Escolar Documentos

Profissional Documentos

Cultura Documentos

alhere

Enviado por

Shameer MajeedTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

alhere

Enviado por

Shameer MajeedDireitos autorais:

Formatos disponíveis

223.

00-5

Fluid Mechanics - Course 223

PIPE FLOW PROBLEMS

So far we have looked at separate aspects of fluid flow

in circular pipes. We now have to consider the combined

effect of these aspects on a complete system. This involves

the use of

(a)

the continuity equation AIVl

(b)

Bernoulli's Equation.

= A2V2.

1

Considering the two points, (1), (2), on the diagram,

Bernoulli's Equation may be written as follows:

\alhere

'1<'_-

-.I:"K

EPE

EKE

EADD

ELOSS

=

=

=

=

=

Pressure Energy

Potential Energy

Kinetic Enerqy

Pump Energy

Energy loss due to surface and fluid

friction

January 1977

1 -

223.00-5

This equation may be written as follows:

vi

P2

Q,

V2

+ gh 2 + -- + ELOSS

Joules/kg

The previous lessons have basically shown us how to calculate ELOSS. We must now apply this to a'real system, where

there may be a change in height and thus a change in potential

energy and a change in section and thus a change in kinetic

energy.

It should be clearly understood that changes in KE,

PE and the losses due to friction" "ONLYaffectp"r"es"sure energy.

It is the pressure energy which is replaced, using a pump, in

a fluid flow system.

Example 1

Water is being pumped at 0.3 m3 /s. The suction line is

10" SCH 40 and the minimum suction pressure at the pump is

15 kPa(a).

Calculate the maximum length of suction line

ILl

when the suction line is fitted with a standard 90 0

elbow and an open gate valve.

~ = 1.005 X 10- 3 Ns/m 2

r-,------,V

I

C\

3m

!L

,'----- 2 -

223~DO-5

From Bernoulli's equation

V~

Pl

- + ghl + fJ,

+ EADD

2

P-L.

fJ,

v~L.

+ gh 2 + - + E LOSS

2

PI = 101 kPa (a) + fJ,gh = 101000 + 998 x 9.8 x 4 Pa

hI

VI

P2

15 kPa(a)

EADD

0

0.3

h2

8 ro ,

V2

508.7 x 10-1+

5.9 m/s

ELOSS = ?

PI

Thus

~

P2

+ gh 2 +

v-2

fJ,

+ ELOSS

gh 2

2

5.9 2

(101000 + 998 x 9.8 x 5 - 15000) - 9.8 x 8 998

135.2 - 78.4 - 17.4

39.4 J/kg

ELOSS = loss due to pipe + loss due to fittings + loss

due to exit/entrance.

KID

standard 90 0

loss due to fittings

elbow

30

13

open gate valve

43

Thus equivalent length

43 x 10 x 2.54

10.9 m

43 diameters

10- 2

Entrance loss - k for projecting pipe

0.78

0.78 x 10 x 2.54 X 10= KD

f = ---'-----"";:'f------

Thus L

VD.9].l

RE

=

=

0.3

508.7 X 10-1+

5.9 x 10 x 2.54 X 10- 2

1.005 x 10- 3

5.9 mls

1000

1.49 x 10 6

-

3 -

223.00-5

Using Chart 1 E/D

Using Chart 2

0.014

Thus entrance loss

Th us ELOS S

. . ELOSS

V2 x

x 2D

0.00018

0.78 x 10 X 2.54

0.014

14.2 m

(x + 10.9 + 14.2)

10- 2

~12

-'-------;2=D~----"--"-'

(x + 10.9 + 14.2)

Thus the maximum length x

41.1 - 10.9 - 14.2

= 16.0

16.0 -

8m

In

8 m

Example 2

The condensate extraction pumps take the condensate from

the hot well and pump it to the deaerator, via the drain cooler

and 6 lp heaters.

F10wrate is 2 x 3855 gpm

Power input to pumps is 2 x 679 bhp

Pump efficiency

Hot well level

255.25 ft

Hot well pressure

Deaerator height

0.83%

Deaerator pressure

5 kPa(a)

352 ft

288 kPa(a)

Calculate:

- 4 -

(a)

The energy loss due to friction through the pipe, heaters,

fittings, etc.

(b)

What percentage of the pump energy available does the

energy loss represent?

223.00-5

Flowrate

=

=

2 x 3855 gpm

2 x 3855 x 4.546 x 10- 3 x 1000

kg/s

60

x 3855 x 4.546 x

" (min

.

lO~3

m~

= 584.2 kg/s

Pressure energy added bv pumps

~

2 x 679 x 0.83 x 746

584.2

1439 J/kg

Rernoullis Equation

PI

.L

r.

~Ih 1

v21

2

+ E 7I T"'II'''\

.......... '-1

P

- 2

+-

qh z +

9-

V22

+ ELOSS

The velocity at the pump is the same as that just before

entering the deaerator.

ig~g + (9.81 x 255.25 x 12 x 2.45 x 10- 2 ) + 1439

2

288000

1000 + (9 . 81 x 352 x 12 x 2.45 x 10- ) + ELOSS

Thus 5 + 736 + 1439

Thus El..C2S

t

: ;,5:--:

288 + 1015 + ELOSS

877 .J/kg

due to friction

= 1 ~~~

x 100

60.9%

ASSIGNME~T

1.

In question #2, calculate the amount of heat energy

added to the condensate, via the pump.

2.

In qUAstion #2, calculate the energy loss due to the

fittings, drain cooler and feed heaters if the pipework

is 80 m of 24" SCH 40. ~ = 0.406 X 10- 3 kg/ms.

3.

Calculate the discharge pressure in question #2.

-

5 -

223.00-5

4.

A pump takes heavy water from a header, which is 12 metres

above the pump, and pumps it to a storage tank 20 metres

above the pump. The suction pipework is 16" SCH 40 and

has two fully open gate valves, three standard elbows and

is 28 metres long.

The discharge pipework is 12" SCH 40 and has a swing check

valve, two gate valves, 5 long sweep elbows and a standard

tee with flow throuah a branch and is 46 metres lonq. The

flowrate is 0.36 m3 /s U = 0.55 X 10- 3 Ns/m 2 Calculate the

current taken by the 3 ph, 4.16 kv, 0.75 pf motor which

drives the pump. The motor is 85% efficient and the pump

is 84% efficient.

How much heat energy does the pump add to the fluid?

J. Irwin-Childs

- 6 -

Você também pode gostar

- Steam Engines Machinery's Reference Series, Number 70No EverandSteam Engines Machinery's Reference Series, Number 70Ainda não há avaliações

- CEE 345 Spring 2002 problem set solutions pump efficiency discharge headDocumento10 páginasCEE 345 Spring 2002 problem set solutions pump efficiency discharge headAdrian Antonio TorresAinda não há avaliações

- Chapter 8 Internal Forced Convection: H H H H Z G G P H Z G G PDocumento20 páginasChapter 8 Internal Forced Convection: H H H H Z G G P H Z G G PKerem GönceAinda não há avaliações

- FLUMECHDocumento4 páginasFLUMECHniel senAinda não há avaliações

- Steady Pipe Flows: Single and Branched Lines: M.S. Ghidaoui (Spring 2006)Documento16 páginasSteady Pipe Flows: Single and Branched Lines: M.S. Ghidaoui (Spring 2006)khalidh20100% (1)

- AE 231 Thermodynamics Recitation 8 Problems - Diffuser, Turbine Cycle, Piston Spring SystemDocumento13 páginasAE 231 Thermodynamics Recitation 8 Problems - Diffuser, Turbine Cycle, Piston Spring SystemOnur ÖZÇELİKAinda não há avaliações

- Exam Solution 2009-10gDocumento9 páginasExam Solution 2009-10gConstAntinosAinda não há avaliações

- ELECTROSTATIC PRECIPITATOR OPTIMIZATIONDocumento12 páginasELECTROSTATIC PRECIPITATOR OPTIMIZATIONrajeshAinda não há avaliações

- Problem 5.2: P V Z P V Z H L D V V K DDocumento11 páginasProblem 5.2: P V Z P V Z H L D V V K Drameshaarya99Ainda não há avaliações

- 2011 SolutionsDocumento15 páginas2011 SolutionsNSunAinda não há avaliações

- Thermo HW SolutionsDocumento35 páginasThermo HW SolutionsekantikdevoteeAinda não há avaliações

- Canal AqueductDocumento21 páginasCanal AqueductFaridAziz0% (1)

- MMMDocumento9 páginasMMMBoddupalli Lohith KumarAinda não há avaliações

- Losses in pipe fittings and systemsDocumento5 páginasLosses in pipe fittings and systemssamir hussenAinda não há avaliações

- Addi Examples Pipe3Documento10 páginasAddi Examples Pipe3Diego MorenoAinda não há avaliações

- Mathematics - B 02/08/1999 Instructions:: Answer Any TwoDocumento4 páginasMathematics - B 02/08/1999 Instructions:: Answer Any TwoKiran Gayakwad100% (1)

- Chapter 5 (Color)Documento56 páginasChapter 5 (Color)Falahiah JudgeAinda não há avaliações

- Elementary Mechanics of Fluids ExplainedDocumento23 páginasElementary Mechanics of Fluids ExplainedAndre Amba MatarruAinda não há avaliações

- Engineering Questions and AnswersDocumento35 páginasEngineering Questions and Answersnoodlehead675Ainda não há avaliações

- ESAS Actual Board. Thank Me LaterDocumento5 páginasESAS Actual Board. Thank Me LaterRhea Pardo PeralesAinda não há avaliações

- Heat Transfer 8 50 (Page 521)Documento1 páginaHeat Transfer 8 50 (Page 521)Naim IkhsaamAinda não há avaliações

- Design of Shell and Tube Heat ExchangerDocumento42 páginasDesign of Shell and Tube Heat Exchanger3004 Divya Dharshini. MAinda não há avaliações

- FE CH 5 AnswerDocumento12 páginasFE CH 5 AnswerAntony ChanAinda não há avaliações

- Breakdown in Insulations 2011 Update - QuizDocumento23 páginasBreakdown in Insulations 2011 Update - QuizKung ChinHanAinda não há avaliações

- Performance Heat Balance and Efficiency Test of A Diesel Electric Power Plant LectureDocumento12 páginasPerformance Heat Balance and Efficiency Test of A Diesel Electric Power Plant LectureRalphMarwinUsonCorpuz50% (2)

- Nsolution 2Documento7 páginasNsolution 2Shankar DakshinamurthiAinda não há avaliações

- Theoretical Analysis Report: Problem DefinitionDocumento6 páginasTheoretical Analysis Report: Problem Definitionwtt1640Ainda não há avaliações

- Calculating thermodynamic properties of an ideal gas undergoing cyclic processesDocumento8 páginasCalculating thermodynamic properties of an ideal gas undergoing cyclic processesBoddupalli Lohith KumarAinda não há avaliações

- Surge AnlysisDocumento5 páginasSurge AnlysisnaveenaeeAinda não há avaliações

- CPD Assognment CH-19048Documento9 páginasCPD Assognment CH-19048Mehreen NaveedAinda não há avaliações

- Tiang Sandaran - TrotoarDocumento13 páginasTiang Sandaran - Trotoarschatz supermanAinda não há avaliações

- Chemical Engineering DepartmentDocumento18 páginasChemical Engineering Departmentiffat100% (1)

- Be Mechanical-Engineering Semester-3 2019 December Thermodynamics-CbcgsDocumento14 páginasBe Mechanical-Engineering Semester-3 2019 December Thermodynamics-CbcgsHarsh KbddhsjAinda não há avaliações

- Environmental Engineering NumericalDocumento23 páginasEnvironmental Engineering NumericalArham SheikhAinda não há avaliações

- Tank Venting According API 2000Documento34 páginasTank Venting According API 2000Youssef Lagrini50% (2)

- Shell and Tube Heat ExchangerDocumento18 páginasShell and Tube Heat ExchangertatvaAinda não há avaliações

- Hydraulics - Problems 1Documento13 páginasHydraulics - Problems 1Alyssa AmistosoAinda não há avaliações

- Waste Management AssignmenrtDocumento3 páginasWaste Management AssignmenrtGouri PrinceAinda não há avaliações

- Chapter 7Documento6 páginasChapter 7Marco LuigiAinda não há avaliações

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsDocumento14 páginasWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsAnu Sandeep AggrawalAinda não há avaliações

- Calculating water pressure and turbine selectionDocumento7 páginasCalculating water pressure and turbine selectionMaulidAinda não há avaliações

- 1 PDFDocumento9 páginas1 PDFalihasan12Ainda não há avaliações

- SAB2513 Hydraulic Chapter 7Documento37 páginasSAB2513 Hydraulic Chapter 7Tuan JalaiAinda não há avaliações

- Tech Drilling SurgeSwabPressDocumento40 páginasTech Drilling SurgeSwabPressdaongocha108Ainda não há avaliações

- Modeling Assignment by Ashenafi ZinabieDocumento48 páginasModeling Assignment by Ashenafi Zinabieashe zinabAinda não há avaliações

- Name: Nguyễn Hải Đăng Advanced program class k6 ID:1521010052 Subject: ECH 152BDocumento6 páginasName: Nguyễn Hải Đăng Advanced program class k6 ID:1521010052 Subject: ECH 152BLe Anh QuânAinda não há avaliações

- Second Exam 09-10 SolutionDocumento5 páginasSecond Exam 09-10 SolutioncolaarawrAinda não há avaliações

- Hydraulics & HydrologyDocumento4 páginasHydraulics & Hydrologyamitkap00rAinda não há avaliações

- Ce Days: Civil War (Aces-Usc)Documento5 páginasCe Days: Civil War (Aces-Usc)Andrei AlidoAinda não há avaliações

- KNOWN: Flowrate, Composition and Temperature of Flue Gas Passing Through Inner Tube of AnDocumento2 páginasKNOWN: Flowrate, Composition and Temperature of Flue Gas Passing Through Inner Tube of AnTimothy JonesAinda não há avaliações

- Thermodynamic Processes and Energy Changes in Gas SystemsDocumento17 páginasThermodynamic Processes and Energy Changes in Gas SystemsOnur ÖZÇELİKAinda não há avaliações

- Full Revised Chapter 7Documento55 páginasFull Revised Chapter 7Diovinyl Kartil67% (3)

- ME3122E - Tutorial Solution 3Documento8 páginasME3122E - Tutorial Solution 3LinShaodun100% (3)

- Proposal No: Contract No: Plant Item No: Document No: PRP/POP/2011/002/B221/DS/30000/X./1202 Data Sheet For Burner SketchDocumento1 páginaProposal No: Contract No: Plant Item No: Document No: PRP/POP/2011/002/B221/DS/30000/X./1202 Data Sheet For Burner SketchShameer MajeedAinda não há avaliações

- Fuel Cells Could Be A "Game-Changer" For Carbon Capture PDFDocumento6 páginasFuel Cells Could Be A "Game-Changer" For Carbon Capture PDFShameer MajeedAinda não há avaliações

- Annexure A (R1)Documento1 páginaAnnexure A (R1)Shameer MajeedAinda não há avaliações

- Annexure ADocumento1 páginaAnnexure AShameer MajeedAinda não há avaliações

- Repowering South Mississippi Electric Power Association's J.T PDFDocumento9 páginasRepowering South Mississippi Electric Power Association's J.T PDFShameer MajeedAinda não há avaliações

- 20042413Documento32 páginas20042413Shameer MajeedAinda não há avaliações

- Turbine Startup ProcedureDocumento3 páginasTurbine Startup ProcedureShameer Majeed100% (1)

- Az - Zour R&M Furnace Dimensions - ADocumento1 páginaAz - Zour R&M Furnace Dimensions - AShameer MajeedAinda não há avaliações

- Az Zour R&M Fuel Data ADocumento4 páginasAz Zour R&M Fuel Data AShameer MajeedAinda não há avaliações

- WWW - Power-Eng - PDF - GTCC Fast StartDocumento18 páginasWWW - Power-Eng - PDF - GTCC Fast StartShameer MajeedAinda não há avaliações

- 20042403Documento54 páginas20042403Shameer MajeedAinda não há avaliações

- 20040304Documento7 páginas20040304Shameer MajeedAinda não há avaliações

- VFDDocumento30 páginasVFDShameer MajeedAinda não há avaliações

- SaskPower Carbon Capture Facility Operating More ReliablyDocumento6 páginasSaskPower Carbon Capture Facility Operating More ReliablyShameer MajeedAinda não há avaliações

- Southern Co. Kemper IGCC Delays, Cost Surges Are Under SEC Scru PDFDocumento6 páginasSouthern Co. Kemper IGCC Delays, Cost Surges Are Under SEC Scru PDFShameer MajeedAinda não há avaliações

- 20040300Documento3 páginas20040300Shameer MajeedAinda não há avaliações

- Fuel Cells Could Be A "Game-Changer" For Carbon Capture PDFDocumento6 páginasFuel Cells Could Be A "Game-Changer" For Carbon Capture PDFShameer MajeedAinda não há avaliações

- Practical Consideration For Pump Baseplates, Grouting and FoundationDocumento6 páginasPractical Consideration For Pump Baseplates, Grouting and FoundationВладимир СмирновAinda não há avaliações

- SND Spray Nozzle Desuperheater-Installation Maintenance ManualDocumento16 páginasSND Spray Nozzle Desuperheater-Installation Maintenance ManualShameer Majeed100% (1)

- 20043200Documento287 páginas20043200Shameer MajeedAinda não há avaliações

- Film Lubrication: Hydrodyn - IcDocumento16 páginasFilm Lubrication: Hydrodyn - IcShameer MajeedAinda não há avaliações

- Nuclear Training CourseDocumento2 páginasNuclear Training CourseShameer MajeedAinda não há avaliações

- Problems encountered in boiler feed pump operationDocumento10 páginasProblems encountered in boiler feed pump operationShameer Majeed100% (2)

- Combined-Cycle HRSG Shutdown, Layup, and Startup Chemistry Control - POWERDocumento15 páginasCombined-Cycle HRSG Shutdown, Layup, and Startup Chemistry Control - POWERShameer MajeedAinda não há avaliações

- Blowdown ValvesDocumento13 páginasBlowdown ValvesShameer MajeedAinda não há avaliações

- N2 Blanketing (Power)Documento7 páginasN2 Blanketing (Power)Shameer MajeedAinda não há avaliações

- ACC PerformanceDocumento2 páginasACC PerformanceShameer MajeedAinda não há avaliações

- Blowdown TankDocumento1 páginaBlowdown TankShameer Majeed0% (1)

- FAC ChemistryDocumento6 páginasFAC ChemistrymarydaughterAinda não há avaliações

- Government Engineering College Surveying Lab ManualDocumento26 páginasGovernment Engineering College Surveying Lab ManualNittin BhagatAinda não há avaliações

- Anchors and Fall Arrest System A Guide To Good Practice: PublicationDocumento22 páginasAnchors and Fall Arrest System A Guide To Good Practice: PublicationEdward C100% (1)

- Distribution A9F74240Documento3 páginasDistribution A9F74240Dani WaskitoAinda não há avaliações

- VGS 8.1.2 Rev.20 - UTDocumento29 páginasVGS 8.1.2 Rev.20 - UTPaul-Petrus MogosAinda não há avaliações

- Estimating/ Construction Planning/ Scheduling and Programming/ Feasibility Project StudiesDocumento4 páginasEstimating/ Construction Planning/ Scheduling and Programming/ Feasibility Project StudiesVholts Villa VitugAinda não há avaliações

- QUS 303 CONSTRUCTION ECONOMICSDocumento21 páginasQUS 303 CONSTRUCTION ECONOMICSjudexnams1on1Ainda não há avaliações

- DMD Documentation Error - Freetronics ForumDocumento3 páginasDMD Documentation Error - Freetronics ForumapofviewAinda não há avaliações

- Odv-065r18ejj-G DS 2-0-3Documento1 páginaOdv-065r18ejj-G DS 2-0-3Евгений Переверзев0% (1)

- Guess Questions of Aramco Written Examination For Hse Supervisor / Engineer / OfficerDocumento31 páginasGuess Questions of Aramco Written Examination For Hse Supervisor / Engineer / OfficerAlam Shamsher0% (1)

- A320 Aircraft CharacteristicsDocumento387 páginasA320 Aircraft CharacteristicsEder LucianoAinda não há avaliações

- Biogas Calculator TemplateDocumento27 páginasBiogas Calculator TemplateAlex Julian-CooperAinda não há avaliações

- 3.17. Creep EquationsDocumento10 páginas3.17. Creep Equationsruchit solankiAinda não há avaliações

- Gps VulnerabilityDocumento28 páginasGps VulnerabilityaxyyAinda não há avaliações

- Motores SumergiblesDocumento68 páginasMotores SumergiblescyberespiaAinda não há avaliações

- GOT2000 - UserManual Monitor - SH 081196 I PDFDocumento614 páginasGOT2000 - UserManual Monitor - SH 081196 I PDFFanny Achmad Hindrarta KusumaAinda não há avaliações

- DC DC DC DC Iiii 6 6 6 6: Spec Spec Spec SpecDocumento12 páginasDC DC DC DC Iiii 6 6 6 6: Spec Spec Spec SpecarsolAinda não há avaliações

- Niveau S Longrine Type Pou05-S Section 20x25: A-A B-B C-C D-DDocumento1 páginaNiveau S Longrine Type Pou05-S Section 20x25: A-A B-B C-C D-DAWOUNANGAinda não há avaliações

- Foundation LayoutDocumento1 páginaFoundation LayoutrendaninAinda não há avaliações

- Power Transmission, Distribution and Utilization: Lecture# 13 &14: Underground CablesDocumento29 páginasPower Transmission, Distribution and Utilization: Lecture# 13 &14: Underground CablesPhD EEAinda não há avaliações

- Airflex 728 Vinyl Acetate-Ethylene Copolymer Modified With Vinyl ChlorideDocumento2 páginasAirflex 728 Vinyl Acetate-Ethylene Copolymer Modified With Vinyl ChlorideNissim Hazar CasanovaAinda não há avaliações

- Pull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLineDocumento7 páginasPull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLinecnuneza4Ainda não há avaliações

- Brochure 45 AntasariDocumento11 páginasBrochure 45 AntasariFisio Terapi100% (1)

- Lab Sheet - Infiltration TestDocumento8 páginasLab Sheet - Infiltration TestDINAMARIANASAMUJI0% (1)

- AP Create Accounting - Options & ExplanationDocumento2 páginasAP Create Accounting - Options & ExplanationSaleem JavedAinda não há avaliações

- Ceramic Terminal BlocksDocumento1 páginaCeramic Terminal BlockselijbbAinda não há avaliações

- 3RInternational Tetzner Model Based Pipeline LDS 07-2003 PDFDocumento6 páginas3RInternational Tetzner Model Based Pipeline LDS 07-2003 PDFRene ParedesAinda não há avaliações

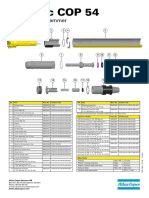

- 9853 1239 01 - COP 54 Service Poster - LOWDocumento1 página9853 1239 01 - COP 54 Service Poster - LOWValourdos LukasAinda não há avaliações

- Zener DataDocumento2 páginasZener Dataapi-27149887Ainda não há avaliações

- Ps 1 SolDocumento3 páginasPs 1 SolPang XsAinda não há avaliações

- AASHTO T283-22 Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced DamageDocumento11 páginasAASHTO T283-22 Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced DamageErnesto Oscar VidelaAinda não há avaliações