Escolar Documentos

Profissional Documentos

Cultura Documentos

Steel Fabrication Specifications (Samples)

Enviado por

SHEKAR RAM LOGANATHANTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Steel Fabrication Specifications (Samples)

Enviado por

SHEKAR RAM LOGANATHANDireitos autorais:

Formatos disponíveis

NEW CAR PARK BUILDING AT THE MINISTRIES COMPLEX, KUWAIT

for the MINISTRY OF FINANCE

DOCUMENT III-2: PARTICULAR SPECIFICATIONS

_________________________________________________________________

SECTION 05810

EXPANSION JOINT COVER ASSEMBLIES

PART 1 - GENERAL

1.01 WORK INCLUDED

A.

B.

1.02

1.03

FLOOR JOINTS

1.

Factory manufactured pre-engineered heavy duty, fire rated floor joint

system: complete with all fixing devices, condensation barriers and

assembly.

2.

Location: Expamsion Joints in floors

CEILING JOINTS

1.

Factory manufactured pre-engineered fire rated ceiling joint:

comprising integral aluminium frame, concertina type gasket and

associated fixing devices.

2.

Location: in suspended ceilings directly above heavy duty floor joint

system.

RELATED WORK SPECIFIED ELSEWHERE:

1.

Concrete Accessories : Section 03150

2.

Insitu Concrete : Section 03300

3.

Suspended Ceilings: Division 9

QUALITY ASSURANCE

A.

INSTALLER'S QUALIFICATIONS:

1.

B.

C.

Joint cover assemblies shall be installed by skilled personnel having

a minimum of 10 years experience of similar systems.

SUPPLIER'S QUALIFICATIONS:

1.

Obtain anchors and fixings from a supplier specialising in expansion

joint cover assemblies having adequate capacity and facilities to

meet specified requirements.

3.

Obtain written approval of Engineer to fixings supplier.

FIRE PERFORMANCE DATA

1.

Fire rating includes for integrity and insulation rating.

2.

Testing and rating of material to be in accordance with BS 476 : part

20 : 1987 or with USA standard ANS/U.L. 263 procedure, giving a 2

hour rating in accordance with NFPA No.21

Expansion Joint Cover Assemblies

Page 05810/1

NEW CAR PARK BUILDING AT THE MINISTRIES COMPLEX, KUWAIT

for the MINISTRY OF FINANCE

DOCUMENT III-2: PARTICULAR SPECIFICATIONS

_________________________________________________________________

3.

1.04

B.

1.06

Floor movement joints to be fire-rated to a period of 2 hours.

b.

Ceiling movement joints to be fire rated to a period of 1 hour.

SAMPLES:

1.

2.00 M length of proposed floor joint system complete with at least

one 90 bend. Submit sample in extruded aluminium, natural finish.

2.

2.00 M length of proposed ceiling - fixed interior joints, complete with

relevant fire barrier, colour of gasket insert to match ceiling tile.

3.

2.00 M length of fire barrier suitable for use with the chosen system

of jointing. Barrier to be self contained using a galvanised retainer

with integral flanges into which mineral wool insulation can be laid

and adequately supported.

SHOP DRAWINGS:

1.

Submit shop drawings in accordance with requirements of Division 1

in time to meet the construction programme, allowing 21 days for

Engineer's review and approval.

2.

Drawings shall show:

a.

Locations, dimensioned plans, large scale details, attachment

devices and other components.

b.

Manufacturers or fabricators product data sheets for each

process, product or material used or specified either in the

construction assembly or finishing work of this section.

c.

Fire rated components : include all relevant certification and

product data sheets for fire rated barrier component.

PRODUCT DELIVERY STORAGE AND HANDLING

A.

Protect all components during transit, delivery, storage and handling to

prevent damage, soiling and deterioration.

B.

Do not deliver until painting, wet work, grinding and similar operations

which could damage, soil or deteriorate have been completed in installation

areas.

PROJECT CONDITIONS

A.

B.

1.07

a.

SUBMISSIONS

A.

1.05

Fire ratings shall be as follows :

Install floor and ceiling joint systems only when applicable, i.e.: when

adjoining finishes are being installed.

Do not install into concrete /screed surfaces until fully cured.

FABRICATION GENERAL

Expansion Joint Cover Assemblies

Page 05810/2

NEW CAR PARK BUILDING AT THE MINISTRIES COMPLEX, KUWAIT

for the MINISTRY OF FINANCE

DOCUMENT III-2: PARTICULAR SPECIFICATIONS

_________________________________________________________________

1.

2.02

Prior to proceeding with placing of orders, obtain field measurements

of joint widths in concrete structures.

PRODUCTS

A.

FLOOR JOINTS

1.

Floor movement joint manufactured from continuous extruded

aluminium frame to seat within a floor recess. Complete with

continuous extruded aluminium serrated cover plate secured by flat

head machine screw and nut onto floor frame. Centre of joint to be

covered with a continuous extruded aluminium secondary centre

plate with a serrated outer finish, complete with securing bolt

assembly and sub-plate.

2.

Aluminium frame to be fixed into recess by screw fixings in plugs at

maximum 600 mm centres.

3.

Assembly to be carefully levelled to provide a flat, even and smooth

surface free from surface irregularities and unevenness.

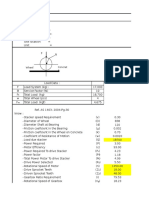

4.

Performance Data:

joint width of 100 mm

5.

B.

Floor recess to be oversized to allow for insertion at perimeters of a

closed cell type compressible foam filler piece with a 10X10 mm HD.

mastic caulk.

CEILING JOINTS

1.

Ceiling movement joint comprising standard extruded aluminium

frame, clear anodised finish with integral flexible gasket seal in

concertina type form.

2.

Aluminium frame secured to suspended ceiling hanging grid by self

tapping screws secured at 600 mm centres.

3.

Flexible gasket colour to match ceiling tile colour.

4.

Installation of joint into the ceiling grid system shall be to the approval

of the Engineer, but shall coincide vertically with the location of the

floor movement joint assembly. Ensure no unevenness or ceiling tile

distortion occurs when fitted.

5.

Performance Data:

joint width of 100 mm

Expansion Joint Cover Assemblies

Page 05810/3

NEW CAR PARK BUILDING AT THE MINISTRIES COMPLEX, KUWAIT

for the MINISTRY OF FINANCE

DOCUMENT III-2: PARTICULAR SPECIFICATIONS

_________________________________________________________________

C.

D.

FIRE RETARDANT COMPONENTS

1.

Shall be obtained from the same source as the pre-engineered floor

and ceiling movement devices.

2.

The fire barrier shall be suitable for use with either movement joint

and be itself comprised of factory made components.

3.

Fire rated mastic : See Section 07900

4.

The fire barrier system shall comprise a 24 gauge galvanised

retaining sheath filled with non-combustible filler, approximately 6 mm

thick with integral flanges forming a U shape profile. The carrier will

be filled with mineral wool insulation and fixed into position suitable

for either a floor or ceiling condition.

FASTENERS AND ANCHORS

1.

2.04

Screws

a.

Select material, size, type and finish required for each use and

where supplied as part of an assembly, these shall be

specifically used for the purpose they are intended for

b.

Screws into concrete or grounds shall be screwed within Nylon

type plugs and be correctly sized and drilled to suit the particular

screw.

APPROVED MANUFACTURERS

A.

MANUFACTURERS AND SUPPLIERS:

1.

C S Group (UK) Ltd.

tel: 01296 399700

2.

Compriband Ltd.

UK

tel: 0191 417 8707

3.

or equal and approved in writing by the Engineer

PART 3 - EXECUTION

3.01

INSPECTION

A.

CONCRETE SURFACES:

1.

3.02

Ensure that concrete surfaces which will be in direct contact with

fixings are finished true to plane.

INSTALLATION GENERALLY

A.

SETTING OUT:

Expansion Joint Cover Assemblies

Page 05810/4

NEW CAR PARK BUILDING AT THE MINISTRIES COMPLEX, KUWAIT

for the MINISTRY OF FINANCE

DOCUMENT III-2: PARTICULAR SPECIFICATIONS

_________________________________________________________________

1.

B.

Set out floor/and ceiling joint systems in accordance with the

Drawings and final shop drawings.

FIXING:

1.

Provide anchors, supports, fasteners and other attachments shown

or necessary to secure joints in place.

2.

Set floor joints into substrate and ensure firm anchorage.

3.

Attach ceiling joints into suspended ceilings and ensure satisfactory

attachment.

4.

Provide suitable levelling shims for use with floor movement joints.

Adequately pack and fully support along the length where required.

Do not spot pack.

END OF SECTION

Expansion Joint Cover Assemblies

Page 05810/5

Você também pode gostar

- UKWA StandardsDocumento12 páginasUKWA StandardsOmkar LokhandeAinda não há avaliações

- Australian Standard: Particleboard Flooring Part 2: InstallationDocumento7 páginasAustralian Standard: Particleboard Flooring Part 2: InstallationJuan Francisco Guzmán Zabala0% (2)

- As 1324.1-2001 Air Filters For Use in General Ventilation and Air Conditioning Application Performance and ConDocumento7 páginasAs 1324.1-2001 Air Filters For Use in General Ventilation and Air Conditioning Application Performance and ConSAI Global - APACAinda não há avaliações

- As 4606-2000 Fire Resistant and Antistatic Requirements For Conveyor Belting Used in Underground Coal MinesDocumento6 páginasAs 4606-2000 Fire Resistant and Antistatic Requirements For Conveyor Belting Used in Underground Coal MinesSAI Global - APACAinda não há avaliações

- P E F C R Uninterruptible Power Supply (UPS) : September 22, 2016Documento53 páginasP E F C R Uninterruptible Power Supply (UPS) : September 22, 2016Karim IsmailAinda não há avaliações

- Welder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Documento2 páginasWelder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Ali TalebiAinda não há avaliações

- AS 60947.8-2005 Low-Voltage Switchgear and Controlgear Control Units For Built-In Thermal Protection (PTC) Fo PDFDocumento8 páginasAS 60947.8-2005 Low-Voltage Switchgear and Controlgear Control Units For Built-In Thermal Protection (PTC) Fo PDFSAI Global - APACAinda não há avaliações

- Article CelluloseDocumento8 páginasArticle CellulosekrizelAinda não há avaliações

- NHBC Brick Corbel LingDocumento8 páginasNHBC Brick Corbel LingAli SialAinda não há avaliações

- 2023 Enerack Solar Mounting System CatalogDocumento29 páginas2023 Enerack Solar Mounting System CatalogIan CarvalhoAinda não há avaliações

- Clyde Bergemann Biomass Solutions ENGLISHDocumento6 páginasClyde Bergemann Biomass Solutions ENGLISHErickAinda não há avaliações

- Boogie Stacker: Concret e WheelDocumento4 páginasBoogie Stacker: Concret e WheelWaris La Joi WakatobiAinda não há avaliações

- Section 2. Visual InspectionDocumento5 páginasSection 2. Visual InspectionblackhawkAinda não há avaliações

- Routine Press Maintenance Routine Press Maintenance Routine Press Maintenance Routine Press MaintenanceDocumento42 páginasRoutine Press Maintenance Routine Press Maintenance Routine Press Maintenance Routine Press MaintenanceMorshedAinda não há avaliações

- As ISO 10006-2003 Quality Management Systems - Guidelines For Quality Management in ProjectsDocumento8 páginasAs ISO 10006-2003 Quality Management Systems - Guidelines For Quality Management in ProjectsSAI Global - APACAinda não há avaliações

- NYP BM0075 Financial Analysis ProjectDocumento10 páginasNYP BM0075 Financial Analysis ProjectKeo NgAinda não há avaliações

- Blastrac Catalogue 2018 ENG LR2Documento122 páginasBlastrac Catalogue 2018 ENG LR2elfigossAinda não há avaliações

- Plans To Improve WH EfficienciesDocumento6 páginasPlans To Improve WH EfficienciesVaibhav VishwakarmaAinda não há avaliações

- Kiln Shell CoolingDocumento4 páginasKiln Shell CoolingjmpbarrosAinda não há avaliações

- Corrosion Resistant Primer Product InfoDocumento2 páginasCorrosion Resistant Primer Product InfoĐinh Thiện SỹAinda não há avaliações

- 9103 PDFDocumento3 páginas9103 PDFEong Huat Corporation Sdn BhdAinda não há avaliações

- Chemrite Injection XPDocumento2 páginasChemrite Injection XPghazanfarAinda não há avaliações

- BS en 12502-3Documento18 páginasBS en 12502-3laboratorium logamAinda não há avaliações

- As 3007.1-2004 Electrical Installations - Surface Mines and Associated Processing Plant Scope and DefinitionsDocumento7 páginasAs 3007.1-2004 Electrical Installations - Surface Mines and Associated Processing Plant Scope and DefinitionsSAI Global - APACAinda não há avaliações

- Kingspan Jindal Final - Industrial and Cold Storage - Brochure - IndiaDocumento21 páginasKingspan Jindal Final - Industrial and Cold Storage - Brochure - IndiaRaja SrinivasAinda não há avaliações

- Hot Rolled SectionsDocumento30 páginasHot Rolled SectionsDuncan HarrisonAinda não há avaliações

- Financial ReportingDocumento133 páginasFinancial ReportingClerry SamuelAinda não há avaliações

- Metric Thread - Extended Thread Size RangeDocumento19 páginasMetric Thread - Extended Thread Size RangeNatashaAggarwalAinda não há avaliações

- Basics of Pressure Relief Valves, Article, Beswick EngineeringDocumento4 páginasBasics of Pressure Relief Valves, Article, Beswick EngineeringAnonymous 818o0FhNpAinda não há avaliações

- Nzs 4121 2001 PDFDocumento130 páginasNzs 4121 2001 PDFpaulAinda não há avaliações

- ECCS Journal - 6 (2013) - No 2 - Racking Shelving - Tilburgs PDFDocumento12 páginasECCS Journal - 6 (2013) - No 2 - Racking Shelving - Tilburgs PDFSebastien CabotAinda não há avaliações

- Elastopor H 1221/92: Technical Data SheetDocumento2 páginasElastopor H 1221/92: Technical Data SheetLassad ZitouniAinda não há avaliações

- Aalco Metals LTD Aluminium Alloy 1050A H14 Sheet 57Documento2 páginasAalco Metals LTD Aluminium Alloy 1050A H14 Sheet 57Eric Amoakwa-BoaduAinda não há avaliações

- As 4428.3-2004 Fire Detection Warning Control and Intercom Systems - Control and Indicating Equipment Fire BRDocumento7 páginasAs 4428.3-2004 Fire Detection Warning Control and Intercom Systems - Control and Indicating Equipment Fire BRSAI Global - APACAinda não há avaliações

- Long Barbed Tape Obstacles: Standard Specification ForDocumento4 páginasLong Barbed Tape Obstacles: Standard Specification ForDarwin DarmawanAinda não há avaliações

- Masonry Contractor - Quality Plan Sample PDFDocumento27 páginasMasonry Contractor - Quality Plan Sample PDFToska ExAinda não há avaliações

- Plant Layout ProblemDocumento52 páginasPlant Layout Problemtony_njAinda não há avaliações

- What is ASTM C1729 standardDocumento2 páginasWhat is ASTM C1729 standardLữ Hành ShutoAinda não há avaliações

- DuctDocumento14 páginasDuctSalehAfadlehAinda não há avaliações

- Implementing Target CostingDocumento31 páginasImplementing Target CostingJonnattan MuñozAinda não há avaliações

- As 4655-2005 Fire Safety AuditsDocumento8 páginasAs 4655-2005 Fire Safety AuditsSAI Global - APACAinda não há avaliações

- Belzona Flange Face Forming Kit Flyer PDFDocumento2 páginasBelzona Flange Face Forming Kit Flyer PDFRida ChaiAinda não há avaliações

- Reform Tub With Ring Distributor: For Smooth Operation and Well-Formed CoilsDocumento2 páginasReform Tub With Ring Distributor: For Smooth Operation and Well-Formed CoilsNicolas ValleAinda não há avaliações

- As 2400.22-2005 Packaging ClosuresDocumento7 páginasAs 2400.22-2005 Packaging ClosuresSAI Global - APACAinda não há avaliações

- Foster Wheeler - CFB BrochureDocumento20 páginasFoster Wheeler - CFB Brochureank_mehraAinda não há avaliações

- Module 003: Construction Contract Management and AdministrationDocumento41 páginasModule 003: Construction Contract Management and AdministrationbotchAinda não há avaliações

- Malaysian Standard: Single-Use Medical Examination Gloves - Specification (Second Revision) (ISO 11193-1:2002, MOD)Documento7 páginasMalaysian Standard: Single-Use Medical Examination Gloves - Specification (Second Revision) (ISO 11193-1:2002, MOD)LEE KAR MENG STEVENAinda não há avaliações

- As 2483-2003 Metal Finishing - Recommended Sampling Plans For The Inspection and Testing of Coatings (ISO 451Documento6 páginasAs 2483-2003 Metal Finishing - Recommended Sampling Plans For The Inspection and Testing of Coatings (ISO 451SAI Global - APAC0% (1)

- Key Issues Energy Efficient Building EnvelopesDocumento8 páginasKey Issues Energy Efficient Building Envelopesaoab50Ainda não há avaliações

- Design Audit ReportDocumento53 páginasDesign Audit Reportdishazb4u6473Ainda não há avaliações

- Planning Cement Terminal OperationsDocumento10 páginasPlanning Cement Terminal Operationsasad55001Ainda não há avaliações

- Flowserve Multiphase PumpsDocumento8 páginasFlowserve Multiphase PumpsveronrazvyAinda não há avaliações

- Load Cell Technology Vpg-01Documento13 páginasLoad Cell Technology Vpg-01Marcos Aldana VillaldaAinda não há avaliações

- Price BookDocumento32 páginasPrice BooksimopairAinda não há avaliações

- Dometic S4 Installation - and - Operating - Manual - 52401 PDFDocumento146 páginasDometic S4 Installation - and - Operating - Manual - 52401 PDFLigron ANaeAinda não há avaliações

- Guide Service Station OpDocumento19 páginasGuide Service Station OpqwertygmailAinda não há avaliações

- Service Activity Reports Complete PS3-PS4Documento45 páginasService Activity Reports Complete PS3-PS4Mohamed MusaAinda não há avaliações

- Proposed Hostel Block for CumminsDocumento4 páginasProposed Hostel Block for CumminssplashierprinceAinda não há avaliações

- Spec DoorDocumento6 páginasSpec DoorvomquyAinda não há avaliações

- Expansion Joint Cover Assembly SpecificationsDocumento5 páginasExpansion Joint Cover Assembly SpecificationsuddinnadeemAinda não há avaliações

- Rainfall EventDocumento1 páginaRainfall EventSHEKAR RAM LOGANATHANAinda não há avaliações

- Min and Max Are of ReinforcementDocumento1 páginaMin and Max Are of ReinforcementSHEKAR RAM LOGANATHANAinda não há avaliações

- Plastic Settlement in Fresh Concrete PDFDocumento1 páginaPlastic Settlement in Fresh Concrete PDFSHEKAR RAM LOGANATHANAinda não há avaliações

- Effect of Corrosion in ReinforcementDocumento1 páginaEffect of Corrosion in ReinforcementSHEKAR RAM LOGANATHANAinda não há avaliações

- A Small Field Testing LaboratoryDocumento6 páginasA Small Field Testing LaboratorySHEKAR RAM LOGANATHANAinda não há avaliações

- Min and Max Are of ReinforcementDocumento1 páginaMin and Max Are of ReinforcementSHEKAR RAM LOGANATHANAinda não há avaliações

- How Tension Reinforcement Affects Concrete DeflectionDocumento1 páginaHow Tension Reinforcement Affects Concrete DeflectionSHEKAR RAM LOGANATHANAinda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Dusting of Concrete Slab SurfaceDocumento4 páginasDusting of Concrete Slab SurfaceSHEKAR RAM LOGANATHANAinda não há avaliações

- MetFabrication SpecificationsDocumento6 páginasMetFabrication SpecificationsSHEKAR RAM LOGANATHANAinda não há avaliações

- Arch Steel Work SpecificationDocumento6 páginasArch Steel Work SpecificationSHEKAR RAM LOGANATHANAinda não há avaliações

- StructSteel SpecificationsDocumento10 páginasStructSteel SpecificationsSHEKAR RAM LOGANATHANAinda não há avaliações

- Sample Steel Structure Cover PageDocumento1 páginaSample Steel Structure Cover PageSHEKAR RAM LOGANATHANAinda não há avaliações

- 1300 Math Formulas - Alex SvirinDocumento338 páginas1300 Math Formulas - Alex SvirinMirnesAinda não há avaliações

- Soil and Water Relationships for Plant GrowthDocumento18 páginasSoil and Water Relationships for Plant GrowthpaajiAinda não há avaliações

- Note On Dam HeightDocumento3 páginasNote On Dam HeightSHEKAR RAM LOGANATHANAinda não há avaliações

- How To Win Every Argument PDFDocumento196 páginasHow To Win Every Argument PDFRice RS100% (7)

- CIVIL 3 4 Sem R2008Documento25 páginasCIVIL 3 4 Sem R2008Shanmu Ga SundaramAinda não há avaliações

- Special Advance Format For Project 2017 2020Documento7 páginasSpecial Advance Format For Project 2017 2020Dennis RojasAinda não há avaliações

- DinDocumento11 páginasDinharshadAinda não há avaliações

- Yanmar - 3tna72lDocumento194 páginasYanmar - 3tna72lTiago Campos100% (1)

- Inergen SpecDocumento19 páginasInergen SpecMargaret DaughertyAinda não há avaliações

- Piping Course هام جداDocumento206 páginasPiping Course هام جداMohamed Ibrahim100% (1)

- Specification Sheets 50100 5202BN TR571Documento3 páginasSpecification Sheets 50100 5202BN TR571MZY Commercial EnterprisesAinda não há avaliações

- Concrete Flag Pavements Design GuideDocumento31 páginasConcrete Flag Pavements Design GuideNguyễn Hoàng Bảo100% (2)

- 1.11 - Fire Following Earthquake PDFDocumento27 páginas1.11 - Fire Following Earthquake PDFNicolas De NadaiAinda não há avaliações

- Energy Recovery Ventilation System Type FHBQ: Air Handling Units, Chillers & FancoilsDocumento6 páginasEnergy Recovery Ventilation System Type FHBQ: Air Handling Units, Chillers & FancoilsЈово КруљAinda não há avaliações

- Mechanic Documents: Drawings and Parts ListsDocumento21 páginasMechanic Documents: Drawings and Parts ListsisnaldoAinda não há avaliações

- Construction Site Visit OverviewDocumento12 páginasConstruction Site Visit OverviewCaereel LopezAinda não há avaliações

- Dr. D. Y. Patil School of Engineering & Technology Department of Civil Engineering Be Project Phase Ii Sheet (Ay2019-20) Sem IiDocumento3 páginasDr. D. Y. Patil School of Engineering & Technology Department of Civil Engineering Be Project Phase Ii Sheet (Ay2019-20) Sem IiRao SahabAinda não há avaliações

- Recyte Clsoed Loop Roof Cover Board 041118Documento2 páginasRecyte Clsoed Loop Roof Cover Board 041118Robertas KupstasAinda não há avaliações

- Quotation For G.I For The Sinar Sweet Factory Building at Kassla State V02Documento4 páginasQuotation For G.I For The Sinar Sweet Factory Building at Kassla State V02abdallah abdurhman aliAinda não há avaliações

- Clean Agent Fire Suppression System SpecificationDocumento14 páginasClean Agent Fire Suppression System Specificationhendrik wibowoAinda não há avaliações

- Prevent Negative Volume in Foam ModelsDocumento9 páginasPrevent Negative Volume in Foam ModelsGustavo Yippeekayyay GusAinda não há avaliações

- Shaft Sinking: Department of Mining Engineering Muet Jamshoro (11-04-2014)Documento21 páginasShaft Sinking: Department of Mining Engineering Muet Jamshoro (11-04-2014)Carlos Arturo Casas HuamánAinda não há avaliações

- Vulkem NEM - Data SheetDocumento2 páginasVulkem NEM - Data SheetRobertAinda não há avaliações

- 2019-05-28 - DA - RSLF Artillery Brigade - Volume 2 PDFDocumento490 páginas2019-05-28 - DA - RSLF Artillery Brigade - Volume 2 PDFDusngi MoAinda não há avaliações

- Iec 60287 Grouping TableDocumento2 páginasIec 60287 Grouping TableAnas Yousuf100% (1)

- Pump (English) TemplateDocumento1 páginaPump (English) TemplateMichael HaiseAinda não há avaliações

- External and Internal Air Pressure Drop CalculatorDocumento8 páginasExternal and Internal Air Pressure Drop CalculatorfghabboonAinda não há avaliações

- Losses in Bends FittingsDocumento26 páginasLosses in Bends FittingsKunalAinda não há avaliações

- Main Pool Lanai NewDocumento10 páginasMain Pool Lanai NewWilfrid DutruelAinda não há avaliações

- Report Case StudyDocumento12 páginasReport Case StudyAnisalya Jamri100% (1)

- Welded Connections DesignDocumento35 páginasWelded Connections DesignBelkacem AchourAinda não há avaliações

- Failure Analysis of W e L D Repaired Turbine RotorDocumento6 páginasFailure Analysis of W e L D Repaired Turbine RotorAli AlyaniAinda não há avaliações

- " Hysil " Calcium Silicate Insulation Blocks & Pipes-SpecificationsDocumento1 página" Hysil " Calcium Silicate Insulation Blocks & Pipes-SpecificationsJCSAinda não há avaliações

- Gravity Retaining Walls: Understanding Rankine's Theory and Stability ConditionsDocumento12 páginasGravity Retaining Walls: Understanding Rankine's Theory and Stability ConditionsKshitija100% (2)

- T.O.S (Surface Active Structures)Documento18 páginasT.O.S (Surface Active Structures)Riddhi Aggarwal100% (1)