Escolar Documentos

Profissional Documentos

Cultura Documentos

J. H. Wilson: Inventor.

Enviado por

lfilippiniTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

J. H. Wilson: Inventor.

Enviado por

lfilippiniDireitos autorais:

Formatos disponíveis

Aug.

14, 1951

2,564,457

J. H. WILSON

Filed June 25, 1948

3 Sheets-Sheet 1

INVENTOR.

John Hart Wits on

BY

'

His gent.

Aug. 14, 1951

J. H. WILSON

2,564,457

SAFETY DEVICE FOR DRILLING RIGS

'

Filed June 25, 1948

Sheets-Sheet 2

20

k

'

41

IN VEN TOR.

J01m Hart l/l/ilson

BY

'

WWW

J6

Aug. 14, 1951

J. H. WILSON

2,564,457

SAFETY DEVICE FOR DRILLING RIGS

Filed June 25, 1948

'

S-Sheets-Sheet 5

IN VEN TOR.

JabnHartWil son

BY

.HGENT.

Patented Aug. 14, 1951

2,564,457

U N I T ED S TATES PAT

OFF I C E

2,564,457

SAFETY DEVICE FOR DRILLING ZRIGS

John Hart Wilson, Wichita Falls, rrex.

Application June 25, 1948, Serial No. 35,239

2 Claims.

'1

This invention relates to improvements in

safety devices for draw works and. particularly

to draw works adapted for use on well drilling

rigs of the rotary type.

Well drilling apparatus of the rotary type or

dinarily includes a rotary table for rotating the

drill-stem in the well. The drill stem is suspended

by a traveling block supported by a numbercof

leads of a cable which cable passes over the crown

(Cl. 254-145)

2

Another object of the invention is to improve

the-control on the traveling block

by the automatic actuation of

clutch thereof, which parts are

resilient safety device mounted

and draw works

the brake and

responsive to a

on the derrick

to cause'the traveling block to stop withina pre

determined distance of travel.

These objects maybe accomplished, accord

ing to the embodiment of the invention as illus

block at the top of the derrick, with one line 10 trated in the accompanying drawings, by the

passingdownward to the drum vof ithedraw works.

provision of a cable passing transversely across

Due to the height of the derrick on which the

the derrick above the traveling block and be

traveling block is used for withdrawing the drill

tween the block lines that support the traveling

stem and pipe from a well, it is necessary to raise

block so that the transverse line will be engaged

the traveling block at high speed, so as to make

by the traveling block as it moves upward in the

rapid progress in the drilling operation. How

derrick above a predetermined point. The en

ever, several dangers are ever present while the

gagement of the transverse cable by the travel

traveling block is being raised at high speed,

ing block will actuate the control mechanism of

either with or without pipe being connected

the .brake and .clutchof the draw works to-oause

thereto. Workmen necessarily have 'to be in the 20 the latter to respond thereto.

derrick while the traveling block is being raised,

The transverse cable that passes above the

and if during this process, the traveling block

traveling block .is connected with pneumatic con

hits the sheaves of the crown "block, this fre

trols that actuate the brake and disengage the

quently results in the breaking .of the cable or in

clutch, upon vthe engagement of the transverse

pulling the derrick in, with possible injury or line by the traveling block. Thus the draw

loss of life to the workmen as result thereof, as

works will be brought to a stop within the prede

well as much damage to the derrick and to the

termined limits of travel of the traveling block

drilling rig, and if pipe is dropped into the well,

so as to cause no undue shock on the .rig.

Any

the .loss of the well may .result.

desired range of stopmay be provided for, from

The stopping of the traveling vblock short of I" instantaneous to the maximum travel accorded

the crown block, has, heretofore, been therespon

by the weight attached to the transverse cable.

sibility of the operator or driller of .the rotary

This embodiment of theinvention is illustrated

rig. Sometimes the distance the traveling block

in the accompanying drawings, in which:

travels before contacting the crown block is very

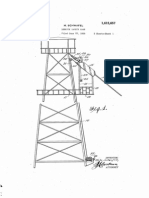

Fig. 1 is a perspective view of a derrick, show

short and necessitates the use of very vcareful 35 'ing the invention applied thereto;

judgment of distance with the traveling block

Fig. '2 is a side elevational view of a traveling

passing up at very high speed, and the driller

block and the lines associated therewith, with

could not .always exercise sufficiently precise

the safety cable shown in section;

judgment.

Fig. 3 is affragmentary View of a portion of a

Such safety devices as have been proposed

derrick, partly in section, showing the weight

heretofore have not been adequate due to the

high speed at which the traveling block travels

upward, and due to the lack of ?exibility and

yieldability which is necessary for the successful

operation of a device for stopping the travel of

a traveling block within a given distance.

The primary object of this invention is .to im

prove the construction of the drilling apparatus

by providing a safety device with a yieldable line

and weight guide member attached thereto;

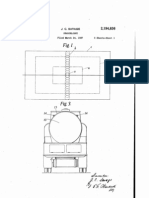

Fig. 4 is a diagrammatic side elevation show

ing the controls actuated by the safety cable;

Fig. 5 is a side elevation of a master clutch.

The invention is shown as applied to a rotary

drilling rig which comprises a derrick I and a

conventional draw works generally designated at

D. The derrick I has mounted at the top there

of, in the usual manner, a conventional crown

block 2 for supporting line 3 which extends

the traveling block and which will yield readily

downward from the crown block 2 in multiple

to action thereon by the traveling block and

loops, in which the traveling block 4 is suspended

line without causing damage to the rig or other

for supporting the drill stem or pipe during the

equipment, if the stopping of the draw works is

raising and lowering operation thereof while

55 drilling a well. Thedrill stem is rotated by the

not instantaneous.

which will move in response to the movement of '

2,564,457

3

conventional rotary table (not shown), which

rotary table is usually driven by the draw works

D mounted on the floor at the base of the der

rick I. The draw works D includes a drum 6

upon which a cable is wound to raise and lower

the traveling block 4, as shown in Figs. 1 and 4.

The line 3 is attached to the drum 6 which is

generally known as the fast line, and which is

adapted to raise and lower the traveling block

in response to the rotation of the drum 6.

Extending transversely through the derrick I

is a safety cable or flexible device 8 passing over

pulleys 9 on opposite sides of the derrick and sup

porting a weight II] on one end thereof. The

weight In is guided on a rod IOa spaced from but

secured to frame lob, which frame is clamped

to the derrick by means of clamps Illc. By hav

ing the weight It] so positioned and guided by

the rod IIla, the transverse cable 8 is relieved of

the weight I0 until such time as the safety de 20

ments are adapted to be controlled by the en

gagement of the safety line 8.

The brake 25 is illustrated as controlled by a

Segment 21 of a gear which is connected with a

pneumatic power device 28, by a chain 21a. Air

is supplied to the pneumatic power device 28

through a line 29 extending to a valve 30, thence

through a line 3i which has a valve 32 therein.

The opposite side of the valve 32 is connected

through a line 33 with a main air source of sup

ply under pressure, as indicated at 34. The valve

32 is adapted to be manually controlled by the

control device generally indicated at 35.

Also connected with the source of air supply

34, is a branch line 36 which contains a control

valve 3'! therein and which branch line 36 leads

to the line 29 and may connect therethrough to

the pneumatic power device 28. The valve 31 is

adapted to be closed alternately with the valve

30, for which purpose the lever 23 engages the

valve stem of the valve 31 at one side of its

pivotal axis, while it engages the valve stem of

the valve so at the opposite side of the axis

vice is brought into action. The frame IIlb re

strains the weight I!) against falling, in event the

cable 8 becomes broken. This safety cable 8 ex

thereof, so that the lever 23 will cause an open

tends through the loops in the line 3 and is dis

posed directly over a V-yoke II secured to the 25 ing of one valve simultaneously with the closing

of the other.

top of the traveling block 4, as shown in Fig. 2.

Also mounted on the shaft 24 is a control arm

Thus the line 8 is in a position to be engaged by

38 connected with a control valve 39 which has

the yoke I I, as the traveling block moves upward

an air line 48 connected with one side thereof

in the derrick I and to be moved thereby from

and leading from the main source of air supply,

the full-line position in Fig. 1 to the dotted-line

as indicated at 35. The valve 39 is connected

position therein, the yoke I! insuring engage

also

through lines AI with the air cylinder that

ment of the safety line B by the traveling block

regulates the master clutch, which is indicated

and causing it to move in response thereto. Nor

mally the movement of the cable 8 would be , at 26 in Fig. 5. The valve 39 is adapted to sup

ply air to the master cylinder 26 for regulating

much less than that shown in the drawings,

the position of the master clutch.

which is somewhat exaggerated for the purpose

In the operation of the control system, it will

of illustration.

be

evident that the upward movement of the trav

The cable 8 may be formed of any suitable ma

eling block 4 and loops 3, which support the

terial, although a wire line is the most satisfac

traveling block, will cause the yoke II to engage

tory for the purpose. However, it may be of

the

safety cable 8 and move it upward from

non-metallic material, if desired, and will func

its normally stretched position in bridging rela

tion satisfactorily to control the operation of

tion between the pulleys 9, and tend to de?ect

the draw works as hereinafter described.

this safety cable 8 out of its normal position.

The line 8 extends along the derrick substan

The safety cable 8 has a weight Iii positioned on

tially to the bottom thereof, where its lower end

the opposite end to that connected to the draw

is attached to an arm I2 mounted on a lever I3

and cooperating with the latter to form substan

tially a bell crank.

The lower end of the lever

works control lever I2.

This weight is adapted

to be lifted when the traveling block 4 engages

transverse safety cable 8, which permits the trav

I3 engages a notch I4 formed in one side of a 50

eling block to move upward several feet, while

lug I5 secured to an operating lever I5.

A connecting rod I1 extends downwardly from

the lever I6 in the form illustrated in Fig. 4, and

allowing the brakes to be applied gradually so

as to prevent undue shock, which would be the

result if the traveling block were stopped instan

is connected at its lower end to an arm of the

taneously upon contacting the cable 8. This pull

bell crank lever generally indicated at I8, which , ing action applied to the cable 8 will lift the

bell crank lever is pivotally mounted at I9. The

outer end of the arm I2, shown in Fig. 4, and

other arm of the bell crank lever I8 has a spring

cause an upward swinging movement of the lever

2!! connected to its extreme lower end, and nor

I3, which forms a safety catch, disengaging the

mally tending to swing the bell crank lever I8

latter from the notch I4. When thus released,

in a clockwise direction, as viewed in Fig. 4. The

the lever I6 may move upward in response to

opposite end of the spring 20 is anchored to a

the tension of the spring 20 acting on the depend

part of the frame 2| of the draw works.

ing arm I8 that is connected therewith through

Also connected with the depending arm of the

the bell crank I8 and the connecting rod I'I.

bell crank lever I8 is a connecting rod 22 which

extends therefrom to one end of a lever 23 piv 65 Normally, these parts are held in the positions

shown in Fig. 4 when the latch I3 engages the

otally mounted on a shaft 24, this lever being

lug I5 on the lever I6.

?xed to the shaft and movable about the axis

This releasing movement of the lever I6, as de

thereof.

scribed, will move the connecting rod 22 toward

The draw works, generally designated in the

the left in Fig. 4, which, thereby, will swing the

drawing as D, include a pneumatic power brake,

lever 23 in a clockwise direction. The effect of

generally indicated at 25, which brake is applied

this will be to close the control valve 30 and to

to retard the movement of or to stop the drum.

open the valve 3?. This will admit air from the

The entire draw works is controlled by a master

supply line 34 through the branch line 36 to the

clutch which is regulated by the pneumatic con

; trol device generally designated at 26. These ele

5 power device 28 in a direction tending to actuate

2,564,457

the latter to apply the brake 25, thus causing

the stopping action of the drum 6.

Simultaneously with the application of the

brake to the drum 6, the rotation of the shaft

24 will swing the arm 38 to move the valve

39 for opening the latter to permit the air to

the power device 26 in a direction to release the

clutch of the draw works, thereby stopping the

application of power thereto and allowing full

effect of the brake 25 to be applied to stop the 10

motion of the draw works and of the drum.

These parts will respond readily and quickly

to the movement of the safety cable 8, because

.6

whereby the movement of said traveling block

may be arrested within the length of the yield

ability of said transverse cable.

2. In a well drilling apparatus a derrick hav

ing girts, a traveling block, a draw works hav

ing a hoist for raising and lowering the traveling

block, which hoist includes winding means, power

means, a clutch for connecting and disconnecting

said power means and said winding means, a

brake for said winding means, ?uid pressure

means for operating said clutch and said brake,

valves controlling the application of said ?uid

pressure means to said clutch and brake, and a

of the use of air power devices that are controlled

pivotally mounted lever operatively connected

thereby. Thus instant response to the actuation 15 with said valves to apply the brake and release

of the safety device is to be had in controlling

the clutch when moved in a given direction,

the action of the draw works. Therefore, it will

sheaves at the upper end of said derrick, said

be controlled e?ectively without danger of in

traveling block being suspended within said der

jury or damage to the equipment or to the work

rick, a line suitably connecting said winding

men.

means, said sheaves, and said block for raising

While the invention has been illustrated and

and lowering the block, a transverse cable posi

described in one embodiment, it is recognized that

tioned across said derrick and spaced downward

variations and changes may be made therein

ly from the top thereof and in the path of move

without departing from the invention except as

ment of said block, a guide member positioned on

speci?ed in the claims.

25 the upper end of said traveling block to guide

I claim:

I

said transverse cable thereinto upon upward

1. In a well drilling apparatus, a derrick, a

movement of said traveling block beyond a pre

draw works having a hoist for raising and low

determined safety point, one end of said cable

ering a traveling block, a clutch and a brake for

being attached to a movable weight positioned

controlling the operation of said hoist, a valve

on a frame that may be selectively secured to a

for controlling said clutch and brake, and a lever

pair of derrick girts within the length of said

pivotally secured near the lower end of the der

derrick, means for removably securing said

rick for actuating said valve, sheaves at the up

weight-carrying frame to said girts, the other end

per end of said derrick, a traveling block sus

of said transverse cable extending down a side

pended within said derrick, a line suitably con

of said derrick, and means for operatively con

necting said hoist, said sheaves, and said block

necting said other end of the cable with said

for raising and lowering the block, a transverse

lever to swing the latter in said given direction

cable positioned across said derrick at a point

so as to arrest the movement of said traveling

spaced downwardly from the top thereof and in

block within the length of the yieldability of

the path of movement of said block, a guide

said transverse cable.

40

member positioned on the upper end of said trav

JOHN HART WILSON.

cling block to guide the transverse cable there

into upon upward movement of said traveling

REFERENCES CITED

block beyond a predetermined safety point, one

The following references are of record in the

end of said cable being attached to a vertically

?le of this patent:

movable weight, a frame receiving said weight

UNITED STATES PATENTS

and. con?ning it to its vertical path of move

ment, means for removably and selectively secur

Number

Name

Date

ing said weight-carrying frame to said derrick,

985,698

Pearson _________ __ Feb. 28, 1911

the other end of said cable extending down a

1,425,569

Arnold __________ __ Aug. 15, 1922

side of the derrick, and means operatively con

2,241,274

Severson _________ .__ May 6, 1941

necting said other end of the cable with said lever,

2,428,578

Nelles ____________ __ Oct. 7, 1947

Você também pode gostar

- Scientific American Supplement, No. 312, December 24, 1881No EverandScientific American Supplement, No. 312, December 24, 1881Ainda não há avaliações

- Filed April 2, 1946Documento4 páginasFiled April 2, 1946lfilippiniAinda não há avaliações

- Tow Target Release Mechanism (1927)Documento5 páginasTow Target Release Mechanism (1927)CAP History LibraryAinda não há avaliações

- Tow Target Cable Drag Mechanism (1941)Documento4 páginasTow Target Cable Drag Mechanism (1941)CAP History LibraryAinda não há avaliações

- Conveyer Screw Stops Bottles for LabelingDocumento3 páginasConveyer Screw Stops Bottles for LabelingChristian MavarezAinda não há avaliações

- Rig-E???': Gill!Documento6 páginasRig-E???': Gill!luiscremaschiAinda não há avaliações

- M. Schwafel: Derrick Safety CageDocumento4 páginasM. Schwafel: Derrick Safety CageRodrigoPomaAinda não há avaliações

- Apron MechanismDocumento7 páginasApron Mechanismgopalpaul0% (2)

- Aerial Tow Target (1943)Documento4 páginasAerial Tow Target (1943)CAP History LibraryAinda não há avaliações

- United States Patent: Dreve, Jr. (45) May 16, 1972Documento6 páginasUnited States Patent: Dreve, Jr. (45) May 16, 1972RodrigoPomaAinda não há avaliações

- Target Kite (1944)Documento7 páginasTarget Kite (1944)CAP History LibraryAinda não há avaliações

- Nov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedDocumento7 páginasNov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedRodrigoPomaAinda não há avaliações

- Side Boom Pipe LayerDocumento4 páginasSide Boom Pipe LayerAndré Meirelles100% (1)

- May 12, 1942-, 'J. D Spaldlng 2,282,615: Brake For DrawworksDocumento10 páginasMay 12, 1942-, 'J. D Spaldlng 2,282,615: Brake For DrawworkslfilippiniAinda não há avaliações

- Cloth Tow Target Low Drag Sleeve (1944)Documento4 páginasCloth Tow Target Low Drag Sleeve (1944)CAP History LibraryAinda não há avaliações

- Az 3420192022Documento4 páginasAz 3420192022IJMERAinda não há avaliações

- United States Patent (19) (11) 4,298,078Documento9 páginasUnited States Patent (19) (11) 4,298,078lfilippiniAinda não há avaliações

- Us 3460614Documento7 páginasUs 3460614scibduser001Ainda não há avaliações

- Us1446763 PDFDocumento7 páginasUs1446763 PDFJin SongAinda não há avaliações

- United States Patent: (10) Patent N0.: Hoifman Et Al. (45) Date 0f PatentDocumento10 páginasUnited States Patent: (10) Patent N0.: Hoifman Et Al. (45) Date 0f Patentmohammadreza91Ainda não há avaliações

- Viii/Ii/Ii": United States Patent (191 (11) Patent Number: 4,708,208Documento9 páginasViii/Ii/Ii": United States Patent (191 (11) Patent Number: 4,708,208mohammadreza91Ainda não há avaliações

- United States "Patents PDFDocumento17 páginasUnited States "Patents PDFTien Nguyen VanAinda não há avaliações

- References Cited Robiatiorlial Movergents. Pat Least One ElaitigallybexaatrlidDocumento7 páginasReferences Cited Robiatiorlial Movergents. Pat Least One Elaitigallybexaatrlidmohammadreza91Ainda não há avaliações

- US2128620 - Bending MachineDocumento5 páginasUS2128620 - Bending MachinedevheadbotAinda não há avaliações

- Opgw StringingDocumento3 páginasOpgw StringingNiraj SinhaAinda não há avaliações

- United States Patent (19) (111 4,230,151: Jonsson (45) Oct. 28, 1980Documento8 páginasUnited States Patent (19) (111 4,230,151: Jonsson (45) Oct. 28, 1980Stanislas AchardAinda não há avaliações

- Us2371574 PDFDocumento5 páginasUs2371574 PDFbelchior alvaroAinda não há avaliações

- United States: (12) Patent Application Publication (10) Pub. No.: US 2012/0227970 A1Documento14 páginasUnited States: (12) Patent Application Publication (10) Pub. No.: US 2012/0227970 A1zbhdzpAinda não há avaliações

- Braiding MachineDocumento7 páginasBraiding Machinejojaberi100% (1)

- United States Patent: BittnerDocumento8 páginasUnited States Patent: BittneronlyaqmalAinda não há avaliações

- Us2467764 PDFDocumento10 páginasUs2467764 PDFRodrigoPomaAinda não há avaliações

- Jan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1Documento5 páginasJan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1luiscremaschiAinda não há avaliações

- Anti Two Blocking System - PatternDocumento11 páginasAnti Two Blocking System - PatternWell LojuminAinda não há avaliações

- (12 Ulllted States Patent (10) Patent N0.: US 6,901,818 B1Documento15 páginas(12 Ulllted States Patent (10) Patent N0.: US 6,901,818 B1brig1960Ainda não há avaliações

- Buoyancy: The "Hidro" Self-Powered Generator of James KwokDocumento14 páginasBuoyancy: The "Hidro" Self-Powered Generator of James KwokAlboresha RafidAinda não há avaliações

- Filed Sept. 30, 1963: C. C. BrownDocumento8 páginasFiled Sept. 30, 1963: C. C. BrownyasamanAinda não há avaliações

- US patent for balanced lifting beam craneDocumento3 páginasUS patent for balanced lifting beam cranegibson_sx87Ainda não há avaliações

- 2,418,540 April 8, 1947.: R. E. BresslerDocumento5 páginas2,418,540 April 8, 1947.: R. E. Bresslerricva_rjAinda não há avaliações

- US2755738 Rocket Fuze 3.5 Inch Rocket M404 PatentDocumento3 páginasUS2755738 Rocket Fuze 3.5 Inch Rocket M404 Patentrichardwb1Ainda não há avaliações

- Us 2109297Documento6 páginasUs 2109297lfilippiniAinda não há avaliações

- Evaluation of Screw ConveyorsDocumento10 páginasEvaluation of Screw ConveyorsbiondavAinda não há avaliações

- Military Searchlight Truck (1937)Documento8 páginasMilitary Searchlight Truck (1937)CAP History LibraryAinda não há avaliações

- Operation of The Teaching Flume at The Cee Hydraulics LaboratoryDocumento13 páginasOperation of The Teaching Flume at The Cee Hydraulics LaboratoryNgo AcaiAinda não há avaliações

- Is 13591 1992 PDFDocumento13 páginasIs 13591 1992 PDFslamienkaAinda não há avaliações

- Us 3960084Documento3 páginasUs 3960084rte678Ainda não há avaliações

- Us965386 PDFDocumento6 páginasUs965386 PDFJin SongAinda não há avaliações

- Pocket Lighter Patent from 1936 Describes Zippo DesignDocumento3 páginasPocket Lighter Patent from 1936 Describes Zippo DesignRakeshAinda não há avaliações

- Cloth Tow Target Sleeve (1935)Documento6 páginasCloth Tow Target Sleeve (1935)CAP History LibraryAinda não há avaliações

- United States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1Documento14 páginasUnited States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1Kalai SelvanAinda não há avaliações

- Us2297693 PDFDocumento8 páginasUs2297693 PDFJin SongAinda não há avaliações

- J.B. HALE'S 1920 BRAIDING MACHINE CARRIERDocumento5 páginasJ.B. HALE'S 1920 BRAIDING MACHINE CARRIERsebastian escobarAinda não há avaliações

- Us 1893840Documento6 páginasUs 1893840Robert BercovitzAinda não há avaliações

- US1685447Documento5 páginasUS1685447Redirecting DecoyAinda não há avaliações

- GT LL: NN W///, WM)Documento5 páginasGT LL: NN W///, WM)lfilippiniAinda não há avaliações

- Aerial Tow Target (1954)Documento13 páginasAerial Tow Target (1954)CAP History LibraryAinda não há avaliações

- Tug Boat Cover Rolling Apparatus Optimized for SEODocumento5 páginasTug Boat Cover Rolling Apparatus Optimized for SEOاحمد عبدالكريمAinda não há avaliações

- European Patent Application - VoidmeterDocumento9 páginasEuropean Patent Application - Voidmeterazlan.shareAinda não há avaliações

- 1,333,9 1 8,. ' Patented Mar. 16, 1920. V: M. HorieDocumento3 páginas1,333,9 1 8,. ' Patented Mar. 16, 1920. V: M. HorieVincent Grangé-PradérasAinda não há avaliações

- Mechanical Appliances, Mechanical Movements and Novelties of ConstructionNo EverandMechanical Appliances, Mechanical Movements and Novelties of ConstructionNota: 4 de 5 estrelas4/5 (2)

- Us 5113943Documento7 páginasUs 5113943lfilippiniAinda não há avaliações

- United States Patent: (12) (10) Patent No.: US 7,188,675 B2Documento13 páginasUnited States Patent: (12) (10) Patent No.: US 7,188,675 B2lfilippiniAinda não há avaliações

- Us 5038863Documento5 páginasUs 5038863lfilippiniAinda não há avaliações

- Us20040221985 PDFDocumento13 páginasUs20040221985 PDFlfilippiniAinda não há avaliações

- United States: (12) Patent Application Publication (10) Pub. No.: US 2009/0126933 A1Documento18 páginasUnited States: (12) Patent Application Publication (10) Pub. No.: US 2009/0126933 A1lfilippiniAinda não há avaliações

- United States Patent: Ryan US 6,176,311 B1Documento9 páginasUnited States Patent: Ryan US 6,176,311 B1lfilippiniAinda não há avaliações

- United States Patent (19) : B JornstadDocumento4 páginasUnited States Patent (19) : B JornstadlfilippiniAinda não há avaliações

- Us4027816 PDFDocumento8 páginasUs4027816 PDFlfilippiniAinda não há avaliações

- United States Patent (19) (11) 4,298,078Documento9 páginasUnited States Patent (19) (11) 4,298,078lfilippiniAinda não há avaliações

- United States Patent US 6,276,452 B1: Davis Et Al. (45) Date of Patent: Aug. 21, 2001Documento8 páginasUnited States Patent US 6,276,452 B1: Davis Et Al. (45) Date of Patent: Aug. 21, 2001lfilippiniAinda não há avaliações

- United States Patent: Ryan US 6,176,311 B1Documento9 páginasUnited States Patent: Ryan US 6,176,311 B1lfilippiniAinda não há avaliações

- Us 6250387Documento15 páginasUs 6250387lfilippiniAinda não há avaliações

- Ulllted States Patent (10) Patent N0.: US 7,610,957 B2Documento8 páginasUlllted States Patent (10) Patent N0.: US 7,610,957 B2lfilippiniAinda não há avaliações

- J. H. Wilson: Inventor.Documento6 páginasJ. H. Wilson: Inventor.lfilippiniAinda não há avaliações

- L'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545Documento12 páginasL'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545lfilippiniAinda não há avaliações

- Us 2109297Documento6 páginasUs 2109297lfilippiniAinda não há avaliações

- GT LL: NN W///, WM)Documento5 páginasGT LL: NN W///, WM)lfilippiniAinda não há avaliações

- May 12, 1942-, 'J. D Spaldlng 2,282,615: Brake For DrawworksDocumento10 páginasMay 12, 1942-, 'J. D Spaldlng 2,282,615: Brake For DrawworkslfilippiniAinda não há avaliações

- Jan-1, 1935 - R. G. de La Mater Er Al 1,985,889Documento8 páginasJan-1, 1935 - R. G. de La Mater Er Al 1,985,889lfilippiniAinda não há avaliações

- Us 2464469Documento8 páginasUs 2464469lfilippiniAinda não há avaliações

- Piper AlphaDocumento3 páginasPiper AlphalfilippiniAinda não há avaliações

- A320 38 Water and WasteDocumento7 páginasA320 38 Water and WasteSudip AcharyyaAinda não há avaliações

- Install & Maintain Alarm Valve ComboDocumento32 páginasInstall & Maintain Alarm Valve ComboMSSAinda não há avaliações

- Patriot Owner's ManualDocumento27 páginasPatriot Owner's Manualintermountainwater0% (1)

- Sewage Treatment ManualDocumento48 páginasSewage Treatment ManualSugumar Panneer Selvam100% (1)

- Flanged Series: Flow-TekDocumento8 páginasFlanged Series: Flow-Teklcs2006mvAinda não há avaliações

- VA4851K41B enDocumento80 páginasVA4851K41B enpostolache mariusAinda não há avaliações

- Chapter 011Documento36 páginasChapter 011Gims BuafAinda não há avaliações

- 2-Rafael-TDSJ-2 Automatic Dry Mixed Mortar Production plant-CIFDocumento26 páginas2-Rafael-TDSJ-2 Automatic Dry Mixed Mortar Production plant-CIFRafael ObusanAinda não há avaliações

- Sauer Danfos Serie 90Documento88 páginasSauer Danfos Serie 90Tavo VergaraAinda não há avaliações

- H 3 1 Third Generation FA5ADocumento6 páginasH 3 1 Third Generation FA5AjlmunozvAinda não há avaliações

- Operating, Installation & Maintenance Manual FOR Series 210 MK - Ii Sample ProbeDocumento44 páginasOperating, Installation & Maintenance Manual FOR Series 210 MK - Ii Sample ProbeSenterver Equipos IndustrialesAinda não há avaliações

- Regulamentul 67 ECE-ONU - Seria 01 de Amendamente PDFDocumento146 páginasRegulamentul 67 ECE-ONU - Seria 01 de Amendamente PDFMihai BairacAinda não há avaliações

- Gas Systems For Laboratory Facilities - 1.12.15Documento8 páginasGas Systems For Laboratory Facilities - 1.12.15Carl CrowAinda não há avaliações

- MCM Fault Code ListDocumento14 páginasMCM Fault Code Listcristian picado100% (2)

- 2 in LACT PipelineDocumento4 páginas2 in LACT PipelineeugeniuciobanuAinda não há avaliações

- Flash TankDocumento7 páginasFlash TankAli Korhan Közer100% (1)

- Absorção ChillerDocumento44 páginasAbsorção ChillergdaronaldoAinda não há avaliações

- Component Maintenance Manual With Illustrated Parts List: Dual Distributor ValveDocumento223 páginasComponent Maintenance Manual With Illustrated Parts List: Dual Distributor ValveFilip F.Ainda não há avaliações

- LeFiell Beef CatalogDocumento68 páginasLeFiell Beef CatalogElenaLavAinda não há avaliações

- Conectores y Accesorios Hoke-GyrolokDocumento56 páginasConectores y Accesorios Hoke-GyrolokJordan YPAinda não há avaliações

- Section 2-Design Codes, Standards & ReferencesDocumento10 páginasSection 2-Design Codes, Standards & ReferencesMorteza alizadehAinda não há avaliações

- Audi 01J Multitronic CVTDocumento99 páginasAudi 01J Multitronic CVTenes_br95% (20)

- 700HTP-2 - Test Pump PDFDocumento2 páginas700HTP-2 - Test Pump PDFCALIBRATION TRACKINGAinda não há avaliações

- Airtek Dryer SC CT40 3000 Manual PDFDocumento41 páginasAirtek Dryer SC CT40 3000 Manual PDF4ew018Ainda não há avaliações

- Process Industry Practices Insulation: PIP INSH2000 Installation of Hot Service Insulation SystemsDocumento15 páginasProcess Industry Practices Insulation: PIP INSH2000 Installation of Hot Service Insulation Systemsantonio diazAinda não há avaliações

- 01 Samss 091Documento15 páginas01 Samss 091balajiAinda não há avaliações

- Models 6, 7, and 11 Light Duty Hydrostatic TransmissionsDocumento25 páginasModels 6, 7, and 11 Light Duty Hydrostatic TransmissionsGabor Daniel100% (1)

- Mechanical Engineering Measurement and Hydraulics CourseDocumento9 páginasMechanical Engineering Measurement and Hydraulics CourseKalpesh MadhaviAinda não há avaliações

- Plumbing 1 QuestionnaireDocumento15 páginasPlumbing 1 QuestionnaireLyla DelylasAinda não há avaliações

- LIT2739 R9 PB308 Instruction ManualDocumento16 páginasLIT2739 R9 PB308 Instruction Manualshirley bustos14Ainda não há avaliações