Escolar Documentos

Profissional Documentos

Cultura Documentos

Kubler - Bellows Couplings

Enviado por

Sayak BoseTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Kubler - Bellows Couplings

Enviado por

Sayak BoseDireitos autorais:

Formatos disponíveis

Accessories

Couplings

Bellow type couplings are recommended

as an inexpensive type of coupling

They are also suitable to compensate

larger angular displacements

Spring washer type couplings for high

speed applications

Easy to mount, two parts

Description and applications

Manufacturing and installation tolerances

as well as the effects of temperature cause

alignment errors between shafts in drive

engineering which can sometimes lead to

extreme overload on the bearings.

This may result in increased wear of the

bearings and may lead to premature failure

of the encoder. By using couplings, these

alignment errors can be compensated,

thereby reducing the load on the bearings

to a minimum.

A distinction should be made between three

different kinds of alignment error: radial,

angular and axial displacement.

Whilst with torsion-free but bendable shaft

couplings, axial shaft displacements

produce only static forces in the coupling,

radial and angular displacements produce

alternating stresses, restoring forces and

moments which may have an impact on

adjoining components (shaft bearings).

Depending on the type of coupling,

particular attention should be paid to

radial shaft displacement which should be

kept to a minimum.

Areas of application:

Metal bellows-type couplings (.1101 and

1201) are recommended as an inexpensive

type of coupling. They are also suitable for

compensating larger angle displacements.

Spring washer-type couplings (.1300 and

.1401) are used mainly in those cases where

high speeds and smaller angular displacements are involved. For applications where

electrical insulation between rotary

encoder and drive is required, the electrically insulating spring whasher-type coupling should be used.

Installation instructions:

3. Tighten locking screws carefully. Avoid

overtightening.

4. During installation protect the coupling

from damage and from overbending.

1. Check shaft for displacement; See technical data for details

2. Align and adjust coupling on shafts.

Type

Max. speed

min-1

Max. torque

Ncm

Max. radial displacement

mm

Max. angular displacement

Grad

Max. axial displacement

mm

Torsion spring parameter Ncm/Grad

Moment of inertia

gcm2

Weight approx.

g

Material: Flange

Bellow or spring washer/casing

Diameter d/d1 from ... to

mm

Max. tightening torque

of locking screws

Ncm

Standard bore

mm

diameter

[d1/d2]

8.0000.1101.XXXX

12000

150

0,2

1,5

0,7

700

5,5

14

Al

stainless steel

3...12

8.0000.1201.XXXX

12000

50

0,2

1,5

0,5

210

1,2

6

Al

stainless steel

3...9

8.0000.1301.XXXX

12000

80

0,4

3

0,4

265

19

16

Al cu Mg Pb

Cu Sn 6 Vern.

3...8

8.0000.1401.XXXX

12000

60

0,3

2,5

0,4

55

35

30

diecast Zinc

PA 6,6 20% gf

4...16

1501.XXXX

12000

200

0,2

1,5

0,6

1300

18

24

Al

stainless steel

3...16

150

12/12

12/10

10/10

6/6

70

8/6

6/6

6/4

4/4

10/8

80

6/6

6/4

80

12/12

12/10

10/10

10/6

6/6

3/8/10

3/8/6

1/4/10

1/4/6

180

15/12

14/12

14/10

06/14

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Accessories

Technical data

Accessories

Couplings

Bellows-type coupling

Order code 8.0000.1501.XXXX

Spring washer coupling

Order code 8.0000.1300.XXXX

cylindrical screw

M2,5 x 9 DIN 912 (2x)

Bellows-type coupling

Order code 8.0000.1101.XXXX

Spring washer coupling

Order code 8.0000.1401.XXXX

cylindrical screw

M3 x 10 DIN 912

Bellows-type coupling

Order code 8.0000.1201.XXXX

Order code:

Description of the Order Code

Type of coupling

1

Bellows-type 19 mm

2

Bellows-type 15 mm

3

Spring washer type

4

Spring washer type*

5

Bellows-type 25 mm

08.0000.1X01.XXXX

Bore diameter d2

(see table)

Bore diameter d1

(see table)

Example: a) d1 = 10 mm and d2 = 12 mm

=> XXXX.XXXX.1012)

Note:

for the bore diameter

d1 = 3/8 please enter Code A1

d1 = 1/4 please enter Code A2

Example: b) Coupling type 1401 with

d2 = 10 mm and d1 = 3/8:

Order code = 1401.A110

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Você também pode gostar

- Rotating Steel ShaftsDocumento3 páginasRotating Steel ShaftsSrini KumarAinda não há avaliações

- Service Bulletin: Subject: Installation & Inspection of Flexible Metal Hose AssembliesDocumento17 páginasService Bulletin: Subject: Installation & Inspection of Flexible Metal Hose AssembliesjussmeeeAinda não há avaliações

- Stress Analysis of Prestressed Bolt and Nut JointDocumento29 páginasStress Analysis of Prestressed Bolt and Nut JointTîwäRî RãJêêvAinda não há avaliações

- Die Max Die SpringsDocumento16 páginasDie Max Die SpringsYogesh PatelAinda não há avaliações

- Karta Katalogowa 198759 Sprzeglo Mieszkowe Enkodera Zestali Nierdzewnej Fi 12 Na 12 MMDocumento4 páginasKarta Katalogowa 198759 Sprzeglo Mieszkowe Enkodera Zestali Nierdzewnej Fi 12 Na 12 MMBart JedrzeAinda não há avaliações

- Ball Screw CalculatorDocumento60 páginasBall Screw Calculatorمنير بوزيدAinda não há avaliações

- 508MAD24 27 KK ScrewDrivesDocumento2 páginas508MAD24 27 KK ScrewDrivesLuis DemyanenkoAinda não há avaliações

- Zubehoer Kupplungen enDocumento4 páginasZubehoer Kupplungen enJosé CunhaAinda não há avaliações

- How To Specify Fasteners: 3/4 - 10 X 5 Hex Cap Screw Grade 5 Zinc 3/4 - 16 X 5 Hex Cap Screw Grade 5 ZincDocumento15 páginasHow To Specify Fasteners: 3/4 - 10 X 5 Hex Cap Screw Grade 5 Zinc 3/4 - 16 X 5 Hex Cap Screw Grade 5 ZincAndré BuysAinda não há avaliações

- MAN ShaftErrosion SL2008-498Documento18 páginasMAN ShaftErrosion SL2008-498flipflop12100% (1)

- LO 4 Handout SLO1,2,3, and 4 All Suboutcome CompleteDocumento38 páginasLO 4 Handout SLO1,2,3, and 4 All Suboutcome Completesushil.vgiAinda não há avaliações

- Design Factors When Using Small Bearings: Part 1: Bearing GeometryDocumento7 páginasDesign Factors When Using Small Bearings: Part 1: Bearing Geometryhittaf_05Ainda não há avaliações

- Design Factors When Using Small Bearings: Part 2: Mounting and FittingDocumento11 páginasDesign Factors When Using Small Bearings: Part 2: Mounting and FittingankitsarvaiyaAinda não há avaliações

- Disc Spring TechnologyDocumento94 páginasDisc Spring TechnologyhacenescribdAinda não há avaliações

- Cross Roller RingDocumento52 páginasCross Roller RingFrank ChoiAinda não há avaliações

- Experience With Large, High-Speed Load Gears: Erwin Dehner and Francois WeberDocumento11 páginasExperience With Large, High-Speed Load Gears: Erwin Dehner and Francois WeberHernan GirautAinda não há avaliações

- Recommended FitsDocumento10 páginasRecommended FitsZiad AkmalAinda não há avaliações

- RUDDER AND RUDDER STOCK INSPECTION GUIDEDocumento12 páginasRUDDER AND RUDDER STOCK INSPECTION GUIDEJORGEAinda não há avaliações

- Bench Top Tube Bender: User's ManualDocumento14 páginasBench Top Tube Bender: User's ManualOmar KhaledAinda não há avaliações

- ASA Couplings (4) Oldham'sDocumento8 páginasASA Couplings (4) Oldham'sIan DonovanAinda não há avaliações

- Hose-Installation-GuideDocumento1 páginaHose-Installation-GuidealimesmatparastAinda não há avaliações

- Lead Screw SelectionDocumento21 páginasLead Screw Selectionaushad3mAinda não há avaliações

- Rubber Design Vibration and Noise ControlDocumento14 páginasRubber Design Vibration and Noise Controlcvishwas1159Ainda não há avaliações

- PV Load Capacity and Life - EnB-04-0655Documento3 páginasPV Load Capacity and Life - EnB-04-0655guilleaguadoAinda não há avaliações

- FL6003 PDFDocumento4 páginasFL6003 PDFMauricio Barrios CastellanosAinda não há avaliações

- KGE1000Ti Service ManualDocumento41 páginasKGE1000Ti Service Manualmarksmods100% (1)

- Distitec Steel Bearing GuideDocumento36 páginasDistitec Steel Bearing GuideMohamad Rahimi BorhannodinAinda não há avaliações

- Shaft Strain Gaging Guide v4Documento11 páginasShaft Strain Gaging Guide v4craigAinda não há avaliações

- General Series Overhead Crane: User ManualDocumento27 páginasGeneral Series Overhead Crane: User ManualjokoAinda não há avaliações

- Pulleys TechDocumento8 páginasPulleys TechashkansoheylAinda não há avaliações

- Acoplamientos TSK PDFDocumento4 páginasAcoplamientos TSK PDFBenicio Joaquín Ferrero BrebesAinda não há avaliações

- Designofcoupling 180525101520 PDFDocumento39 páginasDesignofcoupling 180525101520 PDFankur palAinda não há avaliações

- Leespring EngguideDocumento27 páginasLeespring EngguideAnonymous h6qnMVb8eAinda não há avaliações

- Connecting Rod Repair GuideDocumento32 páginasConnecting Rod Repair GuideJorge Espinoza100% (1)

- Ball Transfer Units GuideDocumento20 páginasBall Transfer Units GuideconradoralAinda não há avaliações

- TDBFP ManulDocumento266 páginasTDBFP ManulJackSparrow8678% (9)

- Nadella - Needle BearingsDocumento230 páginasNadella - Needle Bearingsג'ון ירוקAinda não há avaliações

- Mig WireDocumento10 páginasMig WireSathishkumar SrinivasanAinda não há avaliações

- Bearing Fit ChartDocumento6 páginasBearing Fit ChartAvinash MamillapalliAinda não há avaliações

- Design of A Power Screw: Department of Mechanical Engineering, Bharath University, Selaiyur, Chennai, Tamilnadu, IndiaDocumento5 páginasDesign of A Power Screw: Department of Mechanical Engineering, Bharath University, Selaiyur, Chennai, Tamilnadu, IndiaWahyu DidierAinda não há avaliações

- Masoneilan 39003 Series High Performance Butterfly Valves (HPBV)Documento20 páginasMasoneilan 39003 Series High Performance Butterfly Valves (HPBV)Sergio IvánAinda não há avaliações

- Coupling Catalog PDFDocumento22 páginasCoupling Catalog PDFManick Raj JAinda não há avaliações

- Roller Chain Coupling: Features 1. Simple Structure 1. Advantages of HousingDocumento5 páginasRoller Chain Coupling: Features 1. Simple Structure 1. Advantages of Housingsyaifularifin33Ainda não há avaliações

- TOPIC 4 BearingDocumento44 páginasTOPIC 4 BearingHafiy Qursyeini100% (1)

- Term PaperDocumento23 páginasTerm PaperAman Goyal (B19ME004)Ainda não há avaliações

- Shaft Design and Its ApplicationDocumento19 páginasShaft Design and Its ApplicationAli MahmoudAinda não há avaliações

- TIMKEN Lozyska Do Zestawow Kolowych Wagonow enDocumento71 páginasTIMKEN Lozyska Do Zestawow Kolowych Wagonow enandrebuyuAinda não há avaliações

- AVT Ball & Butterfly Brochure 05 Latest 12 PageDocumento12 páginasAVT Ball & Butterfly Brochure 05 Latest 12 PageshalbyAinda não há avaliações

- Kit de Ferramentas Retirar RolamentoDocumento2 páginasKit de Ferramentas Retirar RolamentoANDERSON WINTHERAinda não há avaliações

- SKF Bearing Fitting Tool Kit TMFT 36: Helps Prevent Premature Bearing FailuresDocumento2 páginasSKF Bearing Fitting Tool Kit TMFT 36: Helps Prevent Premature Bearing FailuresFebriyantoAinda não há avaliações

- 0901d1968008a1ff PDF Preview MediumDocumento2 páginas0901d1968008a1ff PDF Preview Mediump.karthick05Ainda não há avaliações

- SKF Bearing Fitting ToolDocumento2 páginasSKF Bearing Fitting ToolTOKO CAHAYA PERMATAAinda não há avaliações

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsNo EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsNota: 4 de 5 estrelas4/5 (1)

- Weld Like a Pro: Beginning to Advanced TechniquesNo EverandWeld Like a Pro: Beginning to Advanced TechniquesNota: 4.5 de 5 estrelas4.5/5 (6)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesNo EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesNota: 5 de 5 estrelas5/5 (1)

- Temperature Controller: Slim! Easy Operation! CompactDocumento2 páginasTemperature Controller: Slim! Easy Operation! CompactSayak BoseAinda não há avaliações

- Infrared Gas AnalyzerDocumento2 páginasInfrared Gas AnalyzerSayak BoseAinda não há avaliações

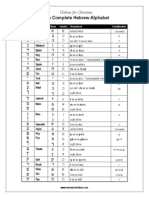

- Hebrew AlphabetDocumento1 páginaHebrew AlphabetJames GregoryAinda não há avaliações

- Temperature Controller: Slim! Easy Operation! CompactDocumento2 páginasTemperature Controller: Slim! Easy Operation! CompactSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- Infrared Gas AnalyzerDocumento2 páginasInfrared Gas AnalyzerSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- 7ML19981DF01Documento12 páginas7ML19981DF01Jose LunaAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- 4 DFGF 654Documento12 páginas4 DFGF 654Sayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- TDocumento1 páginaTSayak BoseAinda não há avaliações

- 4 RDocumento29 páginas4 RSayak BoseAinda não há avaliações

- IP65 Polyester Enclosures for M12, M16, M20 ConnectionsDocumento1 páginaIP65 Polyester Enclosures for M12, M16, M20 ConnectionsSayak BoseAinda não há avaliações

- 4 DFGF 654Documento12 páginas4 DFGF 654Sayak BoseAinda não há avaliações

- Telemecanique PDFDocumento60 páginasTelemecanique PDFMario PerezAinda não há avaliações

- TDocumento1 páginaTSayak BoseAinda não há avaliações

- 4 DFGF 654Documento12 páginas4 DFGF 654Sayak BoseAinda não há avaliações

- Process Control & Instrumentation Part III P&I Symbols: B.T.S FEE (D. Bord Lycée ST Michel - 54) Sem 12Documento3 páginasProcess Control & Instrumentation Part III P&I Symbols: B.T.S FEE (D. Bord Lycée ST Michel - 54) Sem 12Sayak BoseAinda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 2016 Top 900 PricelistDocumento19 páginas2016 Top 900 Pricelistapi-317879840Ainda não há avaliações

- Selection of Wheels in Robotics PDFDocumento5 páginasSelection of Wheels in Robotics PDFSyed Asrar asrarAinda não há avaliações

- What Is Vibration? ExplainedDocumento71 páginasWhat Is Vibration? ExplainedFarhan TalibAinda não há avaliações

- Centrifugal Machines BrochureDocumento8 páginasCentrifugal Machines BrochureSiva VigneswaranAinda não há avaliações

- 1966 Comet Falcon Fairlane Mustang Manual-751-775Documento25 páginas1966 Comet Falcon Fairlane Mustang Manual-751-775shitAinda não há avaliações

- Sci Screw KompDocumento10 páginasSci Screw KompsebastianAinda não há avaliações

- Boiler-Interlocks-Protection 300 MWDocumento75 páginasBoiler-Interlocks-Protection 300 MWPrateek Kumar SinghAinda não há avaliações

- M (V) - 8 Shaft Earthing DeviceDocumento14 páginasM (V) - 8 Shaft Earthing Deviceerkan aksoyAinda não há avaliações

- Cat Lebw0009-00Documento104 páginasCat Lebw0009-00Silvio Roman100% (1)

- Shaft Alignment GN E-Feb14Documento122 páginasShaft Alignment GN E-Feb14supriadi90315Ainda não há avaliações

- RT-123 - A3 Appendix 3 (Issue 3) (Flex 82) Nov 2016Documento7 páginasRT-123 - A3 Appendix 3 (Issue 3) (Flex 82) Nov 2016ajeshkrishnanAinda não há avaliações

- CVC Engineered SpecialtiesDocumento20 páginasCVC Engineered SpecialtiesAlexander Arias VargasAinda não há avaliações

- Condition Assessment - HT MachineDocumento20 páginasCondition Assessment - HT MachineFerozMujawar0% (1)

- Cat Hand Pallet Truck Replacement Parts A4Documento3 páginasCat Hand Pallet Truck Replacement Parts A4GUILLERMO SEGURAAinda não há avaliações

- Catalogue Degaussing 2013 LRDocumento24 páginasCatalogue Degaussing 2013 LRFerryAinda não há avaliações

- BE Power Point PresentationDocumento63 páginasBE Power Point PresentationLuis Valenzuela100% (2)

- Periodic Maintenance - (01-2004) - Us-EnDocumento84 páginasPeriodic Maintenance - (01-2004) - Us-EnChristian Bedoya75% (4)

- Rotary Deck Bushing: Balls Make The Difference... Increased Drilling Production Proves ItDocumento2 páginasRotary Deck Bushing: Balls Make The Difference... Increased Drilling Production Proves ItFedericoButronAinda não há avaliações

- Bearings Engle ZaDocumento22 páginasBearings Engle ZaAndreea Iuliana DrăgușAinda não há avaliações

- 2 Speed Rear Axle SpicerDocumento51 páginas2 Speed Rear Axle SpicerMario Jesus Pedraza CardenasAinda não há avaliações

- 1962-1963 Supplement - Chevrolet Corvair Shop Manual - Section 6e - Automatic Transmission PDFDocumento3 páginas1962-1963 Supplement - Chevrolet Corvair Shop Manual - Section 6e - Automatic Transmission PDFbelchior alvaroAinda não há avaliações

- Breaker LubeDocumento4 páginasBreaker Lubedmb1692Ainda não há avaliações

- Eaton Hydraulics 2000 Steve Skinner, Eaton Hydraulics, Havant, UKDocumento64 páginasEaton Hydraulics 2000 Steve Skinner, Eaton Hydraulics, Havant, UKedpsousa100% (1)

- Universal Levers & Locks Awareness BrochureDocumento28 páginasUniversal Levers & Locks Awareness BrochureUniversal Levers & LocksAinda não há avaliações

- Technical Data Press MaintenanceDocumento6 páginasTechnical Data Press MaintenanceKaran VirbhadreAinda não há avaliações

- Catalogu eDocumento84 páginasCatalogu eRogelio Portillo VelezAinda não há avaliações

- Thrust Restraint Design For DI PipeDocumento24 páginasThrust Restraint Design For DI PipefazyroshanAinda não há avaliações

- Zollern - Plain Bearing - Type ZDocumento20 páginasZollern - Plain Bearing - Type ZYuri BachAinda não há avaliações

- 13 - Toyota Tercel Sistema de SuspensionDocumento57 páginas13 - Toyota Tercel Sistema de SuspensionJuan Soto winterAinda não há avaliações

- MultigrindDocumento40 páginasMultigrindMiles JohnsonAinda não há avaliações