Escolar Documentos

Profissional Documentos

Cultura Documentos

Sample 8D Report

Enviado por

LndIngenieriaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sample 8D Report

Enviado por

LndIngenieriaDireitos autorais:

Formatos disponíveis

Qualittssicherungsvereinbarung mit Produktionsmateriallieferanten

Quality Assurance Agreement with Production Material Suppliers

8D-Report

Vorgang / Concern title

Example:

Axial run-out of precision ring n.o.k.

Reklamationsnummer / Complaint no.

Schaeffler

214999999

Reklamationsdatum /

Complaint opening date

Lieferant / Supplier 12345

2011-08-01

Name Lieferant / Supplier

Sample supplier

Produktionsstandort / Production site

Sample city

Revision 8D-Report

04

Zeichnungsnummer / Drawing no.

F-123456789

Schaeffler Werk(e) / Plant(s)

Herzogenaurach, Hirschaid

Zeichnungsstand / Drawing revision

AC

Liefermenge / Quantity delivered

100

Teilebezeichnung / Part name

Precision ring 20

Beanstandete Menge / Quantity claimed

12

1 Team

Name

Meyer F.

Mueller S.

Huber A.

Revision Datum / Date

2011-08-17

2 Problembeschreibung / Problem description

Abt./ Dept.

Quality

Production

R&D

Teamleiter/ Champion

Boss G.

Q-Mgr.

Kontakt/ Contact (Email, Phone)

meyer@sample.com

mueller@sample.com

huber@sample.com

Axial run-out from face to inner bore n.o.k.

Nominal: 0,05

Ist: bis zu 0,1

boss@sample.com

3 Sofortmanahme(n) / Corrective action(s)

1. Check of stock: No parts on stock at present

2. Check customer stock: In the Herzogenaurach plant another lot with the same defect was found. In the Hirschaid plant

no parts were on stock.

3. Check of stock in transit to customer: At present there are no parts on the way to the customer

4. The stock parts of similar type 18, 19, 21 were checked also for the claimed defect. No defects were found on these.

Einfhrungsdatum /

Implementation date

2011-08-01

2011-08-02

2011-08-01

2011-08-01

Amendment: After return shipment the complained delivery was sorted 100%. During the sorting another 5 defective parts

were found. We kindly ask you to adjust the ppm-relevant quantity in your ERP-system (actual defective quantity = 17).

4 Fehlerursache(n) / Root cause(s)

Fehler tritt erstmalig auf / First occurrence defect

Wiederholfehler/ Repetitive defect

Root cause analysis for creation of the defect (3x5 Why method applied):

The root cause was detected as "wear of the ballscrew spindle" in the face-grinding machine. The wear at the spindle head caused a play in the

spindle guidance. When wearing the grinding wheel the grinding pressure will rise and - in combination with the increasing play in the spindle

guidance- lead to deviations in the axial run-out. A planned maintenance and check of this play was not part of the maintenance plan.

Root cause analysis for non-detection of the defect (3x5 Why method applied):

The defect was not detected during quality inspection (operator self inspection) because the control plan defined the measurement of the axial runout in the machine chuck directly (simulation of end customer application). During analysis we found out that the parts measured directly in the

chuck (thus an elastic deformation of the part) reach the required value for the run-out. When measuring the same parts out of the machine some

do not reach the required value.

Also the point of time for the inspection was not defined and so not all produced parts showed the deviations. The root cause for this is the lower

grinding pressure after dressing of the grinding wheel (after dressing the deviation of the run-out is at the lowest).

5 Geplante Abstellmanahme(n) / Chosen corrective action(s)

5a Wirksamkeitsprfung mit Methode/

Verification check by method of

Corrective actions regarding creation of the defect::

1.Add check of spindle play in the maintenance plan

2. Check if regular moving of the spindle is leading to lower/ no wear of the spindle

3. Conduct clamping tests to identify the effect of the clamping force, if necessary adjustment

Corrective actions regarding detection of the defect:

4. Update control plan: Point of time for check changed to "before dressing" (biggest influence of the

clamping pressure)

5. Purchase tapered gauges for measurement of axial run-out outside the machine

6. Update of control plan: Add additional check of axial run-out with tapered gauges

Check of maintenance plan at machine

Tech. discussion machine manufacturer

Empirical with different clamp. forces

Check of revision in ERP-system

Empirical check, series of measurement

Check of revision in ERP-system

6 Eingefhrte Abstellmanahme(n) / Implemented corrective action(s)

Einfhrungsdatum /

Implementation date

Corrective actions regarding creation of the defect::

1. Check of spindle play added to the maintenance plan

2. Movement of the spindle head added to the maintenance plan

3. Process-FMEA no. M20-12345 updated, new revision = 03; clamping force added

2011-08-10

2011-08-10

2011-08-17

Corrective actions regarding detection of the defect:

4. Control plan updated: Point of time for check changed to "before dressing" (biggest influence of the clamping pressure)

5. Tapered gauges purchased

6. Control plan updated: Additional check of axial run-out with new tapered gauges outside the machine chuck.

2011-08-12

2011-08-17

2011-08-17

S 296001 Teil 4 Anlage 1

S 296001 Part 4 Appendix 1

Seite 1 von 2

Page 1 of 2

Ausgabe: August 2011

Revision: August 2011

Qualittssicherungsvereinbarung mit Produktionsmateriallieferanten

Quality Assurance Agreement with Production Material Suppliers

7 Manahme(n) gegen Wiederholfehler / Action(s) to prevent recurrence

Fr jede Manahme ist ein Nachweis beizulegen/ For each action below a documented evidence must be attached

Einfhrungsdatum /

Implementation date

Update of Design FMEA no.

Update of Process FMEA no. M20-12345-V08

Update of Control plan no. PP001-M20, Revision 03

Update von Arbeitsanweisung(en) / of work instruction(s) no. Maintenance plan machine no. 0815

8 Teamerfolg / Congratulations

2011-08-17

2011-08-17

2011-08-10

.Name Ersteller / Author 8D-Report

.Abschlussdatum Lieferant /

Meyer Fritz

2011-08-17

.8D-Report akzeptiert/ accepted

.Abschluss / Closure Schaeffler

Closing date supplier

Unterschrift / Signature Teamleiter/ Champion

Entscheid / Decision Schaeffler

Ja / Yes

Nein/ No: Update erforderlich bis/

required until

2011-08-18

Schwendtner Ralf

Datum / Date

Name / Unterschrift/ Signature

Anlagen, Fotos, Nachweise / Attachments, photos, evidences:

1. Process-FMEA: Extract of the modified chapter

2. Control plan no. M20-12345-V03: Extract from the modified control plan, tapered gauges added

3. Extract of the modified maintenance plan machine no.0815

4. Photo of new testing method with tapered gauge

S 296001 Teil 4 Anlage 1

S 296001 Part 4 Appendix 1

5. Extract from the 3x5 Why analysis

Seite 2 von 2

Page 2 of 2

Ausgabe: August 2011

Revision: August 2011

Você também pode gostar

- TVS MOTOR COMPANY Audit Date Check Sheet for Significant Production Trial Run (SPTRDocumento5 páginasTVS MOTOR COMPANY Audit Date Check Sheet for Significant Production Trial Run (SPTRSAKTHIVEL AAinda não há avaliações

- Ok Part NG: (Vendor Non-Conformance Report)Documento2 páginasOk Part NG: (Vendor Non-Conformance Report)BeLlCoNtInEnT MAinda não há avaliações

- Auto Part Manufacturing ProcessDocumento4 páginasAuto Part Manufacturing ProcessKuldeep BohraAinda não há avaliações

- Change Management Matrix for Vendor Updates in May 2022Documento1 páginaChange Management Matrix for Vendor Updates in May 2022nitin rathoreAinda não há avaliações

- Control PlanDocumento6 páginasControl PlanFahmy Khoerul HudaAinda não há avaliações

- Part Inspection Standard (May 2013)Documento9 páginasPart Inspection Standard (May 2013)san moedano100% (1)

- PPAP Process Checklist / Sign Off Sheet InstructionsDocumento7 páginasPPAP Process Checklist / Sign Off Sheet InstructionsSharmad TamhaneAinda não há avaliações

- Writing Iap Smarten Up in Maths Age 7 8Documento38 páginasWriting Iap Smarten Up in Maths Age 7 8lphoune100% (1)

- Sample 8D ReportDocumento2 páginasSample 8D Reportajaynegi7167% (3)

- Product Design & Development ProcessDocumento22 páginasProduct Design & Development ProcessMullapudi Bharath KumarAinda não há avaliações

- FMEADocumento6 páginasFMEANavnath TamhaneAinda não há avaliações

- F Qa 48 Ppap Readiness Sheet For 0.7lDocumento4 páginasF Qa 48 Ppap Readiness Sheet For 0.7lVikas RaiAinda não há avaliações

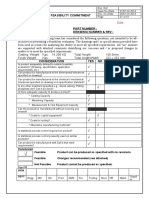

- 02-Team Feasibility CommittmentDocumento1 página02-Team Feasibility CommittmentVinod SaleAinda não há avaliações

- Purpose:: Procedure Manual FifoDocumento3 páginasPurpose:: Procedure Manual FifoartiAinda não há avaliações

- Exedy India Ltd. APQP Process DocumentsDocumento3 páginasExedy India Ltd. APQP Process Documentssam1hi5Ainda não há avaliações

- LH-630 服務手冊Documento378 páginasLH-630 服務手冊LndIngenieria50% (2)

- ASTM D790-15e2 Standard Test Methods For Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials.Documento12 páginasASTM D790-15e2 Standard Test Methods For Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials.ironfaceAinda não há avaliações

- Printout Final IATF 16949 2016 - Key ChangesDocumento89 páginasPrintout Final IATF 16949 2016 - Key ChangesSudhagar100% (3)

- Customer Complaint Analysis - 8D Report: Header To: CC: From: Date: SubjectDocumento3 páginasCustomer Complaint Analysis - 8D Report: Header To: CC: From: Date: SubjectEbitra Hasiholan50% (2)

- Centac Vibration Procedure PDFDocumento20 páginasCentac Vibration Procedure PDFrashm006ranjan100% (1)

- What Is Apqp & PpapDocumento5 páginasWhat Is Apqp & PpapprafakeAinda não há avaliações

- 8D CAPA ProcessDocumento17 páginas8D CAPA ProcessdesurkarbAinda não há avaliações

- Template Seat Heat Peeland Stick Heater Control PlanpostedDocumento6 páginasTemplate Seat Heat Peeland Stick Heater Control PlanpostedvfuntanillaAinda não há avaliações

- RBAC Supplier Packaging Approval FormDocumento1 páginaRBAC Supplier Packaging Approval Formcong daAinda não há avaliações

- PPAP Check ListDocumento4 páginasPPAP Check ListSameer SaxenaAinda não há avaliações

- PROJECT:0.654.0303.00-CMR162-3 DATE: February/2015 APPROVED BY: Leman Özgüler/Quality Manager Revision: 0 Total Page: 1/1Documento1 páginaPROJECT:0.654.0303.00-CMR162-3 DATE: February/2015 APPROVED BY: Leman Özgüler/Quality Manager Revision: 0 Total Page: 1/1Metin DemirciogluAinda não há avaliações

- Quality System Procedure For Change Point ControlDocumento3 páginasQuality System Procedure For Change Point Controlrajesh sharmaAinda não há avaliações

- New CQI-9 4th EditionDocumento6 páginasNew CQI-9 4th EditionDFLQMS50% (2)

- MSA-Gage RRDocumento9 páginasMSA-Gage RRbmyertekinAinda não há avaliações

- Exercise - FANUCDocumento175 páginasExercise - FANUCsubbu.v1987100% (1)

- Indian Standard: Sampling Inspection ProceduresDocumento24 páginasIndian Standard: Sampling Inspection ProceduresarunrathikaAinda não há avaliações

- FMEA - SOD Training - UnibodyDocumento34 páginasFMEA - SOD Training - UnibodyMartin BoianiAinda não há avaliações

- Codex Stan 233-1969 Codex Sampling Plans For Prepackaged Foods (Aql 6.5)Documento9 páginasCodex Stan 233-1969 Codex Sampling Plans For Prepackaged Foods (Aql 6.5)BagaskaraAinda não há avaliações

- 1CQI-9 4th Ed - FINAL Protected June 8 Table ADocumento5 páginas1CQI-9 4th Ed - FINAL Protected June 8 Table AvudinhnambrAinda não há avaliações

- PPAP 101 - What You Need To KnowDocumento9 páginasPPAP 101 - What You Need To KnowQGFAinda não há avaliações

- Your Company Name 1680995-101 1680995-101 Bushing, Guide Slot E 2/1/2003 N/A 12/23/2005 0 John Smith Amy Millimen Jane Doe Bob Miller NameDocumento20 páginasYour Company Name 1680995-101 1680995-101 Bushing, Guide Slot E 2/1/2003 N/A 12/23/2005 0 John Smith Amy Millimen Jane Doe Bob Miller Namekaran11deshmukhAinda não há avaliações

- PPAP - 4th Edition - Course MaterialDocumento18 páginasPPAP - 4th Edition - Course MaterialMy Dad My WorldAinda não há avaliações

- Is 14416 1996Documento20 páginasIs 14416 1996kaustavAinda não há avaliações

- Advance Planning Ensures Timely PPAP ApprovalDocumento19 páginasAdvance Planning Ensures Timely PPAP ApprovalmoezAinda não há avaliações

- g8d FormatDocumento1 páginag8d FormatMadhavan RamAinda não há avaliações

- Stability Study Report PDFDocumento5 páginasStability Study Report PDFDaniel ShawulAinda não há avaliações

- Malati Founders PVT Ltd. Risk Analysis For Rework Rev No Rev DateDocumento1 páginaMalati Founders PVT Ltd. Risk Analysis For Rework Rev No Rev DateDhananjay PatilAinda não há avaliações

- PSWDocumento2 páginasPSWLinda G. CordovaAinda não há avaliações

- Destructive R&RDocumento19 páginasDestructive R&RKalyan SrinivasAinda não há avaliações

- Ashok LeylandDocumento2 páginasAshok Leylandindu296Ainda não há avaliações

- AIAG CQI-9 TUS RequirementsDocumento10 páginasAIAG CQI-9 TUS RequirementsNethajiAinda não há avaliações

- Core Tools Forms V5dDocumento119 páginasCore Tools Forms V5dIng. Alberto AguilarAinda não há avaliações

- APQPDocumento2 páginasAPQPjitenderbawalia0% (1)

- APQP and PPAP ExplainedDocumento3 páginasAPQP and PPAP ExplainedignaunaqAinda não há avaliações

- Format 11 - Appearance Approval ReportDocumento1 páginaFormat 11 - Appearance Approval ReportvijayAinda não há avaliações

- Standard STD 105-0007: Special CharacteristicsDocumento11 páginasStandard STD 105-0007: Special CharacteristicsKrunal PandyaAinda não há avaliações

- DFMEADocumento1 páginaDFMEAPrabh GarchaAinda não há avaliações

- Part Submission Warrant SummaryDocumento4 páginasPart Submission Warrant Summaryaperezpi26606Ainda não há avaliações

- Design FMEA and Quality ChecklistsDocumento16 páginasDesign FMEA and Quality ChecklistsDevendra GandhiAinda não há avaliações

- D 5628 - 96 R01 - Rdu2mjg - PDFDocumento10 páginasD 5628 - 96 R01 - Rdu2mjg - PDFJuan Pablo ApazaAinda não há avaliações

- Samples Inspection ReportDocumento5 páginasSamples Inspection ReportArun GuptaAinda não há avaliações

- Master Form VDADocumento4 páginasMaster Form VDAapi-3856433Ainda não há avaliações

- Keerthi Engineering: Initial Production Part TagDocumento2 páginasKeerthi Engineering: Initial Production Part Tagkeerthi EngineeringAinda não há avaliações

- New Enquiry Feasibility Review FormatDocumento3 páginasNew Enquiry Feasibility Review FormatUlhas KavathekarAinda não há avaliações

- Sae J51-2015Documento11 páginasSae J51-2015NastyAinda não há avaliações

- Updates Dec09 AIAG FMEA-Ranking-TablesDocumento3 páginasUpdates Dec09 AIAG FMEA-Ranking-TablesSuresh Velu100% (1)

- Apqp Advanced Product Quality PlanningDocumento27 páginasApqp Advanced Product Quality PlanningRajesh KumarAinda não há avaliações

- Mizenboushi Method (未然防止法) : Good Design, Good Discussion, Good DissectionDocumento45 páginasMizenboushi Method (未然防止法) : Good Design, Good Discussion, Good DissectionXin Li100% (1)

- Lean Manufacturin and Six SegmaDocumento9 páginasLean Manufacturin and Six Segmashahid_ali21Ainda não há avaliações

- Chains 01Documento3 páginasChains 01LndIngenieriaAinda não há avaliações

- IngenieriaDocumento1 páginaIngenieriaLndIngenieriaAinda não há avaliações

- Ijetae 0714 118 PDFDocumento8 páginasIjetae 0714 118 PDFLndIngenieriaAinda não há avaliações

- Data SheetDocumento7 páginasData SheetLndIngenieriaAinda não há avaliações

- New England Machinery: Machining Centers Hori+Ontal MA+AK Powercenter H-15 Price: 13950 USDDocumento2 páginasNew England Machinery: Machining Centers Hori+Ontal MA+AK Powercenter H-15 Price: 13950 USDLndIngenieriaAinda não há avaliações

- Proximity Sensor Accessories: General Purpose Plastic Mounting BracketsDocumento22 páginasProximity Sensor Accessories: General Purpose Plastic Mounting BracketsLndIngenieriaAinda não há avaliações

- Advanced High SteelDocumento4 páginasAdvanced High SteelLndIngenieriaAinda não há avaliações

- ElectrotecniaDocumento8 páginasElectrotecniaLndIngenieriaAinda não há avaliações

- WM New FeaturesDocumento12 páginasWM New FeaturesTina SloanAinda não há avaliações

- Kopr 07enDocumento18 páginasKopr 07enLndIngenieriaAinda não há avaliações

- Dsls 17022013 SSQ SetupDocumento11 páginasDsls 17022013 SSQ SetupLuisbibianoAinda não há avaliações

- OFT Simulation Software Package for Hydraulics, Pneumatics, Electrics and Logic TrainingDocumento4 páginasOFT Simulation Software Package for Hydraulics, Pneumatics, Electrics and Logic TrainingLndIngenieriaAinda não há avaliações

- T2 Mini SeriesDocumento16 páginasT2 Mini SeriesLndIngenieriaAinda não há avaliações

- Robotics Final Report 2014Documento18 páginasRobotics Final Report 2014LndIngenieriaAinda não há avaliações

- Denford G and M Programming For CNC MillDocumento98 páginasDenford G and M Programming For CNC MillBiljana Đurin MarkovićAinda não há avaliações

- Transformada de Fourier PDFDocumento5 páginasTransformada de Fourier PDFLndIngenieriaAinda não há avaliações

- FAG Detector III Quickstart Manual enDocumento8 páginasFAG Detector III Quickstart Manual enMark_86Ainda não há avaliações

- Logopress3 News 2016 SP0-xDocumento21 páginasLogopress3 News 2016 SP0-xLndIngenieriaAinda não há avaliações

- Untitled 24Documento2 páginasUntitled 24LndIngenieriaAinda não há avaliações

- EJ Stokes 1 PDFDocumento6 páginasEJ Stokes 1 PDFJennifer PaceAinda não há avaliações

- Dsls 17022013 SSQ SetupDocumento11 páginasDsls 17022013 SSQ SetupLuisbibianoAinda não há avaliações

- F ToolDocumento25 páginasF ToolAlvaro Ramos BlacuttAinda não há avaliações

- Folleto Q1Documento2 páginasFolleto Q1LndIngenieriaAinda não há avaliações

- Logopress3 BLANK Technical OverviewDocumento2 páginasLogopress3 BLANK Technical OverviewLndIngenieriaAinda não há avaliações

- Conclusions and RecommendationsDocumento2 páginasConclusions and RecommendationsLndIngenieriaAinda não há avaliações

- Sheet Metal Forming Simulation-Closing The Design Loop: 5. LS-DYNA Anwenderforum, Ulm 2006 Metallumformung IDocumento10 páginasSheet Metal Forming Simulation-Closing The Design Loop: 5. LS-DYNA Anwenderforum, Ulm 2006 Metallumformung ILndIngenieriaAinda não há avaliações

- Fault Report - Inventory Cpf1 Vs Caño LimomDocumento37 páginasFault Report - Inventory Cpf1 Vs Caño LimomJessica RiveraAinda não há avaliações

- Impact of GIC On Power TransformersDocumento141 páginasImpact of GIC On Power TransformersAkash Verma100% (1)

- Splunk Skills Assessment-UpdatedDocumento14 páginasSplunk Skills Assessment-Updatedtsegay.csAinda não há avaliações

- Https WWW - Joinpaknavy.gov - PK Web Checkstatus Rollno 410219516621 PDFDocumento1 páginaHttps WWW - Joinpaknavy.gov - PK Web Checkstatus Rollno 410219516621 PDFZainab KhatoonAinda não há avaliações

- Iygb Gce: Mathematics MP2 Advanced LevelDocumento7 páginasIygb Gce: Mathematics MP2 Advanced Levelsingh cos tanAinda não há avaliações

- Answer Any Three of The Following Questions: Madanapalle Institute of Technology & Science MadanapalleDocumento1 páginaAnswer Any Three of The Following Questions: Madanapalle Institute of Technology & Science MadanapallePraveen KumarAinda não há avaliações

- Final Project Regenerative BrakingDocumento6 páginasFinal Project Regenerative Brakingdims irifiyinAinda não há avaliações

- Weld CheckDocumento6 páginasWeld CheckArnold c ElverAinda não há avaliações

- CFG Grammar: Context Free Grammar BasicsDocumento34 páginasCFG Grammar: Context Free Grammar BasicsEd MolloAinda não há avaliações

- Tools - For - Problem - Solving (Appendix B), R.K. Malik's Newton Classes PDFDocumento48 páginasTools - For - Problem - Solving (Appendix B), R.K. Malik's Newton Classes PDFMoindavis DavisAinda não há avaliações

- Chapter 6 Basic Heat TransferDocumento7 páginasChapter 6 Basic Heat TransferGabo MarquezAinda não há avaliações

- Solutions For Statistics and Probability For EngineersDocumento6 páginasSolutions For Statistics and Probability For EngineersPHAinda não há avaliações

- Design of LQR Controller For The Inverted Pendulum: Lili Wan, Juan Lei, Hongxia WuDocumento5 páginasDesign of LQR Controller For The Inverted Pendulum: Lili Wan, Juan Lei, Hongxia WuVictor PassosAinda não há avaliações

- OM5510 05 (Positioner)Documento16 páginasOM5510 05 (Positioner)JayeshJayarajanAinda não há avaliações

- Mediburn 30Documento35 páginasMediburn 30Vsee EnkoAinda não há avaliações

- Thermocouple Wire Reference Guide: WWW - Omega.co - Uk +44 (0) 161 777 6611 WWW - Omega.co - Uk +44 (0) 161 777 6611Documento1 páginaThermocouple Wire Reference Guide: WWW - Omega.co - Uk +44 (0) 161 777 6611 WWW - Omega.co - Uk +44 (0) 161 777 6611Mohamed MaltiAinda não há avaliações

- Report On The Quantitative Techniques in BusinessDocumento10 páginasReport On The Quantitative Techniques in BusinessBaron FrancisAinda não há avaliações

- TM View Software User - S ManualDocumento190 páginasTM View Software User - S ManualLuis SánchezAinda não há avaliações

- Tutorial - Lecture 3 SolutionsDocumento10 páginasTutorial - Lecture 3 SolutionsBastián Olfos MárquezAinda não há avaliações

- Topic 8-Mean Square Estimation-Wiener and Kalman FilteringDocumento73 páginasTopic 8-Mean Square Estimation-Wiener and Kalman FilteringHamza MahmoodAinda não há avaliações

- Brake SystemDocumento19 páginasBrake SystemSudarshan NepalAinda não há avaliações

- 11.numerical DifferentiationDocumento20 páginas11.numerical DifferentiationAbdulselam AbdurahmanAinda não há avaliações

- Requirements Elicitation and AnalysisDocumento74 páginasRequirements Elicitation and AnalysisSadam GebiAinda não há avaliações

- Chapter 13: The Electronic Spectra of ComplexesDocumento42 páginasChapter 13: The Electronic Spectra of ComplexesAmalia AnggreiniAinda não há avaliações

- Toraiz SP-16Documento89 páginasToraiz SP-16ScappinAinda não há avaliações

- Unit 10 - Week 9: Assignment 9Documento4 páginasUnit 10 - Week 9: Assignment 9shubhamAinda não há avaliações

- 006 PVC & CPVC Schedule 80 Fittings, Unions Tank Adapters, Expansion Joints & Saddles PDFDocumento92 páginas006 PVC & CPVC Schedule 80 Fittings, Unions Tank Adapters, Expansion Joints & Saddles PDFnicacio_89507470Ainda não há avaliações

- 12.6 Perform An Activity - Measuring The Critical Angle For Various MediaDocumento2 páginas12.6 Perform An Activity - Measuring The Critical Angle For Various MediaRajeshri SoniAinda não há avaliações