Escolar Documentos

Profissional Documentos

Cultura Documentos

Cat2310 Ac

Enviado por

Sayak BoseTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Cat2310 Ac

Enviado por

Sayak BoseDireitos autorais:

Formatos disponíveis

Hubbell Industrial Controls, Inc.

Speed Responsive Switches

2310

Catalog 2310-AC July 2008

Non-Contact

Speed Responsive

Switches

General Information

The 2310 Non-Contact Speed Responsive Switch is a selfcontained solid state device capable of sensing the presence

of metal without physical contact. This high-density tubular

package senses metal targets in a nominal 10 mm (0.4)

sensing distance from the sensing head for targets of a typical

size, 30 mm (1.20) square by 1.5 mm (0.06) thick.

Benefits

Solid State speed-Sensing Device

Self-Contained Control Adjustments and Diagnostics

Ease of Installation

Maintenance Free

Automatic Reset Each Cycle

High Impact Housing

Applications

Numerous production control and related applications include

underspeed as with chain, belt, screw, and related conveyors;

also zero-speed sensing for web, belt or coupling breakage,

etc. Specific production uses include start-up of motors for

mixing units, rotary kilns, blower fans, mine pumps, sequencing

conveyors, etc.

Catalog

Number

Part

Number

2310-LSP

HC48910101

Description

Low-Speed Plastic Housing

2310-HSP

HC48910102

High-Speed Plastic Housing

2310-LSNP

HC48910151

Low-Speed Nickel-Plated Sleeve

2310-HSNP

HC48910152

High-Speed Nickel-Plated Sleeve

Operating Characteristics

Load Connection...............Series Load Actuation (See Fig. 2)

Start-Up Time.......................................................0.6 seconds

Speed Range:

Assemblies 101, 151...............6-150 RPM (Single Event)

Assemblies 102, 152.........150-3600 RPM (Single Event)

Sensing Distance........................15mm (See Fig. 4 - Table 5)

Sensing Hysteresis (Distance)........................................2 mm

Operating Hysteresis (Speed)............................................5%

Sensing Tolerance....................Dependent on Target Material

Temperature....................................................-20C to +70C

Voltage...........................................................................+10%

Operating Tolerance (Speed).........................................+10%

Low-Speed Sensors - desinged to operate in speed ranges

6-150 RPM (Single Event)

High-Speed Sensors - designed to operate in speed ranges

150-3600 RPM (Single Event)

To sense slower speeds than those listed, multiple events

should be detected in each revolution.

Hubbell Industrial Controls, Inc.

Speed Responsive Switches

Catalog 2310-AC July 2008

Page 2

Application Details

Easy Installation

The 2310 Non-Contact Speed Responsive Switch is a twowire series, load-activating sensor. It operates on the inductive

proximity switch principle. It obtains its power from the same

120V, 60hz supply as the separately mounted output relay

(supplied by others). The 2310 is series-connected with the

coil of the output relay.

Connect the speed switch per the wiring diagram shown in

Fig. 2 below. Apply power to the speed switch circuit and set

the target in motion. The Red target LED on the rear of the

speed switch should respond as the target passes by the

front of the speed switch. See Fig. 3 below.

Easily recalibrated for home position, the 2310 permits easy

resetting to compensate for belt stretching or slipping on

conveyor applications, and for compensatory adjustments on

variable speed operations.

As indicated earlier, the listed speed ranges are based on a

single event or actuation per revolution. A typical application

would involve sensing the key in a motor or gearbox shaft.

The speed switch is available in two speed ranges:

120V A.C.

Speed

Switch

Contact

Load

2310-LSP & 2310-LSNP - 6 to 150 RPM*

2310-HSP & 2310-HSNP - 150 to 3600 RPM*

In order to sense slower speeds outside the listed ranges,

multiple events or actuations per revolution must be used. An

example of multiple event actuation might be the sensing of

protruding bolt heads from a shaft coupling. If the coupling

provides six bolt heads, the speed ranges would be divided

by six with the slowest sensing speed being 1 RPM for the

101 assembly.

30 mm

1.18

Sensor

30 mm

1.18

Metal

Metal

Fig. 1

Free Zone Area

Select a mounting area, keeping the Free Zone requirements

(Fig. 1) in mind. The target must move laterally across the

face of the speed switch. Actuating distance from the target

to speed switch face is shown in Fig. 4 and Table 5 (Page 3).

The information provides an estimated setup distance prior to

actual starting.

2-Wire A.C. N.O. Outupt

Fig. 2

Connection Diagram

The speed setting within a given sensors range is adjustable

with the 20-turn RPM adjustment potentiometer located behind

the access screw. See Fig. 3 below. The initial setting of this

potentiometer is made by first turning the potentiometer fully

counterclockwise, then turning the potentiometer clockwise

by the number of turns indicated by the speed setting graphs,

Fig. 6 and Fig. 7 (Page 3). For most applications, the initial

settings (clockwise turns) obtained from the graph will provide

adequate accuracy. If greater precision is required, monitor

the target revolutions with a hand tachometer.

If the Red target LED does not respond, move the switch

closer to the target. If the Red LED is continuously on, move

the switch farther away from the target. The operating range

will be determined by the end points explained above. The

ideal location of the speed switch is midway in this operating

range.

Target LED

(Red)

Output LED

(Yellow)

RPM Adjustment

(Access Screw Removed)

Fig. 3

Rear View

The Yellow output LED, Fig. 3, will light when the sensed

speed is above the speed setting. The Yellow output light

also signals that the output triac is on and shows that the

series-connected load is actuated.

Hubbell Industrial Controls, Inc.

Speed Responsive Switches

Page 3

Catalog 2310-AC July 2008

Simplified Setpoint Selection

A small instrument-size screwdriver is supplied by Hubbell

to fit potentiometer for speed setting adjustments according

to charts shown below. If speed tolerance is not critical, this

speed setting can be the final adjustment.

HIGH-SPEED POTENTIOMETER

LOW-SPEED POTENTIOMETER

100

2500

SINGLE EVENT RPM

3750

SINGLE EVENT RPM

150

1250

50

10

250

125

10

20

10

TURNS (Clockwise)

TURNS (Clockwise)

Fig. 6

Fig. 7

20

Standard Ferrous Target

LATERAL SENSITIVITY

Distance From Face (mm)

30 mm x 30 mm 1.5 mm

Use factors from Table 5 below if target material

other than steel is used:

16

14

12

Material Reduction Factors

10

8

Steel..................................................1.0

Stainless Steel..................................0.7 to 0.8

Aluminum..........................................0.3 to 0.5

Brass.................................................0.3 to 0.4

Copper..............................................0.3 to 0.4

6

4

2

14 12 10

6 4 2 0 2 4 6

Distance Across Face (mm)

Fig 4

8 10 12 14

Table 5

Hubbell Industrial Controls, Inc.

Speed Responsive Switches

Page 4

Catalog 2310-AC July 2008

Switch and Accessories - Sizing and Mountig Detail

Optional Accessories

A mounting bracket is available as an accessory for

mounting the Non-Contact Speed Switch. If the jam

nuts provided with the switch are misplaced, they can

be purchased using the part number below.

HC48943000

Note: All Dimensions are approximate

Specifications

Electrical Data

Operating Voltage........................................120V-132V

Line Frequency.................................................50-60hz

On-state voltage drop.......................................5.5 volts

Off-state leakage current....................................10 ma.

Maximum load current**...................................300 ma.

Maximum inrush current (20msec)**.................1.8amp

Output Circuit Configuration................N.O. triac switch

Temperature Range...............................-20C to +70C

Mechanical Data

Size:

Length........................................................100mm

Diameter.......................................................30mm

Thread....................................................m30 x 1.5

Weight:

Plastic............................................................22Kg

Sleeved..........................................................30Kg

Black Mounting Jam Nut - Part No. HC48916001

*Nickel-Plated Brass Jam Nut - Part No. HC48916002

*Metal nut not intended for use wtih plastic housing.

Mounting Requirements............................Observe Free Zone

(See Figure 1)

Enclosure

Plastic Housing (HC48921-)................Assembly 101, 102

Glass Filled Polyester (PBT)

UV Stabilized for Outdoor Use

Nickel-Plated Sleeved Housing (HC48921-)......................

Assembly 151, 152

Brass Sleeve over Glass Filled Polyester (PBT)

UV Stabilized for Outdoor Use

NEMA 4X,13

CSA-LR12268

**E150 Specification

Hubbell Industrial Controls, Inc.

a subsidiary of Hubbell Incorporated

4301 Cheyenne Drive, Archdale, NC 27263

Telephone (336) 434-2800 Fax (336) 434-2803

http://www.hubbell-icd.com

Sales@hubbell-icd.com

Você também pode gostar

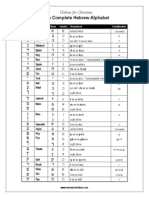

- Hebrew AlphabetDocumento1 páginaHebrew AlphabetJames GregoryAinda não há avaliações

- Infrared Gas AnalyzerDocumento2 páginasInfrared Gas AnalyzerSayak BoseAinda não há avaliações

- Temperature Controller: Slim! Easy Operation! CompactDocumento2 páginasTemperature Controller: Slim! Easy Operation! CompactSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- Temperature Controller: Slim! Easy Operation! CompactDocumento2 páginasTemperature Controller: Slim! Easy Operation! CompactSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- Infrared Gas AnalyzerDocumento2 páginasInfrared Gas AnalyzerSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- 4 DFGF 654Documento12 páginas4 DFGF 654Sayak BoseAinda não há avaliações

- For Gas Measurement in A Heat Treat Furnace: Type:ZFGDocumento6 páginasFor Gas Measurement in A Heat Treat Furnace: Type:ZFGSayak BoseAinda não há avaliações

- 7ML19981DF01Documento12 páginas7ML19981DF01Jose LunaAinda não há avaliações

- TDocumento1 páginaTSayak BoseAinda não há avaliações

- IP65 Polyester Enclosures for M12, M16, M20 ConnectionsDocumento1 páginaIP65 Polyester Enclosures for M12, M16, M20 ConnectionsSayak BoseAinda não há avaliações

- 4 RDocumento29 páginas4 RSayak BoseAinda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Telemecanique PDFDocumento60 páginasTelemecanique PDFMario PerezAinda não há avaliações

- 4 DFGF 654Documento12 páginas4 DFGF 654Sayak BoseAinda não há avaliações

- TDocumento1 páginaTSayak BoseAinda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 4 DFGF 654Documento12 páginas4 DFGF 654Sayak BoseAinda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Process Control & Instrumentation Part III P&I Symbols: B.T.S FEE (D. Bord Lycée ST Michel - 54) Sem 12Documento3 páginasProcess Control & Instrumentation Part III P&I Symbols: B.T.S FEE (D. Bord Lycée ST Michel - 54) Sem 12Sayak BoseAinda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Delay Before Turn On Circuit With A 555 Timer - Pdf-FlattenedDocumento6 páginasDelay Before Turn On Circuit With A 555 Timer - Pdf-FlattenedAmjad RizviAinda não há avaliações

- Micro Ohmmetre Soudure Aluminothermique CadweldDocumento11 páginasMicro Ohmmetre Soudure Aluminothermique CadweldIsmael Martinez AlvaradoAinda não há avaliações

- Full emDocumento435 páginasFull emgamelovereverbornAinda não há avaliações

- Monitor Extrusion Melt Pressure with PCP SensorDocumento4 páginasMonitor Extrusion Melt Pressure with PCP SensorshadiAinda não há avaliações

- Ina851 OpampDocumento52 páginasIna851 OpampKIMAinda não há avaliações

- MeasurIT Red Valve Pinch Series 5200E 0802Documento2 páginasMeasurIT Red Valve Pinch Series 5200E 0802cwiejkowskaAinda não há avaliações

- High Frequency ElectronicsDocumento2 páginasHigh Frequency ElectronicsdvsAinda não há avaliações

- The Human Eye and Colour VisionDocumento6 páginasThe Human Eye and Colour VisionChetan BhardwajAinda não há avaliações

- Introduction To SR and GR by Hans Stephani PDFDocumento418 páginasIntroduction To SR and GR by Hans Stephani PDFDvij252580% (5)

- Control System (Closed Loop and Open Loop)Documento10 páginasControl System (Closed Loop and Open Loop)Fhyras Ayatullah100% (1)

- Electrotherapy Therapic 2000: Model: TH1310Documento2 páginasElectrotherapy Therapic 2000: Model: TH1310RSUD SOLOKAinda não há avaliações

- Electricity Test AnswersDocumento3 páginasElectricity Test AnswersAdelaide MonyethabengAinda não há avaliações

- GriffithsSchiesser 2009 LinearandnonlinearwavesDocumento36 páginasGriffithsSchiesser 2009 LinearandnonlinearwavesiainguilliardAinda não há avaliações

- Darling Ton Synthesis RevisitedDocumento8 páginasDarling Ton Synthesis RevisitedPragash SangaranAinda não há avaliações

- Electical (2 Storey)Documento7 páginasElectical (2 Storey)jazmontzAinda não há avaliações

- Wireless Notice Board Full ReportDocumento38 páginasWireless Notice Board Full Reportobula863100% (11)

- On PLCC Carier CommunicationDocumento4 páginasOn PLCC Carier CommunicationDipak Kumar PatelAinda não há avaliações

- Semiconductor Manufacturing AustriamicrosystemsDocumento47 páginasSemiconductor Manufacturing Austriamicrosystemsmikeshinoda20110% (1)

- Poster, Dissertation and Oral PresentationDocumento27 páginasPoster, Dissertation and Oral PresentationThasleem ReyasAinda não há avaliações

- Visualizer ATR500 User ManualDocumento40 páginasVisualizer ATR500 User Manualgav oviAinda não há avaliações

- Department of Electrical Engineering: Government Engineering College, BharuchDocumento56 páginasDepartment of Electrical Engineering: Government Engineering College, BharuchPatel NeelAinda não há avaliações

- LBX 9014DS VTMDocumento2 páginasLBX 9014DS VTMAlex PereiraAinda não há avaliações

- Student Activity # 5: Mastery of X-Ray Tube Parts, Composition and FunctionDocumento8 páginasStudent Activity # 5: Mastery of X-Ray Tube Parts, Composition and FunctionJnn FrzAinda não há avaliações

- Product Data Sheet: Switch-Disconnector Compact INS400 - 400 A - 3 PolesDocumento2 páginasProduct Data Sheet: Switch-Disconnector Compact INS400 - 400 A - 3 PolesOki MahendraAinda não há avaliações

- 103 Servodyn Standalone Conectivity BoschDocumento130 páginas103 Servodyn Standalone Conectivity BoschOHW SERAinda não há avaliações

- Fan Coil Room Thermostat RDF510, RDF530 : en ZHDocumento2 páginasFan Coil Room Thermostat RDF510, RDF530 : en ZHمحمد عليAinda não há avaliações

- Statcon Company ProfileDocumento91 páginasStatcon Company ProfileArun das100% (1)

- Enraf-Nonius Radarmed 650 950 EN PDFDocumento3 páginasEnraf-Nonius Radarmed 650 950 EN PDFLipin SidhartaAinda não há avaliações

- Magnetron SpecificationsDocumento8 páginasMagnetron Specificationsapi-3721712Ainda não há avaliações

- New use for universal transducer adapterDocumento49 páginasNew use for universal transducer adapterJuanito Saavedra De La Cruz100% (1)