Escolar Documentos

Profissional Documentos

Cultura Documentos

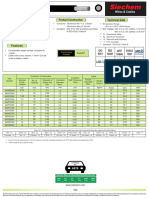

Specification - 11KV 300 SQ - MM XLPE Cable

Enviado por

Asaf Khader AliTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Specification - 11KV 300 SQ - MM XLPE Cable

Enviado por

Asaf Khader AliDireitos autorais:

Formatos disponíveis

125

The PVC sheath shall be embossed with voltage designation 33kV cross-sectional area of

conductor and the manufacturer's name, manufacturing year and with the same manner

described in BSS 6460 and ESI standard 09.3.

9.35

i)

ii)

iii)

iv)

v)

Solid 500 & 400 & 240sq.mm. Single Core 33kV PILC&S Cables:

Conductors: The conductors shall be stranded plain annealed high conductivity copper

wires shaped into circular cores and shall have cross-sectional area of 500sq.mm /

400sq.mm. / 240 sq.mm as may be specified in the Details of Equipment.

Insulation: Thickness shall not be less than 6.8mm and as 9.3.3(ii) above.

Screening: As 9.3.3(iii) above.

Sheathing: Same as 9.3.3(iv) above but with minimum average thickness and minimum at

any point as follows:

for 500sq.mm. & 400sq.mm.

1.9mm & 1.7mm

for 240sq.mm

1.8mm & 1.6mm

Serving: As 9.3.3(v) above.

9.3.6 Solid, 1000sq.mm. 1/Core 33kV XLPE Insulated Cables:

i)

Conductors, shall be of stranded copper wires shaped in circular conductor and shall

have a cross-section area of 1000sq.mm. or 500sq.mm. complying to BSS 6360.

ii)

Insulation, XLPE as specified under clause 9.2.2(b) and in accordance with IEC

502.

iii) Screening, shall be of semi-conducting thermoplastic or thermosetting material over

the conductor and similar layer extruded over the insulation as per IEC standard

502, but thickness should not be less than 8mm.

iv) Outer Sheath, shall be extruded PVC hard grade heat resisting type complying with

BSS.6746(Table 1-type 9) and IEC 502 (clause 12).

9.3.7 Solid 500sq.mm. 1/core 33kV XLPE Insulated Cable:

i)

Conductors: same as 9.3.5 above but conductor cross-section area is 500sq.mm.

ii)

Insulation: same as 9.3.5(ii) above.

iii) Screening: same as in 9.3.5(iii) above.

iv) Outer Sheath, same as in 9.3.5(iv) above.

9.3.8 Solid 630sq.mm. 1/core 11kV XLPE Insulated Cables:

The components of this cable is the same as that described above under 9.3.6. However,

the thickness of insulation, screen sheath, serving and bedding shall suit the rated

voltage of 11kV and cross section of conductor and shall be in accordance with IEC

standard 502.

9.3.8 Solid 500sq.mm & 630sq.mm. 1/core 11kV PILC&S Cables:

i)

Conductors:

The conductors shall be of stranded copper wires shaped into circular cores and shall have

a cross sectional area of 500 and 630sq.mm.

ii)

Insulation: Thickness not less than 2.8mm.

iii)

Sheathing:

Leading alloy E or C or tellurium alloy nominal thickness not less than 1.8mm.

iv)

Serving: As 9.3.3(v) above.

9.3.9 Solid 3/Core 300sq.mm. & 185sq.mm 11kV XLPE Insulated Cables:

i)

Conductors:

The conductors shall be of stranded copper wires shaped into circular cores and crosssectional area of core shall be 300sq.m.. and 185sq.mm. respectively. The conductor shall

comply with BSS6360.

ii)

Insulation:

Cross-linked polythelene XLPE between conductors and between conductor and sheath as

specified under clause 9.2.2(b) above.

126

iii)

iv)

v)

vi)

vii)

Screening:

A semi-conducting screen shall be extruded over the conductor. This layer shall consist of

black semi-conducting thermo-plastic or thermosetting material, and shall be easily

removable from the conductor. This layer shall have an average thickness of 0.38mm

when measured over top of the strands and shall be cylindrical. A similar semi-conducting

screen shall be extruded over the insulation without scratching the surface.

Sheathing:

PVC hard grade heat resisting type complying with BSS 6746 (Table 1- Type 9).

Laying up and Bedding:

The 3-core shall be laid up together with suitable semi-conducting tape, or an extruded

layer of semi-conducting material.

Armour:

The cable shall be armoured with galvanized steel wires to give it mechanical strength and

also act as a low resistance earth return conductor. Electrical contacts shall be maintained

between the core screens and the earthed armour through the conductive beeding.

Short Circuit Rating:

The cable shall carry without damages or undue stress a fault current of 18,000 Amps for

1.25 seconds after a continuous period of full load. Under these conditions, the final

temperature of the conductor shall not be such as to damage the insulation.

9.3.10 Solid 1/Core 630, 500 & 300sq.mm 1000 Volts XLPE Cable:

a)

Construction:

i)

The conductors shall be of stranded copper wires shaped into circular conductors and shall

have a cross-sectional area of 300, 500 & 630sq.mm. shall comply with BSS.No. 6360.

ii)

Insulation: XLPE and it shall be applied by a combined extrusion and vulcanization

process and shall form a compact homogenous body.

iii)

Oversheath:PVC hard grade, heat resisting type complying with BSS.6746:1969 (Table 1Type 9).

b)

Current Rating:

The current ratings of cables for the site and installation conditions mentioned above shall

be stated. These should be based on maximum conductor temperature in normal operating

conditions not exceeding 90C. Where ratings are specified for only standard conditions,

appropriate adjustment factors should be stated for Kuwait conditions.

c)

Short Circuit Rating:

Offers should be accompanied with short circuit current curves with XLPE insulation. It

is assumed the conductor is at its maximum operating temperature of 90C before the

occurance of the short circuit and the maximum conductor temperature after a fault

duration of 0.5 seconds will be 250C.

The cables shall carry the above short circuit currents without damage or undue stress.

The formula used in evaluating the short circuit current should be stated.

9.3.11 34-Core Pilot and Telephone Cables: (associated with 132 kV Cable Feeder Tails)

These cables are required for the conveyance of alarm, control, protection, telephone and

telemetry signals throughout the existing and future networks.

These cables shall be of copper conductors, polythene insulated and polythene inner

sheathed armoured with galvanized steel wire armour and overall sheathed with PVC.

The cable shall be insulated to withstand induced voltage level upto 15 kV and should

generally comply with Electricity Supply Industry (ESI-09-6) standard as a minimum.

a)

Make-up of Pilot Cables:

i)

2-core (one pair): each core shall consist of copper conductor of cross-sectional area 2.5

sq.mm. \polythene insulated and the pair shall be screened for use with Solkor protection

system.

ii)

4-core (two pairs ) : each core shall consist of copper conductor of cross-sectional area 2.5

sq.mm. polythene insulated and each pair twisted and screened for use with intertripping

system.

Você também pode gostar

- Spec 11kV 3 Core CablesDocumento5 páginasSpec 11kV 3 Core CablessasikalaAinda não há avaliações

- Appendix C - Specification For 33kV Cable (v2) PDFDocumento15 páginasAppendix C - Specification For 33kV Cable (v2) PDFOGBONNAYA MARTINSAinda não há avaliações

- 13 PDFDocumento4 páginas13 PDFabd mohamedAinda não há avaliações

- Intruduction Final LV NexansDocumento37 páginasIntruduction Final LV NexansDc DocAinda não há avaliações

- Basic Math For Cable TerminationDocumento17 páginasBasic Math For Cable TerminationAbraham JyothimonAinda não há avaliações

- 33kv Cables SpecsDocumento20 páginas33kv Cables SpecsMohamed WahidAinda não há avaliações

- XLPE Cable 33KV - Rev 2 PDFDocumento12 páginasXLPE Cable 33KV - Rev 2 PDFRatul ChakrabortyAinda não há avaliações

- Cabling and Wiring System: 1. GeneralDocumento12 páginasCabling and Wiring System: 1. GeneralcRi SocietyAinda não há avaliações

- 33 KV Cable Transmission Line Technical SpesificationDocumento10 páginas33 KV Cable Transmission Line Technical SpesificationNima dawa SherpaAinda não há avaliações

- Underground Cables - 010954Documento23 páginasUnderground Cables - 010954lawrence momanyiAinda não há avaliações

- Part - Vii: Power Cables 7.1 Scope of WorkDocumento21 páginasPart - Vii: Power Cables 7.1 Scope of WorkSri RamAinda não há avaliações

- Underground Power Cables Catalogue 03-2010Documento48 páginasUnderground Power Cables Catalogue 03-2010Edgar Sierra Rodriguez100% (1)

- XLPE cable for ungrounded 33kV systemsDocumento12 páginasXLPE cable for ungrounded 33kV systemssaurabh kumarAinda não há avaliações

- Specification No.: Ministry of Electricity Planning and Studies Office Baghdad - IraqDocumento10 páginasSpecification No.: Ministry of Electricity Planning and Studies Office Baghdad - IraqyildirimonlineAinda não há avaliações

- Republic of Iraq Minstrey of Higher Education and Scientific Research University of BabylonDocumento18 páginasRepublic of Iraq Minstrey of Higher Education and Scientific Research University of Babylonمهيمن الابراهيميAinda não há avaliações

- Tech Specs for 11kV Aerial Bunched CablesDocumento6 páginasTech Specs for 11kV Aerial Bunched CablesBilal AhmadAinda não há avaliações

- ITB-KEOC-2013-009 - Section VIII B - Electrical Specifications PDFDocumento115 páginasITB-KEOC-2013-009 - Section VIII B - Electrical Specifications PDFjaliscoruedaAinda não há avaliações

- EE458Documento36 páginasEE458ArishaAinda não há avaliações

- Cap Ngam 240mm2 Cach Dien Xlpe Hay EprDocumento7 páginasCap Ngam 240mm2 Cach Dien Xlpe Hay EprMinh VienAinda não há avaliações

- Cables Specifications and Ratings GuideDocumento4 páginasCables Specifications and Ratings Guidesrigirisetty208Ainda não há avaliações

- BESCOM Technical-Specification-HT-UG-CablesDocumento15 páginasBESCOM Technical-Specification-HT-UG-Cablesಪರಮಮಿತ್ರಸಂಪತ್ಕುಮಾರ್ಶೆಟ್ಟಿAinda não há avaliações

- DO Fuse UnitDocumento8 páginasDO Fuse UnitImran KhanAinda não há avaliações

- XLPE Power Cable 11 & 33 KVDocumento9 páginasXLPE Power Cable 11 & 33 KVArjun M KumarAinda não há avaliações

- Technical Specs - C-EPR - RevbDocumento5 páginasTechnical Specs - C-EPR - Revbgerrzen64Ainda não há avaliações

- Pilot Cable Specs FewaDocumento13 páginasPilot Cable Specs Fewabharat_22nandulaAinda não há avaliações

- 151-5C - 600 - 1000cable-154Documento4 páginas151-5C - 600 - 1000cable-154高欣东Ainda não há avaliações

- Underground Cables for Power TransmissionDocumento40 páginasUnderground Cables for Power TransmissionMagarsaa Qana'iiAinda não há avaliações

- Chapter 20: Technical Specification For Xlpe Cable With TerminationDocumento46 páginasChapter 20: Technical Specification For Xlpe Cable With TerminationSristi MitraAinda não há avaliações

- Tza123 en 1 1Documento8 páginasTza123 en 1 1Ahmed AdelAinda não há avaliações

- Isolator TSDocumento6 páginasIsolator TSanirban 007Ainda não há avaliações

- Intruduction Final LVDocumento37 páginasIntruduction Final LVmealysrAinda não há avaliações

- DEWA 1513403-R0 22kV 11kV XLPE Cables PDFDocumento11 páginasDEWA 1513403-R0 22kV 11kV XLPE Cables PDFHashimAmrAinda não há avaliações

- 11kV - 3-C - 300 - AL - Cable - Specification Final PDFDocumento18 páginas11kV - 3-C - 300 - AL - Cable - Specification Final PDFShubham BaderiyaAinda não há avaliações

- Coaxial Cables - Solid or Stranded CoreDocumento5 páginasCoaxial Cables - Solid or Stranded CoreRicardo Jose Flores GavidiaAinda não há avaliações

- F. Tech. Specifications - 166-216Documento51 páginasF. Tech. Specifications - 166-216mhafeez835156Ainda não há avaliações

- LV Power Cable Specification - 06.11.2009Documento10 páginasLV Power Cable Specification - 06.11.2009ErAkashAryanAinda não há avaliações

- Unit 4: Cable: Distribution Design SystemDocumento24 páginasUnit 4: Cable: Distribution Design SystemScalperAinda não há avaliações

- 33kV ABC Technical SpecificationDocumento7 páginas33kV ABC Technical SpecificationBijuAinda não há avaliações

- Transmission Line and Cable InsulationDocumento3 páginasTransmission Line and Cable InsulationJungkookAinda não há avaliações

- Underground CablesDocumento23 páginasUnderground CablesMizanur RahmanAinda não há avaliações

- Underground Power Cable SystemsDocumento42 páginasUnderground Power Cable SystemsGopinath B L NaiduAinda não há avaliações

- Paper Insulated Distribution CablesDocumento10 páginasPaper Insulated Distribution Cablesdeepak2628Ainda não há avaliações

- Bilal Lateef. Beem-F19-024 Assignment#07 Mechanical Design of Overhead LinesDocumento10 páginasBilal Lateef. Beem-F19-024 Assignment#07 Mechanical Design of Overhead LinesBilal Latif BhuttaAinda não há avaliações

- 110 - Technical Document of JICA-012 PDFDocumento32 páginas110 - Technical Document of JICA-012 PDFManoj RanaAinda não há avaliações

- Premold JointDocumento6 páginasPremold JointbenwkgAinda não há avaliações

- Underground Cable Installation GuideDocumento18 páginasUnderground Cable Installation GuideJalaj GargAinda não há avaliações

- Npcil TSDocumento10 páginasNpcil TSBhavesh KeraliaAinda não há avaliações

- Medium Voltage CablesDocumento12 páginasMedium Voltage Cableswafikmh4Ainda não há avaliações

- NTDC SPECIFICATION P-29:2010 FOR 15kV XLPE POWER CABLESDocumento17 páginasNTDC SPECIFICATION P-29:2010 FOR 15kV XLPE POWER CABLESsohaib0% (1)

- Medium Voltage CableDocumento5 páginasMedium Voltage CableNaveenNavabAinda não há avaliações

- Lecture 11 Underground CablesDocumento8 páginasLecture 11 Underground CablesKenean YeshitelaAinda não há avaliações

- Selecting the Right Medium-Voltage CableDocumento8 páginasSelecting the Right Medium-Voltage CableAsmadi MusaAinda não há avaliações

- HT Cable RFQ Specifications PDFDocumento7 páginasHT Cable RFQ Specifications PDFAshil ThomasAinda não há avaliações

- WTEC 35KV MV Cable LLDPE Rev S 20160226Documento5 páginasWTEC 35KV MV Cable LLDPE Rev S 20160226carloAinda não há avaliações

- XLPE Cable SpecificationDocumento46 páginasXLPE Cable Specificationjtwani100% (2)

- Solution Manual for 100 Genesys Design Examples: Second EditionNo EverandSolution Manual for 100 Genesys Design Examples: Second EditionAinda não há avaliações

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsAinda não há avaliações

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsNo Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsNota: 4 de 5 estrelas4/5 (1)

- Power & Control CablesDocumento27 páginasPower & Control CablesAsaf Khader AliAinda não há avaliações

- Kuwait Labor LawDocumento40 páginasKuwait Labor LawKaraikal S.M. Arif MaricarAinda não há avaliações

- How To InstallDocumento1 páginaHow To InstallAsaf Khader AliAinda não há avaliações

- Application FormDocumento2 páginasApplication FormAsaf Khader AliAinda não há avaliações

- Kahromika Appln CompltdDocumento2 páginasKahromika Appln CompltdAsaf Khader AliAinda não há avaliações

- Catálogp de Conectores para Subestaciones, Ago2011Documento8 páginasCatálogp de Conectores para Subestaciones, Ago2011Otto AcnAinda não há avaliações

- Tips On Shielding and Grounding in Industrial Automation - Technical ArticleDocumento20 páginasTips On Shielding and Grounding in Industrial Automation - Technical Articlepriyanka236Ainda não há avaliações

- Thermal resistance of soil impacts cable loadingDocumento15 páginasThermal resistance of soil impacts cable loadingKy TaAinda não há avaliações

- Integrated Science Form 2 June 2010Documento9 páginasIntegrated Science Form 2 June 2010asjawolverine0% (2)

- RTG Electrical Manual Install Columns CablesDocumento63 páginasRTG Electrical Manual Install Columns Cablessudaryanto100% (1)

- FLALRY CablesDocumento1 páginaFLALRY CablesVijay KarthikeyanAinda não há avaliações

- Soldering Iron NetworkingDocumento13 páginasSoldering Iron NetworkingMae Jane AguilarAinda não há avaliações

- PWD Schedule EM SUB-HEAD-3 NewDocumento11 páginasPWD Schedule EM SUB-HEAD-3 NewEmran HusainAinda não há avaliações

- Teori Pengujian - Hot SetDocumento1 páginaTeori Pengujian - Hot Settwo travellerAinda não há avaliações

- Data Sheet 7KM5412-6BA00-1EA2: ModelDocumento9 páginasData Sheet 7KM5412-6BA00-1EA2: ModelMinh TuAinda não há avaliações

- PVC Catelogue PDFDocumento63 páginasPVC Catelogue PDFsameera priyashanthaAinda não há avaliações

- NCI - LV Cables CatalogueDocumento55 páginasNCI - LV Cables CatalogueMuhammad Abubakar QureshiAinda não há avaliações

- MeggerDocumento6 páginasMeggerKevin NgoAinda não há avaliações

- Chapter 3 - Wiring System and DistributionDocumento65 páginasChapter 3 - Wiring System and DistributionMohamad Syahmi100% (1)

- Bhel Haridwar - Training Report - 800 MW Bar CIM Block 4 (EEE)Documento27 páginasBhel Haridwar - Training Report - 800 MW Bar CIM Block 4 (EEE)Amit Kumar67% (6)

- KSH International Continuously Transposed Cables - Conductors (CTC) BrochureDocumento4 páginasKSH International Continuously Transposed Cables - Conductors (CTC) Brochurekshintl100% (3)

- Catalogue of 66-500kV HV CablesDocumento17 páginasCatalogue of 66-500kV HV Cablessmile100% (1)

- Extracted Tender SpecificationDocumento96 páginasExtracted Tender SpecificationJetn SrisuthumAinda não há avaliações

- PHYSICAL PROPERTIES OF MATERIALS Review QuestionsDocumento2 páginasPHYSICAL PROPERTIES OF MATERIALS Review Questionsprince stevenAinda não há avaliações

- Helkama Bica Marine and Offshore CablesDocumento120 páginasHelkama Bica Marine and Offshore Cablesvenkat tesanAinda não há avaliações

- NTPC Darlipali Super Thermal Power Project HT Power Cables Technical Data SheetsDocumento14 páginasNTPC Darlipali Super Thermal Power Project HT Power Cables Technical Data SheetschautharamAinda não há avaliações

- Advanced Cable CatalogDocumento88 páginasAdvanced Cable Catalogrp30Ainda não há avaliações

- Connector Tooling GuideDocumento180 páginasConnector Tooling GuideReginaldoAinda não há avaliações

- Control Estrela Triangulo SiemensDocumento8 páginasControl Estrela Triangulo SiemensKenneth ThomasAinda não há avaliações

- Aluminum Armor Medium Voltage - GK Wire & Cable SolutionsDocumento34 páginasAluminum Armor Medium Voltage - GK Wire & Cable SolutionsaselaAinda não há avaliações

- Capacitance FormulaDocumento4 páginasCapacitance FormulajamilAinda não há avaliações

- Bu RSW 1Documento8 páginasBu RSW 1Kate Wencelette AraoAinda não há avaliações

- Grounding Catalog Low Res 1-14-08Documento132 páginasGrounding Catalog Low Res 1-14-08Eric EsjAinda não há avaliações

- Rme April 2019 Exam 5 Key PDFDocumento8 páginasRme April 2019 Exam 5 Key PDFJevan CalaqueAinda não há avaliações

- 08 Charging PDFDocumento4 páginas08 Charging PDFFany FabiaAinda não há avaliações