Escolar Documentos

Profissional Documentos

Cultura Documentos

Tebs 4

Enviado por

andrzejTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Tebs 4

Enviado por

andrzejDireitos autorais:

Formatos disponíveis

ES205.

Product

DATA

TEBS4 Brake Module

Doc. No. Y011366 (EN - Rev. 004)

March 2014

PD-214-100

Commercial Vehicle Systems

Function

The electronic braking system for trailers (TEBS)

combines, in one compact Brake Module, the

electronic control unit, the sensor technology and the

pneumatic control.

The braking functions of anti-lock and load sensing

control are both electronically managed within the

module as integrated features. This provides more

accurate and consistent control of the generated

braking force including reduced hysteresis compared

to a conventional braking system, thereby improving

tractor-trailer compatibility, optimising the brake pad

wear and helping to reduce the overall operating costs

of the trailer.

The anti-compounding function is also housed within the

module.

As an additional option, the function Roll Stability Program (RSP) is

available. Should a driver underestimate the vehicle speed when

carrying out a manoeuvre, particularly when the trailer is laden with a

high centre of gravity, there is a real danger that the trailer will become

unstable and roll over. Even if the driver becomes aware of the condition

of the trailer, it is normally too late to prevent an accident.

The RSP function of TEBS helps to avoid this by automatically

applying the brakes of selected trailer wheels. By monitoring lateral

acceleration, load and speed, the system is able to determine when an

unstable condition is imminent. Should this condition arise, the brakes

are automatically applied to reduce vehicle speed and hence lateral

acceleration, thereby enhancing vehicle stability. When the threat of

instability is no longer present, the brakes are automatically released

and the system reverts to normal operation. RSP is available as an option

within TEBS and can be realised without any additional components

having to be installed on the trailer. Operation of the TEBS and RSP

function is independent of the specifications of the tractor.

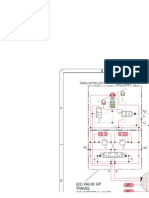

Standard Symbol as DIN ISO 1219

1-2

4 1.2 1.1

23

P

24

42

21

21

21

22

22

22

22

TEBS

RSP is available for semi-trailers, centre-axle, and drawbar trailers.

The following auxiliary functions may be configured to the associated auxiliary connections of the TEBS:

1.

Standard Auxiliary Functions:

1.1 Outputs

Fully Automatic Lift Axle Control: The ECU provides an electrical signal for the Knorr-Bremse lift axle control

valve AE114. and ensures that the legal requirements are fulfilled by preventing overloading of the axles. The

TEBS electronics can control up to two lift axle control valves, each valve may then be connected to 1 or 2 lifting axles

The information contained herein is subject to alteration without notice and therefore may not be the latest release. Please check our website www.knorr-bremseCVS.com for the latest update or contact your local Knorr-Bremse representative.

The figurative mark K and the trademarks KNORR and KNORR-BREMSE are registered in the name of Knorr-Bremse AG. Additional terms and conditions apply; please refer to our website knorr-bremseCVS.com for full Disclaimer.

Note: If service work is carried out on a vehicle based on information provided herein, it is the responsibility of the workshop to ensure the vehicle is fully tested and in full

functional order before the vehicle is returned into service. Knorr-Bremse accepts no liability for problems caused as a result of appropriate tests not being carried out.

Copyright Knorr-Bremse AG - all rights reserved, including industrial property rights applications. Knorr-Bremse AG retains any power of disposal, such as for copying and transferring..

Knorr-Bremse Systeme fr Nutzfahrzeuge GmbH . Moosacher Strae 80 . 80809 Munich . Germany . Tel: +49 89 3547-0 . Fax: +49 89 3547-2767 . www.knorr-bremse.com . www.knorr-bremseCVS.com

Y011366: 004: EN: Released: Mon May 26 16:44:53 CEST 2014:

Knorr-Bremse Group

Item No. K002483

RtR (Reset to Ride): In conventional suspension control systems, the raise/lower valve is often not reset to the

drive position before the vehicle is moved and damage can be caused to the suspension and brakes. To prevent

this happening, the TEBS ECU can be programmed to supply an electrical signal to a raise/lower valve with

suitable functionality such that when the vehicle exceeds a pre-determined threshold speed, this signal causes

the raise/lower valve to automatically switch to the drive position.

PD-214-100

Product Data

ES205.

Doc. No. Y011366 (EN - Rev. 004)

March 2014

TEBS 4 Brake Module

ISS (Integrated Speed Switch): The TEBS provides an electrical output signal when a pre-programmed vehicle

speed has been reached.

This signal may be used to fulfil numerous operational requirements such as locking of steering axles etc.

The signal can be programmed to switch from 0 V to 24V or 24V to 0 V.

The hysteresis, i.e. the difference between switch on and switch off speeds, can be adjusted to 10%, 20%, 40%

or 80%.

24 V Supply: Provides a permanent power supply that may be used to power additional brake and running

gear systems / functions on the trailer.

ABS active: When the ABS of the trailer is active, a 24V signal is transmitted by the ECU. Typically this function

may be used to switch off a retarder installed on the trailer while ABS is active.

RSP active: When the RSP of the trailer is active, a 24V signal is transmitted by the ECU.

TOC (Trailer Occurrence Counter): Every kilometre travelled, the ECU transmits a 24V signal for a period of time

and this may be used to trigger an external mileage counter.

1.2 Inputs:

The TEBS ECU has the ability to evaluate and/or react to three sensor inputs as follows:

Brake Pad Wear control: When an input is received that the wear limit of at least one brake has been reached,

the information is stored by the ECU and can be displayed by a Magic Eye or the information can be accessed at a

later date via PC diagnostocs or TIM. In addition, an electrical signal will be transmitted to the towing vehicle via pin

5 of the ISO 7638 connector causing the yellow warning lamp to flash each time the system is initially powered

and the vehicle is stationary.

A CAN signal is also transmitted via pins 6 and 7 of the ISO 7638 which may be used in the drivers information

display (if the towing vehicle has such a device).

Traction Assist: Raises the front lift axle when the trailer is laden to increase the imposed load on the towing

vehicles drive axle to improve traction. Axle overload and speed restrictions apply when this function in operational.

Disable Lift Axle Control: Signals the lift axle(s) to lower when raised; this allows manual activation via a signal

transmitted by the towing vehicle or by an electrical switch mounted on the trailer. This can be used to assist

manoeuvring or for rolling road testing.

2. Non-Standard Auxiliary Functions (via ADL):

Should a customer require a function, other than those normally available, it is possible to create a non-standard

function by the use of a special program file known as Auxiliary Design Language (ADL) produced by

Knorr-Bremse.

Should such a function be required, contact must be made through the local Knorr-Bremse representative. When

available, the special file needed to fulfil the function can be written to the ECU via the PC Diagnostic Program.

3. Stop Lamp powering:

To obtain full functionality, any trailer electronic braking system requires a permanent power supply (achieved by

using the legally specified ISO 7638 connection in 5 or 7 pin format); this ensures load sensing, anti-lock control

(ABS) and all auxiliary functions are automatically maintained. In the event of a failure of this power supply, whilst trailer

braking will be maintained via the pneumatic back-up function, all electronically controlled functionality would no

longer be active. Continued operation of the vehicle without electrical power to the ECU and so without load sensing

and ABS, may therefore result in tyre flat spotting, trailer instability and higher brake operating temperatures leading

to increased brake pad wear. To overcome this problem, the TEBS ECU can be installed so that it will continue to

operate by taking power from the Stop Lamp circuit and thereby load sensing and anti-lock functions remain active.

NOTE:

The information contained herein is subject to alteration without notice and therefore may not be the latest release. Please check our website www.knorr-bremseCVS.com for the latest update or contact your local Knorr-Bremse representative.

The figurative mark K and the trademarks KNORR and KNORR-BREMSE are registered in the name of Knorr-Bremse AG. Additional terms and conditions apply; please refer to our website knorr-bremseCVS.com for full Disclaimer.

Note: If service work is carried out on a vehicle based on information provided herein, it is the responsibility of the workshop to ensure the vehicle is fully tested and in full

functional order before the vehicle is returned into service. Knorr-Bremse accepts no liability for problems caused as a result of appropriate tests not being carried out.

Copyright Knorr-Bremse AG - all rights reserved, including industrial property rights applications. Knorr-Bremse AG retains any power of disposal, such as for copying and transferring..

Knorr-Bremse Systeme fr Nutzfahrzeuge GmbH . Moosacher Strae 80 . 80809 Munich . Germany . Tel: +49 89 3547-0 . Fax: +49 89 3547-2767 . www.knorr-bremse.com . www.knorr-bremseCVS.com

Knorr-Bremse Group

Y011366: 004: EN: Released: Mon May 26 16:44:53 CEST 2014:

Item No. K002483

Stop Lamp powering should only be considered as a back-up function to ensure some safety features are

retained. Operation of the vehicle over a longer period without a fully functioning ISO 7638 connector is not legal.

ES205.

Doc. No. Y011366 (EN - Rev. 004)

March 2014

TEBS4 Brake Module

Technical Features

Operating pressure:

Max. permissable pressure:

Operating temperature range:

Weight:

Nominal voltage:

10.0 bar

12.5 bar

-40 C to +65 C

ES2050, ES2053 5.7 kg approx.

24 V DC

Towing vehicle requirements

Trailers fitted with an Electronic Braking System (TEBS) only comply with the legal requirements of Regulations 98/12/EC

and ECE Regulation 13/09 Supplement 08, when the towing vehicle is equipped with an electrical interface of the

following specification:

ISO 7638: 1985

ISO 7638: 1997 Part 1 (24 V)

ISO 7638: 1997 Part 1 (24 V)

5 Pin

5 Pin

7 Pin

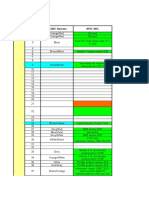

Range Overview

Part No.

Type No.

ES2050

II397983)

II397823)

ES2053

II39782N504)

Possible

ABS

Configuration

Auxiliary Functions

X1 connector 1)

Total Auxiliaries: 2

X2 connector

RSP

Max.

Out

Max.

In

Max.

Out

Max.

In

2S-4S/2M

12)

No

2S-4S/2M

12)

Yes

4S/3M

12)

15)

Yes

Only possible if TIM or Magic Eye are not used; maximum number of configurable Auxiliaries on X1 connector: 2

No Traction Help, no Disable Lift Axle Control

3)

The part number may have the suffix F004 in which case the Module will be supplied with a system plate and an

information sticker.

4)

Replaces II36419 - ES2050 and II39783F - ES2041. The part number will carry a suffix N50 which defines

that it is supplied with packaging.

5)

Two of the X2 Auxiliary Outputs are required to power the external ABS Modulator Valve (BR9234 - see

PD-200-200, Document No. Y011362) in the 4S/3M system

1)

2)

Service Parts:

Item No. K002483

K102802K50

Connector Cover

K108643K50

Port Filter (contains 20 Filters)

K101835K50

Silencer Kit (two kits required per module)

K101836K50

Blanking Plug for X2 Connector

K103003K50

Blanking Plug for WSS Connector

The information contained herein is subject to alteration without notice and therefore may not be the latest release. Please check our website www.knorr-bremseCVS.com for the latest update or contact your local Knorr-Bremse representative.

The figurative mark K and the trademarks KNORR and KNORR-BREMSE are registered in the name of Knorr-Bremse AG. Additional terms and conditions apply; please refer to our website knorr-bremseCVS.com for full Disclaimer.

Note: If service work is carried out on a vehicle based on information provided herein, it is the responsibility of the workshop to ensure the vehicle is fully tested and in full

functional order before the vehicle is returned into service. Knorr-Bremse accepts no liability for problems caused as a result of appropriate tests not being carried out.

Copyright Knorr-Bremse AG - all rights reserved, including industrial property rights applications. Knorr-Bremse AG retains any power of disposal, such as for copying and transferring..

Knorr-Bremse Systeme fr Nutzfahrzeuge GmbH . Moosacher Strae 80 . 80809 Munich . Germany . Tel: +49 89 3547-0 . Fax: +49 89 3547-2767 . www.knorr-bremse.com . www.knorr-bremseCVS.com

Y011366: 004: EN: Released: Mon May 26 16:44:53 CEST 2014:

Knorr-Bremse Group

PD-214-100

Commercial Vehicle Systems

PD-214-100

Product Data

ES205.

Doc. No. Y011366 (EN - Rev. 004)

March 2014

TEBS 4 Brake Module

Dimensions

ES2050

ES2053

EBS-System Plate 1):

Part No.:

II39797F

Size [mm]: 170 x 110

Information sticker, TEBS

power supply

Part No.:

II39796F

Size [mm]: 150 x 100

Trailer EBS

KNORR-BREMSE

Systeme fr Nutzfahrzeuge

EBS

ALB (LSV/CDF)

ABS

VF00075_189.jpg

II39796F

VF00075_188.eps

The System Plate is a sticker which can be printed via the ECUtalk software and a laser printer.

Caution! A laser printer must be used but do not print more than 5 stickers at a time.

The information contained herein is subject to alteration without notice and therefore may not be the latest release. Please check our website www.knorr-bremseCVS.com for the latest update or contact your local Knorr-Bremse representative.

The figurative mark K and the trademarks KNORR and KNORR-BREMSE are registered in the name of Knorr-Bremse AG. Additional terms and conditions apply; please refer to our website knorr-bremseCVS.com for full Disclaimer.

Note: If service work is carried out on a vehicle based on information provided herein, it is the responsibility of the workshop to ensure the vehicle is fully tested and in full

functional order before the vehicle is returned into service. Knorr-Bremse accepts no liability for problems caused as a result of appropriate tests not being carried out.

Copyright Knorr-Bremse AG - all rights reserved, including industrial property rights applications. Knorr-Bremse AG retains any power of disposal, such as for copying and transferring..

Knorr-Bremse Systeme fr Nutzfahrzeuge GmbH . Moosacher Strae 80 . 80809 Munich . Germany . Tel: +49 89 3547-0 . Fax: +49 89 3547-2767 . www.knorr-bremse.com . www.knorr-bremseCVS.com

Knorr-Bremse Group

Y011366: 004: EN: Released: Mon May 26 16:44:53 CEST 2014:

Item No. K002483

1)

ES205.

Doc. No. Y011366 (EN - Rev. 004)

March 2014

TEBS4 Brake Module

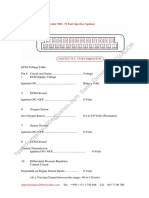

Electrical connections

X1 - connector

X2 - connector

Pin

Diagnosis via K-Line or

TIM or Magic Eye

Diagnosis via CAN

Pin

2S / 2M

4S / 2M

4S / 3M

Diagnostics

Input C - signal

AUX 1 (24 V)

External ABS Modulator (BR9234)

- Hold Valve (1,0 mm2 YE)

Diagnostics - ground

ground

AUX 2 (24 V)

External ABS Modulator (BR9234)

- Release Valve (1,0 mm2 BK)

ISO 11992 CAN low

(ISO 7638: 1,5 mm2 WH / BN)

AUX 3 (24 V)

Modulator - ground

(ISO 7638: 4,0 mm2 BN)

Input supply (5 V)

ISO 11992 CAN high

(ISO 7638: 1,5 mm2 WH / GN)

Input A - signal

Modulator - 24 V

(ISO 7638: 4,0 mm RD)

Input A - ground

ECU - ground

(ISO 7638: 1,5 mm2 YE)

Input B - ground

Warning Lamp

(ISO 7638: 1,5 mm2 WH)

Input B - signal

ECU - 24 V

(ISO 7638: 1,5 mm2 BK)

10

Diagnostics - 24 V

AUX 4 (24 V)

10

11

Stop Lamp - ground

(ISO 1185: 1,0 mm2 BN)

11

ground

12

Stop Lamp - 24 V

(ISO 1185 1,0 mm2 YE)

12

ground

External ABS Modulator (BR9234)

- Ground (1,0 mm2 WH)

Pneumatic connections

Port

Qty

1.1

Supply to reservoir

M22 x 1.5

1.2

Supply to reservoir

M22 x 1.5

1-2

To AE431. park/shunt valve

M22 x 1.5

21

Delivery to brake chambers, right side

M22 x 1.5

22

Delivery to brake chambers, left side

M22 x 1.5

22

Test connector

M16 x 1.5

23

Delivery to spring portions of spring brakes, right side

M16 x 1.5

24

Delivery to spring portions of spring brakes, left side

M16 x 1.5

Brake demand - Control (Yellow) Line

M16 x 1.5

42

Air suspension bag pressure

M16 x 1.5

1)

1)

Used for

Port Thread

If only one supply port is required, 1.1 must be used and 1.2 must be plugged.

Item No. K002483

1)

The information contained herein is subject to alteration without notice and therefore may not be the latest release. Please check our website www.knorr-bremseCVS.com for the latest update or contact your local Knorr-Bremse representative.

The figurative mark K and the trademarks KNORR and KNORR-BREMSE are registered in the name of Knorr-Bremse AG. Additional terms and conditions apply; please refer to our website knorr-bremseCVS.com for full Disclaimer.

Note: If service work is carried out on a vehicle based on information provided herein, it is the responsibility of the workshop to ensure the vehicle is fully tested and in full

functional order before the vehicle is returned into service. Knorr-Bremse accepts no liability for problems caused as a result of appropriate tests not being carried out.

Copyright Knorr-Bremse AG - all rights reserved, including industrial property rights applications. Knorr-Bremse AG retains any power of disposal, such as for copying and transferring..

Knorr-Bremse Systeme fr Nutzfahrzeuge GmbH . Moosacher Strae 80 . 80809 Munich . Germany . Tel: +49 89 3547-0 . Fax: +49 89 3547-2767 . www.knorr-bremse.com . www.knorr-bremseCVS.com

Y011366: 004: EN: Released: Mon May 26 16:44:53 CEST 2014:

Knorr-Bremse Group

PD-214-100

Commercial Vehicle Systems

PD-214-100

Product Data

ES205.

Doc. No. Y011366 (EN - Rev. 004)

March 2014

TEBS 4 Brake Module

Additional Documentation

Documentation is available from your Knorr-Bremse technical sales representative and/or on the Knorr-Bremse

website www.knorr-bremsecvs.com which gives detailed information about the electronic braking system such as

a system description and detailed installation instructions.

Customer News

Information Document

Installation Instructions

Product Data

Product Data

Product information

Product News

Service Information

Service News

Service News

User Manual

ECUtalk Download

TEBS4 Homologation Document

TEBS4

ABS Relay Modulator Valves (PD-200-200)

Cables for Trailer ABS and EBS (PD-272-000)

Electronic Braking System for Trailers

ECUtalk Vista compatibility

Identification of TEBS Module

TEBS4 Installation/Storage/Maintenance

TEBS4 Update Package SW521.17

ECUtalk Diagnostics

Y049770

C16427

Y002324

Y011362

Y095697

P-3528

Y055547

Y018096

Y025056

Y052195

Y031901

Legal Requirements

TEBS has been approved in accordance with the requirements of Annex XIV of the Directive 98/12/EC and Annex 19

of ECE Regulation 13 with respect to ABS performance (see approval report EB 130 and the information document

C16427/E).

The information contained herein is subject to alteration without notice and therefore may not be the latest release. Please check our website www.knorr-bremseCVS.com for the latest update or contact your local Knorr-Bremse representative.

The figurative mark K and the trademarks KNORR and KNORR-BREMSE are registered in the name of Knorr-Bremse AG. Additional terms and conditions apply; please refer to our website knorr-bremseCVS.com for full Disclaimer.

Note: If service work is carried out on a vehicle based on information provided herein, it is the responsibility of the workshop to ensure the vehicle is fully tested and in full

functional order before the vehicle is returned into service. Knorr-Bremse accepts no liability for problems caused as a result of appropriate tests not being carried out.

Copyright Knorr-Bremse AG - all rights reserved, including industrial property rights applications. Knorr-Bremse AG retains any power of disposal, such as for copying and transferring..

Knorr-Bremse Systeme fr Nutzfahrzeuge GmbH . Moosacher Strae 80 . 80809 Munich . Germany . Tel: +49 89 3547-0 . Fax: +49 89 3547-2767 . www.knorr-bremse.com . www.knorr-bremseCVS.com

Knorr-Bremse Group

Y011366: 004: EN: Released: Mon May 26 16:44:53 CEST 2014:

Item No. K002483

The system also fulfils the requirements of the ECE regulation 13/09 Supplement 8 with respect to the prescribed

requirements for vehicles with an electric control line and electric control transmission. (See approval report

No. EB 133 and the information document C16428/E).

ES205.

Doc. No. Y011366 (EN - Rev. 004)

March 2014

TEBS4 Brake Module

Diagnostics

Universal Diagnostic Interface (UDIF)

Function

In order to configure the TEBS, carry out End Of Line testing and system

checks, special hardware and software is required.

The hardware consists of a diagnostic interface and cables to connect

TEBS electronics to the PC. Two different versions of software are

available; a full version for the trailer manufacturer and a diagnostic

version specifically designed for workshops. The software ECUtalk

can be downloaded free of charge from the Internet. To use the

software a PIN is required, which can be purchased over the Internet

after appropriate training has been completed.

Options

The later generations of TEBS do not require a specific diagnostic connection at the side of the trailer as PC

diagnostic can be carried out via pins 6 and 7 of the ISO 7638 interface (CAN connection).

Item No. K002483

This diagnostic interface can be connected to the TEBS via an adapter cable, which is also connected to a standard

ISO 7638 connection (5 pin or 7 pin) to power the TEBS.

Pos.

Name

Part No.

Type No.

Remarks

Diagnostic Set UDIF

II39809F

EZ1031

Including connection cable Z005474

(9-pin sub-D-plug and 9-pin sub-D-socket)

Adapter cable

II39808F

EZ1034

See PD-272-030, Document No. Y107796

Diagnostic cable

II39812F

EZ1032

See PD-272-030, Document No. Y107796

Connection cable

Z007887

Optional for USB-connection to PC

Diagnostic software

Download from www.knorr-bremseCVS.com

The information contained herein is subject to alteration without notice and therefore may not be the latest release. Please check our website www.knorr-bremseCVS.com for the latest update or contact your local Knorr-Bremse representative.

The figurative mark K and the trademarks KNORR and KNORR-BREMSE are registered in the name of Knorr-Bremse AG. Additional terms and conditions apply; please refer to our website knorr-bremseCVS.com for full Disclaimer.

Note: If service work is carried out on a vehicle based on information provided herein, it is the responsibility of the workshop to ensure the vehicle is fully tested and in full

functional order before the vehicle is returned into service. Knorr-Bremse accepts no liability for problems caused as a result of appropriate tests not being carried out.

Copyright Knorr-Bremse AG - all rights reserved, including industrial property rights applications. Knorr-Bremse AG retains any power of disposal, such as for copying and transferring..

Knorr-Bremse Systeme fr Nutzfahrzeuge GmbH . Moosacher Strae 80 . 80809 Munich . Germany . Tel: +49 89 3547-0 . Fax: +49 89 3547-2767 . www.knorr-bremse.com . www.knorr-bremseCVS.com

Y011366: 004: EN: Released: Mon May 26 16:44:53 CEST 2014:

Knorr-Bremse Group

PD-214-100

Commercial Vehicle Systems

PD-214-100

Product Data

ES205.

Doc. No. Y011366 (EN - Rev. 004)

March 2014

TEBS 4 Brake Module

Diagnostics (contd.)

Trailer Information Module (TIM) (II39810F - EZ1035)

Function

The Trailer Information Module (TIM) is a trailer mounted display for direct

reading of diagnostic and trailer related information. It may also be used

as a hand held diagnostic tool. It enables access to information available

within the TEBS ECU without using PC diagnostics.

The display is made up of 4 lines each having 20 characters. Operation is

simple by means of three buttons (see picture). In addition to diagnostic

and checking functions, TIM offers access to the following information:

Active/stored faults

System voltage

Pad Wear

Mileage

Frequency of RSP activity

Axle Load

Note: As with Magic Eye, when using a TIM, no Input C or Output AUX 4 / Output AUX 5 functionality is possible via

the X-connector as an external diagnostic connection is required.

Technical features

Operating temperature range:

Weight:

Nominal voltage:

-20 C to +70 C

EZ1035 0.4 kg approx

24 V DC

Options

Pos.

1

Connection cable

TIM

Part No.

Type No.

Remarks

K007525

EK31071)

ISO 7638 + CAN and ISO1185,

see PD-272-020, Document No. Y107795

II40394F

EK31091)

ISO 7638 + CAN,

see PD-272-020, Document No. Y107795

II39810F

EZ1035

Cable length = 1m

A Mounting Kit (Part No: K005378), consisting of a closure cap, a spring ring and a nut, may be used

The information contained herein is subject to alteration without notice and therefore may not be the latest release. Please check our website www.knorr-bremseCVS.com for the latest update or contact your local Knorr-Bremse representative.

The figurative mark K and the trademarks KNORR and KNORR-BREMSE are registered in the name of Knorr-Bremse AG. Additional terms and conditions apply; please refer to our website knorr-bremseCVS.com for full Disclaimer.

Note: If service work is carried out on a vehicle based on information provided herein, it is the responsibility of the workshop to ensure the vehicle is fully tested and in full

functional order before the vehicle is returned into service. Knorr-Bremse accepts no liability for problems caused as a result of appropriate tests not being carried out.

Copyright Knorr-Bremse AG - all rights reserved, including industrial property rights applications. Knorr-Bremse AG retains any power of disposal, such as for copying and transferring..

Knorr-Bremse Systeme fr Nutzfahrzeuge GmbH . Moosacher Strae 80 . 80809 Munich . Germany . Tel: +49 89 3547-0 . Fax: +49 89 3547-2767 . www.knorr-bremse.com . www.knorr-bremseCVS.com

Knorr-Bremse Group

Y011366: 004: EN: Released: Mon May 26 16:44:53 CEST 2014:

Item No. K002483

1)

Description

ES205.

Doc. No. Y011366 (EN - Rev. 004)

March 2014

TEBS4 Brake Module

Item No. K002483

This document forms part of the Trailer Catalogue (Brake and Air Suspension Products for Trailers),

Document No. Y007570.

The information contained herein is subject to alteration without notice and therefore may not be the latest release. Please check our website www.knorr-bremseCVS.com for the latest update or contact your local Knorr-Bremse representative.

The figurative mark K and the trademarks KNORR and KNORR-BREMSE are registered in the name of Knorr-Bremse AG. Additional terms and conditions apply; please refer to our website knorr-bremseCVS.com for full Disclaimer.

Note: If service work is carried out on a vehicle based on information provided herein, it is the responsibility of the workshop to ensure the vehicle is fully tested and in full

functional order before the vehicle is returned into service. Knorr-Bremse accepts no liability for problems caused as a result of appropriate tests not being carried out.

Copyright Knorr-Bremse AG - all rights reserved, including industrial property rights applications. Knorr-Bremse AG retains any power of disposal, such as for copying and transferring..

Knorr-Bremse Systeme fr Nutzfahrzeuge GmbH . Moosacher Strae 80 . 80809 Munich . Germany . Tel: +49 89 3547-0 . Fax: +49 89 3547-2767 . www.knorr-bremse.com . www.knorr-bremseCVS.com

Y011366: 004: EN: Released: Mon May 26 16:44:53 CEST 2014:

Knorr-Bremse Group

PD-214-100

Commercial Vehicle Systems

PD-214-100

Product Data

ES205.

Doc. No. Y011366 (EN - Rev. 004)

March 2014

TEBS 4 Brake Module

Rev. 003

February 2012

New format for Trailer Catalogue

Rev. 004

March 2014

Service Parts updated

The information contained herein is subject to alteration without notice and therefore may not be the latest release. Please check our website www.knorr-bremseCVS.com for the latest update or contact your local Knorr-Bremse representative.

The figurative mark K and the trademarks KNORR and KNORR-BREMSE are registered in the name of Knorr-Bremse AG. Additional terms and conditions apply; please refer to our website knorr-bremseCVS.com for full Disclaimer.

Note: If service work is carried out on a vehicle based on information provided herein, it is the responsibility of the workshop to ensure the vehicle is fully tested and in full

functional order before the vehicle is returned into service. Knorr-Bremse accepts no liability for problems caused as a result of appropriate tests not being carried out.

Copyright Knorr-Bremse AG - all rights reserved, including industrial property rights applications. Knorr-Bremse AG retains any power of disposal, such as for copying and transferring..

Knorr-Bremse Systeme fr Nutzfahrzeuge GmbH . Moosacher Strae 80 . 80809 Munich . Germany . Tel: +49 89 3547-0 . Fax: +49 89 3547-2767 . www.knorr-bremse.com . www.knorr-bremseCVS.com

Knorr-Bremse Group

Y011366: 004: EN: Released: Mon May 26 16:44:53 CEST 2014:

10

Item No. K002483

Revision Details

Você também pode gostar

- 815 - 430 WabcoDocumento46 páginas815 - 430 WabcoAlberto MiglinoAinda não há avaliações

- Central On-Board Computer 2 (ZBR2) A302Documento55 páginasCentral On-Board Computer 2 (ZBR2) A302esam Philipe100% (1)

- MID 144 Vehicle Electronic Control Unit (VECU), Signal DescriptionDocumento4 páginasMID 144 Vehicle Electronic Control Unit (VECU), Signal DescriptionИгорь БасмановAinda não há avaliações

- MAN Injectie Electronica EDC M S 6 4 PDFDocumento63 páginasMAN Injectie Electronica EDC M S 6 4 PDFarminAinda não há avaliações

- Fms Document V 04Documento60 páginasFms Document V 04Gustavo Luiz Da Silva100% (3)

- WEBASTO Thermo 300 Workshop Manual PDFDocumento66 páginasWEBASTO Thermo 300 Workshop Manual PDFPAVLOS100% (4)

- Wabco Atc CanDocumento36 páginasWabco Atc CanCostel Caraman100% (1)

- Webasto Heater ManualDocumento36 páginasWebasto Heater Manualpite3Ainda não há avaliações

- Vehicle Management Computer (A403)Documento10 páginasVehicle Management Computer (A403)ali100% (3)

- Emitec (Groundfos) System IntroductionDocumento30 páginasEmitec (Groundfos) System IntroductionЕвгений100% (2)

- 20 657GBDocumento194 páginas20 657GBWi Duddaa100% (1)

- Ecas - Optiride PDFDocumento71 páginasEcas - Optiride PDFDinu Gabriel100% (1)

- Aftersales Service Manual Voith Retarder VR 123Documento100 páginasAftersales Service Manual Voith Retarder VR 123WalterAinda não há avaliações

- 53 110 en EbsDocumento58 páginas53 110 en EbsОлег ДочилоAinda não há avaliações

- Eberspacher Heater D5WS Workshop ManualDocumento27 páginasEberspacher Heater D5WS Workshop ManualDaniel OstapovichAinda não há avaliações

- Technical Note - Diagnostics: I - Subject: Programming An Electronic Control UnitDocumento7 páginasTechnical Note - Diagnostics: I - Subject: Programming An Electronic Control Unitsdr savi100% (1)

- ABS 6 System PDFDocumento46 páginasABS 6 System PDFVincent PriceAinda não há avaliações

- Transport Air Conditioning: With BT324 Carrier Sutrak Digital Display (CSDD) or 280P/282P Electronic ThermostatDocumento63 páginasTransport Air Conditioning: With BT324 Carrier Sutrak Digital Display (CSDD) or 280P/282P Electronic Thermostatdario castro100% (1)

- System Start-Up and Diagnosis: 8.1 GeneralDocumento33 páginasSystem Start-Up and Diagnosis: 8.1 GeneralКонстантин ДубенкоAinda não há avaliações

- MAN TGA Wiring Diagrams (001 031) PDFDocumento31 páginasMAN TGA Wiring Diagrams (001 031) PDFAbdelhak Ezzahrioui80% (5)

- MID 216 PSID 11 Brake Light Right SideDocumento3 páginasMID 216 PSID 11 Brake Light Right SideTun Tun Win Kse100% (1)

- Electronically Controlled Air Suspension (ECAS) For Buses and Trucks With CAN II (SAE 1939) Maintenance 0Documento27 páginasElectronically Controlled Air Suspension (ECAS) For Buses and Trucks With CAN II (SAE 1939) Maintenance 0Miller Andres Aroca100% (1)

- Magnum Dxi13 Fuses Relays and ConnectionsDocumento173 páginasMagnum Dxi13 Fuses Relays and ConnectionsFranky FernandezAinda não há avaliações

- Connector C449 - Functions For Automatic Gearbox and Trailer Connection General InformationDocumento3 páginasConnector C449 - Functions For Automatic Gearbox and Trailer Connection General InformationmbpajaAinda não há avaliações

- KB Fault Codes and Trouble ShootingDocumento11 páginasKB Fault Codes and Trouble ShootingDeepak Kumar Raut100% (1)

- Eberspacher Heater D1LC & D3LC Wiring Dia PDFDocumento2 páginasEberspacher Heater D1LC & D3LC Wiring Dia PDFIvailo ZapryanovAinda não há avaliações

- Magnum Dxi13 Timing AssemblyDocumento48 páginasMagnum Dxi13 Timing AssemblyMirek100% (1)

- Bova Hgs RepairDocumento32 páginasBova Hgs RepairAnonymous lNIdocVsWAinda não há avaliações

- Mid 185 - Ppid 294 - Fmi 8Documento4 páginasMid 185 - Ppid 294 - Fmi 8AkbarAinda não há avaliações

- Wabco WurthDocumento10 páginasWabco Wurthameth vegaAinda não há avaliações

- A67 - 03 Edc MS 6 - 4Documento10 páginasA67 - 03 Edc MS 6 - 4marsh2002Ainda não há avaliações

- Bader-451 04511530english - v114 PDFDocumento37 páginasBader-451 04511530english - v114 PDFkumbrovAinda não há avaliações

- Hbab 81991851052 en PDFDocumento164 páginasHbab 81991851052 en PDFFloyd MliloAinda não há avaliações

- Mid 185 - Sid 254 - Fmi 9Documento3 páginasMid 185 - Sid 254 - Fmi 9AkbarAinda não há avaliações

- Zawieszenie Pneumatyczne T79 - 2 - ECAS - EFR - 81995985412 - ENGDocumento534 páginasZawieszenie Pneumatyczne T79 - 2 - ECAS - EFR - 81995985412 - ENGSlawerk100% (1)

- 1 PDFDocumento1 página1 PDFAbolfazl0% (1)

- Mid 185 - Ppid 305 - Fmi 0Documento3 páginasMid 185 - Ppid 305 - Fmi 0AkbarAinda não há avaliações

- MAN Presentation 20171027 PDFDocumento43 páginasMAN Presentation 20171027 PDFIceAinda não há avaliações

- FL PDFDocumento190 páginasFL PDFDan Birkenhead100% (1)

- Wabco Tebs eDocumento224 páginasWabco Tebs eJelena Tasik100% (4)

- MAN TGA FFR Component List PDFDocumento5 páginasMAN TGA FFR Component List PDFAlexander GryshcheniukAinda não há avaliações

- Webasto Thermo 230/300/350 Workshop ManualDocumento78 páginasWebasto Thermo 230/300/350 Workshop ManualDavid Butler100% (2)

- T66 2 Ecam 81995985292 EngDocumento104 páginasT66 2 Ecam 81995985292 EngGonçalo PereiraAinda não há avaliações

- 450 Dxi Wiring Numbers PDFDocumento32 páginas450 Dxi Wiring Numbers PDFvaleriy100% (4)

- 042 Man TruckDocumento4 páginas042 Man TruckFilippos100% (1)

- Fault Codes: Diesel (Engine Control - MS6.1 Bosch)Documento8 páginasFault Codes: Diesel (Engine Control - MS6.1 Bosch)Aleksandar Nikolovski50% (2)

- Leyland Daf 55 AIr SchematicDocumento6 páginasLeyland Daf 55 AIr SchematicEsirpus RekufAinda não há avaliações

- Iveco Fault CodesDocumento7 páginasIveco Fault CodesEsam Phlipe67% (3)

- Volvo b12b Electric Diagrams PDFDocumento78 páginasVolvo b12b Electric Diagrams PDFМихайло Пуравець50% (2)

- VECU Manual de Produccion 70312913 PDFDocumento33 páginasVECU Manual de Produccion 70312913 PDFAbdelhak EzzahriouiAinda não há avaliações

- Fault Codes: Diesel (Engine Control - DMCI Delphi - KOEO (Engine Off) )Documento3 páginasFault Codes: Diesel (Engine Control - DMCI Delphi - KOEO (Engine Off) )Aleksandar Nikolovski0% (1)

- Ix Astronic Lite BlockdiagramDocumento26 páginasIx Astronic Lite BlockdiagramBranko AndricAinda não há avaliações

- Mid128 Psid96 fm1Documento31 páginasMid128 Psid96 fm1Vali Shopart100% (2)

- Workshop Manual Thermo DW 300Documento98 páginasWorkshop Manual Thermo DW 300kumbrovAinda não há avaliações

- WABCO Cable Catalogue enDocumento118 páginasWABCO Cable Catalogue enSilvio BorgesAinda não há avaliações

- Volvo EDC OldDocumento12 páginasVolvo EDC OldMircea Gilca100% (2)

- Mid 185 - Ppid 294 - Fmi 9Documento3 páginasMid 185 - Ppid 294 - Fmi 9AkbarAinda não há avaliações

- MAN K100 Electrical System TGS-TGXDocumento236 páginasMAN K100 Electrical System TGS-TGXrijas rijas100% (2)

- Knorr Bremse TebsDocumento6 páginasKnorr Bremse Tebsenzo7259Ainda não há avaliações

- Installation Instructions 30-1810Documento11 páginasInstallation Instructions 30-1810Michael AliAinda não há avaliações

- Blinkcode Abs WabcoDocumento11 páginasBlinkcode Abs Wabcomucho76100% (1)

- 1 Hydronic D5S-SC Diagnostic Repair Manual 2013Documento25 páginas1 Hydronic D5S-SC Diagnostic Repair Manual 2013Brand CristianAinda não há avaliações

- Yanmar Excavator b12-3 - Europa Electrical Wiring Diagrams + Parts Catalog PDFDocumento127 páginasYanmar Excavator b12-3 - Europa Electrical Wiring Diagrams + Parts Catalog PDFandrzejAinda não há avaliações

- TTB Link300 Installationguide Europe PDFDocumento170 páginasTTB Link300 Installationguide Europe PDFandrzejAinda não há avaliações

- Coduri Eroare Ross TechDocumento254 páginasCoduri Eroare Ross TechCretu Gheorghita50% (4)

- Wabco Tebs eDocumento224 páginasWabco Tebs eJelena Tasik100% (4)

- VW MK5 Jetta Model Introduction SSP 891403Documento86 páginasVW MK5 Jetta Model Introduction SSP 891403Alex Stirbu100% (6)

- Service Manual SectionDocumento30 páginasService Manual SectionJKLUIS_593% (14)

- 366-4 An MidlumDocumento241 páginas366-4 An MidlumandrzejAinda não há avaliações

- Infineon BTS432E2 PDFDocumento14 páginasInfineon BTS432E2 PDFMarcio SantosAinda não há avaliações

- KiaDocumento2 páginasKiaandrzej0% (1)

- New ZW Family en PreviewDocumento28 páginasNew ZW Family en PreviewandrzejAinda não há avaliações

- En 220W PreviewDocumento4 páginasEn 220W PreviewandrzejAinda não há avaliações

- B5.5 Passat PromoPrintDocumento0 páginaB5.5 Passat PromoPrintTanee BoonmalertAinda não há avaliações

- 04IMPLDocumento28 páginas04IMPLCynthia Moraga Alzamora100% (40)

- KiaDocumento2 páginasKiaandrzej0% (1)

- GP15A Thru GP15M: Vishay General SemiconductorDocumento4 páginasGP15A Thru GP15M: Vishay General SemiconductorandrzejAinda não há avaliações

- Wiring Diagram FullDocumento66 páginasWiring Diagram FullAlexander Amaru RuisAinda não há avaliações

- ENG CD HD16-6-12S E1 PDF Hd16-6-12s-Env DRWDocumento1 páginaENG CD HD16-6-12S E1 PDF Hd16-6-12s-Env DRWandrzejAinda não há avaliações

- Lucas Td5 DiagnosticDocumento14 páginasLucas Td5 Diagnosticandrzej100% (1)

- NEW W Family en PreviewDocumento16 páginasNEW W Family en PreviewandrzejAinda não há avaliações

- Service Instructions 6Documento3 páginasService Instructions 6nicho.estilo96Ainda não há avaliações

- ATDocumento164 páginasATjacor96100% (1)

- Eng DS V23072-X0000-A001 0212 072Documento4 páginasEng DS V23072-X0000-A001 0212 072andrzejAinda não há avaliações

- 312d Excavator HydraulicDocumento15 páginas312d Excavator Hydraulichussein_eraki2010100% (2)

- Engine Service Tool Reference ListDocumento4 páginasEngine Service Tool Reference ListandrzejAinda não há avaliações

- KatalogDocumento46 páginasKatalogandrzejAinda não há avaliações

- EasyStart Spec Sheet WEB READY 092314Documento2 páginasEasyStart Spec Sheet WEB READY 092314andrzejAinda não há avaliações

- Seal Kit Assembly Instructions For Coolant Pumps: U4814, U4816, U4817 and U4851Documento2 páginasSeal Kit Assembly Instructions For Coolant Pumps: U4814, U4816, U4817 and U4851andrzejAinda não há avaliações

- 312d Excavator HydraulicDocumento15 páginas312d Excavator Hydraulichussein_eraki2010100% (2)

- Esquema Sistema Electrico 797BDocumento6 páginasEsquema Sistema Electrico 797BGonzalo Araya100% (1)

- Voith Service X-Change Manual 06-26-2020Documento17 páginasVoith Service X-Change Manual 06-26-2020Mohamed MohamedAinda não há avaliações

- Mitsubishi Lancer Evolution Viii MR Service Manual Electrical Wiring DiagramDocumento7 páginasMitsubishi Lancer Evolution Viii MR Service Manual Electrical Wiring Diagramsamantha100% (49)

- Errores JeepDocumento17 páginasErrores JeepsolokikeAinda não há avaliações

- Gu MT Moteur Adblue enDocumento27 páginasGu MT Moteur Adblue engreen_way26Ainda não há avaliações

- AccessTUNER HelpFile MAZDASPEEDDocumento66 páginasAccessTUNER HelpFile MAZDASPEEDloveofprofitAinda não há avaliações

- ECM Audi 80 86 h91Documento2 páginasECM Audi 80 86 h91Nazael DiazAinda não há avaliações

- VOLVO 2010 XC90 Wiring DiagramDocumento157 páginasVOLVO 2010 XC90 Wiring DiagramBrayandPach50% (2)

- Toyota Supra Jza80 Aristo jzs147 2jz Gte Non Vvti - 59cdab9f1723ddf9655ed85b PDFDocumento2 páginasToyota Supra Jza80 Aristo jzs147 2jz Gte Non Vvti - 59cdab9f1723ddf9655ed85b PDFGabriel BurnsAinda não há avaliações

- Cursor 13 Iveco CalibracionDocumento59 páginasCursor 13 Iveco CalibracionWaliixiitoo Landerxito Thv Xikito AL93% (28)

- Automotive AcronymsDocumento133 páginasAutomotive AcronymsadelinodiasAinda não há avaliações

- GV650GT650 R S-FIServiceManualDocumento90 páginasGV650GT650 R S-FIServiceManualJennifer KepaAinda não há avaliações

- Directechs DirectWire - 2023 Toyota Corolla Cross (Smart Key)Documento15 páginasDirectechs DirectWire - 2023 Toyota Corolla Cross (Smart Key)almacen AutoperiquitoAinda não há avaliações

- JCB Manual 1Documento49 páginasJCB Manual 1nandakumar100% (2)

- 6.4.3.5 Engine Control System Connector 6.4.3.5 Engine Control System Connector End Views End ViewsDocumento2 páginas6.4.3.5 Engine Control System Connector 6.4.3.5 Engine Control System Connector End Views End Viewsjulio vicencioAinda não há avaliações

- Automotive Services Solution enDocumento12 páginasAutomotive Services Solution ensaika_1982100% (1)

- Renault Ecu Decoder P125 PDFDocumento13 páginasRenault Ecu Decoder P125 PDFFlávio MarquêsAinda não há avaliações

- 1KR FE+Service+ManualDocumento2.784 páginas1KR FE+Service+ManualCajas Automaticas David100% (5)

- Ecu Comparison Pin Out FinalDocumento16 páginasEcu Comparison Pin Out FinaldavidAinda não há avaliações

- M1 Build: Get StartedDocumento1 páginaM1 Build: Get StartedMaria RajhaAinda não há avaliações

- 2nz Yaris WDocumento4 páginas2nz Yaris WHirwa Jules KlutchAinda não há avaliações

- Fuses: Semcon JLR Owner Guide Ver 1.00 LANGUAGE: english-NAS-en MARQUE: Landrover MODEL: L319Documento5 páginasFuses: Semcon JLR Owner Guide Ver 1.00 LANGUAGE: english-NAS-en MARQUE: Landrover MODEL: L319Cara JohnsonAinda não há avaliações

- Volkswagen LT Faultcodes 0829Documento1 páginaVolkswagen LT Faultcodes 0829Ana EugenAinda não há avaliações

- Structure and Operation: 3. Electronic Control Unit Connection DiagramDocumento86 páginasStructure and Operation: 3. Electronic Control Unit Connection DiagramAung Hlaing Min MyanmarAinda não há avaliações

- 1kz-Te Engine Sup. (Rm790e) PDFDocumento284 páginas1kz-Te Engine Sup. (Rm790e) PDFวัฒน์ ยอดแหลม100% (7)

- 1006601979-Operation and Maintenance Manual PowerKit 20M33 Series Diesel EngineDocumento161 páginas1006601979-Operation and Maintenance Manual PowerKit 20M33 Series Diesel EngineNguyễn Văn ToánAinda não há avaliações

- 2003 - 2003 Yzf-R1 Ecu WiringDocumento1 página2003 - 2003 Yzf-R1 Ecu Wiringlombardiacm75% (4)

- p0069 Autlander 2005Documento12 páginasp0069 Autlander 2005ricardo romeroAinda não há avaliações

- ComAp Protection Relay - Solar RelayDocumento20 páginasComAp Protection Relay - Solar RelayProtection RelaysAinda não há avaliações

- Introduction To Datalogging: SettingsDocumento8 páginasIntroduction To Datalogging: SettingsSimson AnsonAinda não há avaliações