Escolar Documentos

Profissional Documentos

Cultura Documentos

Av02 1995en, 0 PDF

Enviado por

Tribu Vaquero JimenezDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Av02 1995en, 0 PDF

Enviado por

Tribu Vaquero JimenezDireitos autorais:

Formatos disponíveis

VMMK-2103, VMMK-2203, VMMK-2303,

VMMK-2403, VMMK-2503

Reliability Data Sheet

Description

This document describes the reliability performance of

VMMK-2x03 based on a series of reliability tests conducted. VMMK-2x03 is fabricated using Avago Technolodiess

industry leading E-PHEMT technology associated with

chip scale surface mount leadless package with GaAs

encapsulation. VMMK-2x03 are intended for 0.5 11GHz

range of wireless application.

VMMK-2203 and VMMK-2403 had been subjected to extensive reliability stress tests to predict the mean time to

failure and associated distribution. The reliability performance of VMMK-2103, VMMK-2303 and VMMK-2503 were

leveraged on these two products based on similarity in

packaging and wafer fabrication process.

Table 1. High Temperature Operational Life Test Results

Product

Stress Test

Condition

Total Units

Tested

Total Device

Hours

No. of Failed

Units

VMMK-2203

Tch = 150C, Typical DC Bias

48

48,000

VMMK-2403

Tch = 150C, Typical DC Bias

48

48,000

VMMK-2203 Failure criterion: Id degradation > 20%, NF & Gain degradation > 0.5dB

VMMK-2403 Failure criterion: Id degradation > 20%, NF & Gain degradation > 0.5dB, OIP3 degradation > 2dBm

Table 2. Reliability prediction using Table 1 results:

Channel

Temp. (C)

Point Typical

Performance

MTTF hours

90%

Confidence

MTTF hours

Point Typical

Performance

FIT

90%

Confidence

FIT

150

9.600 X 104

4.165 X 104

10416.7

24010.4

125

4.637 X 106

2.012 X 106

215.7

497.1

100

3.766 X 108

1.634 X 108

2.7

6.1

85

7.074 X 109

3.069 X 109

0.141

0.326

65

5.296 X 1011

2.298 X 1011

0.002

0.004

50

1.914 X 1013

8.304 X 1012

0.00005

0.00012

Notes:

1. Arrhenius model with constant failure rate assumed. Activation energy Ea= 2.25eV derived from multi-temperature stress testing.

2. The point MTTF (representing an estimate of the mean point MTTF) is the total device hours divided by either the number of failures or unity if

there are no failures.

3. 90% confident MTTF and failure rate represent the minimum level of reliability performance that is expected from 90% of all samples. This

confidence interval is based on the statistics of the assumed exponential distribution of failures.

4. FIT = failure per 109 device hours.

5. Thermal Resistance qch-b: VMMK-2203 = 107C/W, VMMK-2403 = 161C/W

Note: These devices are esd sensitive, the following precautions are strongly recommended. EnEnsure that an esd approved carrier is used when units are transported

from one destination to another. personal groundings is to be worn at all times when handling these devices. the manufacturer assumes no responsibilities for esd damage due to

improper storage and handling of these devices.

Table 3. Product Qualification Operational Life Test Results [1]

Stress

Product

Conditions

Duration

Failures/number tested

High Temperature

Operating Life (HTOL)

VMMK-2203

Vd = 5V, Id 23mA with junction

temperature of 150C

1000hrs

0/48

VMMK-2403

Vd = 5V, Id 52mA with junction

temperature of 150C

1000hrs

0/48

VMMK-2203

85C/85%RH,

Vd = 5V, Id = 23mA

1000hrs

0/48

VMMK-2403

85C/85%RH,

Vd = 5V, Id = 52mA

1000hrs

0/48

Wet High Temperature

Operating Life (WHTOL)

VMMK-2203 Failure criterion: Id degradation > 20%, NF & Gain degradation > 0.5dB

VMMK-2403 Failure criterion: Id degradation > 20%, NF & Gain degradation > 0.5dB, OIP3 degradation > 2dBm

Table 4. Product Qualification Unbiased Environmental Stress Results [1]

Stress

Product

Conditions

Duration

Failures/number tested

Temperature Cycle

VMMK-2203

JESD22A-104C, Cond B

-55 C /+125C,

15mins dwell (Air to Air)

500 cycles

0/90

500 cycles

0/88

1000hrs

0/90

1000hrs

0/87

1000hrs

0/90

1000hrs

0/85

1000hrs

0/89

1000hrs

0/88

VMMK-2403

Low Temperature

Storage Life

VMMK-2203

JESD22-A119, Cond A

-40C

VMMK-2403

High Temperature

Storage Life

VMMK-2203

JESD22-A103C, Cond A

125C

VMMK-2403

Temperature Humidity

Storage Life

VMMK-2203

85 C/85%RH

VMMK-2403

VMMK-2203 Failure criterion: Id degradation > 20%, NF & Gain degradation > 0.5dB

VMMK-2403 Failure criterion: Id degradation > 20%, NF & Gain degradation > 0.5dB, OIP3 degradation > 2dBm

Note [1]: Life parts were sampled from 3 different wafers.

Table 5. Mechanical Test Results [2]

Stress

Conditions

Duration

Failures/number tested

Drop Test

JESD22-B111

60 drops

0/60

Cycle Bending Test

Amplitude = 2mm

50 cycles

0/60

Vibration

JESD22-B103-B

20Hz -2kHz @ 20Hz/min

For 3 axis (X, Y & Z)

4 cycles / axis

(4mins/axis/cycle)

0/102

Temperature Cycle

JESD22A-104C, Cond G

-40C/125C,

15mins dwell (Air to Air)

500 cycles

0/143

Solder Dip Test

JESD22-B102E

245C5C, Pb Free Solder

5secs / dip

0/66

Failure criterion: resistance change > 200%.

Solder Dip failure criterion: solder coverage < 95% on individual solder pads..

Note [2]: Daisy chain parts were sampled from 3 different wafers.

Table 6. Electrostatic Discharge (ESD) Test Results

VMMK-2103

ESD Test

Reference:

Results

Human Body Model

JESD22-A114

125V (Class 0)

Machine Model

JESD22-A115

50V (Class A)

ESD Test

Reference:

Results

Human Body Model

JESD22-A114

450V (Class 1A)

Machine Model

JESD22-A115

40V (Class A)

ESD Test

Reference:

Results

Human Body Model

JESD22-A114

300V (Class 1A)

Machine Model

JESD22-A115

40V (Class A)

ESD Test

Reference:

Results

Human Body Model

JESD22-A114

675V (Class 1B)

Machine Model

JESD22-A115

50V (Class A)

ESD Test

Reference:

Results

Human Body Model

JESD22-A114

625V (Class 1B)

Machine Model

JESD22-A115

60V (Class A)

VMMK-2203

VMMK-2303

VMMK-2403

VMMK-2503

ESD Failure criterion: Leakage current increase > 10x after exposure to ESD pulse.

HBM

ESD Sensitivity

Class 0 is ESD voltage level < 250V, Class 1A is voltage

level between 250V and 500V, Class 1B is voltage level between 500V and 1000V, Class 1C is voltage level between

1000V and 2000V, Class 2 is voltage level between 2000V

and 4000V, Class 3A is voltage level between 4000V and

8000V, Class 3B is voltage level > 8000V.

Note: The device is classified as ESD sensitive. The following precautions should be taken:

MM

Class A is ESD voltage level <200V, Class B is voltage level

between 200V and 400V, Class C is voltage level > 400V.

1. Ensure Faraday cage or conductive shield bag is used

when the device is transported from one destination to

another.

2. At SMT assembly station, if the static charge is above

the device sensitivity level, place an ionizer near to the

device for charge neutralization purpose.

3. Personal grounding has to be worn at all time when

handling the device.

Moisture Sensitivity Level: Level 2

Preconditioning per J-STD-020 Level 2 was performed on

all devices prior to reliability testing.

For product information and a complete list of distributors, please go to our web site:

www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies in the United States and other countries.

Data subject to change. Copyright 2005-2009 Avago Technologies. All rights reserved.

AV02-1995EN - June 25, 2009

Você também pode gostar

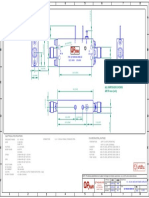

- All Dimensions Shown Are IN MM (Inch) : Ø2.5 (Ø0.10) Thru (4 Places) GroundDocumento1 páginaAll Dimensions Shown Are IN MM (Inch) : Ø2.5 (Ø0.10) Thru (4 Places) GroundTribu Vaquero JimenezAinda não há avaliações

- J1 RF in J2 RF Out D/C: XXXX S/N:XXX P/N: QP-AMLNA-0040-02Documento1 páginaJ1 RF in J2 RF Out D/C: XXXX S/N:XXX P/N: QP-AMLNA-0040-02Tribu Vaquero JimenezAinda não há avaliações

- J1 RF in J2 RF Out D/C: XXXX S/N:XXX P/N: QP-AMLNA-0040-01Documento1 páginaJ1 RF in J2 RF Out D/C: XXXX S/N:XXX P/N: QP-AMLNA-0040-01Tribu Vaquero JimenezAinda não há avaliações

- Model 42100: Power DividersDocumento3 páginasModel 42100: Power DividersTribu Vaquero JimenezAinda não há avaliações

- Microwave Hyperabrupt Tuning VaractorsDocumento2 páginasMicrowave Hyperabrupt Tuning VaractorsTribu Vaquero JimenezAinda não há avaliações

- QP MICROWAVE Bias TeesDocumento2 páginasQP MICROWAVE Bias TeesTribu Vaquero JimenezAinda não há avaliações

- QP MICROWAVE AttenuatorsDocumento2 páginasQP MICROWAVE AttenuatorsTribu Vaquero JimenezAinda não há avaliações

- Ernst Martin - Rechen Machinen Part 6Documento25 páginasErnst Martin - Rechen Machinen Part 6Tribu Vaquero JimenezAinda não há avaliações

- QP MICROWAVE AmplifiersDocumento2 páginasQP MICROWAVE AmplifiersTribu Vaquero JimenezAinda não há avaliações

- Synthesizer User Manual - 00C (Model QP-FSPLL-0040-01) V1.7Documento17 páginasSynthesizer User Manual - 00C (Model QP-FSPLL-0040-01) V1.7Tribu Vaquero JimenezAinda não há avaliações

- Conversiondela Moneda ExtranjeraDocumento84 páginasConversiondela Moneda ExtranjeraBrandonAinda não há avaliações

- An Ultra Broad Band Reflection Type Phase ShifterDocumento7 páginasAn Ultra Broad Band Reflection Type Phase ShifterTribu Vaquero JimenezAinda não há avaliações

- InTech-Coplanar Microstrip Transitions For Ultra Wideband CommunicationsDocumento22 páginasInTech-Coplanar Microstrip Transitions For Ultra Wideband CommunicationsTribu Vaquero JimenezAinda não há avaliações

- Guidelines To Understanding Reliability Prediction - MTBF Report - 24 June 2005Documento29 páginasGuidelines To Understanding Reliability Prediction - MTBF Report - 24 June 2005lsombrio0% (1)

- Circuit Simulation of Varactor Loaded Line Phase Shifter: V C V CDocumento4 páginasCircuit Simulation of Varactor Loaded Line Phase Shifter: V C V CdhvbkhnAinda não há avaliações

- FLM0910 4FDocumento4 páginasFLM0910 4FTribu Vaquero JimenezAinda não há avaliações

- Using Failure Rate Data to Predict Electronic System ReliabilityDocumento34 páginasUsing Failure Rate Data to Predict Electronic System ReliabilityTribu Vaquero JimenezAinda não há avaliações

- CMD201 Ver 1 1 1214Documento10 páginasCMD201 Ver 1 1 1214Tribu Vaquero JimenezAinda não há avaliações

- HG532s Home Gateway Product Description PDFDocumento16 páginasHG532s Home Gateway Product Description PDFTribu Vaquero JimenezAinda não há avaliações

- The Future of MM-Wave PackagingDocumento11 páginasThe Future of MM-Wave PackagingTribu Vaquero JimenezAinda não há avaliações

- Bias Circuits For RF DevicesDocumento20 páginasBias Circuits For RF Devicesmaheshsamanapally100% (1)

- Microtip Resistance Parallel Gap WeldingDocumento2 páginasMicrotip Resistance Parallel Gap WeldingTribu Vaquero JimenezAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- LocationDocumento12 páginasLocationPavithra GowthamAinda não há avaliações

- 1Documento37 páginas1Phuong MaiAinda não há avaliações

- Pakistan Academy School Al-Ahmadi Kuwait Monthly Test Schedule Class: 9 FBISEDocumento16 páginasPakistan Academy School Al-Ahmadi Kuwait Monthly Test Schedule Class: 9 FBISEapi-126472277Ainda não há avaliações

- Fluid Mosaic Paper PDFDocumento0 páginaFluid Mosaic Paper PDFDina Kharida100% (1)

- Flex Module (IFLEX MFLEX UFLEX) Level 1Documento79 páginasFlex Module (IFLEX MFLEX UFLEX) Level 1John Mark EspalmadoAinda não há avaliações

- Video WorksheetDocumento9 páginasVideo Worksheetapi-316047658100% (1)

- QC Story TRAINING SLIDEDocumento47 páginasQC Story TRAINING SLIDEDIPAK VINAYAK SHIRBHATE83% (6)

- Labsheet 1 (Int)Documento3 páginasLabsheet 1 (Int)mail meAinda não há avaliações

- Astrological Signs ExplainedDocumento16 páginasAstrological Signs ExplainedAna-Maria Negrii100% (1)

- Measurement Circularity Preview - GDTDocumento8 páginasMeasurement Circularity Preview - GDTllmm_088Ainda não há avaliações

- Journal No.1:: My Personal TimelineDocumento5 páginasJournal No.1:: My Personal TimelineSheena ChanAinda não há avaliações

- ICAO Annex 19 PresentationDocumento46 páginasICAO Annex 19 PresentationBenoit Paré100% (1)

- Anthroposophy and Eco FascismDocumento68 páginasAnthroposophy and Eco FascismPierre MoineAinda não há avaliações

- Bresnen M. and Marshall N. 2000a Building Partnerships Case Studies of Client Contractor Collaboration in The UK Construction Industry'Documento14 páginasBresnen M. and Marshall N. 2000a Building Partnerships Case Studies of Client Contractor Collaboration in The UK Construction Industry'VivianeLeuchtenbergPEspositoAinda não há avaliações

- Møire 4.01 Docs (1993)Documento15 páginasMøire 4.01 Docs (1993)VintageReadMeAinda não há avaliações

- Principles of Traditional Indian ArchitectureDocumento1 páginaPrinciples of Traditional Indian ArchitectureAr SanjayAinda não há avaliações

- Permutations and CombinationsDocumento15 páginasPermutations and CombinationsThe Rock100% (1)

- Body Language and AttractionDocumento21 páginasBody Language and Attractionpoiqwe1Ainda não há avaliações

- I+ME ACTIA SAE J2534 Support Release NotesDocumento4 páginasI+ME ACTIA SAE J2534 Support Release NotesJose AGAinda não há avaliações

- COMSATS University Pakistan Studies Industrial Sector Challenges ProjectDocumento3 páginasCOMSATS University Pakistan Studies Industrial Sector Challenges ProjectLaiba KhanAinda não há avaliações

- Automatic Payment Program SAP Easy Access GuideDocumento19 páginasAutomatic Payment Program SAP Easy Access GuidePrakash PalanisamyAinda não há avaliações

- Sword FactsheetDocumento2 páginasSword Factsheetskywalk189Ainda não há avaliações

- Session 1 - Introduction To HIP 2017Documento18 páginasSession 1 - Introduction To HIP 2017teachernizz100% (3)

- CERN Initial Letter For Yr 12Documento2 páginasCERN Initial Letter For Yr 12AlexFryAinda não há avaliações

- Playboy 2Documento12 páginasPlayboy 2theraphimAinda não há avaliações

- Heritage Theme Resort: Thesis ReportDocumento8 páginasHeritage Theme Resort: Thesis ReportNipun ShahiAinda não há avaliações

- Electromagnetism WorksheetDocumento3 páginasElectromagnetism WorksheetGuan Jie KhooAinda não há avaliações

- 1 ECI 2015 Final ProgramDocumento122 páginas1 ECI 2015 Final ProgramDenada Florencia LeonaAinda não há avaliações

- Binary Classification MetricsDocumento6 páginasBinary Classification MetricssharathdhamodaranAinda não há avaliações

- SAP Inventory Module ProcessDocumento37 páginasSAP Inventory Module ProcessRajesh ChalkeAinda não há avaliações