Escolar Documentos

Profissional Documentos

Cultura Documentos

Operations

Enviado por

rahuln181Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Operations

Enviado por

rahuln181Direitos autorais:

Formatos disponíveis

Operations Management.

Plant Location-Cases/models

Location Models (Facility location)

Nelson Group of Industries would like to establish a production unit at one of the locations proposed at

site A, B and C. The table given below shows the various factor considered for location decision and the

factor rating assigned to each factor based on its importance for location decision.

Q. As a project consultant, suggest the best alternative out of location A, B and C

It can be analysed by:

1. Factor Rating Method

2. Point Rating Method

3. Location Break-even Analysis

1. Factor Rating Method:

The steps involved are:

List the most relevant factors in the location decision.

Rate each factor ( say from 1for every low and to 5for very high ) according to its relative

importance, i.e. a factor rating is given to each factor, based on its importance, the higher the

ratings the more important is the factor.

Rate each location (say 1 for very low and to 10 for very high) according to its merits on each

factor.

Compute the product of ratings multiplying the factor rating by the location rating for each

factor.

Compute the sum of the product of ratings for each location.

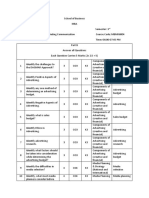

Table: Factor Ratings and Location Ratings for Location Alternatives.

FACTORS

1.

2.

3.

4.

TAX ADVANTAGE

SUITABILITY

OF LABOUR SKILL

PROXIITY

TO CUSTOMERS

PROXIMITY TO

SUPPLIERS

FACTOR

RATING

LOCATION RATING

LOCATION

A

8

LOCATION

B

6

LOCATION

C

3

5.

ADEQUACY OF WATER

6.

RECEPTIVITY OF

COMMUNITY

QUALITY OF

EADUCATIONAL

SYSTEM

ACCESS TO RAIL AND

AIR TRANSPORTATION

SUITABILITY OF

CLIMATE

10

10. POWER AVAILABILITY

7.

8.

9.

PRODUCT OF RATINGS

LOCATION

A

LOCATION

B

LOCATION

C

Total Score

DECISION: Since the total score for location __ is the highest than that of __& __Hence location__is the choice.

Dr..Nitin Kubde

Page 1

SIESCOMS

Operations Management.

Plant Location-Cases/models

2. Point Rating Method:

After evaluating the potential sites A, B & C by comparing costs, the company management decided to

evaluate on the basis of intangible factors for the locations by using the point rating method.

Comparative rating assigned to major intangible location factors to determine the relative importance

for each factor and the points assigned to each location alternative for each of the factors are given

below.

Location Factors

Future availability of fuel

Ease of transportation & growth

Adequacy of water supply

Labour availability

Pollution regulations

Site topography

Living conditions

Points assigned to locations

Maximum Possible

Points

Location A

Location B

Location C

300

200

250

200

200

150

150

150

100

100

100

100

200

170

150

100

50

40

40

50

50

40

30

30

100

50

75

70

Total Score out of 1000

750

795

700

DECISION: - From the table, it is seen that location B has slight advantage over location A & C.

3. Location Break-even Analysis:

In comparing several potential locations on an economic basis, (i.e., intangible and tangible factors) only the

revenue and costs that needs to be evaluated which varies from one location to another. If revenue per unit is

the same, regardless of where the goods are produced the total revenue can be eliminated from consideration. An

economic comparison of location can be made by identifying the fixed costs and the variable costs . It can be

shows by analytical or graphical method.

The potential locations A, B and C have the cost structures shown for producing a product expected to sell at

Rs.100 per unit.

Q1.Find the most economical location for an expected volume of 2000 units/year.

Q2.Also determine the range of annual volume of production for which, each of the

location A, B and C would be most economical.

Location

fixed

cost/year

Variable

unit

A

B

C

Rs.25000

Rs.50000

Rs.80000

Rs.50

Rs.25

Rs.15

Dr..Nitin Kubde

cost

per

Page 2

SIESCOMS

Operations Management.

Plant Location-Cases/models

Solution (a)

To determine the most economical location for an expected annual volume of production of 2000 units, calculate

the total cost of production at each of the locations for the annual production volume Q= 2000 units.

(TC=FC+VC * Q)

1)

2)

3)

DECISION: By comparing the total costs at each of the three locations, it is seen that location ___ is the most

economical location for the volume of production of 2000 nos. per year.

Solution (b)

To determine the range of annual volume of production at which each of the three locations would become most

economical, it is necessary to determine the break-even volumes either by analytical method or graphical method .

Analytical Method

To determine the break even volume between locations A and & B, the total cost for producing the break even

quantity say Qab at each of location A & B are equated.

25000 + 50Qab = 50000 + 25Qab

Qab =

To determine the break even volume between locations B & C, the total cost for producing the break even

quantity say Qbc at each of location B and C are equated.

50000 + 25Qbc = 80000 + 15Qbc

Qbc =

To determine the break even volume between locations A & C, the total cost for producing the break even quantity

say Qac at each of location A and C are equated.

25000 + 50Qac = 80000 + 15Qac

Qac =

Graphical Method: The above break even quantities are shown graphically below.

Dr..Nitin Kubde

Page 3

SIESCOMS

Plant Location-Cases/models

Annual Total Cost

Operations Management.

Location A

Location B

80000

Location C

50000

25000

500

1000 1500 2000 2500 3000

Annual Volume (Unit) (Q)

(CLASS ROOM ASSIGNMENT):

4. Qualitative factor analysis method:

If economic criteria are not sufficiently influential to decide the location alternatives, a system of weighing the criteria might

be useful in making a plant location decision.

XYZ Company is evaluating 4 locations for a new plant and has weighted the relevant scores as given below. Scores have

been assigned with higher values indicative of preferred conditions. Using these scores, develop a qualitative factor

comparison for the 4 locations.

RELEVANT FACTORS

PRODUCTION COST

Dr..Nitin Kubde

ASSIGNED

WEIGHT

0.35

SCORES FOR LOCATION

A

B

C

50

40

60

Page 4

D

30

SIESCOMS

Operations Management.

Plant Location-Cases/models

RAW MATERIAL SUPPLY

0.25

70

80

80

60

LABOUR AVAILABILITY

]

COST OF LIVING

0.20

60

70

60

50

0.05

80

70

40

80

ENVIORMENT

0.05

50

60

70

90

MARKETS

0.10

70

90

80

50

TOTAL

1.00

Solution

FACTORS

WEIGHTED SCORES FOR LOCATION

A

B

C

PRODUCTION COST

RAW MATERIAL SUPPLY

LABOUR AVAILABILITY

]

COST OF LIVING

ENVIORMENT

MARKETS

TOTAL

Location ____ is preferred because of highest weighted score.

THANKS:

.

Dr..Nitin Kubde

Page 5

SIESCOMS

Você também pode gostar

- Overview of Banking Sector and Credit Analysis ofDocumento23 páginasOverview of Banking Sector and Credit Analysis ofrahuln181Ainda não há avaliações

- Marketing PlanDocumento3 páginasMarketing Planrahuln181Ainda não há avaliações

- Depreciation and Provisions, ReservesDocumento23 páginasDepreciation and Provisions, Reservesrahuln181Ainda não há avaliações

- 3 Crisis CommunicationsDocumento15 páginas3 Crisis Communicationsrahuln181Ainda não há avaliações

- OperationsDocumento5 páginasOperationsrahuln181Ainda não há avaliações

- Elasticity and Its ApplicationsDocumento43 páginasElasticity and Its Applicationsrahuln1810% (1)

- RbiDocumento14 páginasRbiAnkur SrivastavaAinda não há avaliações

- Indian Aviation IndustryDocumento10 páginasIndian Aviation Industryrahuln181Ainda não há avaliações

- The Market Forces of Supply and DemandDocumento52 páginasThe Market Forces of Supply and Demandrahuln181Ainda não há avaliações

- Security AnalysisDocumento4 páginasSecurity Analysisrahuln181Ainda não há avaliações

- Diff Factoring Forfeiting SecDocumento4 páginasDiff Factoring Forfeiting Secrahuln181Ainda não há avaliações

- Corporate Governance in SBIDocumento8 páginasCorporate Governance in SBIrahuln181Ainda não há avaliações

- MotherboardDocumento4 páginasMotherboardrahuln181Ainda não há avaliações

- Pms in IndiaDocumento2 páginasPms in IndiaRagini SundarramanAinda não há avaliações

- How To Make ProjectDocumento5 páginasHow To Make Projectrahuln181Ainda não há avaliações

- Comparative Study On Usage of Commercial Vehicles "Best" and Indian Railways''Documento116 páginasComparative Study On Usage of Commercial Vehicles "Best" and Indian Railways''rahuln181Ainda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- I-Great Damai - Product Info - 10012014Documento9 páginasI-Great Damai - Product Info - 10012014MOHD AFIFI HASHIMAinda não há avaliações

- KAIZEN PAPER KALDI Final PaperDocumento34 páginasKAIZEN PAPER KALDI Final PaperClaire ZafraAinda não há avaliações

- MM MaggieDocumento22 páginasMM MaggieCommerce StudentAinda não há avaliações

- CAT 1 Module (NIAT Encoded)Documento245 páginasCAT 1 Module (NIAT Encoded)UFO CatcherAinda não há avaliações

- LK Buku Besar PT Home BycicleDocumento7 páginasLK Buku Besar PT Home BycicleFredi Dwi SusantoAinda não há avaliações

- Tata Steel Key Financial Ratios, Tata Steel Financial Statement & AccountsDocumento3 páginasTata Steel Key Financial Ratios, Tata Steel Financial Statement & Accountsmohan chouriwarAinda não há avaliações

- Objectives / Importance / Benefits of Personal SellingDocumento6 páginasObjectives / Importance / Benefits of Personal Sellingzakirno19248Ainda não há avaliações

- Planning of CRM ProjectDocumento8 páginasPlanning of CRM ProjectcatchardipAinda não há avaliações

- OM101 Quiz5Documento3 páginasOM101 Quiz5Lissy ParkAinda não há avaliações

- Observing Sales Activities & Direct Coverage Secondary Data Analysis at Rollick IndiaDocumento11 páginasObserving Sales Activities & Direct Coverage Secondary Data Analysis at Rollick Indiasouvikpal904Ainda não há avaliações

- Application: The Costs of Taxation: Marwa HeggyDocumento42 páginasApplication: The Costs of Taxation: Marwa HeggyAnonymous cioChTZoVAinda não há avaliações

- Laurentian BakeriesDocumento10 páginasLaurentian BakeriesNhan Ph100% (1)

- Final Question Paper For CAT-2 Part B & CDocumento4 páginasFinal Question Paper For CAT-2 Part B & CShailendra SrivastavaAinda não há avaliações

- What Are Advantages of Brand AlliancesDocumento3 páginasWhat Are Advantages of Brand Allianceskristal brownAinda não há avaliações

- Marketing Strategy Internship ReportDocumento37 páginasMarketing Strategy Internship ReportA H LabuAinda não há avaliações

- Husky Group7Documento2 páginasHusky Group7Shruti Mandal80% (5)

- Pillar 7 Office TPMDocumento9 páginasPillar 7 Office TPMapumu sexbombyaAinda não há avaliações

- Chapter 1 - Introduction To EconomicsDocumento51 páginasChapter 1 - Introduction To EconomicsBhavana PrakashAinda não há avaliações

- AVE ReportDocumento32 páginasAVE ReportManoAinda não há avaliações

- Formlabs Case - 311Documento8 páginasFormlabs Case - 311Jake MarzoffAinda não há avaliações

- Bond Market Chapter SummaryDocumento5 páginasBond Market Chapter SummaryZarifah Fasihah67% (3)

- Entrepreneurship PPT PresentationDocumento87 páginasEntrepreneurship PPT PresentationNida Tayaban0% (1)

- AnalyzingAPayoffMatrixAssignment (AutoRecovered)Documento2 páginasAnalyzingAPayoffMatrixAssignment (AutoRecovered)JG bhjAinda não há avaliações

- Nineteenth-Century Cost Accounting ExplainedDocumento10 páginasNineteenth-Century Cost Accounting ExplainedJannat JavedAinda não há avaliações

- Marketing Plan For FTTHDocumento5 páginasMarketing Plan For FTTHsheinmin thuAinda não há avaliações

- Chapter 3 - Organizational EthicsDocumento17 páginasChapter 3 - Organizational EthicsNguyễn Quốc HưngAinda não há avaliações

- Lafarge Surma CementDocumento2 páginasLafarge Surma CementNur AlahiAinda não há avaliações

- BY Dr. Kumar Saurav Segmentation Targeting and Positioning About The STP Process?Documento11 páginasBY Dr. Kumar Saurav Segmentation Targeting and Positioning About The STP Process?Sneha SahaAinda não há avaliações

- Pull and JIT PDFDocumento66 páginasPull and JIT PDFpranayrulzAinda não há avaliações

- Supply Chain Management: Key ConceptsDocumento21 páginasSupply Chain Management: Key ConceptsRocker BrosAinda não há avaliações