Escolar Documentos

Profissional Documentos

Cultura Documentos

U-Bolts Supports PDF

Enviado por

Nguyen Thanh NguyenDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

U-Bolts Supports PDF

Enviado por

Nguyen Thanh NguyenDireitos autorais:

Formatos disponíveis

COMLIN ISOLATION PRODUCTS

Comlin is a family of elastomeric materials developed over a number of years

to meet the arduous and very specific requirements of the process pipework

engineer.

The primary functions of the product groups shown

in this section are:

The reduction or elimination of noise and

fatigue due to vibration of pipework against

the supporting structure.

The prevention of galvanic corrosion due to the

contact of dissimilar metals in the presence of

an electrolyte.

The prevention of wear and/or crushing of

composite, thin-wall or non-ferrous pipework.

The materials we offer have been selected to

provide optimum performance characteristics over

a wide range of applications; our HTFR grade is a

flame-retardant material suitable for continuous

operation at 350C. Our low-friction grades, whilst

providing very low resistance to sliding pipework,

still retain the inherent flexibility of the backing

material with no limitation as to how small the

pipe can be.

We offer two standard product forms: one for

applications using pipe clamps where the Comlin is

inserted between the clamp and pipe, this is known

as clamp strip. The second is for U-bolt

applications where the U-bolt is sheathed with

Comlin and provided with a seating strip for

protection to the underside of the pipe.

121

10

11

COMLIN MATERIAL CHOICE

COMLIN SG60

Our standard grade of material, a general purpose

grade suitable for most applications within the

temperature range of 40 to 100C. Based on

modified rubbers reinforced via accretion with

specially selected PVC resins, in many instances its

physical properties exceed those of established

thermoplastic elastomers. It has exceptionally good

tensile and tear strength combined with good

resistance to ozone, UV and oil.

COMLIN RG45

A specially formulated low modulus polymer alloy

suitable for applications that require a very soft,

flexible support whilst retaining all the advantages

of this type of material.

It has excellent low-temperature performance and

is capable of operating within the temperature

range 60 to 125C, with the added advantage of

being stable in an irradiated environment. It has

very good compression set characteristics and

withstands ozone/UV attack and weathering.

This material can be supplied in our own unique

low-friction form incorporating integral ribs of

polypropylene embedded into the contact face of

the product. This is achieved without loss of

properties or reduction of temperature range. This

grade is designated Comlin RG45LF.

COMLIN FR80

Our special fire-retardant grade of material has a

UL94 flame rating of V-0 and an oxygen index of

only 25%; it has good resistance to ozone/UV

attack and has very good flex fatigue. It also has

good fluid resistance and good performance in

polar chemicals.

Suitable for most applications within the

temperature range of 50 to 150C, the material

has excellent compression set properties,

weathering resistance and mechanical strength.

Again, this material can be supplied in our lowfriction form, and is designated Comlin FR80LF.

COMLIN HTFR65

This high temperature material is suitable for

applications within the temperature range of 60 to

350C. Based on silicone technology, it has excellent

resistance to fire, very low toxicity and can operate

continuously at 350C with minimum loss of

properties. This material has excellent resistance to

ozone, UV and weathering, very good compression

set and is generally resistant to oils.

Due to the high temperature range capability of

this material, it is not possible to provide it with

our low-friction facing.

122

COMPARISON OF COMLIN

MATERIALS WITH NEOPRENE

Our general purpose grade, Comlin SG60,

compares better than neoprene in all respects

other than temperature range: both are restricted

to an upper temperature limit of 100C. However,

with respect to ozone, UV resistance, weathering,

mechanical strength and long-term compression

set, Comlin SG60 is superior.

Comlin RG45 and Comlin FR80 grades compare

favourably with neoprene with respect to

resistance to ozone/UV attack and weathering, but

are far superior when considering compression set,

operational temperature range and mechanical

strength.

Comlin HTFR65 performs considerably better in all

respects than neoprene: resistance to ozone, UV,

weathering, temperature and fire are all superior.

U-BOLT MATERIAL

Standard material for U-Bolts is carbon steel,

electroplated with zinc. For material specifications,

see page 88. U-Bolts can also be supplied with

Xylan coating or manufactured from stainless steel.

COMLIN MATERIAL PROPERTIES

Property

Test

Method

Unit

SG60

RG45

Hardness, 5 Sec

D2240

Shore A

60

45

80

65

50

85

Specific Gravity

D297

1.17

0.97

1.24

1.31

1.05

1.31

Ultimate Tensile

Strength

D412

MPa

11.0

1.2

7.2

7.5

1.2

7.2

Ultimate Elongation

D412

350

300

410

350

300

410

100% Modulus

D412

MPa

5.8

1.2

3.2

4.0

1.2

3.2

Compression Set

@ 168 Hrs. 25 C

D395B

37.0

13.0

27.1

10.0

13.0

27.1

Compression Set

@ 168 Hrs. 100 C

D395B

45.0

22.0

46.3

15.0

22.0

46.3

Tension Set

D412

11.0

5.0

10.0

12.0

5.0

10.0

Brittle Point

D746

-45.0

-76.0

-56.0

-70.0

-76.0

-56.0

100

125

150

350

125

150

D2863

25.0

35.0

25.0

UL94 HB

V-0

V-0

V-0

V.Good

V.Good

V.Good

V.Good

V.Good

V.Good

2.2

2.3

2.44

2.8

2.3

2.44

Maximum Continuous

Temperature

Oxygen Index

Horizontal Burn

Ozone/UV Resistance

Dielectric Constant

Material Grade

FR80

HTFR65 RG45LF

FR80LF

Colour Code

Type 801

Black

Grey

Type 802

Red

Grey

Type 901

Black

Type 902

Red

Type 816

Red

Beige

Green

Grey

Type 817

Red

Beige

Green

Grey

Type 818

Green

Type 916

Beige

Green

Type 917

Beige

Green

Type 918

Green

10

*Available upon special request non-stocked products.

11

123

-60C TO +350C

A/2

801 COMLIN GRIP-TYPE U-BOLT

FOR STAINLESS STEEL & GALVANISED PIPES

A

C

DIMENSIONS (mm)

PART

NUMBER

DIMENSIONS (mm)

THD

Length

801-021

21

37

60

20

30

60

801-027

27

43

65

20

32

64

801-034

34

50

65

20

28

801-043

43

10

69

70

25

10

801-049

49

10

75

80

25

801-061

61

10

87

90

801-072

72

12

98

801-089

89

12

801-115

115

12

801-140

140

12

166

PART

NUMBER

THD

Length

801-168

168

16

210

180

35

15

49

128

801-219

219

16

261

200

35

15

44

123

60

801-245

245

16

287

210

35

15

41

120

19

69

801-273

273

16

315

225

35

15

42

121

10

26

76

801-324

324

16

366

250

35

15

41

120

25

10

30

80

801-356

356

16

398

265

35

15

40

119

95

25

10

25

83

801-407

407

16

449

300

35

15

50

129

115

100

25

10

22

80

141

110

25

10

19

77

135

25

10

31

89

ORDER BY: PART NUMBER AND COMLIN GRADE

MATERIAL: U-BOLT: CARBON STEEL

FINISH: ZINC PLATED.

NOTE: U-BOLTS CAN BE XYLAN COATED.

PLEASE REQUEST WHEN ORDERING.

802 COMLIN GRIP-TYPE U-BOLT

FOR COPPER & CUPRO-NICKEL PIPES

-60C TO +350C

DIMENSIONS (mm)

PART

NUMBER

DIMENSIONS (mm)

THD

Length

802-016

16

32

60

20

32

60

802-025

25

41

65

20

33

65

802-030

30

46

65

20

30

802-038

38

10

64

70

25

10

802-045

45

10

71

80

25

10

802-057

57

10

83

90

25

10

ORDER BY: PART NUMBER AND COMLIN GRADE

MATERIAL: U-BOLT: CARBON STEEL

124

PART

NUMBER

THD

Length

802-076

76

12

102

100

25

10

28

86

802-089

89

12

115

110

25

10

32

90

62

802-108

108

12

134

120

25

10

32

90

21

70

802-159

159

16

201

165

35

15

39

118

28

78

802-219

219

16

261

200

35

15

44

123

32

82

FINISH: ZINC PLATED.

NOTE: U-BOLTS CAN BY XYLAN COATED.

PLEASE REQUEST WHEN ORDERING.

Você também pode gostar

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Ainda não há avaliações

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsNo EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsNota: 5 de 5 estrelas5/5 (1)

- ComlinDocumento13 páginasComlinSammar AdhikariAinda não há avaliações

- AFICO Heavy Density Pipe Insulation - NewDocumento4 páginasAFICO Heavy Density Pipe Insulation - NewNickolas HeadAinda não há avaliações

- FloatingDocumento12 páginasFloatingrobson2015Ainda não há avaliações

- New Blygold PoluAl BrochureDocumento2 páginasNew Blygold PoluAl BrochuresabasabzAinda não há avaliações

- Up Graded Thermal Insulation DCLDocumento14 páginasUp Graded Thermal Insulation DCLSubrata NagAinda não há avaliações

- Sigma Coatings Is A Brand of The Sigmakalon GroupDocumento8 páginasSigma Coatings Is A Brand of The Sigmakalon Groupmedkom2000Ainda não há avaliações

- Afico Faceed InsulationDocumento4 páginasAfico Faceed Insulationhello1230Ainda não há avaliações

- MinWool 1200Documento2 páginasMinWool 1200avmurugan87Ainda não há avaliações

- Catalogue Băng Keo Alberta 80 FusionDocumento2 páginasCatalogue Băng Keo Alberta 80 FusionHà Trần MạnhAinda não há avaliações

- Advanced ContraFlame 02 09 2011 - 12pp PDFDocumento12 páginasAdvanced ContraFlame 02 09 2011 - 12pp PDFfredo405Ainda não há avaliações

- Superlon 16 Pages CatalogDocumento16 páginasSuperlon 16 Pages CatalogDevan SanmugamAinda não há avaliações

- Glasswool SPI: TechnicalDocumento2 páginasGlasswool SPI: Technicalavmurugan87Ainda não há avaliações

- EMS Long Fibre Reinforced PolyamidesDocumento44 páginasEMS Long Fibre Reinforced PolyamidesnimonhAinda não há avaliações

- Aluminium Foil Af546 SWDocumento2 páginasAluminium Foil Af546 SWfhsn84Ainda não há avaliações

- Perlite Sproule1200 Data SheetDocumento2 páginasPerlite Sproule1200 Data Sheetkresimir.mikoc9765Ainda não há avaliações

- Sialon ENDocumento2 páginasSialon ENsusu222000Ainda não há avaliações

- Am Jf211 - Jul 04Documento4 páginasAm Jf211 - Jul 04ilham_metallurgy6744Ainda não há avaliações

- KflexDocumento8 páginasKflexEddie BoyzAinda não há avaliações

- General CatalogDocumento18 páginasGeneral CatalogMiguel ParejaAinda não há avaliações

- GRP Web Technical ContentDocumento4 páginasGRP Web Technical ContentJai-Hong ChungAinda não há avaliações

- CA Bayonet PDFDocumento56 páginasCA Bayonet PDFwww.erwer9Ainda não há avaliações

- Bonding, Sealing, Potting / Encapsulation and Coating With RTV Silicone Rubber CompoundsDocumento38 páginasBonding, Sealing, Potting / Encapsulation and Coating With RTV Silicone Rubber CompoundsrezaAinda não há avaliações

- Cabling Products and Solutions: CATALOGUE 2010/2011Documento196 páginasCabling Products and Solutions: CATALOGUE 2010/2011Georgi PanayotovAinda não há avaliações

- Pipeclad Product Brochure Sherwin Williams EnglishDocumento12 páginasPipeclad Product Brochure Sherwin Williams EnglishCésarAinda não há avaliações

- Isolast: Perfluoroelastomer SealsDocumento12 páginasIsolast: Perfluoroelastomer SealsRPINILLA (EICO S.A.)Ainda não há avaliações

- FTI FibaRoll InstallationApplicationMethods Rev3 3de+2009Documento30 páginasFTI FibaRoll InstallationApplicationMethods Rev3 3de+2009okanbo1Ainda não há avaliações

- JZ Siliocne Composite Tape Bochure-EN 20230427Documento9 páginasJZ Siliocne Composite Tape Bochure-EN 20230427JZ HuangAinda não há avaliações

- Oil-Resistant Rubbers: Machine DesignDocumento5 páginasOil-Resistant Rubbers: Machine Designrajeevup2004Ainda não há avaliações

- Aislamiento Termico-Broch Cryogel ZDocumento2 páginasAislamiento Termico-Broch Cryogel ZJavier Caamaño VillafañeAinda não há avaliações

- NBR Vs EPDM 0616Documento4 páginasNBR Vs EPDM 0616ammarashraf91Ainda não há avaliações

- Flexfab Distributor CatalogDocumento51 páginasFlexfab Distributor CatalogVRR COMERCIO DE PECAS LTDAAinda não há avaliações

- Catalogue Băng Keo Alberta 80 SamalDocumento2 páginasCatalogue Băng Keo Alberta 80 SamalHà Trần MạnhAinda não há avaliações

- Company-Profile 2Documento27 páginasCompany-Profile 2Solar OngridAinda não há avaliações

- JZ-20220423 Siliocne Composite Tape Bochure-ENDocumento12 páginasJZ-20220423 Siliocne Composite Tape Bochure-ENLongsun KejiAinda não há avaliações

- Calcium Silicate Data SheetDocumento2 páginasCalcium Silicate Data Sheetkresimir.mikoc9765Ainda não há avaliações

- Leaflet Cabinet & Casing ProtectionDocumento4 páginasLeaflet Cabinet & Casing ProtectionMuhammad Javed BhattiAinda não há avaliações

- Recotec Rotafil enDocumento16 páginasRecotec Rotafil enJordan RileyAinda não há avaliações

- CHDX04 Module 1 MaterialsDocumento18 páginasCHDX04 Module 1 Materialsargiun20Ainda não há avaliações

- Architectural Catalogue RenukootDocumento103 páginasArchitectural Catalogue Renukootprchoudharykp100% (2)

- ColorcoatŽ PE 25 DatasheetDocumento2 páginasColorcoatŽ PE 25 Datasheetprimoz1Ainda não há avaliações

- Leaflet Heat Exchanger ProtectionDocumento4 páginasLeaflet Heat Exchanger Protectionmrashid286Ainda não há avaliações

- Morgan Thermal Ceramics Product Data - Book - 2016Documento179 páginasMorgan Thermal Ceramics Product Data - Book - 2016Alex MontielAinda não há avaliações

- Popular Insulation TypesDocumento2 páginasPopular Insulation TypesArshad AminAinda não há avaliações

- Kaiflex-ST Catalogue 09.15Documento8 páginasKaiflex-ST Catalogue 09.15vhin84Ainda não há avaliações

- Aspen Aerogels Industrial InsulationDocumento4 páginasAspen Aerogels Industrial InsulationGino De LandtsheerAinda não há avaliações

- Bushing Instllation Manual-ABB Type AIRRIP-RTKFDocumento13 páginasBushing Instllation Manual-ABB Type AIRRIP-RTKFariel celaAinda não há avaliações

- OKULENDocumento8 páginasOKULENDe SaripudinAinda não há avaliações

- Composite Insulators Ed1Documento8 páginasComposite Insulators Ed1Eduardo_Godoy_6160Ainda não há avaliações

- Acabados SigmaDurDocumento8 páginasAcabados SigmaDurRPAinda não há avaliações

- 2750 515-131 en Rev 1Documento12 páginas2750 515-131 en Rev 1Abohicham AbhAinda não há avaliações

- EG Tech Bulletin ASTM C1695Documento3 páginasEG Tech Bulletin ASTM C1695AuburnMfgAinda não há avaliações

- Sproule WR 1200 Perlite TDSDocumento2 páginasSproule WR 1200 Perlite TDSnaseema1Ainda não há avaliações

- Marine Joinery Outfitting PDFDocumento43 páginasMarine Joinery Outfitting PDFÇÇağdaş_1Ainda não há avaliações

- Aluminium (Al) - Forms Casting BasedDocumento13 páginasAluminium (Al) - Forms Casting BasedSansar PanchalAinda não há avaliações

- Klueberbio ALO 32-4000 009019 PI GB enDocumento2 páginasKlueberbio ALO 32-4000 009019 PI GB enMuhammad SaputraAinda não há avaliações

- IBP1304 - 19 Are The Key To Reducing Corrosion Under Insulation (Cui)Documento7 páginasIBP1304 - 19 Are The Key To Reducing Corrosion Under Insulation (Cui)barraocos emailsAinda não há avaliações

- Usi SectionaleDocumento18 páginasUsi SectionaleFlorian MihaleAinda não há avaliações

- Polyethylene: Section GuideDocumento31 páginasPolyethylene: Section GuidemjinspectorAinda não há avaliações

- Uputstvo Za Advance Steel 2019Documento55 páginasUputstvo Za Advance Steel 2019Zoran SimićAinda não há avaliações

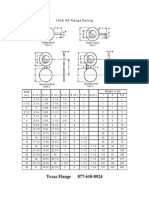

- Welding Neck Orifice Class 900: In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. MMDocumento1 páginaWelding Neck Orifice Class 900: In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. MMNguyen Thanh NguyenAinda não há avaliações

- Jpep 0 1360 T 4141 PDFDocumento44 páginasJpep 0 1360 T 4141 PDFNguyen Thanh NguyenAinda não há avaliações

- Flanges Pn40 Din En1092 1Documento2 páginasFlanges Pn40 Din En1092 1Nguyen Thanh NguyenAinda não há avaliações

- Welding Neck Orifice Class 1500Documento1 páginaWelding Neck Orifice Class 1500Nguyen Thanh NguyenAinda não há avaliações

- Welding Neck Orifice Class 2500Documento1 páginaWelding Neck Orifice Class 2500Nguyen Thanh NguyenAinda não há avaliações

- Welding Neck Orifice Class 2500Documento1 páginaWelding Neck Orifice Class 2500Nguyen Thanh NguyenAinda não há avaliações

- Welding Neck Orifice Class 600Documento1 páginaWelding Neck Orifice Class 600Nguyen Thanh NguyenAinda não há avaliações

- Slip-On Orifice Class 300: In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. MMDocumento2 páginasSlip-On Orifice Class 300: In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. MMNguyen Thanh NguyenAinda não há avaliações

- Threaded Orifice Class 300Documento1 páginaThreaded Orifice Class 300Nguyen Thanh NguyenAinda não há avaliações

- Welding Neck Orifice Class 300Documento1 páginaWelding Neck Orifice Class 300Nguyen Thanh NguyenAinda não há avaliações

- Welding Neck Orifice Class 400: In. Mm. In. MMDocumento1 páginaWelding Neck Orifice Class 400: In. Mm. In. MMNguyen Thanh NguyenAinda não há avaliações

- 600 Spect Blind PDFDocumento1 página600 Spect Blind PDFNguyen Thanh NguyenAinda não há avaliações

- 900 Spect BlindDocumento1 página900 Spect BlindNguyen Thanh NguyenAinda não há avaliações

- Stud Out 1500Documento1 páginaStud Out 1500Nguyen Thanh NguyenAinda não há avaliações

- Class 600 Studding Outlet: Flat Bottom Shell/Head Mount Tangential MountDocumento1 páginaClass 600 Studding Outlet: Flat Bottom Shell/Head Mount Tangential MountNguyen Thanh NguyenAinda não há avaliações

- Class 2500 Studding Outlet: TEXAS FLANGE 877-610-8924Documento1 páginaClass 2500 Studding Outlet: TEXAS FLANGE 877-610-8924Nguyen Thanh NguyenAinda não há avaliações

- 300 Spec BlindDocumento1 página300 Spec BlindNguyen Thanh NguyenAinda não há avaliações

- 150 Spect BlindDocumento1 página150 Spect BlindNguyen Thanh NguyenAinda não há avaliações

- Class 900 Studding Outlet: Flat Bottom Shell/Head Mount Tangential MountDocumento1 páginaClass 900 Studding Outlet: Flat Bottom Shell/Head Mount Tangential MountNguyen Thanh NguyenAinda não há avaliações

- Texas Flange 877-610-8924: Weld Neck Flange BoresDocumento1 páginaTexas Flange 877-610-8924: Weld Neck Flange BoresNguyen Thanh NguyenAinda não há avaliações

- Class 300 Studding Outlet: Flat Bottom Shell/Head Mount Tangential MountDocumento1 páginaClass 300 Studding Outlet: Flat Bottom Shell/Head Mount Tangential MountNguyen Thanh NguyenAinda não há avaliações

- Class 150 - Standard Connection SpecificationsDocumento7 páginasClass 150 - Standard Connection SpecificationsNguyen Thanh NguyenAinda não há avaliações

- Electrical TutorialDocumento15 páginasElectrical TutorialNguyen Thanh NguyenAinda não há avaliações

- Texas Flange: Dimensions of Ring-Joint FacingsDocumento6 páginasTexas Flange: Dimensions of Ring-Joint Facingsmanu_giteAinda não há avaliações

- Conectores GraylocDocumento0 páginaConectores Graylocpablotorresbozzo2686Ainda não há avaliações

- Hvac TutorialDocumento43 páginasHvac TutorialNguyen Thanh NguyenAinda não há avaliações

- Cadpipe BS TutorialDocumento44 páginasCadpipe BS Tutorialrayzone1Ainda não há avaliações

- Design of Portal Frames - NotesDocumento32 páginasDesign of Portal Frames - NotesAdi Andriescu0% (1)

- Blood TestDocumento6 páginasBlood TestMaharani Indri100% (1)

- E5 Lab Sheet Measurement of Jet ForcesDocumento9 páginasE5 Lab Sheet Measurement of Jet ForcesHoongAinda não há avaliações

- Lecture 22-23-24 ChlorAlkali IndustryDocumento83 páginasLecture 22-23-24 ChlorAlkali IndustryAnilKumar33% (3)

- I - Grades & Materilas InfoDocumento32 páginasI - Grades & Materilas InfoEswara ReddyAinda não há avaliações

- Lattice Enthalpy, Ionisation Energy, Born-Haber Cycles, Hydration EnthalpyDocumento8 páginasLattice Enthalpy, Ionisation Energy, Born-Haber Cycles, Hydration Enthalpyzubair0% (1)

- Wave Induced AccelerationDocumento6 páginasWave Induced AccelerationAnonymous g5FCwMRAinda não há avaliações

- Most Important) Unit ConversionsDocumento3 páginasMost Important) Unit ConversionsNur ShafineeAinda não há avaliações

- Section 9 Introduction To Welding ProcessesDocumento16 páginasSection 9 Introduction To Welding ProcessesS GoudaAinda não há avaliações

- TilesDocumento84 páginasTilesgagan raoAinda não há avaliações

- DLL SCIENCE 9 Dec 9-13Documento49 páginasDLL SCIENCE 9 Dec 9-13Raiza Lainah MianoAinda não há avaliações

- Properties EpoxyCOMPOSITEDocumento9 páginasProperties EpoxyCOMPOSITESanket AntreAinda não há avaliações

- Phenolics TableDocumento2 páginasPhenolics TableKULDEEP THAKUR100% (1)

- Stress Strain Curve ExplanationDocumento8 páginasStress Strain Curve ExplanationGptc Chekkanurani0% (1)

- Soal Try Out 6 (Bhs. Inggris) UTBKDocumento6 páginasSoal Try Out 6 (Bhs. Inggris) UTBKWahyu Tejo MulyoAinda não há avaliações

- 13.9 Numerical Procedures For Binary, Ternary LLE: Excel ProcedureDocumento2 páginas13.9 Numerical Procedures For Binary, Ternary LLE: Excel ProcedureAlyssaRamosAinda não há avaliações

- DNV Structure Steel Fabrication PDFDocumento0 páginaDNV Structure Steel Fabrication PDFmastorfaizalAinda não há avaliações

- TeslaDocumento13 páginasTeslaAmal ShajiAinda não há avaliações

- Cutting FluidDocumento8 páginasCutting FluidDevarakonda KondayyaAinda não há avaliações

- Ampho 149Documento18 páginasAmpho 149Luis Andre SilvaAinda não há avaliações

- Assigment of NDTDocumento3 páginasAssigment of NDTHamid AliAinda não há avaliações

- Sierra Megonnell and Kyle Lovisone ExpDocumento1 páginaSierra Megonnell and Kyle Lovisone Expapi-528179516Ainda não há avaliações

- Chemistry Period 8 Ben & Calum Honors Chem Hydrate LabDocumento4 páginasChemistry Period 8 Ben & Calum Honors Chem Hydrate Labapi-239596021Ainda não há avaliações

- 1 Lab Handout PDFDocumento5 páginas1 Lab Handout PDFKhud SarAinda não há avaliações

- Asme SB466Documento9 páginasAsme SB466Stéphane LevasseurAinda não há avaliações

- Cleaning and Care Instructions Marbond and SentecDocumento12 páginasCleaning and Care Instructions Marbond and Sentecon onAinda não há avaliações

- Variation QuestionDocumento5 páginasVariation Questionanshul4clAinda não há avaliações

- Respirable Dust Sampler Envirotech Apm460BlDocumento19 páginasRespirable Dust Sampler Envirotech Apm460BlECRDAinda não há avaliações

- Same 023Documento2 páginasSame 023amardeepbediAinda não há avaliações

- Lec8 RTMDocumento31 páginasLec8 RTMmoonrock1Ainda não há avaliações