan As Per PICSDocumento26 páginasValidation Master Plan As Per PICSFari ShaikhAinda não há avaliações

- VAL-085 Process Validation Guideline SampleDocumento2 páginasVAL-085 Process Validation Guideline SampleVizit31Ainda não há avaliações

- Revalidation SOPDocumento12 páginasRevalidation SOPIlayaraja Boopathy100% (2)

- SOP of SamplingDocumento8 páginasSOP of SamplingaKureishiAinda não há avaliações

- SOPDocumento5 páginasSOPcongacon3a0% (1)

- Risk Management for Medical Device Manufacturers: [MD and IVD]No EverandRisk Management for Medical Device Manufacturers: [MD and IVD]Ainda não há avaliações

- Validation master plan Complete Self-Assessment GuideNo EverandValidation master plan Complete Self-Assessment GuideAinda não há avaliações

- IQOQ ProtocolDocumento4 páginasIQOQ ProtocolVijay RajaindranAinda não há avaliações

- Urs TemplateDocumento7 páginasUrs TemplatehaiAinda não há avaliações

- Validation of Water SystemDocumento25 páginasValidation of Water Systemsukanya100% (2)

- Temperature Mapping Study and QualificationDocumento19 páginasTemperature Mapping Study and QualificationJewel Hernandez100% (2)

- Pharmaceutical Quality by Design: A Practical ApproachNo EverandPharmaceutical Quality by Design: A Practical ApproachWalkiria S. SchlindweinAinda não há avaliações

- SOP For Equipment Qualification - Pharmaceutical GuidelinesDocumento4 páginasSOP For Equipment Qualification - Pharmaceutical GuidelinesMuthuraman M100% (2)

- Supplier Quality Management System A Complete Guide - 2020 EditionNo EverandSupplier Quality Management System A Complete Guide - 2020 EditionAinda não há avaliações

- Process Validation Sample Protocol - PharmaguidelineDocumento3 páginasProcess Validation Sample Protocol - PharmaguidelineD Tech Dental Technologies100% (1)

- VMP Guide PDFDocumento6 páginasVMP Guide PDFsitimunawarohAinda não há avaliações

- Production of Plasma Proteins for Therapeutic UseNo EverandProduction of Plasma Proteins for Therapeutic UseNota: 3 de 5 estrelas3/5 (5)

- Validation Master Plan A Complete Guide - 2019 EditionNo EverandValidation Master Plan A Complete Guide - 2019 EditionAinda não há avaliações

- Alarm Verification SOPDocumento7 páginasAlarm Verification SOPBALU LTD BALU PHARMACEUTICALAinda não há avaliações

- SOP of Sanitation of PW SystemDocumento6 páginasSOP of Sanitation of PW Systemanon_350461302100% (1)

- Process Validation Protocol (500 MG Tablet)Documento6 páginasProcess Validation Protocol (500 MG Tablet)Mohammed Zubair100% (1)

- New Zealand Healthcare Pharmacists' Association Compounding Nutrition & Oncology SIGDocumento31 páginasNew Zealand Healthcare Pharmacists' Association Compounding Nutrition & Oncology SIGcleanroom100% (1)

- Stability Chamber Calibration ProcedureDocumento1 páginaStability Chamber Calibration ProcedureNageshwar Thadakamalla100% (1)

- How To Validate An AutoclaveDocumento3 páginasHow To Validate An AutoclaveqhpuongAinda não há avaliações

- Monitoring Environmental Parameters of Incubators, Fridge-Freezers QC-05-05 EPADocumento17 páginasMonitoring Environmental Parameters of Incubators, Fridge-Freezers QC-05-05 EPAAna M VrrAinda não há avaliações

- GMP Quality Supplier Audit Questionnaire 1663569818Documento15 páginasGMP Quality Supplier Audit Questionnaire 1663569818Cyclone Pharmaceuticals Pvt Ltd PuneAinda não há avaliações

- Management of Out of Specification (OOS) For Finished ProductDocumento12 páginasManagement of Out of Specification (OOS) For Finished Productpires35100% (1)

- Performance Qualification PQ GuidlineDocumento8 páginasPerformance Qualification PQ Guidlinejanu1211Ainda não há avaliações

- PERFORMANCE QUALIFICATION FinalDocumento5 páginasPERFORMANCE QUALIFICATION Finalkrishna murthyAinda não há avaliações