Escolar Documentos

Profissional Documentos

Cultura Documentos

Colin MacKenzie's Harding Lecture

Enviado por

rasanavaneethanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Colin MacKenzie's Harding Lecture

Enviado por

rasanavaneethanDireitos autorais:

Formatos disponíveis

British Tunnelling Society

at

The Institution of Civil Engineers

THE

2002 HARDING LECTURE

Reflections on 40 years in Tunnel Contracting

Colin Mackenzie BSc(CE)

atThe Institution of Civil Engineers

20 June 2002. 5.30pm

THE 2002 HARDING LECTURE

Editorial

Anthony Umney,BSc CEng FICE,

Chairman, British Tunnelling Society

here has been an increasing demand for the use of underground space in urban areas around the world as our

cities have become more and more congested. Tunnelling technology has equally taken enormous strides forward over the last 30 years. This has enabled tunnellers to meet these new demands whilst the improved performances of the Tunnel Boring Machines (TBMs) have held the costs of tunnelling against the generally increasing

costs of construction.

Inevitably these advances with tunnel technology have been matched by ever increasing demands and the challenges faced by todays tunnellers have led to difficulties in two areas. The first has been the difficulties experienced

with the insurance of tunnel works, and a second the recent collapse of gardens at Lavender Street on a Channel Tunnel

Rail Link TBM Contract. For the former the BTS has been working with the Association of British Insurers (ABI) to

develop a Joint Code of Practice for the Procurement, Design and Construction of Tunnels and Associated

Underground Structures in the United Kingdom. The objective of this Code of Practice is to promote and secure best

practice for the minimisation and management of risks associated with the design and construction of tunnels.

Contract insurers will require compliance with the Code of Practice, and although the Code has not yet been published

the industry is already effectively using the current draft of the Code. For the latter, the BTS is proposing the re-establishment of the Closed Face Working Group (CFWG), originally established to report on serious failures on two recent

UK tunnelling projects at Portsmouth and Hull. Union Railways have agreed to this tunnel review as being a constructive move to reassure not only the HSE but also the ABI. It is intended that the CFWG will be chaired by an independent person and its brief will be to include the assembly of data from incidents that have occurred in other parts of the

world.

The BTS have also recently established an All Party Group for Underground Space (APGUS). This has provided an

important opportunity to lobby Government on the benefits of the use of underground space and the capabilities of

our tunnelling industry. The BTS has experienced a welcome increase of membership and the number of entries

received this year from the Second Tunnel Industry Awards reflects an increased focus on the important part tunnelling

is taking in UK construction today.

The Fourth Harding Memorial Lecture was delivered by Colin MacKenzie. Colin has spent some 40 years in tunnel

construction and in his lecture he has been able to pass on to the younger engineers in particular the benefits of his

experience. Colin is probably the longest serving graduate of the Institution of Civil Engineers! This he relates was due

to all his documents, prepared for his professional interview, being destroyed in a site office fire and with his busy workload and without modern means of reproducing his documents he never managed to sit the interview. Colins career

has covered a very full range of tunnel construction in the UK and more importantly his contribution to it. His lecture

demonstrates the importance he has placed on safety from an early age and some lessons that can be learnt.

This Fourth Harding Memorial Lecture should be essential reading for todays aspiring tunnel engineers.

THE 2002 HARDING LECTURE

Colin Mackenzie

BSc(CE)

Colin Mackenzie retired in May 2001 after a 40 year career in Civil Engineering, much of which was on Tunnelling projects.

In 1961 he graduated with a degree in civil engineering from the University of Aberdeen, and immediately went to work for Mitchell

Construction on the Awe Hydro-Electric project in Argyll in Scotland.

After three years of rock tunnelling and dam construction, he left wonderful Loch Awe to join Mowlem on the Victoria Line Project in

London and there got his introduction to soft ground tunnelling.

He remained with Mowlem for 24 years, with that time split about 50/50 between tunnelling and other branches of Civil Engineering.

The projects with which he was involved include the Victoria Line (Victoria to Oxford Circus), the New London Bridge (where he was

Construction Manager for four years), the first Piccadilly Line extension into Heathrow, the East West Tyne & Wear Metro Tunnels, the

Lewes Road Tunnel, the Carsington Aqueduct Tunnels, the Don Valley Sewer Tunnels, the two Dorchester Bypasses, the Okehampton

Bypass, the QE2 Conference Centre Substructure in Westminster and the Molesworth Cruise Missile Shelters.

From 1982 to 1988 he was a Director of Mowlem Civil Engineering Ltd.

In 1988 he transferred his allegiance to AMEC, initially as Director for Tunnelling, and subsequently in a wider role encompassing other

Civil and Airport works.

The AMEC tunnelling works included two major sections of the London Ring main, the Fylde Coast Tunnels in Blackpool, tunnels for

Anglian Water at Clacton and at Ipswich, together with numerous other projects scattered across the UK.

He completed his career with a three year stint as the Resident Project Director on Contract 102 of the Jubilee Line Extension Project (the

section which included Westminster and Waterloo).

Colin served on the BTS committee for nine years, including two years as Chairman in the early 90s.

Colin is a recipient of the Telford Gold Medal of the Institution of Civil Engineers and of the James Clark Memorial Medal of the British

Tunnelling Society.

The author (left), at the Clacton Clearwater Project of Anglian Water,

with his daughter Karen, AMEC Project Manager Alan Barker, and

AMECs much-travelled and very capable 2.5m od Lovat TBM

named Karen Fiona Mackenzie after his daughter.

THE 2002 HARDING LECTURE

Harding Memorial Lecture

Reflections on 40 yearsin Tunnel Contracting

The fourth Sir Harold Harding Memorial Lecture was delivered by Colin Mackenzie BSc(CE)at the meeting of

the British Tunnelling Society held at the Institution of Civil Enigineers on Thursday,20th June 2002, 5.30pm

I never knew Sir Harold at a personal level, but

I did have contact with him when I worked for

Mowlem, and I frequently saw him in action as

the first Chairman of this Society. At the time that the

BTS came into being, in 1972, I was working on the

first Piccadilly Line Extension into Heathrow and I

lived in Pimlico, just round the corner from the ICE. It

was easy, therefore, for me to attend every meeting,

and that is just what I did, without fail.

1.

Harding was a formidable Chairman, often

calling directly on individuals to make a contribution when proceedings were a little sluggish. I recall one occasion, when the merits of rock

TBMs were being discussed, the Managing Director

of Nuttalls, Richard Triggs, sitting near the front,

minding his own business, when out of the blue he

was assailed by Harding with the following question tell us Mr Triggs, do you feel that these new-fangled

machines have a future, or would we be better

advised to continue to drill and blast, as God intended ?. To his great credit, Triggs rose and gave a very

interesting dissertation on the current state of development of rock TBMs. I dont know whether Harding

had a prior agreement with Triggs to call upon him,

but he made it appear to be spontaneous, and Triggs

didnt appear to know that it was coming. Together

they made it memorable, the proof of which is that

here I am telling you about it thirty years later.

2.

Some years afterwards, when I was the

Mowlem director responsible for tunnelling,

London Transport commissioned Mott

MacDonald to make a report on the condition of all

the cast iron linings of all the LUL tunnels. Among

other things, the report was required to identify the

manufacturers of the cast iron segments. Eventually,

Motts managed to do that, with the exception of one

type of segment which had a manufacturers casting

mark which nobody could identify. It existed in a

length of tunnel built by Mowlem some time before

the First World War. Motts contacted me in Mowlem.

I couldnt help. I contacted John King. He couldnt

help either, but he suggested that I might try Sir

Harold. I telephoned Sir Harold, who by that time was

well into his eighties and in retirement in the West

Country. He said that he was not familiar with that

particular casting mark, but he undertook to look for

it in some old papers which he had retained when

leaving Mowlem.

3.

4.

A week later he came up with the goods, in a

letter which started off -Dear Mackenzie.

That showed that Sir Harold hadnt lost any of

his old Mowlem style. In old Mowlem you didnt have

a first name. To Sir Harold I was therefore just

Mackenzie, to be addressed in correspondence as

Dear Mackenzie.

I telephoned him to thank him for his efforts.

He was delighted to have solved a puzzle that

had beaten everybody else, so delighted that

he regaled me with tales of how, in those far off days,

cast iron segments were manufactured in the North

and transported by ship to Hays Wharf in the Pool of

London, from where they were delivered to tunnel

sites by horse and cart, with each segment swathed in

straw to prevent it suffering damage as the carts clattered their way through the cobbled streets. I was

really sorry when he eventually hung up. I could have

listened to him for hours. As I reflect on that conversation now, I think of how appropriate it is that the

Society honours his memory each year. Long may it

continue to do so.

5.

INTRODUCTION TO LECTURE

I turn now to the lecture itself. When Peter

South, on behalf of the BTS Committee, invited me to give the lecture, I asked him if he had

any particular theme in mind. He replied that, while I

had a relatively free hand, he thought that reflections

on what I had learned during my forty years in the

industry would be suitable. So that is what I have

done. I propose to talk about some things that I have

learned which are relevant to the management of

tunnel contracts, and which I would like to pass on,

mainly to the younger members of our profession.

But you are not going to hear about Lovats and World

Records and so on. I, and many others, have spoken

enough about them in the past and theyve been

reported in great detail in the technical press. Im

going to talk about such things as Safety, Assessment

of Ground Conditions, Partnering, Costing,

Productivity, Payment of Labour, and about some

issues concerning Engineers for tunnelling.

6.

THE 2002 HARDING LECTURE

force. Yet, despite all those advantages, safety performance, as measured by Accident Frequency Rate,

was not as good as on some of our other contracts.

I think that I should make you all aware that I

have only ever been a contractor. In a career

spanning almost exactly forty years I have

worked for only three companies - all contractors.

Firstly, for Mitchell Construction, for three years on a

Scottish Hydro-Electric Scheme Secondly, for

Mowlem for twenty four years on a wide variety of

Civil Engineering projects and, lastly, with AMEC

for the final thirteen years of my career. I have never

worked for a consulting engineer, nor for a client.

Even my formal design experience was gained in a

contractors design office. Accordingly, I speak as a

contractor. So, if in giving my views from such a narrow base, I stray from the paths of reasonableness, I

have no doubt that I shall be held to account for it,

preferably in the bar afterwards.

7.

Accident Frequency Rate is the number of

Reportable Accidents per one hundred

thousand working hours. It is a long established measure recognised in many parts of the

world. The 100,000 hours was, originally, an approximation to a full industrial working life in the middle

of the twentieth century. That is, approximately 50

years by 2000 hours per year. A modern working life

will rarely have so many working hours, but the

100,000 is still a valid reference period.

10.

By late 1997, on Contract 102, despite our

best efforts, the rolling twelve month

Accident Frequency Rate was close to 1.0.

With a workforce of about 1250, and a staff of about

250, we seemed to be reporting a three day accident

every week. Some of them were trivial, but each one

was some form of personal injury, with all the unhappiness that that brings. We were simply not able to

drive down the frequency to our target level of 0.6. We

made all sorts of detailed examinations and analyses

of the accidents. These showed that the majority of

the accidents were attributable to such things as deficiencies in access arrangements, edge protection,

manual handling arrangements, and conflict

between plant and personnel in restricted working

space. Particularly worrying were the number of accidents arising from improvised expedient actions

taken by foremen and engineers to cover gaps in

detailed planning and method statements.

11.

SAFETY

The first subject which I am going to discuss is

safety. That will come as no surprise to anybody who has worked for me. Safety was

always the first item on my agenda. It is an issue close

to my heart, possibly because I was introduced to

industrial safety when I was very young. My father

was a Marine Mechanical Engineer with a business in

the port of Stornoway in the Western Isles of

Scotland, mainly supporting visiting cargo vessels,

the local fishing fleet and distant-waters trawlers

operating out of Hull, Grimsby and Fleetwood. I,

therefore, grew up in a state of constant awareness of

the hazards which exist in an engineering environment, because of the amount of time which I spent in

the workshops or on ships and boats with my father.

A concern for safety which developed in me at that

time has remained with me ever since. That background is also what stimulated my interest in mechanised tunnelling.

12.

Safety is a huge subject. I shall therefore

confine myself to some personal observations concerning safety in tunnelling. Good

safety management requires leadership from the

most senior levels of any company. If there is any

doubt of the sincerity of the commitment of the

directors and managers to safety, that doubt will

become a reality down the management line of a

contract and it will make it impossible to achieve

the best safety results. However, on some projects,

providing the right sort of leadership is not enough.

Sometimes individual projects present challenges

which have to be resolved at ground level. I shall

give you an example from Jubilee Line Extension

Project Contract 102 where we came up with an idea

which turned out to have impressive results.

Contract 102 was the section which included

Westminster and Waterloo. It was a 50/50 Balfour

Beatty-AMEC Joint Venture, (BBA). It had the full

safety support of both companies. It had excellent

staff on site, excellent safety professionals, an excellent safety management plan and a variety of safety

incentive schemes. It also had a very capable work-

I had my own reasons for concern. I had a

lot of contact with the workforce through

my frequent personal safety inspections. I

found most of the members of the workforce to be

intelligent and conscious of the potential safety hazards to which they could be exposed. Much of my

contact came through my making of on the spot

awards for useful contributions to site safety and tidiness. The awards were made to individuals and were

in the form of tax-free Marks & Spencer vouchers for

8.

By early 1998 we came to the conclusion

that none of our accepted safety management techniques could produce the

results we wished to achieve. We therefore decided to

have discussions with two HSE specialists who took a

regular interest in the contract, independently of the

HSE Inspectors and at a different intellectual level.

Their names were Jim Nielsen and Steve Peckitt. We

gave them free rein to examine all our arrangements

and to talk to anybody in BBA. Their key finding was

that the undoubted determination of my senior colleagues, and of myself, to make the contract a safe

place to work, was being diluted on its way down

through the layers of site management to the workplace. I had suspected this myself but I was surprised

by how widespread the HSE specialists had found it

to be.

9.

13.

THE 2002 HARDING LECTURE

10, 20 and 50. (BBA paid the tax). Sometimes,

when I queried why an individual was not dealing

with an obvious defect, such as faulty edge protection

at a high level within the Westminster box, I would

find that he was unwilling to stop doing the work

allocated to him by his foreman, in order to deal with

the defect, because he was fearful of the reaction of

the foreman to him taking such action on his own initiative. It seemed to me that the attitude of some of

the foremen was that the workers were there to do

what they were told to do, and that anarchy would

reign if workers were given the freedom to do things

on their own initiative. I believe that this attitude is

prevalent throughout the construction industry, and

that it is a key factor in our safety problems.

We concluded that we would have to find a

means of delegating real authority to a level

close to the actual execution of work. Of

course, such delegation would not relieve myself and

my senior colleagues of responsibility for safety on

the site. We decided to place our trust in the hands of

our Section Engineers and in senior members of the

workforce.

14.

After much deliberation, we decided to create, on each of the sites, groups which we

named Safety Task Teams. Each Task Team,

usually of eight persons, included trades chargehands and was led by a Senior Section Engineer.

Initially, no foremen were included in the Task Teams.

The Task Teams were supported by Safety

Professionals.

15.

16.

In common with many other sites the most

important categories of accidents were as

shown below.

a. Falls and trips at same level

(Gravity) (Clear walkways)

Falls of objects from above

(Gravity) (Edge protection)

Falls of persons to a lower level

(Gravity) (Handrails, stairs)

b. Manual handling

c. Contact with machinery

d. All other groups

50%

20%

20%

10%

My references to gravity are to draw attention to the

fact that the force which drives all falls is the force

of gravity. It is powerful and it is ever-present. We

must guard against exposing ourselves to its effects at

all times. The reference to stairs is intended to draw

attention to my practice of insisting on the use of proprietary staircases rather than ladders. I generally

permitted ladders to be used only where it was virtually impossible to install staircases.

17.

We asked the Task Teams to give priority to

categories a, b and c, putting the

falls category as top priority. It was

explained that, while the Task Team would receive

corporate policy on safety management from

above, its decisions on safety actions would NOT

have to be sanctioned from above these were to be

implemented, forthwith, at section level by the

Section Project Manager, with copies of the Task

Team notes being passed to Project Director level in

order to keep senior management fully informed of

developments.

At two week intervals, each Safety Task

Team made a formal inspection of its section of the works, and then held a meeting

to discuss the findings, to decide how to deal with the

safety deficiencies found on site, and how to prevent

such deficiencies occurring in the future. The inspection and the discussion usually occupied about four

hours. Following the site inspection the Team marked

a standard inspection scorecard whose format had

been agreed with myself and my fellow directors. A

sample scorecard from Westminster is shown in

Appendix 1. The Section Engineer then completed a

succinct record of the teams discussion and decisions, and prepared a coloured graph of the scorecard

results for that day, with comparisons with the scores

of previous inspections to illustrate trends in the

scores. A sample report chart is shown in Appendix 2.

The decisions and recommendations of the Task

Team were usually implemented without delay

through the Chargehands and the Section Project

Manager, the latter ensuring the full cooperation of

the Foremen.

18.

The improvements in safety performance

were surprising and rapid, and applied

across all types of work. Within a few weeks

of the introduction of the new arrangements the accident frequency dropped markedly and set out on a

trend which culminated in over 1.6 million manhours

being worked without a single reportable accident, ie

a frequency rate of 0.06 approximately ten times

better than our supposedly ambitious accident frequency target at the time when the Safety Task Team

concept was introduced. Thereafter, the improvement was sustained to the completion of the contract, albeit at a figure slightly above 0.06.

19.

Some people have tried to pooh-pooh

the importance which we have attributed

to the Safety Task Team concept, but

nobody has put forward a sustainable alternative

explanation of the dramatic improvement which we

experienced. I believe that the implementation of the

concept achieved the observed results through the

following factors.

a. It mobilised the latent capabilities of a large

intelligent workforce.

b. It immobilised the antiquated attitudes of

some of the Foremen.

c. It proved to everybody that a ZERO accident

frequency over an extended period is a realistic

objective.

20.

THE 2002 HARDING LECTURE

information provided with the tender documents,

placing particular emphasis on the borehole information. That approach seemed to me to be rather

simplistic, as the geology I had studied in university

made me aware of just how non-uniform soils and

rocks can be. However, it appeared to be the accepted practice, and we often got paid for what appeared

to me to be rather fine differences. The argument

often used by the contractor, and accepted by the

Engineer, was that the typical tender period of a few

weeks did not really give the bidders time to carry out

extensive research. Almost needless to say, I was

taught to only ever mention worse conditions,

never conditions better than those in the tender.

I am convinced that a dramatic improvement in the safety performance of the

industry could be achieved if formal

basic safety education were to be given to every

member of the workforce and if companies had the

confidence to trust them to apply it, as we did on

Contract 102.

21.

There is one other aspect of safety

which I wish to mention. It is that I

noted, over the years, that certain engineer managers had fewer accidents on their sites

than others who, superficially, appeared to be just as

well qualified and just as interested in safety. These

were the engineers who had done a lot of temporary

works drawings and programming. It seemed to me

that in the planning of temporary works these engineers had developed enhanced visualisation skills.

They therefore spotted safety hazards well in advance

of actual construction and either designed out these

hazards or drew attention to the need to manage

them. This could have important implications for

safety as more and more drawing is done, as a specialist activity, by CAD technicians rather than, as

part of their regular duties, by site engineers.

22.

These arrangements may have provided

a more or less equitable means of dealing with so-called unforeseen conditions when tunnelling was being carried out by

handwork or by open faced Greathead shields. But

they do not provide for adequate assessment and

management of ground risks when closed face tunnelling machines are being used. In an open-faced

shield it is usually possible to see the problem and get

access to it to deal with it. With a TBM, especially an

EPBM, it is rarely possible to see the problem or to get

access to it to do something about it. A relatively

minor unforeseen condition can therefore have a disproportionate impact on a TBM drive. So disproportionate, in some cases, as to completely nullify the

benefits which are supposed to flow from the use of a

TBM.

26.

The ability to visualise, especially from

drawings, is a vital facet of good safety

management. This has important implications in tunnelling as, in my experience, very few

tunnel foremen are good at reading engineering

drawings. Somebody who hasnt got good visualisation skills isnt likely to spot hazards until it is too late

to manage them properly. Such a person may therefore take dangerous expedient actions when the hazards are unexpectedly encountered, especially if he is

in a position of authority to instruct the workforce to

take such actions.

23.

I feel that a very rigorous approach needs

to be to taken to the matter of ground risk

when TBMs are to be used, and that there

should be a requirement on the bidder to make clear

exactly what he has allowed for in his bid, in a manner similar to that in which these things are dealt with

in a Partnering contract.

27.

However, the latest 3D CAD software

offers us the opportunity to use Virtual

Reality techniques to take everybody,

stage by stage, through graphical displays of the proposed construction procedures. When I say everybody, I especially include the relevant trades of the

workforce. 3D graphics proved useful on Contract 102

for giving everybody an appreciation of what we were

constructing, a much better appreciation than was

possible from conventional drawings which very few

site personnel could fully interpret.

24.

If the client proposes to award the contract to the lowest bidder, he would be

well advised to make sure that the bid is

genuinely the lowest by requiring each bidder to provide a fully evaluated risk schedule detailing what he

has allowed in his bid for those risks which he may

expect to share with the client.

28.

It almost goes without saying that all this

will be pointless if the client doesnt

already have an Engineer properly experienced in tunnelling works. Contractors are expert at

finding ways of portraying tender information in the

most favourable light so as to get the cost allowances

in the submitted bid as low as possible, and yet provide a believable basis for subsequently claiming

additional reimbursement. There is no doubt that

these practices have too often made a farce of bidding under traditional forms of contract.

29.

GROUND CONDITIONS ASSESSMENT

I turn now to the matter of assessment

of ground conditions. As an engineer

working for a contractor, generally

under conditions of contract in which ground risk

was shared with the client, I was taught that I must be

alert to changes in ground conditions and to the possibility that these might provide a basis for claiming

additional payment. I was taught to base my assessment of what was reasonably foreseeable on the

25.

THE 2002 HARDING LECTURE

Therefore, I was delighted when, around

the end of the eighties, more collaborative forms of contract came into use. It

then became possible for all the contracting parties

to pool their knowledge, together with the knowledge

of any geo-technical experts engaged by them, to

make a genuine, in-depth assessment of the ground

in which the tunnel is to be placed, and of the risks

associated with all the potentially difficult variations

which might be found in that ground.

30.

But how should the assessment of the

ground conditions be made ?. In recent

years, I have usually adopted the following

policy for TBM drives. Having put together a bid

team, we start by asking the best Engineering

Geologist available to us to discuss with us the general geology of the region in which the tunnel is to be

located. We consult BGS Geology Maps, BGS Regional

Geology handbooks and any other information available to us. We then ask the geologist to put the SI

information into the context of the overview which

we have just discussed. We then usually ask the

Engineering Geologist to describe to us how the

ground came to be where it is now, and to describe

the processes which, in the passage of geological

time, have led to it having its present physical properties. That request usually results in the geologist

giving us a lecture about desert conditions, or about

deposition in shallow marine water, or about glacial

rivers, or about Tundra phenomena, etc., as appropriate.

31.

In almost every case it is possible to identify a region on the Earth where, at the

present time, one can find conditions

similar to those which gave rise to the soils or rocks in

which it is proposed to drive the tunnel.

If one then consults photographs or diagrams of

that region in geology text-books, such as Holmes

Principles of Physical Geology, (1), it is usually possible to get a good appreciation of the variations

which occur in the general conditions, variations

which one may have to deal with, but which have not

been exposed by the boreholes. The TBM will have to

be made capable of penetrating these variations. In

some cases this will lead to the TBM having features

added to it, at substantial cost, to cope with something whose probability of occurrence might be

rather remote, but whose potential costs would be

many times greater than the costs of equipping the

TBM to cope with that particular condition.

32.

These deliberations usually require input

from every discipline in the team. I made

it obligatory that the decision on which

type of TBM to select, and how to tool it, be made by

a multi-disciplinary team, and be ratified by the

Tunnelling Divisions Board. In my view, no individual should be empowered to make that decision on

his own. Anybody who takes it upon himself to do so

is, in my opinion, asking for trouble.

33.

In passing, I should mention that I have

seen companies attempt to place all the

commercial risk inherent in these decisions on the TBM supplier. My experience leads me

to conclude that that is not appropriate. My view is

that the risk should lie somewhere with the contracting parties. If the contracting parties cannot handle

it, they shouldnt be tackling a tunnelling job.

34.

Going back to geological issues, the diagram in Appendix 3, taken from Professor

Peter Fookes 1997 Glossop Lecture, (2), is

helpful to the gaining of an understanding of the relevant geological processes which have created the

rocks and soils of the UK. This diagram provides a

wonderful insight into our geological history, and an

understanding of how, for example, we come to have

coal, Bunter Sandstone and so on. These tectonic

movements are still taking place, at velocities similar

to those at which our fingernails grow, according to

an expert on a recent Radio 4 broadcast !.

35.

PARTNERING

Turning now to Partnering. Earlier in this

lecture I have used the expression collaborative contracts, because that is a

generic expression which I have seen used by others.

In most cases what I really mean is Partnering.

Almost all the contracts for which I was responsible

in the final ten years of my career were formal

Partnering contracts, both in tunnelling and in general civil engineering. I have been amazed by what we

achieved on some of these contracts.

36.

I should mention at this point that I am

not a Johnny-come-lately to Partnering.

My first experience of what could be

regarded as a formal Partnering contract was in 1968,

with Mowlem. It was the contract for the construction of the East Greenwich Relief Sewer for the GLC. It

was a rush job because a large, and politically

important, contract for the southern approaches to

the Blackwall Tunnel had been let before it was

realised that, as a consequence of its design, a new

sewer tunnel would have to be built some distance

away from the approach works. This new sewer was

not small. It was seven feet in diameter, in Thames

Gravel, close to the river, and with its invert three

metres below the water table. In addition, for a substantial part of its length, the only alignment available for the new sewer was alongside, and within a

few metres of, the Southern Outfall Sewer which carried, I was told, something like a quarter of Londons

sewage. I used to worry that, if we got it wrong, about

a quarter of the population of London wouldnt be

able to go to the toilet !. Now, that really is something

to get worried about !. The potential for embarrassment was acute.

37.

THE 2002 HARDING LECTURE

tendering because everything is out in the open from

the start. It eliminates virtually all the ingenious contractual manipulation which has characterised competitive tendering, and which has run so many contracts into trouble. It mobilises the talents of the

whole team and makes everybody concentrate on the

out-turn result from the very outset of the project. It

is the out-turn that the client wants to know, not the

starting price. Clients do not like uncertainties.

I dont know the details of how Mowlem

came to have the contract, but I understand that it was the result of very rapid

and close negotiation between Vincent Collingridge,

the Mowlem Tunnelling Director, and senior GLC

Engineers. The result was a form of contract based on

the ICE conditions, but with open books accounting, with limits on profit and loss, and with facilities

for close cooperation between the GLC and Mowlem

in regard to the management of the project.

38.

I anticipate that Partnering, in the course

of time, will sort the more capable tunnellers from the less capable. Partnering,

because of the openness of partner selection, gives a

client an opportunity to run the rule over potential

contractors, and designers, to an extent not open to

him in other forms of contract. Clients have choices.

Basic logic suggests that a client will choose to partner only with the best available to him.

43.

It worked very well. The works were completed inside the very tight programme

necessary to avoid disruption of the other

contract, and within budget. Despite the tunnel

being relatively short in length, it was advanced on

four faces simultaneously from two working shafts,

with all tunnelling being carried out in compressed

air. All faces were advanced using clay pocketing

methods with Greathead shields and full horizontal

face planking.

39.

Long term Framework Partnering

enables clients to get even greater benefits, benefits which arise from continuous performance improvement. On the now-famous

BAA Paving Team infra-structure works on UK airports, the clients objective was to reduce his costs by

30%, in real terms, over a period of five years. That

was one hell of an ask, but it was achieved. It would,

almost certainly, not have been achieved if the work

had been packaged as a series of individual repetitive

Partnering contracts, even though these would, individually, have produced better results than other

forms of contract.

44.

But the success achieved in Greenwich

wasnt just due to the form of contract,

nor to good Mowlem or GLC engineering. We were blessed with two wonderful things. The

first blessing was a complete set of first class drawings which were not varied as the work progressed.

We completed the works using the same bound set of

drawings as we had been issued with at the start of

the contract. The second blessing was a GLC Resident

Engineer named Harold Bubbers, a brother, I believe,

of the famous Bernard Bubbers of Motts. Harold was

a superb engineer with a wonderfully calm diplomatic style which worked wonders with the many neighbours and authorities affected by our works.

40.

Although the client is the real winner

from Partnering, the other parties also

win. For example, Framework Partnering, and Partnering on large projects, enable contractors to invest in highly productive, but expensive,

equipment and enables designers to develop the

most cost effective designs and permanent works

components. These developments make contractors

and designers more competitive when pursuing later

opportunities.

45.

The list below shows that Greenwich had

most of the factors which my subsequent

experience has shown to be vital to the

successful and harmonious execution of tunnelling

works.

a.

People who knew what they were doing, ie

appropriate specialists

b.

Clear and unchanging construction

requirements

c.

A comprehensive assessment of

construction risks

d.

Contingency arrangements for dealing with

these risks

e.

A realistic budget

f.

Open Books Accounting

g.

Collaborative management of the project

h.

An excellent engineering representative of

the client who put a lot of effort into

ensuring that construction never met third

party Red Lights.

41.

But not everybody can partner successfully. It calls for styles of personal conduct to which some people can not conform. The traditional, fiercely competitive, and sometimes secretive, nature of the tunnelling industry has

nurtured quite a lot of people who endeavour to maximise their results through less than honourable

commercial behaviour. There are also those who relish absolute power and to whom collaborative decision-making is anathema. These are to be found

among all of the contracting parties, not just among

the contractors.

46.

I sincerely believe that there is no better

way than Partnering for a client to get

the required quality, the lowest costs for

that quality, and the best programme. Partnering is

superior to traditional forms of so-called competitive

These factors have been recognised by

several clients, as a result of which we

have found ourselves on a number of

occasions being assessed by Behavioural

Psychologists engaged by the client to assist him in

42.

47.

8

THE 2002 HARDING LECTURE

contractor selection.

Even people with good

Partnering characteristics take time to make the

adjustment from traditional forms of contract to

Partnering. I said earlier that my first experience of

Partnering was at Greenwich in the late sixties. My

next experience of it was at Tooting Bec, with Thames

Water and AMEC, at the end of the eighties.

A major problem had arisen on Ring

Main Contract 1A at the time when

Thames Water was being privatised.

There was a significant difference between AMEC

and Thames Water over extra payment for dealing

with the problem. This was a most unwelcome complication of the privatisation arrangements. It was

imperative that it be resolved in a manner which

would enable Thames Water to have an immaculate

privatisation prospectus. Thames Water therefore

decided to switch from the traditional form of contract, on which the contract had been let, to an open

books form of contract embodying Partnering. All

historic differences were settled quickly, in order to

create the right climate for the remainder of the

works. The job went well thereafter, but some staff on

both sides found the transition difficult. On the contractors side, some found it difficult to be open about

such things as internal plant hire rates, and about

how to calculate workforce bonus payments. On the

clients side, some found it difficult to treat the contractors staff as equals and to face up to sharing

responsibility for decision-making in regard to programme. But, in both cases, good cooperative behaviour became established after about two months.

That cooperation became closer and closer as ideas

emerged to overcome, completely, a potential programme delay of about eighteen months, and as

more and more difficult work was successfully completed.

48.

It has never been clear to me whether

Partnering was introduced at Tooting Bec

as an expedient solution to a pressing

privatisation problem, or whether it was meant to be

the first step in a long term policy for the execution of

capital works. As time passed, it turned out to be the

latter, and provided both the technical and contractual foundations for all subsequent Ring Main contracts, with their remarkable successes and achievements. The industry owes a lot to Roger Remington of

Thames Water, whose introduction of the I Chem E

form of contract to tunnelling was such a courageous

and far-sighted decision.

49.

Roger subsequently drew my attention to

a specific, and important, benefit which

Partnering gives to clients. It concerns

the effective use of capital. There was a stage in

Thames Waters capital works programme when

Roger had responsibility for capital works worth

about 200 Million, all of which were on an open

books Partnering basis. He was called to the

Highways Agency to discuss Thames experiences of

Partnering. The person he met in the Highways

50.

Agency was also responsible for capital works worth

about 200 million, but all of these were on the traditional non-partnering basis. They compared the

amounts of capital immobilised by each of them as

provisions for legitimate contractual claims. In

Rogers case, the amount was 0.5 Million. In the

Highways Agencys case, the amount was 40 Million.

I acknowledge that that is a simplistic comparison,

but it serves to illustrate a fundamental point Partnering gives clients greater certainty in regard to

out-turn costs, and thereby enables capital to be used

more confidently and efficiently.

After the Ring Main, we used our newfound skills to win and execute further

Partnering projects with Thames Water in

the South, with United Utilities in the North West,

and with Anglian Water in the East. These jobs were

not without their setbacks, but in only one case did

we and our client fail to deliver the goods. The one

exception was a Thames Water contract in East Ham,

where the contractor/client relationship at site just

did not gel, and AMEC lost a lot of money because we

had to meet the costs of overshooting the Final Target

Cost. So the contractor doesnt always make money

on Partnering contracts. That example proved to me

the crucial importance of the leaders at site being

fully committed to Partnering, and of not reverting to

traditional attitudes when the going gets tough. That

was the third contract in a series of twelve partnering

projects executed by AMEC Tunnelling up to the time

of my retirement. It was never allowed to happen

again.

51.

In the course of these contracts we had

some wonderful partners. In this context

I feel that it is appropriate to comment

on the contributions to success made by three of the

best partners with whom it has been my pleasure to

work. They are Andy Miller of Thames, Steve Smith of

United Utilities, and Adrian Henderson of Anglian. All

of them are knowledgeable, unusually competent,

and so self-effacing that I feel compelled to mention

them for fear of them otherwise not being given the

credit they deserve. In addition, each of them displayed remarkable forbearance in putting the common objective above any personal ambition or goal.

And, none of them ever tried to be the contractors

Agent, a common failing of some client representatives in the early days of a Partnering contract.

Engineers like these are worth their weight in gold.

52.

Although I have said that East Ham was

our only Partnering failure, that is true of

my AMEC experience. However, as a Joint

Venture partner of Balfour Beatty, we had a notable

failure on Contract 102 on the Jubilee Line, where

Partnering initiated by BBA was not reciprocated by

the JLE. It was their loss. In my opinion, it cost them

millions.

53.

THE 2002 HARDING LECTURE

feel you need onto a single A4 sheet of paper, then

youre trying to collect too much data, and it will progressively bury you. You will end up trying to figure

out whats wrong with the data rather than trying to

figure out what the data is telling you. So keep it as

simple as you can. Pay particular attention to trends.

I emphasise that point. Its the cumulative result that

matters, not flash in the pan fluctuations which

may be due to clerical indiscretions or to unusually

favourable transient circumstances. Appendix 5 illustrates my single sheet approach. It shows a sample

single sheet of the direct costs of a typical medium

diameter EPBM tunnel, unidentified for reasons of

confidentiality.

So, Partnering has been a wonderful

development for tunnelling, and we

should do everything possible to foster

its adoption by all clients, but, in exchange, we shall

have to continue to get better and better at what we

do, to win and retain the confidence of clients in the

Partnering concept.

54.

COSTING

I now turn, but only briefly, to the subject

of costs. I have been surprised by how

many engineers have shown little knowledge of costs. To some extent this has been due to

contractors being very secretive about costs, and permitting only the most senior staff to be privy to them.

Such a policy is a serious impediment to the proper

professional development of engineers. I dont see

how an engineer can do justice to his responsibilities

without a reasonable working knowledge of what

things cost. Youve got to be on top of your costs to be

on top of your job.

55.

PRODUCTIVITY

I shall now talk briefly on the subject of

productivity. Something that is much

more highly developed in tunnelling

than in most branches of civil engineering. There is

much published material on the subject, so I shall

confine myself to some of the aspects which I found

to be of particular relevance to soft ground tunnelling.

60.

It has been my practice to get my staff on

each job to compile for me a single sheet

listing the current local costs of relevant

materials and resources. I started doing so in

Mowlem and I kept doing so until retirement. These

exercises were intended to be as much for their benefit as mine.. Appendix 4 shows an example of one of

my standard lists of local basic costs. I had a similar

sheet for plant costs.

56.

Productivity is not production. It is a

measure of the efficiency of production. In

soft ground tunnelling it is usually about

finding the most cost effective balance between input

of resources and rings in the ground.

61.

Tunnelling equipment is in a continuous state of development. It has always

been so, and it will continue to ever be

so. As a result, contractors, when planning or bidding

for new work, regularly have to make assessments of

the productivity which will be achieved by new

equipment. They are able to do this by fragmenting

the main production activity into a number of subactivities, for most of which they will have existing

productivity information. For example, a new type of

tunnelling machine may be capable of excavating

much more quickly in a certain type of ground than

was previously possible. In estimating the time for

one complete ring cycle the contractor will be able to

rely on existing data for many components of that

cycle.

62.

Engineers should always have access to at

least this level of basic costs. They cant do

local budgeting without them. Basic costs

dont vary a lot from contractor to contractor. So there

is no great risk inherent in a breach of confidentiality.

What does vary is the productivity which each contractor achieves with these resources. The out-turn

cost per unit of work can therefore vary substantially

between contractors.

57.

Again, Partnering has been very good

for the advancement of engineers

familiarity with costs and productivity.

The open books nature of these contracts has compelled the contractors to develop costing systems

which make information available much more rapidly than before, and more widely. The formality of

open books accounting enforces a strict discipline

on forecasting and costing, and on comparisons

between the two a better discipline than ever existed previously in most contractor organisations.

58.

But where does all this existing data

come from ?. Well, it usually comes from

hours and hours of activity observation

and activity analysis by young engineers. Most of us

have done it. In my case it started with recording data

when rock tunnelling on the Awe Hydro-Electric

Project in Argyll. Mitchell Construction recorded

comprehensive details of every round fired in every

face on the project. That data was distilled and

analysed at the end of each month. It resulted in very

high outputs with modest resources. Discipline was

tight, and downtime was virtually non-existent. I suppose it is no surprise that the company held the world

63.

Engineers have to be careful not to try to

become amateur accountants. Reams of

figures, giving every detail of every aspect

of everything, are not what engineers need.

Engineers need succinct, reliable information, rapidly. I believe in the single sheet approach. If, at each

level of the project, you cant get the information you

59.

10

THE 2002 HARDING LECTURE

high speed record for rock tunnelling at that time.

From there, I went to Mowlem on the

Victoria Line in London, and got introduced to a more sophisticated level of

work study and activity analysis on the LUL Running

Tunnel drum diggers. That set the pattern for my subsequent twenty four years with Mowlem, both in tunnelling and in general civil engineering.

64.

So, my advice to all younger engineers,

and to some more senior ones, is to collect and analyse productivity data at

every relevant opportunity and apply the conclusions

of these analyses to continuously improve productivity either by refining existing methods of production

or by inventing new ones. You may find tedious the

many hours you have to spend collecting and

analysing data in the early parts of your careers but

your efforts will be rewarded handsomely later in

your lives.

65.

There is one aspect of tunnel drive production which I wish to touch upon

before leaving this subject. It concerns

the early parts of tunnel drives, the so-called

Learning Curve Period. I mention it because it is

rarely shown on Gantt Chart programmes and has

been a regular source of differences, between the

contracting parties, in the reporting of progress. Its

something that I have been asked about many times.

66.

Over the years, I have analysed the records

of many mechanised tunnel drives, and I

have reached some conclusions as to how

to assess the so-called Learning Curve Effect on the

early part of tunnel drive programmes. At this point it

is necessary to refer to Appendices 6, 7, 8 and 9.

67.

Appendix 6 shows a typical tunnel drive

programme, in Time/Chainage format, for a medium diameter EPBM-type

drive launched through a pre-formed eye in the side

of a shaft. It shows the TBM advancing a short distance, using only the very short equipment train

which it was possible to accommodate in the shaft,

and then stopping to install more parts of the equipment train. Advance then resumes until sufficient

tunnel has been driven to accommodate the full

equipment train and pit bottom facilities. Following

that final equipment installation phase, the drive

resumes and continues to completion. Note that I

have not shown a reduction of output when completion is approaching. The final curve of the so-called

S-Curve, so beloved of work study experts, is hardly

ever noted in UK soft ground tunnelling, in my experience.

68.

Appendix 7 shows the same programme

with the equipment installation periods

removed. Having reduced many TBM

drive records to this format I found that the tangent

point between the learning curve and the straight

69.

11

line of the sustained output after the tangent point

tended to be found at approximately 300 metres from

the start of the drive. Analyses which I made in the

1970s, mainly concerning drives in clay, showed the

tangent point to be found at a distance from the start

approximately equal to three times the length of the

equipment train being towed behind the TBM. With

EPBMs the distance to the tangent point tends to be

a little greater, ie the 300 metres referred to above.

The difference may be due to the extra distance needed for the EPBM drivers to find the operational

parameters for optimum machine performance in

the more arduous ground conditions in which

EPBMs are used. My conclusion is that a distance of

300 metres, from start to tangent point, is a good figure to use in programming all advanced TBM/EPBM

drives. However, that conclusion only fixes the distance. It is still necessary to find a means of establishing the time to reach the tangent point.

Appendix 8 shows the same programme

line as in Appendix 7 but with two additional lines.

a. The first additional line is a line joining the origin to the tangent point. I found that the slope of that

line was approximately 50% of the slope of the

straight line of the sustained output after the tangent

point. There was a range of values for the slope of the

line but, as 50% was approximately a mean value, I

feel that the 50% figure is a reasonable figure to use

for general programming purposes, especially as,

when the programme is being developed, the

straight line after the tangent point is still an estimate. Most engineers and estimators seem to able to

assess the sustained output after the tangent point

with a reasonable degree of accuracy, but many have

difficulty assessing learning curves. So, it seems reasonable to link the slope of the line between the origin and the tangent point to the slope of the straight

line after the tangent point. That being the case, I recommend that the 50% figure be used, ie the average

output over the learning curve period be taken to be

50% of the planned sustained output after the learning curve period. The position of the tangent point at

the end of the learning curve can thereby now be

fixed in terms of both distance and time, for the purposes of both estimating and programming.

b. The second additional line is a dotted line

extrapolating, downwards, the straight line of the

sustained output after the learning curve to intersect the horizontal axis, ie the time axis. The intercept, The Learning Curve Effect, between the origin

and the intersection of the dotted line with the axis,

can be calculated using the recommendations made

above. However, the magnitude of that intercept will

be between 2 weeks and 3 weeks for most practical

TBM outputs. I recommend that the intercept be

taken, for preliminary programming purposes, to be

2 weeks for TBMs less than 4 metres in diameter, and

3 weeks for TBMs above that diameter. That takes us

to Appendix 9.

70.

THE 2002 HARDING LECTURE

other workmen. They told me that the best of them

had lung capacities close to double the norm, at

rest heart rates in the forties per minute, and superb

bone structure and muscle development. In addition,

most of them had been introduced to physical work

at an early age and had developed mind-sets which

could cope with unbroken hours of arduous toil.

Interestingly, these are the same characteristics

which distinguish the crack Tour de France cycle riders from general sportsmen.

Appendix 9 is intended to show a simplistic

programme for preliminary programming

purposes. This simplistic Time/Chainage

programme is constructed by marking off, on the

horizontal axis, an intercept equal in length to the

sum of, (i) the time allowed for equipment installation after the TBM has been launched, and, (ii) either

2 weeks or 3 weeks, as appropriate, for the Learning

Curve Effect. A straight line can then be drawn from

the end of that intercept to the end of the drive. The

slope of the straight line is the same slope as for the

straight line sustained output after the learning

curve.

71.

The point which I am trying to make is

that the high wages paid to handwork

miners were EARNED by extraordinary

individuals from incentive payment schemes from

which typical construction workers would have

earned only typical construction wages. There is no

fundamental reason why the high payments made to

these supermen should be made to normal individuals just because they are working in tunnels.

76.

PAYMENT OF THE WORKFORCE

Im now on to my second last section. Its

about the payment of the workforce. A

sensitive subject, but, now that Im

retired, I suppose that I can speak more freely than I

could as a tunnelling director.

72.

Machines have removed most of the need

for supermen. It makes no sense to invest

in machines AND pay handwork wages

for using them. However, it is a fact of life that, in the

UK, levels of pay for mechanised tunnelling have

been allowed to drift upwards to levels previously

associated with handwork. This is not the case outside the UK. It is not my intention to discuss the reasons for the UK anomaly. I shall say simply that I have

never been happy about it.

77.

It seems that a lot of people think that the

high levels of payment made, historically,

to face workers on handwork drives were

due to the conditions in tunnel faces, to the arduous

nature of the work, to having to work shifts, and so

on. That is a misconception. These payments were

EARNED under piecework arrangements in which

the targets for the various elements of work were

broadly in line with the targets for other types of civil

engineering works. What was different was the men.

They were the physical crme de la crme of the

human race. They could have earned the level of

money they got in tunnelling on other types of construction work. I have seen handwork miners EARN

tunnelling money on deep cut and cover pipe

installation and on major concrete pours.

73.

When I came to London in 1964 to work

for Mowlem on the Victoria Line, all

underground work was carried out on

the basis of piecework, with all piecework Tasks

being expressed in Hours rather than in money.

One Hour was worth the Working Rule Agreement

rate for one hour for the grade of employee for which

the task was set. That meant that there was a lot of

stability in these Tasks because general inflation

had no effect on them. Some Tasks on the Victoria

Line had been in existence for many years,

unchanged, from earlier LUL projects. However, in

1972, following industrial unrest across the whole of

the construction industry, there was a 25% increase

in the base rate in the Working Rule Agreement.

Tunnelling contractors decided, as a group, to stop

setting prices in Hours and to switch to setting

them in monetary terms. It was an effort to mitigate

the effects of such a substantial increase, but it meant

that thereafter all pricing was exposed to the effects

of general inflation. The stability of pricing was lost

forever. Estimators and managers were then presented with serious difficulties in setting prices and

Tasks. The entry of Trades Unions into tunnelling,

and the end of Hire and Fire, both in the mid seventies, generated even more uncertainty.

78.

For example, Mowlem had a pipeline

contract in Edinburgh at a time when

tunnelling work was in very short supply

North of the border. A group of Donegal tunnel miners asked to be considered for employment on the

pipeline. They were told that they would have to

accept the bonus task already set out for a civil engineering workforce. They did so, and proceeded to

produce outputs which earned them as much money

as they would have earned in tunnelling. The same

bonus task had been used with a civils workforce

before the Edinburgh contract, and was used again

afterwards, without outputs and payment levels

being achieved comparable with those achieved by

the miners.

74.

It wasnt until I was at Greenwich, and we

had to send miners for compressed air

medicals, and the doctors started asking

questions about where we got these men from, that I

came to realise that handwork miners were not normal human beings like the rest of the population. The

doctors could always pick out the miners from the

75.

As an Agent, and as a Contracts Manager,

I had a difficult time after 1972 endeavouring to assess movements in the labour

market and trends in the pricing of Tasks and bonus

79.

12

THE 2002 HARDING LECTURE

schemes. But, I kept good records, with the result that

by 1980 I had sufficient data to allow me to draw up a

set of tentative guidelines for my own use. I found

them to be effective and I have updated them privately ever since. They have their roots in the old

Hours system, in an attempt to eliminate the effects

of general inflation.

Appendix 10 is a graph of how I link payment to output for a TBM Ringbuilder

the grade of employee which I have

selected for use as a benchmark. Ringbuilders are

important. They install the permanent works which,

after all, is the object of the whole tunnelling operation. Appendix 11 shows my guidelines for linking the

payment of the Ringbuilder to the payment of the

various other grades of employee on a typical TBM

tunnelling contract.. Appendix 12 shows how to calculate the costs of employing these grades at these

levels of payment. (Note that the example given in

this appendix is for output matching programme

requirement.) Appendix 13 shows my guidelines for

the payment of a top class handwork Miner

engaged on works requiring excavation to be carried

out using hand-held pneumatic clay spades, and

spoil to be loaded by shovel. A handwork Miner is

usually a member of a tightly knit gang whose numbers are dependent on the diameter of the works

being undertaken. As an approximate general guide,

the Leading Miner of the gang is paid 7.5% more than

the Miner, and the Miners Labourers 7.5% less than

the Miner. The determination of the level of payment

to be made to handwork miners should only be in

the hands of engineers/managers who are very experienced in this type of work. Top class handwork

miners should be treated with the utmost respect.

The enormous effort which they put into their work is

a much more personal thing than the effort put in by

workers engaged on machine tunnelling, where the

main brunt of the work is borne by the machine. Men

are not machines, and should never be treated as

such.

80.

I hope that you will find the information

to be useful. I emphasise that it is for

guideline purposes only. The figures

should be reviewed in the light of all the circumstances of any specific contract and may have to be

tuned to suit. I would be interested in hearing from

others who have done similar exercises.

81.

Tunnelling is no place for suck it and

see engineering. Everything needs to

be fully engineered, and planned in

detail, before any construction work is put in hand.

Some decisions in tunnelling are virtually irreversible. For example, it is not possible to switch

TBMs in the manner in which it is possible to switch

even the biggest machines on surface works.

Tunnelling simply has to have top notch engineers.

All the easy tunnels have already been driven. The

future will almost certainly consist of hi-tech railway

and road tunnels, and difficult water industry tunnels. We shall need very good engineers for these

works.

83.

To get them, we need to persuade

some of the best products of our

schools to become tunnelling engineers because it is a stimulating and rewarding

career, and one which is worth pursuing through university education and subsequent professional qualification. But, we have to compete for the talents of

these young people against the many excellent

opportunities open to them in other professions. We

shall only do so successfully if the financial rewards

of following a tunnelling career are comparable with

those available from following other professional

careers. I am being deadly serious when I say that I

think that we need to approximately double the

salaries we pay currently in tunnelling to our best

professional engineers. I have done as much as I have

been able to do, to achieve that objective, within the

constraints of the human resources policies in the

large public companies in which I have held director

responsibilities. I have been fortunate to have had

some excellent engineers work for me. Not just civil

engineers, but mechanical engineers, electrical engineers, electronics engineers and mining engineers

all essential to successful tunnelling. I used to derive

a modest satisfaction from seeing the salaries paid to

them sitting at the top, or near to the top, of the company salary lists. But these salaries were still not high

enough to really catch the attention of top notch

school leavers.

84.

ENGINEERS

Likewise, I feel that we need to

improve the working conditions for

engineers. For example, I feel that they

should not be obliged to work twelve hour shifts as a

matter of course. In fact, I feel that we should drop

twelve hour shifts altogether, for everyone. I shall

come to that later.

Finally, I wish to say a few words

about engineers. Tunnelling is as

technically challenging as any branch

of civil engineering, with the possible exception of

bridge engineering. Consider the challenges of the

Channel Tunnel Rail Link (CTRL) and the Jubilee Line

Extension Project (JLEP), and then consider if there

are other civil engineering projects comparable with

them.

Some of you will, no doubt, tell me

that we cant afford to increase engineers salaries by as much as I have

suggested, because of the cost increases which will

flow from doing so. I shall try to demonstrate that the

effects will not be dramatic, and that they are well

within the improvements in costs which flow from

Partnering and from general improvements in efficiency of working. I show, in Appendix 14, a table

82.

13

85.

86.

THE 2002 HARDING LECTURE

which shows a typical pattern of costs for soft ground

tunnelling using a medium sized EPBM in a

Partnering environment. These costs are expressed as

percentages of Total Direct Costs, ie the total of

Temporary Works and Materials, Permanent

Materials, Subcontractors, Labour and Plant. That is

the form of presentation which I, at a personal level,

have found to be the most meaningful for examining

tender summaries. Dealing with the cost of engineers, you can see that the typical cost of all staff is

12% of Total Direct Costs and, therefore, 8.7% of the

Total Selling Price. Less than half of that figure is the

cost of engineers, the remainder being the cost of

other staff. Doubling the salaries paid to engineers

would therefore, superficially, add around 4% to the

Tender Total. But I dont believe that the figure would

actually be as high as that. The higher salaries would

attract the very best engineers, whose abilities would

go some way, if not all the way, to offset the superficial increase in costs arising from the increased

salaries. So, it might actually turn out to be a no cost

proposition.

Having already mentioned my distaste for twelve hour shifts, I would

like to finish by putting forward an

immaculate economic argument for putting an end

to them, but I find that I am not able to do so. I find

myself facing the same difficulty as must have faced

reformers who argued for an end to slavery a couple

of centuries ago. The argument is essentially a

humanitarian one, but with an underlying conviction

that economic benefits will flow from a decision to

stop employing a working practice which has outlived its time.

90.

Nevertheless, I do have some evidence

to support that conviction. I have had

many contracts which operated a twelve

hour double shift work pattern, a number which have

operated an eight hour treble shift pattern, and a

number which have operated a ten hour double shift

pattern with a two hour gap between shifts. The pattern of ten hour shifts with two hour gaps produced

the most satisfactory overall results. Production tended to be very good, and downtime tended to be very

low. And, perhaps most importantly, staff and workforce were happier than under the other arrangements.

91.

I recognise that there is an argument

that an increase in engineer salaries

would create pressures to increase the

salaries of other staff. While I wont try to deny that

argument, I dont feel that that is a particularly strong

one, because the salaries of some other grades are

already high enough to meet market demands, for

example foremen, and no other grade of employee

is as fundamentally vital to the industry as engineers.

87.

The twelve hour shift pattern is simply

too brutal. The eight hour pattern is

fine for the workforce, and for some of

the staff, but its intensity puts too much pressure on

the senior managers and supervisors who cannot be

on an eight hour pattern. My experience is that these

senior managers and supervisors get completely

worn out on contracts with eight hour shift working.

On balance, therefore, I strongly favour ten hour

shifts Monday to Thursday, and eight hours on

Fridays (to conform to European Working Hours regulations).

92.

If you reject completely the idea that a

reduction of the increased costs would

be achieved through having the best

engineers, you could simply regard the 4% to 5% as

being the cost of attracting top quality school leavers

into civil engineering tunnelling something that

appears to be necessary in any case from inspection

of recent trends in numbers of entrants to UK universities to study engineering.

88.

I recognise that some clients may not

be over the moon with this proposal,

but, over recent years, we have given

them enormous advances in predictability, quality

and speed of construction, together with substantial

cost savings through Partnering. I would like to think

that most of our client partners would agree that we

have earned the right to a more civilised existence.

93.

The increase which I have advocated

above would have to be made incrementally over, say, a five year period,

but there would have to be some form of unequivocal

public commitment to it, to make potential students

aware that it was being made. In my judgement that

commitment will have to be made soon, or we shall

not have the engineers to meet the needs of the country.

89.

References

(1) Holmes, Professor Arthur & Dr Doris, 1978, Principles of Physical Geology, Third Edition, published by Thomas Nelson & Sons Ltd,

Sunbury on Thames.

(2) Fookes, Professor Peter G., 1997, The First Glossop Lecture, The Quarterly Journal of Engineering Geology, published by the

Geological Society, Volume 30, Part 4, Nov 1997.

14

THE 2002 HARDING LECTURE

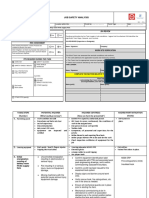

Appendix 1

15

THE 2002 HARDING LECTURE

Appendix 2

16

THE 2002 HARDING LECTURE

Appendix 3

Source: Fookes, Professor Peter G., 1997, The First Glossop Lecture

17

THE 2002 HARDING LECTURE

Appendix 4

18

THE 2002 HARDING LECTURE

Appendix 5

19

THE 2002 HARDING LECTURE

Appendix 6

Appendix 7

20

THE 2002 HARDING LECTURE

Appendix 8

Appendix 9

21

THE 2002 HARDING LECTURE

Appendix 10

22

THE 2002 HARDING LECTURE

Appendix 11

23

THE 2002 HARDING LECTURE

Appendix 12

24

THE 2002 HARDING LECTURE

Appendix 13

25

THE 2002 HARDING LECTURE

Appendix 14

26

THE 2002 HARDING LECTURE

27

Você também pode gostar

- PHD Ochmanski Enc PDFDocumento285 páginasPHD Ochmanski Enc PDFSérgio BernardesAinda não há avaliações

- RockEng09 ProceedingsDocumento258 páginasRockEng09 Proceedingsdafo407Ainda não há avaliações

- Temporary Stability of Steep Noncemented and Lightly Cemented Soil SlopesDocumento11 páginasTemporary Stability of Steep Noncemented and Lightly Cemented Soil Slopesdafo407Ainda não há avaliações

- Liquefaction 7Documento8 páginasLiquefaction 7Ganesa Panjaitan100% (1)