Escolar Documentos

Profissional Documentos

Cultura Documentos

010-MS For Grouting PDF

Enviado por

Köksal PatanDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

010-MS For Grouting PDF

Enviado por

Köksal PatanDireitos autorais:

Formatos disponíveis

Pearl GTL

Project

Shell Project No: HP-3000-QAT

Project Document Number: T- 4.234.076

Purchase Order Number:

2MH127

Tag/Item Number(s):

N/A

Unit(s):

ASU

PCWBS:

LINDE ENGINEERING

Contractor Project No :

Project Rev.: C

Page 2 of 30

5887

QATAR SHELL GTL PROJECT (PEARL)

C2 AIR SEPARATION UNITS CONSTRUCTION

01.12.08

Ready For construction

SB

EO

AG

RFC

24.08.08

Issued for Company Comments

SB

EO

AG

ICC

09.01.08

Ready For construction

IU

UA/IO

MC/ZG

RFC

01.10.07

Issued for Company Comments

MS

MC

ZG

ICC

Issued for Review

MS

MC

ZG

IFR

Issued for Internal Review

MS

MC

ZG

IIR

GAMA

Rev.

No.

Project

Rev

No.

Date

Prepared Checked Approved

By

By

By

ORIGINATOR

Description

Status

Document Title:

METHOD STATEMENT FOR GROUTING

LINDE ENGINEERING AG

Document No.

Contractor

Gama Qatar Co. W. L. L.

LOC470

GAM

MTS

CIV

GTL

010

Org.

Code

Doc.

Type

Disc.

Code

Geogr.

Area

Seq.

No

Rev.

No

Project Document Number: T-4.234.076

Vendor Code

Rev No: C

Q A T A R

Doc. Title

GAM-MTS-CIV-GTL-010 Rev. F

Method Statement for Grouting

Date

01.12.2008

TABLE OF CONTENTS

1.

PURPOSE _____________________________________________________________________ 5

2.

SCOPE ________________________________________________________________________ 5

3.

HSSE _________________________________________________________________________ 5

4.

REFERENCES _________________________________________________________________ 6

5.

DEFINITIONS _________________________________________________________________ 6

6.

METHOD OF EXECUTION _____________________________________________________ 7

7.

QUALITY ASSURANCE _______________________________________________________ 11

8.

ATTACHMENTS ______________________________________________________________ 11

T-4.234.076 Rev. C

Page 4 of 30

Q A T A R

Doc. Title

GAM-MTS-CIV-GTL-010 Rev. F

Method Statement for Grouting

Date

01.12.2008

1. PURPOSE

This document describes the methods proposed to be used for the non-shrink grouting works that will be

carried out as part of ASU Construction Works of QSGTL Pearl Plant in Ras Laffan Industrial City of Qatar.

2. SCOPE

Grouting facilities will take place on the dedicated place(s) as per approved layout area. The construction &

erection activities will be carried out by Gama.

3. HSSE

All works will be in compliance with the State of Qatar laws and regulations, Ras Laffan Industrial City and

international standards/codes, and Company and Contractor requirements and instructions.

All personnel will go through Gama, Contractor and Company Safety Induction courses as well as other

trainings as identified by their supervisor. Please see Document Number GTL-GM-001-A-5635 for details.

A Job Safety Analysis (JSA) specific for this work including a Risk Assessment, is prepared as per Gama

procedure GTL-GM-001-A-5626 and is attached herein. Such JSA addresses the hazards associated with

each task within the scope of this Method Statement and introduces the controls that will be implemented to

reduce the associated risks to acceptable levels. The JSA will be used by the Site Supervisor as the basis of

his TSTI / TSTO and Toolbox Talks.

All personnel will have PPE required for their specific tasks in addition to the minimum PPE (coveralls, safety

goggles, safety shoes, high-visibility vests, gloves) at site at all times as required.

In the event of a release, fire or explosion, employees will secure their area and evacuate to the nearest

muster point. Once all employees are evacuated the supervisor will conduct a headcount to verify all

employees are out of harms way. The supervision will report this to Contractor. Emergency Contact numbers

for Company, Contractor and Gama will be posted onsite.

All vehicles and equipment used for the subject work will be inspected and certified as required.

Drivers and operators will be competent and will have attended all required trainings set forth in project

procedures and specifications.

T-4.234.076 Rev. C

Page 5 of 30

Q A T A R

Doc. Title

GAM-MTS-CIV-GTL-010 Rev. F

Method Statement for Grouting

Date

01.12.2008

4. REFERENCES

Qatar Construction Standard

DEP 34.19.20.31-Gen

Reinforced Concrete Foundations and Structures

T-13.376.358

Amendments and/or Supplements to Reinforced Concrete Foundations and

Structures

ASTM C109

Compressive Strength of Hydraulic-Cement Mortars

ASTM C156

Test Methods for Water Retention by Concrete curing Material

ASTM C531

Linear Shrinkage and Coefficient of Thermal Expansion of ChemicalResistant Mortars and Monolithic

ASTM C579

Compressive Strength of Chemical-Resistant Mortars, Grout, and Monolithic

Surfacing

ASTM C827

Change in Height of Early Ages of Cylindrical specimens from Cementations

Mixtures

ASTM C1107

Standard Specification for Packaged Dry Hydraulic Cement Grout (Nonshrink)

DEP 31.29.00.10

Installation of Rotating Equipment (Amendments Supplements to API

RP 686

BS 1881 Part 116 1983 Standard for Grout Compressive Strength.

5. DEFINITIONS

Company

: QSGTL and/or its PMC

Contractor

: Linde Engineering AG

Subcontractor or Gama

: Gama Qatar Company Co. W. L. L.

Contract

: QSGTL Pearl Plant C2 ASU Construction Works

QCR

: Quality Control Record

QCP

: Quality Control Procedure

QA/QC

: Quality Assurance / Quality Control

ASTM

: American Society for Testing and Materials

ACI

: American Concrete Institute

T-4.234.076 Rev. C

Page 6 of 30

Q A T A R

Doc. Title

GAM-MTS-CIV-GTL-010 Rev. F

Method Statement for Grouting

Date

01.12.2008

6. METHOD OF EXECUTION

6.1.

EQUIPMENT AND MANPOWER

Equipment

-

Low speed hand Mixer

Water Tanker (10 Tons)

Grout Mixer for manual Mixing

: Manufactures Recommendation

: 1 (if needed)

: 4 (if needed)

Manpower

-

Civil Foreman

HSSE Officer

QA/QC Technician

Carpenter

Grouting Personnel

Helper

Operator

Truck Driver

6.2.

:1

:1

:1

:3

:4

:8

:1

:1

GENERAL SURFACE PREPARATION & APPLICATION

Foundations for Rotating / Reciprocating Equipment:

Surface preparation of foundations for rotating/reciprocating equipment will be done as per

paragraph 4 of DEP 31.29.00.10-Gen., Installation of Rotating Equipment.

Special attention will be paid to the extent of the grouting. As mentioned in DEP 31.29.00.10Gen., the foundation will be sized so that grouting can be extended to 50 mm beyond the

base/sole plate or the shims.

If the size of concrete foundation is greater than the base/sole plate, formwork will be used to

match the 50 mm.

Foundations for Steel Structures and Stationary Equipment:

The surface of the foundation under the base plate of the object to be grouted will be chipped

and brushed to remove the weak upper layer of the concrete, damaged concrete and any oilsoaked concrete areas. Prior to grouting, loose concrete or dust will be removed, preferably by

compressed air.

Before grouting commences the concrete surfaces will be soaked with clean water for 24 hours,

unless the grout Manufacturer specifies otherwise.

T-4.234.076 Rev. C

Page 7 of 30

Q A T A R

Doc. Title

GAM-MTS-CIV-GTL-010 Rev. F

Method Statement for Grouting

Date

01.12.2008

Grouting of Steel Structures and Stationary Equipment:

The installation of the grout will be carefully supervised.

Special attention will be paid to prevent distortion of the item being grouted.

The placing of sand-cement grout mortar will commence not later than 15 minutes after

completion of the mixing. No grout mortar will be used that has not been placed after 30 minutes

from completion of mixing.

Under no circumstances will re-mixing or knocking up be allowed.

Proprietary grouts will be mixed, placed and cured in strict accordance with the grout

Manufacturer's instructions.

Vent holes should be drilled in base plates to avoid air pockets.

The grout will fill all voids between the base plate or sole plate and the foundation, and will have

full surface contact.

Cement-based grout will be kept moist during the first 7 days after placing and will be protected

from sunshine and drying out by protective covering as per DEP 34.19.20.31 Clause 10.3.2.

After hardening, wedges will be removed and the resulting voids filled with grout.

The grout thickness will be minimum 25 mm but will not exceed 50 mm.

Grouting will be extended 50 mm beyond the base/ sole plate if the concrete foundation is

greater than the base/sole plate. Form work will be used to match the 50 mm.

The edge of the grout will be provided with a chamfer of approximately 25 mm.

The Gout is regarded as Non- shrink if its volume is not less than the Initial Volume, after

Hardening for 28 days. During this period the test specimens shall have been completely

protected against drying, evaporating, Carbonation and exposure to temperatures outside the

range 230 C 30 C as per the DEP 34.19.20.31 Clause 10.1.2.

6.3.

MATERIALS AND USAGE

Only materials approved by Contractor will be used. Fosroc - Conbextra BB 80 OR BASFMaster Flow 928 T)

6.3.1) FOSROC CONBEXTRA BB 80:

It is a non-shrink cementitious bearing grouting (dry powder) material will be used Flanged

Lighting Columns, Heavy stanchion bases and base plates for reciprocating pumps, anchor

bolts, Steel Structures etc

The grouting material is packed in 25 Kg air tight plastic bags used up to the section thickness

up to 100mm. For the thicker sections more than 100mm, the clean washed 5-10mm silt free

aggregate will be mixed (Max.Ratio1:1) with the grouting powder as per the manufacturer

recommendations.

Storage mixing & placing and curing shall be in accordance with the manufacturer

recommendations.

T-4.234.076 Rev. C

Page 8 of 30

Q A T A R

Doc. Title

GAM-MTS-CIV-GTL-010 Rev. F

Method Statement for Grouting

Date

01.12.2008

The grouting material will be mixed with a measured amount of clean water at WATER:

POWDER ratio of 0.15 at a maximum temperature of 250C.Water Temperature will be Monitor

by use of Thermometer.

The Compressive Strength of the grout must be 45 N/mm2 @ 24 Hours, 60 N/mm2 @ 3 days,

70N/mm2 @ 7 days and 85 N/mm2 @ 28 Days as per manufacturers data sheet

recommendations and as per BS 1881 Part 116 1983.

6.3.1.1)

PRE-SOAKING

Bolt holes and fixing pockets must be blown clean of any dirt or debris.

For a minimum of 24 hours prior to pouring, the area of cleaned substrate should be soaking

with wet Hessian with fresh water to minimize localized absorption and to assist in the free flow

of the grout.

Immediately before grouting, any free water should be removed. Particular care should be taken

to blow out all holes and pockets.

Forms will be waxed or use of Silica as necessary to prevent sticking and leak proof as

Conbextra BB 80 is a free flow grout. An intensive care will be paid to ensure that the grout

cannot squeeze out from below and around the forms during placing and setting.

Ensure the Form work is secure and watertight to prevent movement and the area should be

free from excessive vibration. Shut down all machineries until the grout has hardened.

6.3.1.2)

MIXING & PLACING

For the best result, the grouting material shall be mixed with mechanical mixer for larger

quantity. Dont use a colloidal impeller mixer for mixing.

To produce a fluid grout, add 3.75 Lit. of water (below 250C) will be to a 25Kg bag of Conbextra

BB 80.The water should be accurately measured into the mixer. Slowly add the total content of

the Conbextra BB 80 powder and mix continuously for 5 minutes on high shear / speed until the

smooth and even consistency is obtained.

Place the grout within 15 minutes of mixing to attain full strength.

Conbextra BB 80 can be placed in thickness up to 100 mm in a single pour.

Continuous grouting operation will be takes place until the process is finished.

The mixed grout shall be poured only from one side of the void to eliminate the entrapment of

air or surplus pre-soaking water.

6.3.1.3)

CURING

On completion of the grouting operation, exposed areas should be thoroughly cured. This should

be done by the use of continuous application of water with Hessian up to 7 days as per DEP

34.19.20.31 Gen Clause 10.3.2.

The Grouted area shall be covered with Wet Hessian with Polythene double Layer and/or as per

DEP 34.19.20.31(Gen) Amendments plus Manufacture recommendation.

T-4.234.076 Rev. C

Page 9 of 30

Q A T A R

Doc. Title

GAM-MTS-CIV-GTL-010 Rev. F

Method Statement for Grouting

Date

01.12.2008

6.3.2) BASF - MASTER FLOW 928T

1)

APPLICATION PROCEDURE :

a) All procedure is same as above mentioned in Conbextra BB 80.

b) The area shall be maintained as damp without water before grouting.

2)

MIXING, PLACING & CURING

a) Same as above mentioned in the Conbextra BB 80.

b) The mixing and placing process will be done at less than 300C. In cold weather, the

temperature will be minimum 100C maintained as per manufacturers recommendations.

c) Immediately after Master Flow 928T grout is placed, cover all exposed grout with clean

damp Hessian, and keep moist until grout is firm enough to accept a curing membrane.

d) Curing will be done as per DEP 34.19.20.31- Clause 10.3.2, for 7 days with wet Hessian

Covered with double layer polythene sheet.

For mixing of grouting material, follow the manufacturers recommended table:

Flow

Application

Consistency

Flow Table

Water(Lit) / 25 Kg Bag

C

o

Min

Max

n

e

Grouting Machinery

Fluid

----

20 - 30

4.5

5.0

Grouting Machinery

Flowable

130

3.5

4.0

Plastic

60

3.0

3.5

Dry-pack

2.0

2.5

Bedding Pre-cast

Filling Tie-bar voids

Note: (1) If grout shoulders require finishing work, this should be carried out prior to application of

the curing membrane.

(2) Under no Circumstances should Master flow 928T be re-tempered by the later addition

of water.

(3) For the Compressive strength of Grout, the details in the Manufacture data sheet also

Followed.

T-4.234.076 Rev. C

Page 10 of 30

Q A T A R

Doc. Title

GAM-MTS-CIV-GTL-010 Rev. F

Method Statement for Grouting

Date

01.12.2008

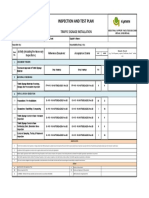

7. QUALITY ASSURANCE

A Quality Assurance System will be operated conforming to related standards. Controls and checks will be

established and documented through relevant T- 4.234.545 (QCP), T- 4.234.576 (ITP) and QCR s.

8. ATTACHMENTS

8.1.

JOB SAFETY ANALYSIS

8.2.

MATERIAL DATA SHEET FOR MASTER FLOW

928 T & CONBEXTRA BB 80

8.3. DEP 34.19.20.31 GEN PAGE NO : 20 , 21( GROUTING)

T-4.234.076 Rev. C

Page 11 of 30

Q A T A R

JOB SAFETY ANALYSIS FORM

JSA For: T-4.234.076

NEW

Job being analysed: Grouting

Department/Section doing JSA: HSSE & Construction

Normal Approvals:

JSA by:

Page No: 1 of 8

REVISED

Name

JSA Members:

Job Performers:

Signature

Date

Job Supervisor:

Additional Approvals (Determined by Job Supervisor in correlation with Linde HSSE Manager).

Name

Signature

Discipline Superindent (Linde)

Date

General job requirements / Common Personal

Protective Equipment.

1. The following Personal Protective

Equipment shall be worn:

Approved coveralls, safety goggles, safety

helmet, safety shoes and gloves.

HSSE Representative (Linde)

2.Permit To Work.

OTHERS (List Below):

Approval required for hazardous work detailed in the Linde Work Permit Procedure.

Changing conditions and emergency procedures

Stop work. Switch off equipment.Supervisor directs personnel to nearest and safest muster point considering wind direction. Supervisor counts all employees. Missing

employees are reported to Linde HSSE Dept. When all clear is given, check with Linde HSSE before returning to work.

LINDE EMERGENCY TELEPHONE NO.

HSSE MANAGER:

Pearl HOT LINE :

JOB SAFETY ANALYSIS / RISK ASSESSMENT

FOR T-4.234.076

Q A T A R

HAZARDS / POTENTIAL

ITEM

ACTIVITY

CONSEQUENCES

1

Unloading rebar from 1.1 Falling or dropped loads.

delivery truck with

crane to rebar stock

1.2 Overturning of machine.

area.

Initial Risk

RISK

P C

RANK

C

HIGH

MED

SCOPE :

GROUTING WORKS

Residual Risk

1.1.1

1.1.2

1.1.3

1.2.1

1.2.2

1.2.3

MAIN

CONTROLS

Third party crane inspections.

Daily crane checks.

Competent riggers.

SWL properly displayed.

Qualified and 3rd party certified

operators.

Set up crane on solid level ground

1.1.1.1

1.2.1.1

1.2.1.2

1.3

Improper rigging.

1.3.1

1.3.2

C

1.4

HIGH

Damaged, worn or

unusable rigging

equipment and/or gears.

1.3.3

1.4.1

1.4.2

C

HIGH

1.4.3

1.5

Manually transferring 2.1

of stock rebars, to

rebar cutting

machine.

People struck by

suspended or swinging

load.

1.5.1

B

MED

Manual handling.

1.5.2

1.5.3

1.5.4

2.1.1

2.1.2

LOW

2.1.3

2.1.4

2.1.5

Competency check for all riggers.

Rigging supervisor to monitor rigger

performance.

Ensure that the riggers are

competent and Third Party certified.

1.3.1.1

1.3.1.2

Quarterly inspection of lifting gear by 1.4.1.1

Third party and color coded.

Removal and isolation of all worn or

damaged lifting equipment.

Rigging gear shall be color coded as 1.4.1.2

per Contractor procedure.

Barricade and secured area and

1.5.1.1

install safety sign boards.

Use tag lines to control load.

DO NOT lift load over people.

Do not allow people to walk under the

load.

Worker to wear appropriate gloves. 2.1.1.1

Break the load into manageable

portions.

Lift with your legs not your back.

Use the buddy system, Get help.

Provide pictorial sign boards with

correct lifting position.

ADDITIONAL

CONTROLS

Supervisor/foreman shall ensure

that the TSTI is properly executed

at the work front and hazards

Supervisor/foreman shall ensure

that the TSTI is properly executed

at the work front and hazards

discussed.

Ensure daily check is performed

prior to each use.

Supervisor/foreman shall ensure

that the TSTI is properly executed

at the work front and hazards

discussed.

Rigging operations shall be

performed by competent and

qualified riggers.

Supervisor/foreman shall ensure

that the TSTI is properly executed

at the work front and hazards

discussed.

Ensure that all rigging gear are

has 3rd party certificates.

Supervisor/foreman shall ensure

that the TSTI is properly executed

at the work front and hazards

discussed.

LOW

LOW

LOW

LOW

LOW

LOW

Provision for lifting aids when

practical.

JOB SAFETY ANALYSIS / RISK ASSESSMENT

FOR T-4.234.076

Q A T A R

ITEM

ACTIVITY

Measuring and

cutting rebar to

length.

HAZARDS / POTENTIAL

CONSEQUENCES

2.2 Debris and materials

causing slip, trips and

falls.

3.1

Initial Risk

RISK

P C

RANK

LOW

2.2.3

3.1.1

LOW

Manual handling of rebar.

3.2.1

B

3.3

Hand and finger injuries.

B

3.2

Residual Risk

2.2.1

2.2.2

B

LOW

Rebar cutting machine.

3.3.1

3.3.2

B

3.4

LOW

Defective equipment.

3.3.3

3.4.1

LOW

3.4.2

3.4.3

Transferring cut

rebars from cutting

machine to rebar

bending machine.

4.1

Manual handling.

4.1.1

4.1.2

C

4.2

Debris causing slip trips

and falls.

LOW

LOW

SCOPE :

GROUTING WORKS

4.1.3

4.1.4

4.2.1

4.2.2

MAIN

CONTROLS

Adequate stacking of materials.

Regular housekeeping practices and

removal of trash and unnecessary

items.

Maintain access and walk paths.

Wear approved PPE, safety goggles,

safety helmet, safety shoes, gloves,

high-vis vests

Approved quality hand gloves,

available in a full range of sizes to

ensure proper fit to maintain

dexterity.

Competent operators, trained on the 3.3.1.1

machine they operate.

Ensure that the guards are properly

installed and are being used.

3.3.1.2

Post near machine the

manufacturers safe operating

procedures in different languages.

3.3.1.3

Daily inspection of equipment by

operator prior to use according to

manufacturers recommendations.

Current Contractor inspection

certificate.

Monthly equipment inspection and

color code.

Worker to wear appropriate gloves.

Break the load into manageable

portions.

Lift with your legs not your back.

Use the buddy system, Get help.

Adequate stacking of materials.

Regular housekeeping practices and

removal of trash and unnecessary

items.

3.4.1.1

4.1.1.1

ADDITIONAL

CONTROLS

Post the manufacturer safe

operating manual near the

machine and HSSE office.

Supervisor/foreman shall ensure

that the TSTI is properly executed

at the work front and hazards

discussed.

Minimum 4 persons-Team leader

with 3 helpers.

Proper maintenance performed by

maintenance department

according to manufacturers

recommendations.

LOW

LOW

LOW

LOW

LOW

LOW

LOW

Provision for lifting aids when

practical.

JOB SAFETY ANALYSIS / RISK ASSESSMENT

FOR T-4.234.076

Q A T A R

ITEM

5

ACTIVITY

Setting up rebar

bending machine to

perform desired

bend.

HAZARDS / POTENTIAL

CONSEQUENCES

5.1 Hand and finger injuries.

Initial Risk

RISK

P C

RANK

5.1.1

LOW

5.1.2

5.1.3

Measuring and

bending rebar.

6.1

Hand, finger and foot

injuries.

6.1.1

6.1.2

6.1.3

D

MED

6.1.4

6.1.5

6.2

6.3

Dropped rebar from

height.

Unauthorized people in

rebar bending area or

radius.

6.2.1

D

MED

LOW

6.2.2

6.3.1

SCOPE :

GROUTING WORKS

MAIN

CONTROLS

Follow manufacturers

5.1.1.1

recommendations for properly and

safely setting up rebar bending

machine.

Control of hazardous energy, LO/TO. 5.1.1.2

de-energize equipment" before

making adjustments to moving parts. 5.1.1.3

Wear approved hand gloves for the

task.

Install stops on the edge of

workbench.

Approved hand gloves, available in a

full range of sizes to ensure proper fit

to maintain dexterity.

Follow manufacturers

recommendations for operating and

adjusting machine for rebar size.

Competent and properly trained

operator.

Keep away hand & finger from

moving parts.

6.1.1.1

6.1.1.2

6.1.1.3

6.1.1.4

6.1.1.5

Install appropriate stops on the edge 6.2.1.1

of workbench.

Ensure adequate number of workers

to control the operation.

Barricade and secure area and post

safety sign boards Authorized

Employees Only.

Residual Risk

ADDITIONAL

P C

R

CONTROLS

Supervisor/foreman shall ensure

that the TSTI is properly executed

at the work front and hazards

discussed.

Minimize number of people at work

B 1

LOW

area of bending/cutting machine.

Mark the work area.

Supervisor/foreman shall ensure

that the TSTI is properly executed

at the work front and hazards

discussed.

Ensure that equipment manual is

available near the machine.

Post names of authorized

operators near the machine.

Minimum 3 persons-Team leader

with 2 helpers.

Post the rebar bending machine

safe operating procedures and

safety precautions at the job site.

Supervisor/foreman shall ensure

that the TSTI is properly executed

at the work front and hazards

discussed.

LOW

LOW

LOW

JOB SAFETY ANALYSIS / RISK ASSESSMENT

FOR T-4.234.076

Q A T A R

ITEM

ACTIVITY

HAZARDS / POTENTIAL

CONSEQUENCES

6.4 Improper use of rebar

bending machine.

Initial Risk

RISK

P C

RANK

Residual Risk

6.4.1

6.4.2

B

Assembly of

reinforcement bars.

7.1

LOW

Use of tie-wire causing

hand, face or eye injury.

6.4.3

7.1.1

7.1.2

C

7.2

MED

Dropped or collapse of bar

structure or stand.

7.1.3

7.1.4

7.2.1

7.2.2

C

SCOPE :

GROUTING WORKS

MAIN

CONTROLS

Competent and properly trained

operator.

Follow manufacturers

recommendations for operating and

adjusting machine for rebar size.

Post near machine the

manufacturers safe operating

procedures in the appropriate

languages

6.4.1.1

6.4.2.1

6.4.3.1

Use proper tie wire techniques.

7.1.1.1

Wear approved PPE, safety glasses,

safety helmet and safety foot wear.

Appropriate hand tools.

Appropriate hand gloves.

7.1.1.2

Use approved stands to support

7.2.1.1

rebar load.

Visually inspect daily support stands.

LOW

7.2.1.2

Surface preparation

for construction

joints.

8.1

8.1.1

Use of hand held power

tool, grinding buffing and

air compressor.

8.1.2

B

LOW

8.1.3

8.2

Electrocution and burns.

8.2.1

LOW

8.2.2

8.2.3

Ensure that guards are kept in place

and not removed.

Do not wear loose clothing or jewelry.

Long hair shall be pulled back and

kept from dangling.

PPE ( hearing protection as

appropriate).

GFCI and using the correct operating

voltage.

Competent personnel.

Equipment inspections performed by

competent personnel and has valid

inspection sticker with color coding.

ADDITIONAL

CONTROLS

Supervisor/foreman shall ensure

that the TSTI is properly executed

at the work front and hazards

discussed.

Ensure that equipment manual is

available near the machine.

Post names of authorized

operators near the machine.

Supervisor/foreman shall ensure

that the TSTI is properly executed

at the work front and hazards

discussed.

Ensure that workers carrying the

task is properly trained and

competent.

Supervisor/foreman shall ensure

that the TSTI is properly executed

at the work front and hazards

discussed.

Ensure that workers performing

the task is properly trained and

competent.

LOW

LOW

LOW

LOW

LOW

JOB SAFETY ANALYSIS / RISK ASSESSMENT

FOR T-4.234.076

Q A T A R

ITEM

ACTIVITY

HAZARDS / POTENTIAL

CONSEQUENCES

8.3 Sub-standard equipment.

Initial Risk

RISK

P C

RANK

8.3.1

B

Install formworks.

9.1

MED

Use of hand and power

tools.

8.3.2

9.1.1

9.2

LOW

Handling shutters (Back

injury).

9.2.1

9.2.2

B

9.3

9.4

Debris and materials

causing slip, trips and

falls.

LOW

LOW

9.3.3

9.4.1

Fall hazards.

Install rebar re10.1 Falling or dropped loads.

enforcement steel

into form works with

gantry crane.

9.2.3

9.2.4

9.2.5

9.3.1

9.3.2

10

LOW

9.4.2

HIGH

10.1.1

10.1.2

10.1.3

10.1.4

SCOPE :

GROUTING WORKS

MAIN

CONTROLS

Distribution panel inspected by

8.3.1.1

Contractor before being energized.

Inspection and color-coding of power

tools monthly with a visual inspection

prior to each use.

All work is to be completed with

approved PPE, including safety

glasses with side shields, safety

helmet, coveralls and steel toe

footwear and gloves.

9.1.1.1

9.1.1.2

Provision for lifting aids when

9.2.1.1

practical.

Break the load into manageable

portions.

Lift with your legs not your back.

Use the buddy system, Get help.

Provide pictorial sign boards with

correct lifting position.

Adequate stacking of materials.

Regular housekeeping practices and

removal of trash and unnecessary

items.

Maintain access and walk paths.

Use approved ladder i.e. scaffold

9.4.1.1

material to gain height advantage.

Work from ground level or use

approved platform.

Third party crane inspections.

Daily crane checks.

Competent riggers.

Quarterly and Daily inspection of

rigging gear and equipment (color

coding).

10.1.5 Third party crane operator.

Residual Risk

ADDITIONAL

P C

R

CONTROLS

Ensure all sub-standard equipment

should be remove from site and

tag as unsafe.

B 2

LOW

Supervisor/foreman shall ensure

that the TSTI is properly executed

at the work front and hazards

discussed.

Post the table saw and

combination saw machine safe

operating procedures and safety

precautions at the job site.

Supervisor/foreman shall ensure

that the TSTI is properly executed

at the work front and hazards

discussed.

LOW

LOW

LOW

LOW

LOW

Ensure that all employees working

at height are properly trained.

10.1.1.1 Supervisor/foreman shall ensure

that the TSTI is properly executed

at the work front and hazards

discussed.

10.1.1.2 Ensure the area is properly

barricaded and secured.

JOB SAFETY ANALYSIS / RISK ASSESSMENT

FOR T-4.234.076

Q A T A R

ITEM

ACTIVITY

HAZARDS / POTENTIAL

CONSEQUENCES

10.2 Improper rigging.

Initial Risk

RISK

P C

RANK

HIGH

10.3 Damaged, worn or

unusable rigging

equipment.

C

10.4 People struck by

suspended or swinging

load.

11

Pour concrete.

HIGH

MED

11.1 Fall hazards.

B

LOW

11.2 Use of hand held power

tools, vibrator.

B

LOW

LOW

11.3 Electrocution and burns.

SCOPE :

GROUTING WORKS

Residual Risk

MAIN

CONTROLS

10.2.1 Competency check for all riggers.

10.2.2 Rigging supervisor to monitor rigger

performance.

10.2.3 Third party certified and competent

riggers.

10.2.1.1

10.2.1.2

10.3.1 Quarterly inspection of lifting gear by 10.3.1.1

Third party and color coded.

10.3.2 Removal and isolation of all worn or

damaged lifting equipment.

10.3.3 Rigging gears shall be color coded as 10.3.1.2

per project procedure.

10.4.1 Barricade and secured area and

10.4.1.1

install safety sign boards.

10.4.2 Use tag lines to control load.

10.4.3 "DO NOT" lift load over people.

10.4.4 Do not allow people to walk under the

load.

11.1.1 Use approved ladder i.e. scaffold

11.1.1.2

material to gain height advantage.

11.1.2 Work from ground level or use

approved platform.

11.2.1 All work is to be completed with

11.2.1.1

approved PPE, including safety

glasses with side shields, safety

helmet, coveralls and steel toe

footwear and gloves.

11.3.1 GFCI and using the correct operating

voltage.

11.3.2 Competent personnel.

11.3.3 Dont touch electrically live parts with

skin or wet clothing.

11.3.4 Ensure good electrical connection.

ADDITIONAL

CONTROLS

Supervisor/foreman shall ensure

that the TSTI is properly executed

at the work front and hazards

discussed.

Rigging operations shall be

performed by competent and

qualified riggers.

Supervisor/foreman shall ensure

that the TSTI is properly executed

at the work front and hazards

discussed.

Ensure that all rigging gears are

has 3rd party certificates.

Supervisor/foreman shall ensure

that the TSTI is properly executed

at the work front and hazards

discussed.

Ensure that all employees working

at height are properly trained.

Ensure that all employees are

properly trained to use the

assigned tools.

LOW

LOW

LOW

LOW

LOW

LOW

JOB SAFETY ANALYSIS / RISK ASSESSMENT

FOR T-4.234.076

Q A T A R

ITEM

ACTIVITY

HAZARDS / POTENTIAL

CONSEQUENCES

11.4 Sub-standard equipment.

Initial Risk

RISK

P C

RANK

MED

11.5 Concrete pump truck

boom malfunctioning.

B

MED

LOW

LOW

LOW

11.6 Concrete splash. (Eye

injury).

11.7 Skin injury.

11.7 Foot injury.

11.8 Concrete waste.

LOW

SCOPE :

GROUTING WORKS

Residual Risk

MAIN

ADDITIONAL

P C

R

CONTROLS

CONTROLS

11.4.1 Distribution panel inspected by

11.4.1.1 Ensure all sub-standard equipment

Contractor before being energized.

is removed from site and tagged

11.4.2 Inspection and color-coding of power

as unsafe.

B 2

LOW

tools monthly with a visual inspection

prior to each use.

11.5.1 Contractor inspections.

11.5.1.1 Supervisor/foreman shall ensure

11.5.2 Daily operator inspection of vehicle

that the TSTI is properly executed

and associate pump equipment.

at the work front and hazards

11.5.3 Competent operator trained on the

discussed.

equipment in which he operates.

11.5.4 Visual inspection of boom prior to

each use.

11.5.5 Ensure whip check is nstalled.

11.6.1 Approved PPE( including face shield

by employees working is close

proximity of concrete pour).

11.6.2 Competent personnel.

11.6.3 Eye wash available.

11.7.1 Wearing of approved coveralls and

gloves, with the hose man wearing

additional non-permeable suit.

11.7.1 Appropriate footwear

11.8.1 Use of plastic, spread on the ground

to contain waste.

11.8.2 Operator to properly control pump

boom movement.

11.8.3 Workout set approved area.

LOW

LOW

LOW

LOW

LOW

Você também pode gostar

- 029-QCP For Roads & Paving PDFDocumento22 páginas029-QCP For Roads & Paving PDFKöksal PatanAinda não há avaliações

- 004-Civil - MS Construction of Temporary Roads PDFDocumento17 páginas004-Civil - MS Construction of Temporary Roads PDFKöksal Patan100% (2)

- 008-CIVIL-MS Backfilling Works PDFDocumento16 páginas008-CIVIL-MS Backfilling Works PDFKöksal Patan100% (1)

- 013-MS Utilization of Hilti DX 76 PDFDocumento51 páginas013-MS Utilization of Hilti DX 76 PDFKöksal PatanAinda não há avaliações

- 009-Civil-Ms Concrete Works PDFDocumento27 páginas009-Civil-Ms Concrete Works PDFKöksal PatanAinda não há avaliações

- 015-Method Statement For Painting Works (Building) PDFDocumento21 páginas015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- 004-MS For Erection of Equipment Platforms, Handrails, Gratings, Stairways PDFDocumento9 páginas004-MS For Erection of Equipment Platforms, Handrails, Gratings, Stairways PDFKöksal Patan100% (1)

- Data Comparison for ANA Training Center FencingDocumento3 páginasData Comparison for ANA Training Center Fencingkarimakki100% (1)

- Method Statement For Asphaltic CourseDocumento30 páginasMethod Statement For Asphaltic CoursesuhailalmallahAinda não há avaliações

- Method Statement For Installation Anchor BoltsDocumento7 páginasMethod Statement For Installation Anchor BoltsSyed AtherAinda não há avaliações

- 005-CIVIL-MS Disposal of Excavated Materials PDFDocumento15 páginas005-CIVIL-MS Disposal of Excavated Materials PDFKöksal PatanAinda não há avaliações

- MS-G-003 - General Method Statement For Horizontal PumpDocumento19 páginasMS-G-003 - General Method Statement For Horizontal PumpNGUYEN VINHAinda não há avaliações

- rev01-METHOD STATEMENT FOR INSTALLATION OF LINER TANK FOUNDATIONDocumento7 páginasrev01-METHOD STATEMENT FOR INSTALLATION OF LINER TANK FOUNDATIONMahaboob PashaAinda não há avaliações

- Efficient Framing and Sheeting ErectionDocumento6 páginasEfficient Framing and Sheeting Erectionjoseph chewAinda não há avaliações

- Blasting and Painting ProcedureDocumento27 páginasBlasting and Painting ProcedurePerlie BellomosAinda não há avaliações

- RT Mod MS 001Documento10 páginasRT Mod MS 001Kelly BatesAinda não há avaliações

- Method of Statement For Excavation, Trenching, Backfilling & Compaction WorkDocumento9 páginasMethod of Statement For Excavation, Trenching, Backfilling & Compaction WorkAhmed Ibrahim100% (1)

- Method Statement Excavation WorksDocumento24 páginasMethod Statement Excavation Worksnishadabdulkader100% (2)

- 021-Itp For Site Preparation and Earth Works PDFDocumento6 páginas021-Itp For Site Preparation and Earth Works PDFKöksal Patan100% (2)

- Method Statement For The, Gulf Eagle Project: Installation, Commissioning & Load Testing of CraneDocumento14 páginasMethod Statement For The, Gulf Eagle Project: Installation, Commissioning & Load Testing of CraneFAYIZAinda não há avaliações

- EN131528-TCCSA-CS-M04-0003 (02) - Method Statement For Mass Concrete ConstructionDocumento32 páginasEN131528-TCCSA-CS-M04-0003 (02) - Method Statement For Mass Concrete Construction章宇Ainda não há avaliações

- 014-MS For General Scaffolding PDFDocumento33 páginas014-MS For General Scaffolding PDFKöksal Patan100% (2)

- Method Statement For Earth WorkDocumento5 páginasMethod Statement For Earth Workgvs raoAinda não há avaliações

- WM Statement For General Welding WorkDocumento6 páginasWM Statement For General Welding Workahsan khaleeqAinda não há avaliações

- Concrete Placement (Spec)Documento18 páginasConcrete Placement (Spec)Vetrivel MuruganAinda não há avaliações

- Method of Statement For HDPE Pipe InstallationDocumento2 páginasMethod of Statement For HDPE Pipe InstallationYe Yint100% (2)

- Contractor method statement for awning installationDocumento8 páginasContractor method statement for awning installationShaikh Muhammad AteeqAinda não há avaliações

- 022 Itp For Fence Gate PDFDocumento5 páginas022 Itp For Fence Gate PDFJithesh.k.sAinda não há avaliações

- 044-ITP For Installation of Gypsum Board (Buildings) PDFDocumento10 páginas044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- MIP17-MS-3003 METHOD OF STATEMENT FOR PIPELINE CROSSING ABOVE EXISTING CORRIDOR Rev.0Documento22 páginasMIP17-MS-3003 METHOD OF STATEMENT FOR PIPELINE CROSSING ABOVE EXISTING CORRIDOR Rev.0AmeerHamzaWarraichAinda não há avaliações

- Traffic Signage Installation ITPDocumento1 páginaTraffic Signage Installation ITPmoytabura96Ainda não há avaliações

- EXCAVATION METHOD STATEMENT FOR HIGHLANDS HIGHWAY REHABILITATIONDocumento9 páginasEXCAVATION METHOD STATEMENT FOR HIGHLANDS HIGHWAY REHABILITATION施智捷100% (1)

- Method Statement For Stone WorksDocumento10 páginasMethod Statement For Stone WorksvisanuAinda não há avaliações

- Concrete Works Method StatementDocumento6 páginasConcrete Works Method StatementmemekenyaAinda não há avaliações

- MS-001-Form Work, Reinforcement Steel & Concrete WorksDocumento12 páginasMS-001-Form Work, Reinforcement Steel & Concrete WorksFrancis Phillip CapistranoAinda não há avaliações

- Method Statement For Approval of Layer Thickness - Rev.01Documento9 páginasMethod Statement For Approval of Layer Thickness - Rev.01Jox Biol100% (1)

- Method Statement For Taxiway Edge Lights & ManholesDocumento7 páginasMethod Statement For Taxiway Edge Lights & ManholesRomeoAryan100% (1)

- Method Statement SandingDocumento1 páginaMethod Statement SandingShah AlamAinda não há avaliações

- Dewatering Method StatementDocumento6 páginasDewatering Method StatementMohsen KeramatiAinda não há avaliações

- Ibb Mcup & Modification of K-12 Building: Safco/Ibb Mobile Coating Unit PojectDocumento19 páginasIbb Mcup & Modification of K-12 Building: Safco/Ibb Mobile Coating Unit PojectShewale PravinAinda não há avaliações

- Method of Statment CONCRETEDocumento7 páginasMethod of Statment CONCRETESyed AtherAinda não há avaliações

- SKANDHANSHI INFRA PROJECTS EXCAVATION METHOD STATEMENTDocumento6 páginasSKANDHANSHI INFRA PROJECTS EXCAVATION METHOD STATEMENTVinod MasaniAinda não há avaliações

- 1b. MS 02 Installation of FencingDocumento17 páginas1b. MS 02 Installation of Fencinghamidsk100% (1)

- Method Statement-Excavation Sipchem JubailDocumento8 páginasMethod Statement-Excavation Sipchem JubailzanemtAinda não há avaliações

- Earthwork Excavation-Method StatementDocumento4 páginasEarthwork Excavation-Method StatementKhaled AbdelbakiAinda não há avaliações

- Curing Compound ApplicationDocumento3 páginasCuring Compound Applicationmoytabura96Ainda não há avaliações

- Method Statement: Emergency Contact DetailsDocumento9 páginasMethod Statement: Emergency Contact DetailsShazwaniAinda não há avaliações

- Method Statement Fo Reinforcement Works BlogDocumento8 páginasMethod Statement Fo Reinforcement Works BlogMohasin Khan100% (1)

- Resource Deployment Plan - HehDocumento2 páginasResource Deployment Plan - HehMyjaz Jaz100% (1)

- Block Work MS (Sample)Documento18 páginasBlock Work MS (Sample)jones100% (1)

- Method Statement for Installing Conduit PipesDocumento7 páginasMethod Statement for Installing Conduit Pipestoni_saputroAinda não há avaliações

- Non-Shrink Grout Application ProcedureDocumento6 páginasNon-Shrink Grout Application Proceduremoytabura96Ainda não há avaliações

- 1.method Statement Dewatering PDFDocumento5 páginas1.method Statement Dewatering PDFشاز إياس100% (3)

- 2648 - Aco 9 2001 661 t7 4 0 Method Statement For Asphalt Road WorksDocumento13 páginas2648 - Aco 9 2001 661 t7 4 0 Method Statement For Asphalt Road WorksmohsinAinda não há avaliações

- Especifications For Jet Grouting PDFDocumento7 páginasEspecifications For Jet Grouting PDFMarco Dos Santos NevesAinda não há avaliações

- Table of Contents for Work Method StatementTITLE Work Method TableDocumento38 páginasTable of Contents for Work Method StatementTITLE Work Method TableTahir MubeenAinda não há avaliações

- Method Statement For BackfillingDocumento6 páginasMethod Statement For BackfillingTariq Ali Sial100% (1)

- 013-MS For Mass Concrete Works PDFDocumento26 páginas013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- 012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFDocumento18 páginas012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFKöksal PatanAinda não há avaliações

- 005-Ms-Painting and Repair Works PDFDocumento24 páginas005-Ms-Painting and Repair Works PDFKöksal Patan100% (1)

- 015-MS For Night Works PDFDocumento16 páginas015-MS For Night Works PDFKöksal Patan80% (5)

- 011-Method Statement For Repair of Concrete Works PDFDocumento25 páginas011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- 017-CIVIL-MS For Installation of Fence & Gate PDFDocumento18 páginas017-CIVIL-MS For Installation of Fence & Gate PDFKöksal Patan100% (6)

- 016-CIVIL - MS Anchor Bolt Installation PDFDocumento14 páginas016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- 010-MS For Welding and Hot Works For General Activities at TSF Area PDFDocumento17 páginas010-MS For Welding and Hot Works For General Activities at TSF Area PDFKöksal PatanAinda não há avaliações

- 012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFDocumento16 páginas012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFKöksal Patan91% (11)

- 014-MS For Bolt Tightening (Piping& Equipments) PDFDocumento23 páginas014-MS For Bolt Tightening (Piping& Equipments) PDFKöksal PatanAinda não há avaliações

- 015-Method Statement For Painting Works (Building) PDFDocumento21 páginas015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- 014-MS For General Scaffolding PDFDocumento33 páginas014-MS For General Scaffolding PDFKöksal Patan100% (2)

- 012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFDocumento18 páginas012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFKöksal PatanAinda não há avaliações

- 013-MS For Mass Concrete Works PDFDocumento26 páginas013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFDocumento18 páginas046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanAinda não há avaliações

- 050-Itp For Installation of Air Intake Filter PDFDocumento17 páginas050-Itp For Installation of Air Intake Filter PDFKöksal PatanAinda não há avaliações

- 049-Itp For Lighting and Small Power (Building) PDFDocumento15 páginas049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- 048-Itp For Installation of Hvac Unit PDFDocumento8 páginas048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- 043-ITP FOR Water Proofing (Buildings) PDFDocumento13 páginas043-ITP FOR Water Proofing (Buildings) PDFKöksal Patan100% (3)

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFDocumento10 páginas045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- 009-Method Statement - Main Erection Sequence For Acc PDFDocumento68 páginas009-Method Statement - Main Erection Sequence For Acc PDFKöksal Patan100% (6)

- 041 - ITP For Painting (Building) PDFDocumento12 páginas041 - ITP For Painting (Building) PDFKöksal Patan78% (9)

- 047-Itp For Oxygen Lines Fabrication and Installation PDFDocumento28 páginas047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanAinda não há avaliações

- 044-ITP For Installation of Gypsum Board (Buildings) PDFDocumento10 páginas044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- 040-ITP For Repair of Steam Distribution Manifold PDFDocumento11 páginas040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanAinda não há avaliações

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFDocumento23 páginas008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanAinda não há avaliações

- 039-Itp For Embedded Plate PDFDocumento7 páginas039-Itp For Embedded Plate PDFKöksal PatanAinda não há avaliações

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFDocumento25 páginas007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanAinda não há avaliações

- 038-Itp For Coldboxes PDFDocumento25 páginas038-Itp For Coldboxes PDFKöksal PatanAinda não há avaliações

- Joints in Steel Construction - Simple Connections - Part 01 PDFDocumento4 páginasJoints in Steel Construction - Simple Connections - Part 01 PDFkakem61Ainda não há avaliações

- Puente de DiodosDocumento4 páginasPuente de DiodosDanoolandAinda não há avaliações

- BAUSER Brochure Time Counters Pulse Counters Modules Time Switchers 1709 en v1.6Documento40 páginasBAUSER Brochure Time Counters Pulse Counters Modules Time Switchers 1709 en v1.6Csaba SándorAinda não há avaliações

- Hyperion Admin Guide PDFDocumento490 páginasHyperion Admin Guide PDFChristopher CashAinda não há avaliações

- Lab 1Documento6 páginasLab 1Areeb KhanAinda não há avaliações

- FLCR470501 PDFDocumento8 páginasFLCR470501 PDFgolg1de1994Ainda não há avaliações

- HSN 0101Documento130 páginasHSN 0101Jessica PerryAinda não há avaliações

- Pdn1000 3us Valvair IIDocumento10 páginasPdn1000 3us Valvair IIMihai Cosmin PaunAinda não há avaliações

- Prodelin 1385Documento33 páginasProdelin 1385bebebrenda100% (1)

- Catalogo Jiskoot 210Documento44 páginasCatalogo Jiskoot 210Cristian Andres Gonzalez0% (1)

- DELIVERYDocumento2 páginasDELIVERYBrayan Calcina BellotAinda não há avaliações

- Service Manual: Advanced Air Conditioning SystemsDocumento42 páginasService Manual: Advanced Air Conditioning SystemsSuciu MariusAinda não há avaliações

- Two Step Cluster AnalysisDocumento10 páginasTwo Step Cluster AnalysisRex Rieta VillavelezAinda não há avaliações

- STM 5275 Linked 03-14-18 PDFDocumento412 páginasSTM 5275 Linked 03-14-18 PDFиван Троянов100% (1)

- Precision Automatic Voltage Regulator With Bypass PWM IGBT 7kVA 8kVA 10kVA 208V 220V230V 230vac 240V 240vac Single Phase VRP 7500 10000Documento2 páginasPrecision Automatic Voltage Regulator With Bypass PWM IGBT 7kVA 8kVA 10kVA 208V 220V230V 230vac 240V 240vac Single Phase VRP 7500 10000Muhammad YusufAinda não há avaliações

- BS en 12859-2011 PDFDocumento40 páginasBS en 12859-2011 PDFkarditobambang23Ainda não há avaliações

- Opening A Case With TAC: AppendixDocumento6 páginasOpening A Case With TAC: AppendixIvanik BlancoAinda não há avaliações

- D4239-05 Sulfur High Temperature TubeDocumento8 páginasD4239-05 Sulfur High Temperature TubeVladimir KrzalicAinda não há avaliações

- Journal Bearing ClearanceDocumento2 páginasJournal Bearing ClearanceLookman FajarAinda não há avaliações

- Goip Sms Interface enDocumento10 páginasGoip Sms Interface enNoli Bellen RafalloAinda não há avaliações

- Coke Drum Monitoring Inspection Assessment and Repair For Service Life Improvement Chadda Foster Wheeler DCU Rio de Janiero 2014Documento31 páginasCoke Drum Monitoring Inspection Assessment and Repair For Service Life Improvement Chadda Foster Wheeler DCU Rio de Janiero 2014Piyush PrasadAinda não há avaliações

- MC78T05Documento13 páginasMC78T05Aditya SinghAinda não há avaliações

- RefactoringDocumento185 páginasRefactoringKrishna PrasadAinda não há avaliações

- Controlled quality documents processDocumento8 páginasControlled quality documents processUlhas KavathekarAinda não há avaliações

- 2D Graphics Programming PracticalsDocumento41 páginas2D Graphics Programming PracticalsAshish SharmaAinda não há avaliações

- Smart Zoning CiscoDocumento3 páginasSmart Zoning Ciscousa_sAinda não há avaliações

- Intergard 774Documento4 páginasIntergard 774Doby YuniardiAinda não há avaliações

- Bharat Stage Emission StandardsDocumento15 páginasBharat Stage Emission StandardsJustin LoweAinda não há avaliações

- CLOT KPI Analysis Guideline (RJIL) - v1.0Documento135 páginasCLOT KPI Analysis Guideline (RJIL) - v1.0shaikhAinda não há avaliações

- ALV Programming GuideDocumento45 páginasALV Programming GuideBipin ShuklaAinda não há avaliações