Escolar Documentos

Profissional Documentos

Cultura Documentos

Sulfaat Attack 1

Enviado por

RudanekDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sulfaat Attack 1

Enviado por

RudanekDireitos autorais:

Formatos disponíveis

SULPHATE ATTACK AND

CHLORIDE ION PENETRATION:

THEIR ROLE IN CONCRETE

DURABILITY

Concrete durability continues to be a subject of controversy among design professionals, specifiers, Government

instrumentalities, builders and developers, despite the significant changes made in the 90s to the Australian Concrete

Code. This paper addresses two aspects of concrete serviceability, which has been the subject of extensive recent

discussion and research: sulphate attack and chloride ion penetration.

The basic chemistry involved in each of these processes is outlined and differentiated and their effects on concrete and

reinforcing steel described. The paper reports the recent introduction of performance tests intended to provide a means

of assessing the contribution to resistance to these chemical actions of various cementitious binder options now

available for inclusion in concrete. Reference is made to the increasing significance of supplementary cementitious

materials in Australian concrete technology.

The paper relies for actual test data, showing relative performance of binder options, on experimental work carried out

by researchers at the CSIRO Division of Building, Construction, and Engineering. The paper includes reference to

other key factors contributing to concrete durability, in particular water/cement ratio, cover to steel, compaction and

curing.

INTRODUCTION

Up until the 1970s the durability of concrete was rarely

a concern to the community at large, design

professionals, builders, developers or Government

specifiers in particular. All this changed through into

the 80s with phrases such as concrete cancer

becoming common place in the media and society.

The response to what was to become a furore in some

areas in this country, and indeed in many other

countries, was much analysis and research into

occurrences and their causes. This led in Australia to

significant changes in the Concrete Structures Code (Ref

1) and review of site practices contributing to the

situation.

The emphasis in the upgrading of AS 3600 at that time

was to differentiate between exposure conditions

basically dependent upon proximity of particular

concrete structures to the sea, and/or the conditions to

which immersed or buried concrete structures or

elements might be exposed. Dependent upon these

conditions, the quality of the concrete was upgraded in

terms of strength; this was correlated with the amount of

concrete cover the reinforcing steel required, which was

increased in many structures.

The basis of these Code changes was summed up by Dr

George Somerville of the British Cement Association

(Ref 2) in the mid 80s with his Four Cs of Concrete

Durability:

Constituents of the concrete mix;

Cover to the reinforcing steel;

Compaction; and

Curing.

The key constituents of all concrete mixes in this context

(and most others) are the binder system and the amount

of water present, most importantly as they combine in

the calculation of water/binder ratio. The AS 3600

upgrade reflects the fact that in achieving higher

strengths the necessary water/binder ratio must be

reduced as shown in Figure 1. With that reduction in

water/binder ratio comes a reduction in permeability of

the concrete as shown in Figure 2. This then results in

enhancement of the resistance of the concrete to

physical penetration by all liquids no matter what they

might contain. As discussed later, good construction

practices, most significantly compaction and curing,

assist in enhancing resistance to liquid penetration. If

that liquid should contain sulphate salts and/or chloride

ions the chemistry of the binder system in the mix comes

into play. The resistance of concrete to such chemical

ANALYSIS

QCL Group Technical Note

Sulphate Attack and Chloride Ion Penetration: Their Role in Concrete Durability

Page 1

March 99

QCL GROUP

attack/penetration has been the subject of much research

in recent years.

in the concrete. These processes and factors have been

the subject of intense study across the world in recent

years and outcomes are reported widely, for example,

the CSIRO work relating to Australian studies (Ref 5).

From these studies it can be summarised that at a

concentration of about 0.2% sulphate content in the

ground water, concrete may suffer sulphate attack; that

magnesium sulphate can be more aggressive than

sodium; and that there are three key chemical reactions

between sulphate ions and hardened cement pastes.

These reactions are:

recrystallisation of ettringite;

formation of gypsum; and

decalcification of the main cementitious phase (C-SH).

Figure 1: Relationship between concrete strength and

W/C ratio at various ages (Ref 3).

In the presence of the calcium hydroxide formed in

cement paste, when the latter comes in contact with

sulphate ions, the alumina containing hydrates are

converted to the high sulphate form ettringite. These

ettringite crystals grow, expand, or swell by

mechanisms, which are still the subject of controversy

among researchers. While there is agreement that most

(but not all) ettringites will expand in this formation, the

exact causes are not agreed.

The formation of gypsum as a result of cation exchange

reactions is also capable of causing expansion but is

normally linked to loss of mass and strength (Ref 5).

CSIRO work shows that gypsum can cause considerable

local expansion and cracking especially when formed in

large masses.

The decalcification of the C-S-H has not received as

much discussion as the other two types of sulphate

attack, but can be just as important, particularly where

the sulphate solution is lower in pH (ie more acidic).

This particular reaction, with more gypsum formation,

leads to both strength loss and expansion. This is a

particular situation in which blended cements with

lower initial calcium/silica (C/S) ratios in the C-S-H gel

are shown to be less susceptible to this type of attack.

Figure 2:

Relationship between coefficient of

permeability and water/cement ratio (Ref 4).

THE CHEMISTRY OF

SULPHATE ATTACK

The end result of sulphate attack can be excessive

expansion, delamination, cracking, and loss of strength.

The degree to which this attack can occur depends on

water penetration (as referred to above), the sulphate

salt and its concentration and type (eg sodium or

magnesium), the means by which the salt develops in

the concrete (eg is it rising and drying causing

crystallisation), and the chemistry of the binder present

THE EFFECTS OF CHLORIDE

ION PENETRATION

Once again, the first step in considering this process is

the physical resistance to penetration into the concrete

of all liquids, by reducing the water/binder ratio, and

adequately consolidating and curing the concrete. By

contrast with the complex chemistry of the sulphate

attack process, chloride ion penetration is more physics

in action with ion bonding and reduction, if not

elimination, of these ions reaching the reinforcing steel.

While the subject of much debate, the chloride threshold

for corrosion is believed to be in the range 0.2 to 0.4%.

QCL Group Technical Note

Sulphate Attack and Chloride Ion Penetration: Their Role in Concrete Durability

Page 2

March 99

QCL GROUP

Once these ions reach the steel they depassivate the area

surrounding the steel and in the presence of air/water,

the steel commences to corrode. The products of

corrosion are greater in volume (up to 600%) than the

original steel resulting in an expansion and later spalling

of the concrete.

development, followed by introduction of performance

criteria in at least some areas. This process has not

been without controversy and even today debate

continues about some of these tests, none perhaps more

so than with regard to assessment of sulphate resistance

and chloride ion penetration.

However, in terms of the role of the binder, the

objective is to come up with options, which will prolong

the time to initiation of the corrosion and cracking. The

development of this process has been graphically

summarised in Figure 3 (Ref 6).

Resistance to Sulphate Attack

Figure 3: Lifetime model (from Tutti).

Corrosion is, in effect, an electrochemical process

necessitating the formation of corrosion cells, with the

formation of an anode and a cathode, either on one

piece of steel or between two dissimilar metals. The

anode reaction involving ionisation of metallic iron will

not go far unless there is electron flow at the cathode:

to achieve this there must be air and water at the surface

of the cathode.

Thus the importance of reducing permeability of the

concrete by mix design and construction practice

become vital factors in reducing chloride ion

penetration, steel corrosion and concrete cancer.

TEST METHODS FOR ASSESSMENT

OF PERFORMANCE

Over the last decade there have been increasing

pressures from the community and the construction

industry to change standard Codes and specifications

from a prescription to a performance base. This for

example is manifest in the Building Code of Australia.

The challenge for specification writers and users in this

context in relation to concrete has been the lack of

applicable and appropriate performance tests. This has

resulted in extensive research and subsequent test

Review of world practice shows that there are two

current standards in operation; in the order in which

they were developed they came from the American

Society for Testing and Materials (ASTM) (Ref 7)

followed in 1996 by Standards Australia (Ref 8). It

must be noted immediately that both these tests

relate to mortar and not concrete and therefore focus

on the binder system. While the basic concepts of

the two test methods are similar there are some

differences. For example, while they are both

expansion

assessment

tests,

the

sample

configurations, sand types, mortar mix designs, and

curing regimes are different, as are the performance

assessment criteria.

The overall objective with these tests is to assess the

relative sulphate resistance of various binder options

from traditional (basically low C3A content) sulphate

resistant cements, to the various blended cements

which are now found to have excellent properties in

this particular aspect of concrete technology. At this

point in time the Australian test is being widely used

in rating various binder options although as provided

for in the Preface to the test method some

refinements of the procedure may be agreed after its

first two years of operation. At the present time the

key issue seems to be the duration of the test

(presently 16 weeks), the permeability of the mortar,

and the degree to which a longer test will make it

easier to differentiate the binder options.

Chloride Ion Penetration

At this time there is no applicable Australian

Standard test. There are two American tests in use,

with two very widely different approaches, each

subject to controversy. Each test has had a range of

variations to the procedure suggested by researchers.

From ASTM (Ref 9) was developed a rapid chloride

permeability test with an electric charge being used

to accelerate chloride ion penetration through a thin

section of concrete.

The American Association of State Highway and

Transportation Officials (AASHTO) (Ref 10)

developed the other approach. This involves a

chloride ponding test of much longer duration.

Each of these procedures has their advocates and

also their critics. For example, the ASTM test is the

QCL Group Technical Note

Sulphate Attack and Chloride Ion Penetration: Their Role in Concrete Durability

Page 3

March 99

QCL GROUP

subject of much debate (Refs 11 & 12). The key

issues here appear to be associated with pore

chemistry and heat generated. The end result is of

concern, in particular with regard to the test data

obtained when there are materials such as fly ash,

slag or silica fume in the mix. In the meantime,

some organisations in Australia, such as CSIRO,

have developed their own test methods. The

chloride ion data reported in this Paper from CSIRO

are based primarily on chloride profiles obtained on

test specimens submerged in salt water.

AUSTRALIAN USE OF

SUPPLEMENTARY CEMENTITIOUS

MATERIALS (SCMs)

Fly ash and finely ground granulated iron blast furnace

slag have been used in concrete in Australia since the

mid 60s (Ref 13) and currently 800,000 to 1,000,000

tonnes of each are being used in concrete around

Australia. Their use varies with geographic area,

primarily dependent upon the location of the black coal

fired power stations and steelworks in relation to the

markets. The State of Queensland is well endowed with

quality fly ash sources over much of the State but

because it must rely on steelworks in New South Wales

for slag, there is only limited use of this material outside

the south eastern corner of the State.

Condensed silica fume, a by-product of the manufacture

of silicon metal or ferro silicon alloy, is manufactured

from only one source in Australia (south of Perth).

Much has been imported from countries such as

Norway. It is a very fine powder which is a powerful

pozzolan but carries with it a significant cost premium.

The use of SCMs to reduce the amount of clinker per

tonne of cement used can thus significantly reduce

greenhouse gas emissions from the cement industry.

Indeed the cement industrys target of reducing

greenhouse gas emissions by the year 2005 to 17%

below those in 1989 would be extremely difficult if not

impossible to achieve without the ever increasing use of

SCMs.

DATA

DERIVED ON RELATIVE

PERFORMANCE

In this decade, there has been intensive activity in a

wide spectrum of laboratories throughout Australian

assessing the relative performance of various binder

options in resisting sulphate attack and chloride ion

penetration.

Data derived in CSIRO research is reported below and

indicates the particular attractions of using fly ash and

slag in enhancing these critical aspects of concrete

durability.

Sulphate Resistance Test Data

The effect of fly ash on mortar specimens prepared

as per AS 2350.14 and cured in what quickly

becomes an alkaline environment are shown in

Figure 4. Introduction of 20% fly ash immediately

and significantly reduces expansion. Indeed, this

addition rate is marginally better than both 30 and

40% fly ash, but in any event, from 16 weeks, the fly

ash mixes far outperform the GP cement mix.

The use of these SCMs has been found to impart a

range of benefits to plastic and/or hardened properties

of concrete, provided they are used properly.

The key to the successful use of these materials is

knowing the technology of both the materials

themselves and of the cements with which they are

being associated. Mix designs, proportions of binder

components, curing needs, relative rates of strength gain

are all factors which must be remembered when using

SCMs to provide the many benefits which can be

derived.

These include the well-established

improvements in workability and pumping, reduction in

generation of heat, and control of alkali silica reaction.

To these must now be added improvement in resistance

to chemical attack.

While consuming what are otherwise industrial wastes

in a value-adding approach, the use of SCMs makes

another significant contribution to the community. The

high temperature cement clinker manufacturing process

and subsequent cement milling processes can produce

up to one tonne of greenhouse gas per tonne of clinker.

Figure 4: Effect of fly ash on expansion - AS 2350.14

(ultimate alkaline environment - pH 12).

In Figure 5, similar relative results are obtained with

fly ash using the ASTM C1012 method.

QCL Group Technical Note

Sulphate Attack and Chloride Ion Penetration: Their Role in Concrete Durability

Page 4

March 99

QCL GROUP

Chloride Ion Penetration Data

As indicated earlier, the CSIRO research team

working in this area has preferred to use an

absorption based laboratory test and measured

chloride profile with time. At the same time they

have been carrying out field studies on chloride

profiles and the data obtained are set out below.

Figure 5: Effect of fly ash on expansion - ASTM

C1012 (ultimate alkaline environment - pH 12).

In Figure 6, ASTM C1012 data is shown using a

range of levels of slag replacement. However, while

the benefits at ages up to 20 weeks are similar to

those obtained with fly ash, at ages after 30 weeks

the 40 and 60% slag replacement specimens start to

expand. This highlights that key area of controversy

with AS 2350.14. A strong case is being argued at

present to extend the length of test from the present

16 weeks. In applying the Australian Standard data

it should be remembered that the specification limit

for sulphate expansion is 900 microstrain after those

16 weeks.

Figure 6: Effect of slag on expansion - ASTM C1012

(ultimate alkaline environment - pH 12).

Figure 7: Chloride profiles - Laboratory results: 32

MPa concretes, 80 mm slump, 3 days moist curing,

6 months of half immersion (tidal zone exposure) in

ocean water.

Figures 7 and 8 show chloride concentrations at

different depths on 32 and 60 MPa concretes with

ranges of fly ash contents.

The significant

improvement generated by inclusion of fly ash in

both mixes is clearly apparent.

Figure 8: Chloride profiles - Laboratory results: 60

QCL Group Technical Note

Sulphate Attack and Chloride Ion Penetration: Their Role in Concrete Durability

Page 5

March 99

QCL GROUP

MPa concretes, 100 mm slump, 3 days moist curing,

6 months of half immersion (tidal zone exposure) in

ocean water.

Further CSIRO data relating to 2 year ocean water

immersion studies on concretes with total binder

contents of 280 and 420 kg/m3 are shown in Figures

11 and 12. Here the benefits of slag replacements

are shown, while fly ash field performance data in a

concrete seawall over 30 years old are shown in

Figure 13. Further data on fly ash effects in a 2 year

tidal zone test is shown in Figure 14.

Figure 9: Chloride profiles - Laboratory results: 32

MPa concretes, 80 mm slump, 3 days moist curing,

6 months of half immersion (tidal zone exposure) in

ocean water.

The corresponding data for 60% slag replacement of

GP cement in 32 and 60 MPa concrete mixes are

shown in Figures 9 and 10. However, it is most

noticeable that in the higher strength, lower

water/binder ratio (and therefore lower permeability)

mixes, there is less difference between the OPC and

fly ash and slag modified concrete.

Figure 11: Chloride profiles after 2 years immersion

in ocean water - binder content 280 kg/m3.

Figure 12: Chloride profiles after 2 years immersion

in ocean water - binder content 420 kg/m3.

Figure 10: Chloride profiles - Laboratory results: 60

MPa concretes, 100 mm slump, 3 days moist curing,

6 months of half immersion (tidal zone exposure) in

ocean water.

QCL Group Technical Note

Sulphate Attack and Chloride Ion Penetration: Their Role in Concrete Durability

Page 6

March 99

QCL GROUP

compaction and curing. The achievement of dense

impermeable concrete, no matter what the binder

system, is fundamental to maximising concrete

durability. Elimination of voids by good consolidation

and full hydration of the binder to achieve a high quality

concrete structure and least possible permeability by

curing are objectives well known to concrete

practitioners but all too rarely achieved in practice.

Optimum use of SCMs to achieve maximum resistance

to sulphate attack or chloride ion penetration typically

uses mix proportions which can be vulnerable to

premature termination (if started at all) of curing.

CONCLUSION

Figure 13:

Influence of fly ash on chloride

penetration - field data (concrete seawall + 30

years).

These test data, and those from many other

researchers, highlight the benefits to be obtained in

terms of reducing sulphate attack and chloride ion

penetration from incorporating SCMs in concrete

exposed to these aggressive conditions. However, in

order to minimise such attacks, attention must be

given to ensuring good construction practices.

Resistance to sulphate attack and chloride ion

penetration are two of the latest areas of durability

concern to specifiers and users of concrete.

Traditionally they were addressed by specifying

cements of particular chemical composition, which were

not always compatible (eg low C3A for sulphate

resistance, a higher C3A for marine chloride resistance).

The advent of quality assured SCMs capable of being

evaluated using a range of performance tests is

providing a sound base for revisiting the specification of

concrete to achieve these particular durability

objectives. While economic constraints may place

some limits on the range of SCMs available in different

areas of Queensland, data is being obtained which

indicate that there is great potential for the use of SCMs

to address these and other challenges in achieving

durable concrete structures. Based on data reported

from the CSIRO research project above, it would appear

that in specifying concrete to resist sulphate attack or

chloride ion penetration, a suitable approach would be

as follows:

1.

2.

fc of 40 MPa (to achieve a maximum

water/cement ratio of 0.45 to reduce permeability);

and

incorporation of at least 20% fly ash or 60% slag

(either of which would also be beneficial in

reducing any tendency for alkali silica reaction).

The technological developments reported in this paper,

while significant in themselves, do not obviate the

ongoing challenges to the concrete construction industry

of the world, in particular ensuring full compaction of

concrete in situ and provision of adequate curing.

Figure 14: Chloride profiles - Field results: 40 MPa

concretes, 80 mm slump, 3 days of moist curing, 2

years of marine tidal zone exposure.

REFERENCES

1.

CONSTRUCTION PRACTICES

2.

The key issues in all forms of concrete construction, but

in particular where durability is a concern most notably

when exposed to aggressive environments, are

Standards Australia, AS 3600-1994 Concrete

Structures, 154 pp.

Somerville G, The Design Life of Concrete

Structures, The Structural Engineer, Vol 64A, No

2, February 1986, pp 60-71.

QCL Group Technical Note

Sulphate Attack and Chloride Ion Penetration: Their Role in Concrete Durability

Page 7

March 99

QCL GROUP

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

QCL Test Data, Water / Cement Ratio versus 28

Day Compressive Strength, Darra Type GP

Cement, 1997.

Bureau of Reclamation, Concrete Manual, Eighth

Edition, 1975, p 37.

Trinh Cao, Bucea L, and Ferguson O, Sulphate

Resistance of Cementitious Materials Mechanisms, Deterioration Processes, Testing

and Influence of Binder, Proc. Concrete 97,

Adelaide, May 1997, Concrete Institute of

Australia, pp 263-268.

Tutti K, Corrosion of Steel in Concrete, CBI

Research Report 4.82, Swedish Cement and

Concrete Research Institute, Stockholm, 1982, 469

pp.

American Society for Testing and Materials

ASTM C1012-89, Standard Test Method for

Length Change of Hydraulic-Cement Mortars

Exposed to a Sulfate Solution, 1989, pp 482-486.

Standards Australia, AS 2350 Methods of Testing

Portland and Blended Cements, Part 14, 1996,

Determination of Sulfate Resistance of Portland

and Blended Cement Mortars.

American Society for Testing and Materials

ASTM C1202-91, Standard Test Method for

Electrical Indication of Concretes Ability to

Resist Chloride Ion Penetration, Feb 1992.

American Association of State Highway and

Transportation Officials, Method of Test for

Resistance of Concrete to Chloride Ion

Penetration, AASHTO T259-80, 1980.

Trinh Cao, Meck E and Morris H, A Review of the

ASTM C1202 Standard Test and its Applicability

in the Assessment of Concretes Resistance to

Chloride Ion Penetration, Concrete in Australia,

October 1996, pp 23-26.

Collins F, ASTM C1202 Tests, Concrete in

Australia, December 1996-March 1997, pp 4-5.

Ryan WG, Review of the Australian Experience,

Proc. Concrete Workshop 88, International

Workshop on the Use of Fly Ash, Slag, Silica

Fume and Other Siliceous Materials in Concrete,

Sydney, July.

Adjunct Professor "Mick" Ryan

QCL Group Technical Note

Sulphate Attack and Chloride Ion Penetration: Their Role in Concrete Durability

Page 8

March 99

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- BPG Replacing A Consumer Unit - DomesticDocumento10 páginasBPG Replacing A Consumer Unit - DomesticRudanek100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- NPTEL - Tranmission Tower Design - Facotrs of Safety and LoadDocumento70 páginasNPTEL - Tranmission Tower Design - Facotrs of Safety and LoadLakshmi Narayanan100% (3)

- Best Practice Guide 2 Issue 3Documento20 páginasBest Practice Guide 2 Issue 3RudanekAinda não há avaliações

- Best Practice Guide 5Documento24 páginasBest Practice Guide 5RudanekAinda não há avaliações

- Best Practice Guide 4Documento20 páginasBest Practice Guide 4Stephen BridgesAinda não há avaliações

- The Requisites Nuclear Medicine 4th (Elsevier, 2014)Documento456 páginasThe Requisites Nuclear Medicine 4th (Elsevier, 2014)Sabrina Moraru100% (4)

- Guidance On RCDsDocumento6 páginasGuidance On RCDsRudanekAinda não há avaliações

- Quality Control Answer Key PINK PACOPDocumento40 páginasQuality Control Answer Key PINK PACOPKharel Ezra de Guzman67% (3)

- Best Practice Guide 6Documento12 páginasBest Practice Guide 6RudanekAinda não há avaliações

- Science G9 Ext Educator-14.1.2020 WebDocumento355 páginasScience G9 Ext Educator-14.1.2020 WebNadya AnggrainiAinda não há avaliações

- The History Behind The Discovery of Benzene RingsDocumento1 páginaThe History Behind The Discovery of Benzene Ringsekadarma55100% (5)

- LightningDocumento108 páginasLightningRudanekAinda não há avaliações

- Application of Electrochemical Techniques and Simulation in CorrosionDocumento25 páginasApplication of Electrochemical Techniques and Simulation in CorrosionRudanek100% (1)

- Atmospheric Corrosion: G O LloydDocumento8 páginasAtmospheric Corrosion: G O LloydKaliya PerumalAinda não há avaliações

- 03 Work Power & EnergyDocumento16 páginas03 Work Power & EnergyRudanekAinda não há avaliações

- Best Practice Guide 3Documento20 páginasBest Practice Guide 3RudanekAinda não há avaliações

- Best Electrical Practice GuideDocumento12 páginasBest Electrical Practice GuidePRINCE MUFAAinda não há avaliações

- Best Practice Guide 9Documento16 páginasBest Practice Guide 9RudanekAinda não há avaliações

- Best Practice Guide 8 Issue 2Documento12 páginasBest Practice Guide 8 Issue 2RudanekAinda não há avaliações

- IP-65 RatingsDocumento2 páginasIP-65 RatingsRudanekAinda não há avaliações

- Pocke Guide 6 Rev 2-03-08Documento2 páginasPocke Guide 6 Rev 2-03-08RudanekAinda não há avaliações

- Pocket Guide16 IP CODESDocumento2 páginasPocket Guide16 IP CODESRudanekAinda não há avaliações

- Pocke Guide 6 Rev 2-03-08Documento2 páginasPocke Guide 6 Rev 2-03-08RudanekAinda não há avaliações

- NIE-EIC Electrical Installations in Thatch 2013Documento5 páginasNIE-EIC Electrical Installations in Thatch 2013RudanekAinda não há avaliações

- Part P GuideDocumento2 páginasPart P GuideRudanekAinda não há avaliações

- Pocket Guide 10 (Fire Alarms in Dwellings)Documento2 páginasPocket Guide 10 (Fire Alarms in Dwellings)RudanekAinda não há avaliações

- 5 Structural ArrangementDocumento21 páginas5 Structural Arrangementfandhiejavanov2009Ainda não há avaliações

- Wind OHLxDocumento81 páginasWind OHLxRudanekAinda não há avaliações

- P1 34 227Documento5 páginasP1 34 227RudanekAinda não há avaliações

- EddyDocumento6 páginasEddyRudanekAinda não há avaliações

- EddyDocumento6 páginasEddyRudanekAinda não há avaliações

- P1 34 227Documento5 páginasP1 34 227RudanekAinda não há avaliações

- Material Properties of SteelDocumento33 páginasMaterial Properties of Steelpinku_thakkarAinda não há avaliações

- 08 024Documento40 páginas08 024Hoang QuyAinda não há avaliações

- PetDocumento8 páginasPetTsetsaAinda não há avaliações

- Corrosion-Resistant-Pumps - Ib116-C - Bom InoxDocumento9 páginasCorrosion-Resistant-Pumps - Ib116-C - Bom InoxKhang TrầnAinda não há avaliações

- B1 Distrubutory DesignDocumento17 páginasB1 Distrubutory DesignNeil AgshikarAinda não há avaliações

- 2294E2-0000-DE10-SPC-0001 Rev 0 PDFDocumento11 páginas2294E2-0000-DE10-SPC-0001 Rev 0 PDFamirAinda não há avaliações

- Anib 46 3-4Documento491 páginasAnib 46 3-4Nicholas AlmslawyAinda não há avaliações

- Livro Shape Memory AlloysDocumento218 páginasLivro Shape Memory AlloysJefferson SegundoAinda não há avaliações

- Making SaltsDocumento24 páginasMaking SaltsFatema KhatunAinda não há avaliações

- Basic Environmental Engineering PDFDocumento18 páginasBasic Environmental Engineering PDFvenkatesh100% (1)

- Liquid Ring Vacuum Pump: LPH 55312, LPH 55316, LPH 55320Documento12 páginasLiquid Ring Vacuum Pump: LPH 55312, LPH 55316, LPH 55320Edu CordonAinda não há avaliações

- Chemistry Viva QuestionsDocumento3 páginasChemistry Viva QuestionsShivamAinda não há avaliações

- 0 - Relative Atomic MassDocumento7 páginas0 - Relative Atomic MassMohamedAinda não há avaliações

- Cbiescss 09Documento7 páginasCbiescss 09Ayush BeheraAinda não há avaliações

- 12 SM Chemistry English 2019 20 PDFDocumento359 páginas12 SM Chemistry English 2019 20 PDFMahi JaiswalAinda não há avaliações

- LNG Comes of AgeDocumento3 páginasLNG Comes of AgeRamon Velasco StollAinda não há avaliações

- Light and Shadow FormationDocumento13 páginasLight and Shadow FormationNikil J.PAinda não há avaliações

- Isolation of Acetylsalicylic AcidDocumento4 páginasIsolation of Acetylsalicylic AcidPrince Pulvera100% (1)

- Carbohydrate Polymers: Feng Jiang, You-Lo HsiehDocumento9 páginasCarbohydrate Polymers: Feng Jiang, You-Lo HsiehAaron WongAinda não há avaliações

- CAPE® Chemistry Free ResourcesDocumento4 páginasCAPE® Chemistry Free Resourcesabbey4623Ainda não há avaliações

- UOP 539 Refinery Gas Analyzer #1201Documento4 páginasUOP 539 Refinery Gas Analyzer #1201Afzal ImamAinda não há avaliações

- Plastics Engineering: Process Equipment and Piping Systems For Optimum Reliability and Cost-EffectivenessDocumento9 páginasPlastics Engineering: Process Equipment and Piping Systems For Optimum Reliability and Cost-EffectivenesskoushkiAinda não há avaliações

- Fischer-Tropsch: IncorporationDocumento6 páginasFischer-Tropsch: Incorporationamirhosein saqafiAinda não há avaliações

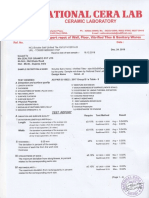

- 12 - National Cera Lab Test Report - 600x1200 MM - 24.12.2019Documento3 páginas12 - National Cera Lab Test Report - 600x1200 MM - 24.12.2019Shaikh MohammedHanifSultanAinda não há avaliações

- Ionpro LXDocumento2 páginasIonpro LXAlon CarlosAinda não há avaliações

- Sanosil S010 - EngDocumento11 páginasSanosil S010 - EngSophie TranAinda não há avaliações

- Flown Ex Simulation EnvironmentDocumento12 páginasFlown Ex Simulation EnvironmentSanthosh LingappaAinda não há avaliações