Escolar Documentos

Profissional Documentos

Cultura Documentos

Cryogenic Ball Valve: Lishui Oak Valve Parts Co,.Ltd

Enviado por

Shams TabrezTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Cryogenic Ball Valve: Lishui Oak Valve Parts Co,.Ltd

Enviado por

Shams TabrezDireitos autorais:

Formatos disponíveis

CRYOGENIC BALL VALVE

LISHUI OAK VALVE PARTS CO,.LTD

www.oakvalveparts.com

ABOUT US

Lishui Oak Valve Parts Co,.Ltd, a member of Oviko Valve Group

companies, specialized in the manufacturing of ball valves and valve

components. Over the years, OAK has built up 2 production plants in

Lishui and Oubei of Wenzhou, covering over 60,000 sqm with 400

employees. Its customers include valve manufacturers, distributors,

and end users in power, oil and gas, mining, construction, chemical

processing and refinery industries.

OAK operates in accordance with the ISO9001-2008 standard;

strictly controls every procedure from design to delivery. It can offer

all kinds of ball valve products, including floating ball valve, trunnion

pipeline ball valve, Double Block and Bleed Ball Valve, Full-Welded

Ball Valve, Top Entry Ball Valve, Metal Seated Ball Valve, Orbital Ball

Valve, V-Type Ball Valve, Jacket Ball Valve, Cryogenic Ball Valve,

One-Piece Ball Valve etc. Size from 1/248 inches, Class from

1502500. With rich experience in international standard, OAK is

able to company with API6D, API607 Fire Proof, ASTM, ANSI, JIS,

BS, DIN etc.

www.oakvalveparts.com

www.oakvalveparts.com

CRYOGENIC BALL VALVE

USAGE

The cryogenic ball valve is used to cut off or connect the media in various pipeline of Class 150~Class

1500. The valves made of different materials are suitable for various media and different temperature.

The lowest working temperature is -196. The driving modes include manual operation, worm and worm

gear transmission, pneumatic operation and electric operation. The connection ends can be flange or

welding.

STRUCTURAL FEATURES

The Cryogenic ball valves are classified into cryogenic floating ball valves and cryogenic trunnion ball

valves. Refer to the data of floating ball valve and trunnion ball valve for the product range, face-to-face

dimensions, connection flange dimensions and etc. For the ball valves with temperature high than -50

the long neck structure is not designed. For the ball valves with temperature lower than -50, the neck

length is generally designed according to standard requirements or according to user requirements.

The cryogenic ball valve is used for low temperature service condition, especially the dangerous media

service conditions such as natural gas. Our company has accumulated rich experience in designing,

manufacturing, testing and inspecting the cryogenic ball valve.

Material Selection

Common Steel will show low temperature brittleness under low temperature. Therefore, it is a key for

design and manufacturing to select suitable body materials according to the lowest working temperature

www.oakvalveparts.com

of the cryogenic ball valve. Refer to the following table for the lowest working temperature of body

materials. The low temperature materials shall be subjected to low temperature impact test according to

standard requirements. For valves with working temperature lower than -100, the body, bonnet and

stem must be subjected to cryogenic treatment after tough machining. The ball and seat sealing face

should be subjected to cryogenic treatment hard alloy spray welding/overlay welding. Then grinding and

assembly can be carried out, so as to ensure the adaptability of materials under low temperature. In

addition, the pacing, gasket, bolt and nut shall be made of materials suitable for low temperature service

condition.

Lowest Working Temperature of Shell Materials And Main Parameters

Lowest Working Temperature of Shell Materials

Casting

Forging

Materials

Lowest Temperature

ASTM A352 LCB

-46

Materials

Lowest Temperature

-46

ASTM A350 LF2

ASTM A352 LCC

-46

-46

ASTM A352 LC1

-59

ASTM A350 LF5

-59

ASTM A352 LC2

-73

ASTM A350 LF9

-73

ASTM A352 LC3

-101

ASTM A350 LF3

-101

ASTM A351 CF8

-254

ASTM A182 F304

-254

ASTM A351 CF8M

-254

ASTM A182 F316

-254

ASTM A351 CF3

-254

ASTM A182 F304L

-254

ASTM A351 CF3M

-254

ASTM A182 F316L

-254

Main Parameters

Design and Manufacturing

BS 6364-1998, JB/T7749-1995

Face to Face Dimensions

ASME B16.10

Type of Connection

Flange

ASME B16.5

Wafer

Pressure Test

API 598

Transmission Mode

Manual, worm gear transmission, pneumatic, electric

ASME B 16.25

Structural Design and Machining and Manufacturing Features

According to standard requirements, the ball valves with temperature low than -50 generally adopts the

long neck structure design to improve the temperature at the packing and ensure reliable sealing of stem

packing. The neck length is generally designed according to standard requirements or according to

contract requirements if users have special requirements.

For the valve used for low temperature media, when the valve is at the closed position, the low

temperature liquid staying in the middle cavity of valve will be gasified with the rise of temperature, which

causes the volume to expand rapidly and leads to abnormal pressure rise in the middle cavity, or even

valve breakage if serious. The ball valve is provided with function of middle cavity automatic pressure

relief. In case of abnormal pressure rise in the middle cavity, the medium in the middle cavity will

overcome the spring pre-tightening effect through its own force and push the seat out of the ball to realize

automatic pressure relief, so as to ensure valve safety.

www.oakvalveparts.com

According to contract requirements, cryogenic test can be carried out to test operating torque, sealing

performance and other indexes under low temperature.

The parts of the valve have been subjected to cryogenic treatment to ensure stability of form and size of

parts under low temperature.

www.oakvalveparts.com

Other product ranges available from Oak Valve Includes:

z

z

z

z

z

z

z

z

z

z

z

z

z

z

Floating Ball Valve

Trunnion Pipeline Ball Valve

Double Block And Bleed Valve

Fully Welded Ball Valve

Top Entry Ball Valve

Metal Seated Ball Valve

Orbital Ball Valve

V-Type Ball Valve

3-Way / 4-Way Ball Valve

Mounting Pad Ball Valve

Jacket Ball Valve

Cryogenic Ball Valve

NPT-Ends Ball Valve

One-Piece Ball Valve

Lishui OAK Valve Parts Co,. Ltd

A. Wenzhou Factory (Primary Contact):

Heyi Industrial Zone, Oubei Town,

Wenzhou City, Zhejiang

Province, China

P.O.box 325105

B.Lishui Factory Address:

No. 799-1, Jinniu Street, Bihu Industrial

Zone, Lishui.

Emailoak@oakvalveparts.com

TEL :0086 577 6799 1788

FAX :0086 577 6799 1786

For detail information, please visit

www.oakvalveparts.com

While this information is presented in good faith and believed to be accurate, Oak Valve, A Division of Oviko Valve Group,

does not guarantee satisfactory results from reliance on such information. Nothing contained herein is to be construed as a

warranty or guarantee, expressed or implied, regarding the performance, merchantability, fitness or any other matter with

respect to the products, nor as a recommendation to use any product or process in conflict with patent. Oak Valve reserves

the right, without notice, to alter or improve the designs or specifications of the products described herein.

Você também pode gostar

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988No EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockAinda não há avaliações

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityAinda não há avaliações

- Cryogenic Service Ball ValveDocumento2 páginasCryogenic Service Ball ValvesaminasritnAinda não há avaliações

- Double Block and Bleed Valves - Instrumentation - Oliver ValvesDocumento4 páginasDouble Block and Bleed Valves - Instrumentation - Oliver ValvesKehinde AdebayoAinda não há avaliações

- Mastershield Coatings Guide For SURFACE PREPARATION - ODcwMDDocumento18 páginasMastershield Coatings Guide For SURFACE PREPARATION - ODcwMDVincent LecoursAinda não há avaliações

- 028120-SPL-004 Pipeline Weight Coating Rev. CDocumento11 páginas028120-SPL-004 Pipeline Weight Coating Rev. CRokan Pipeline100% (1)

- Offshore Magazine November 2015Documento88 páginasOffshore Magazine November 2015Shu En SeowAinda não há avaliações

- Corporate DatasheetsDocumento10 páginasCorporate DatasheetsNyomanIdabagusAinda não há avaliações

- 00300E04Documento30 páginas00300E04halim_kaAinda não há avaliações

- Pulsation of Flow and Pressure in Piping of Reciprocating CompressorsDocumento26 páginasPulsation of Flow and Pressure in Piping of Reciprocating CompressorsSuhas JoshiAinda não há avaliações

- Non Metallic Flat GasketsDocumento4 páginasNon Metallic Flat GasketsMarko ZoricicAinda não há avaliações

- Standards For Pipeline Coatings: CanadDocumento11 páginasStandards For Pipeline Coatings: CanadMohamed DewidarAinda não há avaliações

- Protecta FR Board: Technical Data SheetDocumento2 páginasProtecta FR Board: Technical Data SheetDejan DosljakAinda não há avaliações

- Double Block and Bleed ValvesDocumento20 páginasDouble Block and Bleed ValvesToan LeAinda não há avaliações

- Sure Flow StrainersDocumento13 páginasSure Flow StrainersNinad SherawalaAinda não há avaliações

- Engineering Failure Analysis: Hossein Ghaednia, Sreekanta Das, Rick Wang, Richard KaniaDocumento12 páginasEngineering Failure Analysis: Hossein Ghaednia, Sreekanta Das, Rick Wang, Richard KaniaJennifer Julieth Triana ForeroAinda não há avaliações

- 3 Lead Engineer For Subsea Pipeline Systems LDNDocumento2 páginas3 Lead Engineer For Subsea Pipeline Systems LDNVijay_DamamAinda não há avaliações

- Ball Valve Catalogue-2Documento12 páginasBall Valve Catalogue-2tndeshmukhAinda não há avaliações

- HERTEL Metal GasketsDocumento40 páginasHERTEL Metal Gasketshvdb72Ainda não há avaliações

- 05887E01Documento96 páginas05887E01brome2014Ainda não há avaliações

- PMSS Ball ValveDocumento1 páginaPMSS Ball ValveGourav SharmaAinda não há avaliações

- Mokveld-Brochure Axial Check Valve enDocumento12 páginasMokveld-Brochure Axial Check Valve enteacgAinda não há avaliações

- PE PandGJ AMPL PDFDocumento4 páginasPE PandGJ AMPL PDFTinuoye Folusho OmotayoAinda não há avaliações

- Typical Ball Valve Material SelectionDocumento12 páginasTypical Ball Valve Material SelectionabsherlockAinda não há avaliações

- Understanding Virtual LeaksDocumento0 páginaUnderstanding Virtual LeaksGeorge BadgerAinda não há avaliações

- L&T Ball ValveDocumento12 páginasL&T Ball ValvecdsenthilAinda não há avaliações

- Pghu Eh Lspds 002004 Rev 0Documento43 páginasPghu Eh Lspds 002004 Rev 0BhoyPachoAinda não há avaliações

- Swaged Sleeve Welding For Pipe in PipeDocumento12 páginasSwaged Sleeve Welding For Pipe in PipeSridharan ChandranAinda não há avaliações

- Looking Back at The Phillips 66 Explosion in Pasadena, Texas - 30 Years LaterDocumento8 páginasLooking Back at The Phillips 66 Explosion in Pasadena, Texas - 30 Years LatereirinaAinda não há avaliações

- 《Pip Ineg1000美国的保温标准》Documento35 páginas《Pip Ineg1000美国的保温标准》1339979Ainda não há avaliações

- Insulating Gaskets & Its Practical DifficultiesDocumento6 páginasInsulating Gaskets & Its Practical Difficulties4A28Sparsh JainAinda não há avaliações

- Acoustic Induced Vibration - Flare Systems PDFDocumento2 páginasAcoustic Induced Vibration - Flare Systems PDFsri9987Ainda não há avaliações

- Company Specification: Steel Plates For Pressure VesselsDocumento9 páginasCompany Specification: Steel Plates For Pressure VesselsGeorgeAinda não há avaliações

- Modeling and Simulation of The Temperature Profile Along Offshore Pipeline of An Oil and Gas Flow: Effect of Insulation MaterialsDocumento8 páginasModeling and Simulation of The Temperature Profile Along Offshore Pipeline of An Oil and Gas Flow: Effect of Insulation MaterialsInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- Ansi Valve Leakage Standards Gemco ValveDocumento1 páginaAnsi Valve Leakage Standards Gemco ValvenithyaAinda não há avaliações

- CAT-16-2 Novel Method of Increasing Refinery Profitability During CFHT Outages - Bruce Lam - Shell and Todd Hochheiser, Johnson MattheyDocumento32 páginasCAT-16-2 Novel Method of Increasing Refinery Profitability During CFHT Outages - Bruce Lam - Shell and Todd Hochheiser, Johnson MattheyAle SanzAinda não há avaliações

- Double Block and Bleed With Ultra-Low Emission Options: Catalog 4190-FPDocumento17 páginasDouble Block and Bleed With Ultra-Low Emission Options: Catalog 4190-FPAnandAinda não há avaliações

- Rotork GP & GH RangeDocumento8 páginasRotork GP & GH RangeJavier BarreraAinda não há avaliações

- DBBV-Double Block and BleedDocumento16 páginasDBBV-Double Block and BleedUncircleDecoderAinda não há avaliações

- Flame ArrestorsDocumento6 páginasFlame Arrestorsrsb72Ainda não há avaliações

- NGLDocumento3 páginasNGLBalzhan KeikinaAinda não há avaliações

- Lesson Learnt From SNC On Stress AnalysisDocumento3 páginasLesson Learnt From SNC On Stress AnalysiszahoorAinda não há avaliações

- Pipe Size Calc - Gas - LINDocumento1 páginaPipe Size Calc - Gas - LINjollyAinda não há avaliações

- LNG - Cryogenic Piping SystemDocumento9 páginasLNG - Cryogenic Piping SystemAn le100% (1)

- Manage TEG Liquid and Corrosion in Sales Gas Pipelines PDFDocumento7 páginasManage TEG Liquid and Corrosion in Sales Gas Pipelines PDFfhtgerthrgergAinda não há avaliações

- Failure Analysis of Dissimilar Weld in Heat Exchanger Carlos R. Corleto, Gaurav R. ArgadeDocumento8 páginasFailure Analysis of Dissimilar Weld in Heat Exchanger Carlos R. Corleto, Gaurav R. Argademini2018Ainda não há avaliações

- Monolithic Insulated Joint BrochureDocumento8 páginasMonolithic Insulated Joint Brochuremarita_msAinda não há avaliações

- B31.3 Process Piping Course - 15 Nonmetallic Piping PDFDocumento26 páginasB31.3 Process Piping Course - 15 Nonmetallic Piping PDFSutarto AbutamisAinda não há avaliações

- Impact of Mining Subsidence On Natural Gas PipelinDocumento11 páginasImpact of Mining Subsidence On Natural Gas PipelinPranavAinda não há avaliações

- Guide For Estimation of Flaring and Venting VolumesDocumento59 páginasGuide For Estimation of Flaring and Venting VolumesSakhibAinda não há avaliações

- My Steam Trap Is Good - Why Doesn't It WorkDocumento9 páginasMy Steam Trap Is Good - Why Doesn't It WorkMauricio RojasAinda não há avaliações

- Avoid Brittle Fracture in Pressure VesselsDocumento12 páginasAvoid Brittle Fracture in Pressure VesselsHieuAinda não há avaliações

- Transportation of Natural and Other Gas by Pipeline: Minimum Federal Safety Standards 49 CFR 192Documento23 páginasTransportation of Natural and Other Gas by Pipeline: Minimum Federal Safety Standards 49 CFR 192nankingAinda não há avaliações

- Design Handbooks Table of ContentsDocumento1 páginaDesign Handbooks Table of ContentsForcus onAinda não há avaliações

- Floating and Trunnion Ball Valves PDFDocumento15 páginasFloating and Trunnion Ball Valves PDFAlienshowAinda não há avaliações

- Upheaval Buckling of Pipelines-2016 PDFDocumento13 páginasUpheaval Buckling of Pipelines-2016 PDFwaseemiqbal133Ainda não há avaliações

- Factory Applied External Pipeline Coatings For Corrosion ControlDocumento32 páginasFactory Applied External Pipeline Coatings For Corrosion ControlMatt AgonyaAinda não há avaliações

- Ball Valve - Training Material (Compatibility Mode)Documento115 páginasBall Valve - Training Material (Compatibility Mode)kart_rl80% (10)

- BAF-ball Valves Rev 1 PDFDocumento40 páginasBAF-ball Valves Rev 1 PDFJack ChavanAinda não há avaliações

- Forged Steel Valves PDFDocumento12 páginasForged Steel Valves PDFDiwakar NigamAinda não há avaliações

- Meteb Noora Co. - P249Documento3 páginasMeteb Noora Co. - P249Shams TabrezAinda não há avaliações

- RT RequestDocumento56 páginasRT RequestShams TabrezAinda não há avaliações

- HIRA-Metalic Pipe ErectionDocumento13 páginasHIRA-Metalic Pipe ErectionShams Tabrez100% (2)

- Mos - PaintingDocumento11 páginasMos - PaintingMuthuram NAinda não há avaliações

- 14 03Documento1 página14 03Shams TabrezAinda não há avaliações

- MOS-RO Pressure Vessel InstallationDocumento16 páginasMOS-RO Pressure Vessel InstallationShams TabrezAinda não há avaliações

- STEAM TURBINE Project Training ReportDocumento25 páginasSTEAM TURBINE Project Training ReportShams TabrezAinda não há avaliações

- CV - Geotechnical Survey Specification. Rev ADocumento19 páginasCV - Geotechnical Survey Specification. Rev AShams TabrezAinda não há avaliações

- Aramco KTRDocumento1 páginaAramco KTRShams TabrezAinda não há avaliações

- Travel Screen Activities (Detailed)Documento4 páginasTravel Screen Activities (Detailed)Shams TabrezAinda não há avaliações

- Jubail Project BCDDocumento12 páginasJubail Project BCDShams TabrezAinda não há avaliações

- Scaffolding Inspection Supervisor All ModulesDocumento190 páginasScaffolding Inspection Supervisor All ModulesShams Tabrez88% (8)

- 2nd Submission-Hamza ReplyDocumento3 páginas2nd Submission-Hamza ReplyShams TabrezAinda não há avaliações

- Reinstating of Sea Water Cooling Phase Ii: Manpower LoadingDocumento10 páginasReinstating of Sea Water Cooling Phase Ii: Manpower LoadingShams TabrezAinda não há avaliações

- RRD-TUR Manpower ListDocumento1 páginaRRD-TUR Manpower ListShams TabrezAinda não há avaliações

- Contract # 6600026589Documento29 páginasContract # 6600026589Shams TabrezAinda não há avaliações

- API Standard ListDocumento8 páginasAPI Standard ListShams TabrezAinda não há avaliações

- HEISCO FormDocumento1 páginaHEISCO FormShams TabrezAinda não há avaliações

- Whiting Petroleum CorporationDocumento3 páginasWhiting Petroleum CorporationShams TabrezAinda não há avaliações

- 44444Documento8 páginas44444Shams TabrezAinda não há avaliações

- ACFrOgDxfhbYLVlrIax5lAq9aMwC X0CjcEq1Y9Z8j0OTmY6BnV699GPu1fJ2yJb15ybjIdHRTNqGp7L6gYz2uBxUEfKTyUKwqVGWkWjfU2twoI 2b 4t1HziPNS2JcDocumento17 páginasACFrOgDxfhbYLVlrIax5lAq9aMwC X0CjcEq1Y9Z8j0OTmY6BnV699GPu1fJ2yJb15ybjIdHRTNqGp7L6gYz2uBxUEfKTyUKwqVGWkWjfU2twoI 2b 4t1HziPNS2JcShams TabrezAinda não há avaliações

- Arabian Fal Holding Approval To Receive The Rpo Contract # 6600026589Documento8 páginasArabian Fal Holding Approval To Receive The Rpo Contract # 6600026589Shams TabrezAinda não há avaliações

- Vehicles & EquipmentsDocumento10 páginasVehicles & EquipmentsShams TabrezAinda não há avaliações

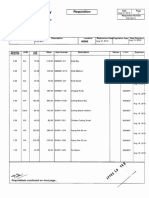

- Arabian Fal Company: RequisitionDocumento6 páginasArabian Fal Company: RequisitionShams TabrezAinda não há avaliações

- Account Modification FormDocumento2 páginasAccount Modification FormSwaraaazAinda não há avaliações

- Welcome Ea InfosysDocumento1 páginaWelcome Ea InfosysShams TabrezAinda não há avaliações

- Postspacings PDFDocumento1 páginaPostspacings PDFShams TabrezAinda não há avaliações

- Tube and CouplerDocumento1 páginaTube and CouplerShams TabrezAinda não há avaliações

- Underhung (Suspended) ScaffoldDocumento5 páginasUnderhung (Suspended) ScaffoldShams TabrezAinda não há avaliações

- Underhung (Suspended) Scaffold PDFDocumento2 páginasUnderhung (Suspended) Scaffold PDFShams Tabrez100% (1)

- Storage-Tanks Titik Berat PDFDocumento72 páginasStorage-Tanks Titik Berat PDF'viki Art100% (1)

- Assessment - UK Forestry Data ICT THEORY For CAT1Documento13 páginasAssessment - UK Forestry Data ICT THEORY For CAT1Joanna AchemaAinda não há avaliações

- VTB Datasheet PDFDocumento24 páginasVTB Datasheet PDFNikola DulgiarovAinda não há avaliações

- NauseaDocumento12 páginasNauseakazakom100% (2)

- All About TarlacDocumento12 páginasAll About TarlacAnonymous uLb5vOjXAinda não há avaliações

- Embedded Software Development ProcessDocumento34 páginasEmbedded Software Development ProcessAmmar YounasAinda não há avaliações

- CHAPTER I Lesson II Seven Environmental PrinciplesDocumento17 páginasCHAPTER I Lesson II Seven Environmental PrinciplesTrixie jade DumotAinda não há avaliações

- Intercultural Personhood and Identity NegotiationDocumento13 páginasIntercultural Personhood and Identity NegotiationJoão HorrAinda não há avaliações

- LT3845ADocumento26 páginasLT3845Asoft4gsmAinda não há avaliações

- Pipe Freezing StudyDocumento8 páginasPipe Freezing StudymirekwaznyAinda não há avaliações

- Macros and DirectiveDocumento7 páginasMacros and DirectiveAbdul MoeedAinda não há avaliações

- Unit 1 Building A Professional Relationship Across CulturesDocumento16 páginasUnit 1 Building A Professional Relationship Across CulturesAlex0% (1)

- Amerex Ansul Badger Ul Catalogo Por PartesDocumento37 páginasAmerex Ansul Badger Ul Catalogo Por PartesPuma De La Torre ExtintoresAinda não há avaliações

- Jy992d66901 CDocumento6 páginasJy992d66901 CMaitry ShahAinda não há avaliações

- Lahore Waste Management CompanyDocumento45 páginasLahore Waste Management CompanyHadia NasirAinda não há avaliações

- Setting and Plot: Old YellerDocumento8 páginasSetting and Plot: Old YellerWalid AhmedAinda não há avaliações

- Buddha Mind PDFDocumento32 páginasBuddha Mind PDFVishal GadeAinda não há avaliações

- Data Mining in IoTDocumento29 páginasData Mining in IoTRohit Mukherjee100% (1)

- GST RATE LIST - pdf-3Documento6 páginasGST RATE LIST - pdf-3Niteesh KumarAinda não há avaliações

- Teaching PowerPoint Slides - Chapter 5Documento19 páginasTeaching PowerPoint Slides - Chapter 5Azril ShazwanAinda não há avaliações

- Class 1 KeyDocumento3 páginasClass 1 Keyshivamsingh.fscAinda não há avaliações

- Rare Watches (Christie's) 16. 05. 2016.Documento236 páginasRare Watches (Christie's) 16. 05. 2016.Simon LászlóAinda não há avaliações

- Effective TeachingDocumento94 páginasEffective Teaching小曼Ainda não há avaliações

- Lesson Plan Letter SDocumento4 páginasLesson Plan Letter Sapi-317303624100% (1)

- Matutum View Academy: (The School of Faith)Documento14 páginasMatutum View Academy: (The School of Faith)Neil Trezley Sunico BalajadiaAinda não há avaliações

- Charter of The New UrbanismDocumento4 páginasCharter of The New UrbanismBarabas SandraAinda não há avaliações

- Nascsa - Sponsor Solicitation List: January 06, 2021Documento35 páginasNascsa - Sponsor Solicitation List: January 06, 2021Prasoon SimsonAinda não há avaliações

- Free ConvectionDocumento4 páginasFree ConvectionLuthfy AditiarAinda não há avaliações

- Or HandoutDocumento190 páginasOr Handoutyared haftu67% (6)

- The Sandbox Approach and Its Potential For Use inDocumento13 páginasThe Sandbox Approach and Its Potential For Use invalentina sekarAinda não há avaliações