Escolar Documentos

Profissional Documentos

Cultura Documentos

9075 Reflux Classifier Brochure

Enviado por

Neeraj AgrawalDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

9075 Reflux Classifier Brochure

Enviado por

Neeraj AgrawalDireitos autorais:

Formatos disponíveis

Ludowici Reflux Classifier

www.ludowici.com.au

w w w. l u d o w i c i . c o m . a u

Reflux Classifier

Ludowici offers the latest technology in Fine Particle Beneficiation known

as the Reflux Classifier (or RC). Ludowici undertook the development of

Reflux Classifier in collaboration with the University Newcastle. Ludowici

is TUNRAs worldwide licensee for this patented technology.

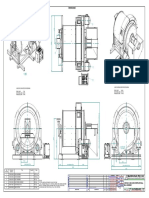

The operation of the RC relies on settling of particles in an upward

flowing stream of water. The upward water flow is created at a distributor

plate in the bottom of the RC. The upward water flow can be further

supplemented with additional water in the feed section. The RC has a

set of lamella plates above the feed entry section. These lamella plates

increase the rate of settling of the particles and then cause a zone of

increased slurry density immediately below the lamella plates.

This higher density zone enables the RC to sort particles on a density

basis rather than particle size.

The lighter particles float to the top, along with the majority of water

and slimes. The denser particles sink through the zones of higher slurry

density, and accumulate on the distributor plate, which is an inverted

pyramid shape that allows the denser particles to migrate toward a

central discharge port. The rate of dense particle discharge is controlled

by two automated pinch valves.

The Reflux Classifier has been proven in the RC600 over a wide range

of feed types and conditions, and at feed rates between 11 and 32

tph of feed solids. Currently we have several full scale RC1800s in full

operation to demonstrate that the RC technology is more efficient and

compact than the competing fine coal cleaning equipment. This unit is

conservatively rated at 150 tph of -2.0 +0.25 mm fine coal feed solids.

The RC is notable for its high throughput, which is potentially around 4 to

5 times the throughput per surface area of the TBS - although we have

only doubled the TBS rating at the capacity of 165 tph, thus giving a

conservative approach. This conservative capacity has been adopted due

to the increases in efficiency that results from a lower feed rate. The RC

also runs more consistently when operating at relatively low RD cutpoints

and has demonstrated less shift in RD cutpoint versus particle size than a

TBS, which means overall yields at any given target ash will be improved.

w w w. l u d o m i n . c o m

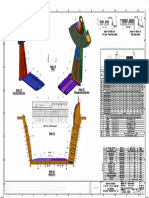

The materials of construction used in the RC1800 are wear resistant

3CR12 stainless steel for all wetted surfaces, and painted mild steel for

the support brackets and flanges. The automated reject control valves

are a dart valve and seat, and a knife gate dump valve. The reject valves

are sequentially controlled via a DP Cell, which automates the amount

of reject being discharged. In high yield processing only the dart valve

is used for proportional control, and in low yield processing the second

valve is fully opened and the fine tuning of the yield is determined by

the first proportional valve. This reject control is automatic and has a

seamless changeover between one and two reject valves operating.

This allows a selected pulp density (and hence RD50 cutpoint) to be

maintained in the reject chamber of the RC over a wide range of feed

conditions.

The feed and products for the RC will typically require desliming to gain

the full potential of the unit. The feed should be deslimed in a Classifying

cyclone or Sieve Bend, although the RC1800 is more tolerant of slimes

than conventional concentration equipment. The product from the

RC1800 will contain any slimes in the feed, hence will require desliming

via a Sieve Bend or cyclone prior to dewatering in a Fine Coal Centrifuge

or High Frequency Screen.

1.00

-2.0+1.4 mm

-1.4+1.0 mm

-1.0+0.70 mm

-0.70+0.50 mm

-0.50+0.25 mm

Partition Number

0.75

0.50

0.25

0.00

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2.0

2.1

2.2

Relative Density

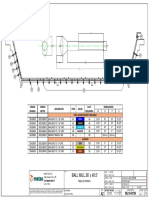

Figure 5

Partition curves obtained for Run G1 for the narrow size fractions, -2.0+1.4, -1.4+1.0, -1.0+0.70, -

BRISBANE - Head Office

38 Ivedon Street, Banyo

Brisbane Australia

Ph: (07) 3292 4444

Fax: (07) 3267 0990

ROCKLEA - Hose & Rubber

Ph: (07) 3274 3222

Fax: (07) 3274 1133

ROCKHAMPTON

Ph: (07) 4926 1366

Fax: (07) 4926 1322

MACKAY

Ph: (07) 4952 1577

Fax: (07) 4952 3718

MOUNT ISA

Ph: (07) 4749 2266

Fax: (07) 4749 2166

NEWCASTLE

Ph: (02) 4966 0700

Fax: (02) 4966 0722

ADELAIDE

Ph: (08) 8340 2788

Fax: (08) 8340 1061

KALGOORLIE

Ph: (08) 9093 1200

Fax: (08) 9093 1522

PERTH

Ph: (08) 9365 4222

Fax: (08) 9455 5133

CHINA

LUDOWICI MINERAL PROCESSING

EQUIPMENT LIMITED

Ph: +86 535 2165280

Fax: +86 535 2165281

INDIA

LUDOWICI INDIA PRIVATE LIMITED

Ph: +91 4232 7313

Fax: +91 4232 7315

USA

LUDOWICI INNOVATIVE

Ph: +1 (304) 855 7880

Fax: +1 (304) 855 8601

CHILE

LUDOWICI MINERAL PROCESSING

EQUIPMENT S.A.

Ph: +56 2 411 3600

Fax: +56 2 411 3601

Visit our website for the complete range of Ludowici products:

www.lud o wici.co m.au

SOUTH AFRICA

LUDOWICI AFRICA (PTY) LTD

Ph: +27 11 452 2239

Fax: +27 11 452 9923

Ludowici Australia Pty Ltd

ABN 88 010 340 566

9075 8/07

Você também pode gostar

- 660D14 Painting Schedule For Silo 1 - Rev 0Documento1 página660D14 Painting Schedule For Silo 1 - Rev 0Mohammad AdilAinda não há avaliações

- Less Is MoreDocumento3 páginasLess Is Moresnarf273Ainda não há avaliações

- Tac4598 - 3350KW - Instruction ManualDocumento48 páginasTac4598 - 3350KW - Instruction ManualMiguel Angel RodriguezAinda não há avaliações

- World Non US Gasification DatabaseDocumento9 páginasWorld Non US Gasification DatabaseKhairi Maulida AzhariAinda não há avaliações

- Manufacturing BOM / Multi LevelDocumento4 páginasManufacturing BOM / Multi LevelJulver Goyzueta ArceAinda não há avaliações

- Cerro Verde Production Unit Expansion: Coarse Ore Vibrating Screens Lifting Pipe Details Document No. SN-100462-MD21Documento5 páginasCerro Verde Production Unit Expansion: Coarse Ore Vibrating Screens Lifting Pipe Details Document No. SN-100462-MD21jhonAinda não há avaliações

- f18p01 m00 000 General ArrangementDocumento1 páginaf18p01 m00 000 General ArrangementAngga Purnama PutraAinda não há avaliações

- New Microsoft Office Excel WorksheetDocumento10 páginasNew Microsoft Office Excel WorksheetACCOUNTS AMBIKAPURAinda não há avaliações

- Platform Semitrailers S.PR Configurator: Services Technology TrailerDocumento14 páginasPlatform Semitrailers S.PR Configurator: Services Technology TrailerForomaquinasAinda não há avaliações

- Cerro Verde Production Unit Expansion: Calculations For Coarse Ore Vibrating Screens Document No. SN-100462-MD09Documento4 páginasCerro Verde Production Unit Expansion: Calculations For Coarse Ore Vibrating Screens Document No. SN-100462-MD09jhonAinda não há avaliações

- METSO DOA Dimesion ReportDocumento8 páginasMETSO DOA Dimesion ReportNaresh KumarAinda não há avaliações

- Monitoring Open OrderDocumento66 páginasMonitoring Open OrderdbedadaAinda não há avaliações

- 76 Band Dryers PDFDocumento1 página76 Band Dryers PDFPhilip WalkerAinda não há avaliações

- Cerro Verde Production Unit Expansion: Ludowici Vibrating Screens Installation Sequence Document No. SN-100462-MD18Documento5 páginasCerro Verde Production Unit Expansion: Ludowici Vibrating Screens Installation Sequence Document No. SN-100462-MD18jhonAinda não há avaliações

- Tankcell® Flotation Machine: Bolt ConnectionsDocumento6 páginasTankcell® Flotation Machine: Bolt ConnectionsJulver Goyzueta Arce100% (1)

- Electric Specification: 1. Components Characteristics and AdjustmentsDocumento9 páginasElectric Specification: 1. Components Characteristics and AdjustmentsMoreno Adrian BenitezAinda não há avaliações

- Cerro Verde Production Unit Expansion: Bill of Materials Per Operating Screen Document No. SN-100462-MD03Documento7 páginasCerro Verde Production Unit Expansion: Bill of Materials Per Operating Screen Document No. SN-100462-MD03jhonAinda não há avaliações

- CycloSim SingleDocumento124 páginasCycloSim SingleGaby Nancy Catura MaynaAinda não há avaliações

- Pierre MagisDocumento11 páginasPierre MagisArpan MahajanAinda não há avaliações

- Cascade Air Separator KVT enDocumento6 páginasCascade Air Separator KVT enkamjulajayAinda não há avaliações

- Kent McGrew - CCD Vs AFP - FinalDocumento7 páginasKent McGrew - CCD Vs AFP - FinalCesar Cordova NuñezAinda não há avaliações

- ML19-0199 PernosDocumento1 páginaML19-0199 PernosElias PaxiAinda não há avaliações

- DK1915 CH10Documento55 páginasDK1915 CH10gao379Ainda não há avaliações

- Irl GekkoDocumento51 páginasIrl GekkojcAinda não há avaliações

- Grinding Mill Plan PDFDocumento1 páginaGrinding Mill Plan PDFBender Doblador RodriguezAinda não há avaliações

- SANDVIK What Is Stainless SteelDocumento7 páginasSANDVIK What Is Stainless Steelpipedown456Ainda não há avaliações

- BESSER PartsCtlg 11apr2018Documento174 páginasBESSER PartsCtlg 11apr2018Carlos CetinaAinda não há avaliações

- Dm-dcld-f-cm-0017 Rev 4 Ems Test ChargesDocumento112 páginasDm-dcld-f-cm-0017 Rev 4 Ems Test ChargesPervaiz BaigAinda não há avaliações

- Tycan F-Class: Operation, Maintenance and Parts ManualDocumento60 páginasTycan F-Class: Operation, Maintenance and Parts ManualAlexAinda não há avaliações

- PaperC Optimization of Crushing Stage Using On-Line Speed Regulation On Cone Crushers PDFDocumento9 páginasPaperC Optimization of Crushing Stage Using On-Line Speed Regulation On Cone Crushers PDFRagab AbulmagdAinda não há avaliações

- Rev3Documento2 páginasRev3Deyvi Osmar Zegarra Villena0% (1)

- EXCEL High Performance Parts For HP-Cone-Crushers - MetsoDocumento7 páginasEXCEL High Performance Parts For HP-Cone-Crushers - MetsoabcAinda não há avaliações

- Csp703-Sluicepipe 1: Detail ADocumento1 páginaCsp703-Sluicepipe 1: Detail AKarlyCharlisAinda não há avaliações

- Diagrama de Flujo Circuito Chancado Minera Condestable S.ADocumento1 páginaDiagrama de Flujo Circuito Chancado Minera Condestable S.AdonaldoAinda não há avaliações

- Paneles Autolimpiantes MetsoDocumento4 páginasPaneles Autolimpiantes Metsodaniel floresAinda não há avaliações

- Design of Wash Stage in Copper Solvent Extraction: April 2020Documento37 páginasDesign of Wash Stage in Copper Solvent Extraction: April 2020JeromeAinda não há avaliações

- MANUAL1 - Copia - 4Documento50 páginasMANUAL1 - Copia - 4Jose NoriegaAinda não há avaliações

- Magotteaux Millliners Cement Brochure en LR 4Documento6 páginasMagotteaux Millliners Cement Brochure en LR 4Mostafa Ahamed Mhoumed RatibAinda não há avaliações

- Induction Motor Data: Siemens Industry, Inc. Norwood, OhioDocumento3 páginasInduction Motor Data: Siemens Industry, Inc. Norwood, OhioelvisAinda não há avaliações

- IPJ2400 Version 5 PDFDocumento37 páginasIPJ2400 Version 5 PDFRoberto CalderonAinda não há avaliações

- Large Scale Mixer Settlers DesignDocumento8 páginasLarge Scale Mixer Settlers DesignRodrigo GarcíaAinda não há avaliações

- ZARANDASDocumento3 páginasZARANDASRaphael PalaciosAinda não há avaliações

- 14C28N Draft Data SheetDocumento3 páginas14C28N Draft Data SheetWarren NelAinda não há avaliações

- Heat Treatment of Iron Ore PelletDocumento39 páginasHeat Treatment of Iron Ore PelletPRASSAN SHAH100% (1)

- Vibrating ScreenDocumento1 páginaVibrating Screenprashant mishraAinda não há avaliações

- Planos SAG Shell PDFDocumento1 páginaPlanos SAG Shell PDFA̶l̶x̶a̶n̶d̶e̶r̶ PaniAinda não há avaliações

- Chuong 2-Roller MillDocumento23 páginasChuong 2-Roller MillvipinAinda não há avaliações

- Inline Leach Reactor Operators Manual inDocumento50 páginasInline Leach Reactor Operators Manual indiksajonaAinda não há avaliações

- SIG de 22 Diagrama de Cableado TD3 B102 E 10Documento10 páginasSIG de 22 Diagrama de Cableado TD3 B102 E 10Jorge PalacioAinda não há avaliações

- Multotec Injection Moulded Screening Systems-Digital-4c504Documento6 páginasMultotec Injection Moulded Screening Systems-Digital-4c504Nilton Inca TitoAinda não há avaliações

- CrushSim OpenDocumento124 páginasCrushSim Openedwin javier valdivia guillenAinda não há avaliações

- Katalog enDocumento75 páginasKatalog enErsin SucuAinda não há avaliações

- Fine Grinding in The Australian Mining IndustryDocumento11 páginasFine Grinding in The Australian Mining IndustryATon GarsaAinda não há avaliações

- Mill Power - Rod MillsDocumento4 páginasMill Power - Rod MillsFredy PeñaAinda não há avaliações

- CrushParam OpenDocumento116 páginasCrushParam Openedwin javier valdivia guillenAinda não há avaliações

- Screeningtheory PDFDocumento54 páginasScreeningtheory PDFluis martinezAinda não há avaliações

- HEPICS Whitepaper Improved MP1000 Liner PerformanceDocumento3 páginasHEPICS Whitepaper Improved MP1000 Liner PerformanceYousef AlipourAinda não há avaliações

- AFG Alpine Fluidised Bed Opposed Jet Mills (En)Documento10 páginasAFG Alpine Fluidised Bed Opposed Jet Mills (En)alevandrorAinda não há avaliações

- HRSCC ManualDocumento2 páginasHRSCC ManualAdimoolam Narayana100% (1)

- Christ Conesep MLDocumento6 páginasChrist Conesep MLVijayakumar AndiAinda não há avaliações

- Feeder or Conveyor: What's The Difference and Why Does It Matter?Documento4 páginasFeeder or Conveyor: What's The Difference and Why Does It Matter?Neeraj AgrawalAinda não há avaliações

- SGC Pride SchemeDocumento1 páginaSGC Pride SchemeNeeraj AgrawalAinda não há avaliações

- MATLAB Tut2Documento6 páginasMATLAB Tut2Neeraj AgrawalAinda não há avaliações

- Pulp and Solution Chemistry Ralston Et Al 2007Documento33 páginasPulp and Solution Chemistry Ralston Et Al 2007Neeraj AgrawalAinda não há avaliações

- JahangirDocumento2 páginasJahangirNeeraj AgrawalAinda não há avaliações

- Large Hadron ColliderDocumento15 páginasLarge Hadron ColliderNeeraj AgrawalAinda não há avaliações

- BPO Sector in India - Opportunities, Threats and ChallengesDocumento3 páginasBPO Sector in India - Opportunities, Threats and ChallengesNeeraj AgrawalAinda não há avaliações

- 1405Documento19 páginas1405Neeraj Agrawal100% (1)

- Globalisation-A Blessing or A CurseDocumento2 páginasGlobalisation-A Blessing or A CurseNeeraj AgrawalAinda não há avaliações

- Geared Coupling CatalogueDocumento4 páginasGeared Coupling CatalogueNeeraj AgrawalAinda não há avaliações

- Osram Microlithography HboDocumento56 páginasOsram Microlithography HboghobaAinda não há avaliações

- Safety Data Sheet: 1. IdentificationDocumento9 páginasSafety Data Sheet: 1. IdentificationMike Chua TorresAinda não há avaliações

- Presented By: Obtaining Biogas For Residential BuildingsDocumento16 páginasPresented By: Obtaining Biogas For Residential BuildingsKotla AbhinavAinda não há avaliações

- Workbook Unit 9Documento8 páginasWorkbook Unit 9LAURA MARIA RECARTE CANALESAinda não há avaliações

- Medical Lab Technology CurriculumDocumento192 páginasMedical Lab Technology Curriculumlayyah20130% (1)

- Flexible PackagingDocumento15 páginasFlexible PackagingAngela GarciaAinda não há avaliações

- Defend VPS-HvyBody MSDS 1-1-2011Documento1 páginaDefend VPS-HvyBody MSDS 1-1-2011M. White DentalAinda não há avaliações

- State of New Jersey v. State of New York and City of New York, Commonwealth of Pennsylvania and State of Delaware, Intervenors, 347 U.S. 995 (1954)Documento8 páginasState of New Jersey v. State of New York and City of New York, Commonwealth of Pennsylvania and State of Delaware, Intervenors, 347 U.S. 995 (1954)Scribd Government DocsAinda não há avaliações

- Infection Control Construction PermitDocumento2 páginasInfection Control Construction PermitWisniardhy Suarnata PradanaAinda não há avaliações

- Yatrik Chapters 1 and 2.Documento31 páginasYatrik Chapters 1 and 2.greatbongAinda não há avaliações

- Construction Safety HandbookDocumento133 páginasConstruction Safety HandbookSwapnil Gund100% (4)

- User Manual Yokogawa CPU PDFDocumento250 páginasUser Manual Yokogawa CPU PDFsatyavir singhAinda não há avaliações

- Contract Closeout FormDocumento5 páginasContract Closeout FormMarvin Pavo0% (1)

- 5m3d MBR Packaged STP 2017.3.28Documento13 páginas5m3d MBR Packaged STP 2017.3.28DevAinda não há avaliações

- Sunsilk Product RevisionDocumento3 páginasSunsilk Product RevisionLuis AlcalaAinda não há avaliações

- Modul Perkembangan Pembelajaran: Bahasa Inggeris Kertas 4Documento8 páginasModul Perkembangan Pembelajaran: Bahasa Inggeris Kertas 4ardzulna0% (1)

- Hội Các Trường Chuyên Vùng Duyên Hải Và Đồng Bằng Bắc Bộ Trường Thpt Chuyên Nguyễn Trãi Tỉnh Hải Dương Đề Thi Chọn Học Sinh Giỏi Lần Thứ Xi Môn: Tiếng Anh - Khối 10Documento18 páginasHội Các Trường Chuyên Vùng Duyên Hải Và Đồng Bằng Bắc Bộ Trường Thpt Chuyên Nguyễn Trãi Tỉnh Hải Dương Đề Thi Chọn Học Sinh Giỏi Lần Thứ Xi Môn: Tiếng Anh - Khối 10Alin Nguyen0% (2)

- Wet Scrubber ManualDocumento15 páginasWet Scrubber ManualYusak Santoso Use100% (1)

- Samsung Wf8622nhwDocumento252 páginasSamsung Wf8622nhwLaura FulgaAinda não há avaliações

- AHA-005, Removal Asbestos Contaminated MaterialDocumento7 páginasAHA-005, Removal Asbestos Contaminated MaterialBuddhikaAinda não há avaliações

- Hydronic Piping SystemsDocumento2 páginasHydronic Piping SystemsNestor S. ReEyesAinda não há avaliações

- The Production of GlueDocumento18 páginasThe Production of GlueMarylene MullasgoAinda não há avaliações

- 5482 3a11c5kubDocumento4 páginas5482 3a11c5kubNandar Min HtetAinda não há avaliações

- Environmental IssueDocumento28 páginasEnvironmental Issuelees10088Ainda não há avaliações

- Mortara ELI 150c, 250c ECG - User ManualDocumento80 páginasMortara ELI 150c, 250c ECG - User ManualabeklAinda não há avaliações

- GFII PresentationDocumento43 páginasGFII PresentationJacqueline Acera BalingitAinda não há avaliações

- MSDS Edenor ST 03 MyDocumento4 páginasMSDS Edenor ST 03 MytopguitarAinda não há avaliações

- Table Blender: User ManualDocumento112 páginasTable Blender: User ManualMarian Marius SerbanAinda não há avaliações

- Corporate Social ResponsibilityDocumento15 páginasCorporate Social Responsibilitypranay100% (1)

- Workshop Equipments SPECIFICATIONDocumento68 páginasWorkshop Equipments SPECIFICATIONAnonymous uXdS9Y7Ainda não há avaliações