Escolar Documentos

Profissional Documentos

Cultura Documentos

Tesab 1012T OperationManual Issue4

Enviado por

gugiTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Tesab 1012T OperationManual Issue4

Enviado por

gugiDireitos autorais:

Formatos disponíveis

RK1012T ROTOCRUSHER

RK1012T ROTOCRUSHER

Jan 2005 Issue

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

CONTENTS

Jan 2005 Issue

TABLE OF CONTENTS

SECTION 1:

1.0

1.1

1.2

1.3

1.4

1.5

EU directive

Declaration

Machine Specification Details

Foreword / Reservation Of Rights

Familiarisation

General Specification

SECTION 2:

2.0

2.1

2.2

2.3

2.4

SAFETY

Safety Introduction

Safety Notes

Position of Emergency Stops

Emergency Situation

Lockout Procedure

SECTION 3:

3.0

3.1

3.2

3.3

3.4

INTRODUCTION

TRACKING INSTRUCTIONS

Tracking Familiarisation

Tracking the Machine

Tracking using the Remote Control

Tracking using the Dog Lead

Remote Control Battery Charging

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

CONTENTS

Jan 2005 Issue

TABLE OF CONTENTS

SECTION 4:

4.0

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

4.11

4.12

4.13

4.14

4.15

4.16

4.17

4.18

Set-up Procedure Safety

Installation

Loading & Off-Loading

Starting Engine

Engine Starting Procedure

Tracking Instructions

Tracking the Machine

Tracking using the Remote Control

Tracking using the Dog Lead

Remote Control Battery Charging

Positioning

Preparing for Initial Startup

Dirt Conveyor Unfolding

Crib Folding and Assembly

Feeder Beacon

Feed-In Chute

Hoist

Crusher Settings

Dust Suppression

SECTION 5:

5.0

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

5.10

5.11

5.12

5.13

SET-UP PROCEDURE

OPERATION

Operation Safety

Operation Lockout Procedure

General Information

Pre Operation Check List

Feeder Information

Feeder Instructions

Machine Starting

Setting Engine Revs

ESM Main Unit

Engaging Clutch

Product Conveyor Starting

Dirt Conveyor Starting

Feeder Starting

Machine Shutdown Sequence

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

CONTENTS

Jan 2005 Issue

TABLE OF CONTENTS

SECTION 6:

6.0

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

6.10

6.11

6.12

6.13

6.14

6.15

6.16

6.17

6.18

6.19

6.20

6.21

6.22

6.23

6.24

6.25

6.26

6.27

6.28

6.29

6.30

MAINTENANCE

The RK1012 Rotocrusher

Replacing or Turning Hammers

Setting The Crusher Gap

Replacing or Turning Impact Bars

Manual Clutch

Hydraulic Clutch

Maintenance

General Information

Safety Information

Hydraulic System

Tracks

Hydraulic Fluids

Oil Tank, Pipes & Fittings

Diesel Engine

Product Conveyor Reduction Gear

Feeder

Bearing & Lubrication

General Specification Inspection

Routine Maintenance Schedule

Daily Maintenance

Weekly Maintenance

Six Monthly Maintenance

Belt Tracking

V-Belt Tensioning

Recommended Gear Oil

Recommended Lubricants

Automatic Greasing System (Autolube)

Autolube Maintenance

Autolube Troubleshooting

Recommended Fluids

Fault Finding

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

CONTENTS

Jan 2005 Issue

TABLE OF CONTENTS

SECTION 7:

7.0

Preparing for Transport

SECTION 8:

8.0

RK1012 CRUSHER PARTS LIST

Index

Main Assembly

Chamber Wear Plates

Shaft and Bearing Assembly

Top Apron Adjuster Assembly

Middle Apron Adjuster Assembly (Manual Adjustment)

Bar Carrier Adjuster Assembly (Manual Adjustment)

Middle Apron & Bar Carrier Adjuster Assembly (Hydraulic Adjustment)

SECTION 10:

10.0

10.1

10.2

10.3

10.4

10.5

10.6

10.7

WARRANTY

Warranty

SECTION 9:

9.0

9.1

9.2

9.3

9.4

9.5

9.6

9.7

PREPARING FOR TRANSPORT

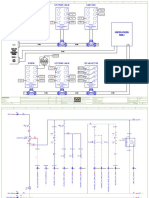

HYDRAULIC & ELECTRIC DIAGRAMS

Hydraulic Diagram (Standard)

Hydraulic Diagram (inc. Conveyor Folding)

Electric Diagram (Fuse Relay Description)

Electric Diagram (Panel Layout)

Electric Diagram

Electric Diagram

Electric Diagram

Electric Diagram

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

RK1012T ROTOCRUSHER

Jan 2005 Issue

Section 1

INTRODUCTION

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

RK1012T ROTOCRUSHER

Section 1

The TESAB RK 1012T ROTOCRUSHER complies with the EU directive 89/392/

EEC and all relevant amendments.

READ THIS MANUAL CAREFULLY AND LEARN HOW TO OPERATE AND

SERVICE YOUR MACHINE CORRECTLY.

FAILURE TO DO SO COULD RESULT IN PERSONAL INJURY OR EQUIPMENT

DAMAGE.

REMEMBER:

GOOD HOUSEKEEPING PAYS UNTOLD DIVIDENDS IN

INCREASED PRODUCTION AND EXTENDED PLANT

LIFE !

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

GENERAL INFORMATION

Section 1

1.1 EC DECLARATION OF CONFORMITY

We hereby declare that the following machinery complies with the Essential Health

and Safety requirements of the EU Machinery Directive 89/392/EEC as amended

by 91/368/EEC, 93/44/EEC and 93/68/EEC.

Manufactured by:

Tesab Engineering Ltd.

7B Gortrush Industrial Estate

Omagh

Co. Tyrone

Northern Ireland BT78 5EJ

Machine Description:

Mobile Crushing Plant

Model:

RK 1012T ROTOCRUSHER

Serial No:

This machinery has been designed and manufactured in accordance with all the

relevant ESRs of the EU Machinery Directive.

A technical construction file for this machinery is retained at the following address:

Tesab Engineering Ltd.

7B Gortrush Industrial Estate

Omagh

Co. Tyrone

Northern Ireland BT78 5EJ

Signed:

Name:

Brian A. Mills

Position:

Project Manager

Date:

Being the nominated representative of Tesab Engineering Ltd.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

GENERAL INFORMATION

Section 1

1.2 MACHINE SPECIFICATION DETAILS

MACHINE SERIAL NUMBER:

ENGINE TYPE:

ENGINE SERIAL NUMBER:

CLUTCH TYPE:

CLUTCH SERIAL NUMBER:

DESPATCH DATE:

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

GENERAL INFORMATION

Section 1

1.3 FOREWORD/RESERVATION OF RIGHTS

The TESAB RK 1012T ROTOCRUSHER is a robust skilfully engineered piece of

equipment incorporating diesel, hydraulic and mechanical components of the

highest quality.

In the interest of continuous plant reliability, it is essential that the machine is

maintained with meticulous care and attention. This operation and maintenance manual has been produced to assist the user to obtain the maximum

output from the machine and to trace and remedy faults, should they arise,

failure to do so could result in personal injury or equipment damage. We recommend that the user should pay particular attention to the maintenance and

safety sections of this manual.

Consider this manual a permanent part of your machine. Keep a copy of this

manual at the operational site.

This operation and maintenance manual must not be copied, reproduced

or loaned to a third party without written consent of

TESAB ENGINEERING LTD.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

GENERAL INFORMATION

Section 1

1.4 FAMILIARISATION

The following conventions have been used throughout this operation and maintenance manual when describing component locations:

Right and left hand sides -

as viewed from the product conveyor end of

machine.

Front

product conveyor end of machine.

Rear

feeder end of machine.

REAR

RIGHT

LEFT

FRONT

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

GENERAL INFORMATION

Section 1

1.4 FAMILIARISATION contd.

1.

Feeder

2.

Crusher Unit

3.

Dirt Conveyor

4.

Chassis

5.

Drive System

6.

Product Conveyor

7.

Tracks

3. Dirt conveyor front view

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

GENERAL INFORMATION

Section 1

1.5 GENERAL SPECIFICATION

Chassis

The chassis is constructed of heavy-duty profiles and welded steel plates ribbed

and stiffened to withstand all operational and travelling stresses. The chassis is

mounted on 3.75m centre heavy-duty tracks, with remote control or dog lead operational facility.

Feeder

The 4.25m x 0.9m spring mounted heavy duty vibrating feeder is of twin shaft

design. The controls and variable speed are located on the feeder catwalk or

alternatively the feeder can be operated from the tracks remote control, this allows

the operator full control of crusher feed rate. The bar frame cassette can be manufactured to the customers specification depending on application and site conditions. The customer has the option of feeding the fines onto the product conveyor

belt or onto a 3.6m x 500mm side dirt conveyor. The feeder is fitted with hydraulic

folding heavy-duty cribs to give extra hopper capacity.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

GENERAL INFORMATION

Section 1

1.5 GENERAL SPECIFICATION contd.

Crusher Unit

The RK 1012 crusher unit is fitted with four hammers, 1000mm wide. It has a feed

opening of 1020 x 780mm and a rotor diameter of 1200mm. There are two adjustable aprons and a final bar carrier which can be adjusted from 4 to 80mm depending on material feed size and reduction required. It is driven through 8 V-Belts and

the chamber can be easily accessed by hydraulic control lever. There is a deadbox

fitted under the crusher to allow easy flow of material onto the product conveyor. A

speed sensor is fitted to the rotor that cuts of the feed before the crusher overloads.

Product Conveyor

The product conveyor is fitted with a 1000mm heavy duty 4 ply belt and runs on

heavy duty troughing rollers, impact bars are fitted under crusher to give belt full

support at crusher exit. The conveyor is driven hydraulically through a flexible coupling at the rubber lagged top end drum.

Power Unit

The engine is a Caterpillar C9 (300HP at 1800rpm) Power Pack and the crusher is

driven through a heavy duty Twin Disc IBF 314 (3 plate) PTO. The pulley on the

clutch can be easily changed to alter the rotor speed or if finer tuning is required the

engine speed can vary between 1700 and 2200rpm. The conveyors, feeder, and

rams are all driven hydraulically through pumps fitted to the engines auxiliary drive.

Catwalks and Guards

All relevant catwalks, handrails and guards are fitted to this machine allowing access to all relevant maintenance points. Emergency stops are fitted to all necessary

points. The machine carries the European CE mark and therefore complies with all

Essential Safety Requirements.

Options

-

Self-cleaning magnet

Dust suppression

Re-cycling apron

Vibrating feeder under crusher

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

RK1012T ROTOCRUSHER

Jan 2005 Issue

Section 2

SAFETY

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SAFETY

Section 2

2.0 SAFETY INTRODUCTION

In this next section you will find the safety sign conventions used throughout

this manual and on the machine.

Please read this section carefully and become familiar with the signs used.

These signs are used frequently throughout this manual to indicate any potential warning or danger when operating this machine.

DANGER

ELECTRICAL HAZARD

1.

2.

3.

DANGER

Electrical Hazard. Risk of serious injury or

death.

Never work on the electrical system of any

equipment unless you are fully familiar with

system details.

Work on the electrical system must be

carried out by a qualified electrician.

NIP HAZARD

1.

2.

3.

DANGER

Nip Hazard. Do not reach into an

unguarded machine.

In-running nip points can cause

serious injury or death.

Switch off and lockout machine

before opening or removing guard doors.

FALL HAZARD

1.

2.

3.

Fall Hazard. Do not climb onto moving or

working machinery.

Switch off and lockout machine before

attempting maintenance on the machine.

Always use a suitable lifting platform before

attempting maintenance above 2m (6-6).

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SAFETY

WARNING

Section 2

CRUSH HAZARD

1.

2.

3.

WARNING

Crush Hazard. Beware of dangerous hand

and foot crush points.

Do not use any body parts e.g. hands or

feet to check hole alignment or support

machinery.

Always use pins and/or mechanical

supports provided.

PROTECTION

1.

2.

3.

WARNING

Loose or baggy clothing can get caught in

running machinery.

Always wear correct fitting (EN/ANSI

approved) protective clothing.

Protective clothing includes Hard Hat,

Safety Clothing, Ear Defenders, Overalls,

Steel Toed Boots, and a High Visibility Vest.

CONSULT MANUAL

1.

2.

3.

WARNING

Read and understand the operators manual

before you work at this machine.

Study the different safety signs on this

machine.

Only qualified and trained personnel should

attempt to work at this machine.

LOCKOUT

1.

2.

3.

When performing maintenance or

adjustment to this machine always switch

off engine and remove the ignition key. (if

electric isolate power supply at source).

Keep ignition key on person during

maintenance.

Never work alone.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SAFETY

WARNING

HIGH PRESSURE

1.

2.

3.

CAUTION

WARNING

2.

WARNING

Fall rock hazard. Do not walk near material

discharge areas. You are at risk of serious

injury or death.

Wear a Hard Hat at all times when working

in the vicinity of the machine.

BATTERY HAZARD

1.

2.

BATTERY

Burn or Heat Hazard. Beware of hot sur

faces at engine and exhaust areas.

HEAD PROTECTION

1.

EXPLOSIVE

Beware of escaping hydraulic oil. High

pressure hydraulic oil can penetrate the

skin causing serious injuries.

Always relieve pressure from the hydraulic

system before attempting maintenance.

If oil is injected under the skin, it must be

surgically removed or gangrene will result.

HOT SURFACE

1.

ACID

Section 2

Battery Hazard. Battery electrolyte contains

acid and can cause serious injury. Avoid

any contact.

Batteries give off flammable fumes which

can explode. Avoid the formation of sparks

and naked lights in the vicinity of the

batteries. Do not smoke when working in

this area.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SAFETY

Section 2

2.1 SAFETY

Operators should be trained in the

correct and safe use of all equipment including the studying of this

manual, failure to do so could result in serious injury.

Any work on and with the machine

must be executed by reliable, trained

and authorised personnel only. Statutory minimum age limits must be observed.

Work on the electrical system and

equipment of the machine must be

carried out only by a skilled electrician or by instructed persons under the supervision and guidance of

a skilled electrician and in accordance with electrical engineering

rules and regulations.

Work on the hydraulic system must be

carried out by personnel with special

knowledge and experience of hydraulic equipment.

There are several specific signs on

your machine. Please take time to

familiarise yourself with the safety

signs and the operation and maintenance manual.

See to it that safety instructions and

warnings attached to the machine are

always complete and completely legible.

Replace unreadable or missing labels

with new ones before operating the

machine.

Wear a hard hat, protective glasses,

hearing protection, close fitting

overalls, steel toed boots and high

visibility vest (E.N / A.N.S.I. approved) as required by job conditions.

Do not wear loose clothing or jewellery and tie back long hair that can

catch on controls or moving parts.

Make certain all protective guards

and covers are secured and in place

at all times. All guards should be in

place whenever maintenance is not

being performed. Never disable or

remove any safety mechanism or

guard.

Where possible when working close to

engines or machinery, only do so when

they are stopped. If this is not practicable, remember to keep tools, test

equipment and all other parts of your

body well away from the moving parts.

Understand service procedure before doing work. Keep all areas

clean and dry.

Keep warning and instruction labels

clean.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SAFETY

2.1

Section 2

SAFETY contd.

Never lubricate, clean, service or

adjust machine while it is moving.

Keep hands, feet and clothing clear

of power driven parts and nippoints. Disengage all power and

operate controls to relieve pressure.

Stop the engine. Implement lockout

procedure. Allow machine to cool.

Keep all parts in good condition and

properly installed. Fix any damage immediately and replace any broken

parts with genuine TESAB parts. Remove any built up of grease, oil or debris.

For the execution of maintenance

work, tools and workshop equipment adapted to the task on hand

are absolutely indispensable.

Isolate all electrical supplies before

carrying out repairs or maintenance,

and should only be carried out by qualified personnel.

Stay clear of all rotating and moving parts. Do not attempt to clear

obstructions or debris by hand before isolating the equipment by implementing the lockout procedure.

In running nip points can cause serious injury even death. Do not reach

into an unguarded machine.

Take the necessary precautions to

ensure that the machine is used

only when in a safe and reliable

state.

In the event of malfunctions or operational difficulty stop the machine immediately and lockout. Have any defects

rectified immediately.

Do not attempt repairs or adjustments to the machine while it is running.

Relieve all pressure in hydraulic systems before any lines, fittings or related

items are disconnected or removed.

Hydraulic lines must be laid and fitted properly. Ensure that no connections are inter-changed. The fittings

lengths and quality of the hoses

must comply with the technical requirements.

Always practice extreme cleanliness

when servicing hydraulic components.

Hydraulic fluid under pressure is

very dangerous, it can penetrate the

skin causing serious injury.

If fluid is injected under the skin it must

be surgically removed immediately.

Switch off engine and lockout machine before opening or removing

guards or doors.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SAFETY

Section 2

2.1 SAFETY contd.

Always use a piece of cardboard to

check for leaks. Do not use your

hand.

Use caution while removing filler caps,

filters, drain plugs or hydraulic fittings,

hold a rag over the connection to prevent being sprayed or splashed by liquids.

Diesel engine exhaust emissions

contain products of combustion

which may be harmful to your

health. Ensure the machine is in a

well ventilated area, if the machine

is operating in an enclosed area

vent the emissions elsewhere.

Observe the regulations in force at that

site.

Dust found on the machine or produced during operation should be

removed by extraction not blowing.

Disconnect the battery leads and tape

the leads to prevent accidental start

up when performing maintenance or

servicing.

Battery electrolyte contains acid

and can cause serious injury. Avoid

contact with skin and eyes. Use

gloves and protective glasses.

Batteries give off flammable fumes

which can explode. Ensure that

there is proper ventilation. Avoid

the formation of sparks and naked

lights in the vicinity of the batteries. Do not smoke when working in

this area.

Fires may result from lubricating oil or

fuel spraying on hot surfaces.

Avoid smoking whilst refuelling or

in the refuelling area.

Do not climb on conveyor belts or

stand on components that cannot support your weight, always use ladders,

steps and walkways when mounting

and dismounting machine.

Only use emergency stop buttons

in an emergency situation or during

safety checks.

Do not use fingers to check hole alignments as this can cause serious injury.

Do not stand beneath equipment as

it is being raised or lowered into position.

Never check the tension of V-belts

whilst machine is running.

Whenever maintenance and servicing is being carried out a minimum

of two persons must be present at

all times.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SAFETY

Section 2

2.1 SAFETY contd.

The preparations to transport the

machine should be supervised by a

minimum of two persons.

TESAB ENGINEERING LTD. have

provided walkways and platforms to

enable operatives to carry out daily inspection and maintenance from a position of safety. More irregular maintenance tasks will necessitate persons

to work on the machine at a height

were fall hazards exist. (It is the responsibility of the operators management to provide the necessary safe

working access).

Falling from and/or onto a TESAB

machine can cause serious injury or

even death. Do not climb on the machine and never use machine parts

as a climbing aid.

Always use an EN/ANSI approved

harness if reaching any points 2m (7ft)

or more above ground level.

Keep all handles, steps, handrails,

walkways and ladders free from dirt,

oil, snow and ice.

Observe the adjusting, maintenance

and intervals set out in these operating instructions, except where warning

light or indicator calls for immediate

action or adverse conditions require

more frequent servicing.

When the machine is completely shut

down for maintenance or repair work,

it must be secured against inadvertent starting by implementing the lockout procedure (see lockout section for

details).

Never allow anyone to remove large

or heavy components without adequate lifting tackle.

To avoid the risk of accidents, individual

parts and large assemblies being removed for replacement purposes

should be carefully attached to the lifting tackle and secured.

The fastening of loads and the instructing of crane operators should

be entrusted to experienced personnel only.

Any safety devices removed for setup,

maintenance or repair must be fitted

and checked immediately upon completion of the work.

Before activating the machine in any

manner, or energising the electrical

and/or hydraulic controls, make certain that no person or obstruction

is standing in or in the immediate

vicinity of the machine.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SAFETY

Section 2

2.1 SAFETY contd.

Always be aware that fully automatic machinery with moving parts

may move at any time without warning. Never assume the machine to

be safe because of the lack of movement.

Never alter any equipment or parts of

any equipment which may effect safety

without consulting and gaining permission from TESAB ENGINEERING

LTD.

Improperly disposing of waste can

threaten the environment and ecology. Potentially harmful waste used

with the TESAB machine include oil,

fuel, coolant, filters and batteries.

Use leakproof containers when draining fluids. Do not use food or beverage containers that may mislead

someone into drinking from them.

Do not open any door of the crusher

until the rotor has stopped completely and the control power have

been broken, in the case of the diesel powered unit the clutch is disengaged, the engine has stopped

and the ignition key has been removed.

Never start the machine until all doors

on the crusher are closed and locked.

When removing hammers and impact plates always use protective

goggles.

When the crusher chamber has been

opened ensure that the chamber is

pinned open.

When working at the inside of the

crusher lock the rotor inserting a

locating bar.

Do not pour the fluids onto the

ground, down a drain or into any

water source.

Ensure that all consumables and replaced parts are disposed of correctly

and with the minimum environmental

impact.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SAFETY

Section 2

1.

LHS & RHS

4.

RAMS CONTROL

CONSOLE

3.

FEEDER

CONSOLE

2.

LHS & RHS

2.2 POSITION OF EMERGENCY STOPS

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SAFETY

2.3

Section 2

EMERGENCY SITUATION

WARNING

In the case of an incident of any part failure on the

machine you must follow the following procedure.

1.

Engage the nearest emergency stop.

2.

Switch of engine and remove the ignition key.

3.

Implement the lockout procedure (see Section 2.4).

4.

Only when the machine is fully switched off and the crusher

rotor has completely stopped revolving (approximately 120

seconds), should an attempt be made to solve the problem.

5.

It is always important to never work alone.

Restart after Emergency Stop.

1.

Ensure the problem has been rectified.

2.

Ensure that all personnel are clear of the machine.

3.

Ensure that all guards and relevant safety devices have

been fitted / refitted correctly.

4.

Release all emergency stops.

5.

Restart the machine (see section 4.3)

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SAFETY

Section 2

2.4 LOCKOUT PROCEDURE

WARNING

1.

2.

3.

When carrying out maintenance, repairs

or adjustment to the TESAB RK 1012T

ROTOCRUSHER the following lockout

procedure must be followed.

Deactivate all controls, switch off engine and remove key.

Activate, or, if fitted, lock one emergency stop button.

Relieve all pressures in the hydraulic system.

IMPORTANT: THE PERSON CARRYING OUT THE WORK ON THE

MACHINE MUST KEEP THE KEYS WITH THEM AT ALL

TIMES.

IMPORTANT SAFETY NOTICE

ENSURE ISOLATOR SWITCH IS IN THE OFF POSITION

PRIOR TO WELDING.

ISOLATOR IN OFF POSITION

ISOLATOR IN ON POSITION

Engine Access Catwalk

ENGINE CANOPY

CONTROL PANEL

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

RK1012T ROTOCRUSHER

Jan 2005 Issue

Section 3

TRACKING INSTRUCTIONS

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

TRACKING INSTRUCTIONS

3.0

Section 3

TRACKING FAMILIARISATION

READ THIS SECTION CAREFULLY BEFORE OPERATING TRACKS ON YOUR

TESAB RK1012T ROTOCRUSHER.

FAILURE TO DO SO COULD RESULT IN PERSONAL INJURY OR EQUIPMENT

DAMAGE.

1.

Familiarisation

The following terms/panel names have been used in this instruction leaflet, below

shows the names and there locations.

4

2

4

4

1

4

6 3

1.

Main engine starter panel.

2.

Remote control box.

3.

Dog lead controller.

4.

Emergency stop.

5.

Remote control

6.

Fast Track Console

Remote Control

Dog Lead Control

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

TRACKING INSTRUCTIONS

3.0

Section 3

TRACKING FAMILIARISATION contd.

IMPORTANT

THIS RK1012T ROTOCRUSHER IS FITTED WITH TWO MANUAL VALVES FOR

CONTROLING THE CRUSHING AND TRACKING OPERATIONS. PLEASE READ

THE FOLLOWING CAREFULLY SO AS TO UNDERSTAND THE OPERATION OF

THE SYSTEM.

WHEN TRACKING THE MACHINE

Please ensure the both levers inside the Fast Track Console are located in the Track

Operation position prior to starting the engine. This can be seen in the diagram

below.

Both levers in

Track Position

WARNING

>

>

>

DO NOT ACTIVATE LEVERS WHILE ENGINE IS RUNNING.

ALWAYS ENSURE BOTH VALVES ARE IN THE TRACK OR CRUSH

POSITION PRIOR TO STARTING ENGINE.

NEVER OPERATE THE MACHINE WITH EITHER VALVE IN THE

NEUTRAL(middle) POSITION

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

TRACKING INSTRUCTIONS

3.1

Section 3

TRACKING THE MACHINE

The following sections describe how to track your machine, read the complete

manual before tracking. Check that there is a clear area around the machine and

that all control levers including clutch lever are in the neutral position.

Engine Control Panel

IGNITION STARTER

a

b

a)

Check that no emergency stops are in the on position, if an emergency stop is in the on position lamp A (green) will NOT be

illuminated.

b)

Turn the starter ignition key B to position no. 1 which is the on

position.

c)

Turn the key to position no. 3 and hold, the start delay siren will

sound for approximately 7 seconds then the engine will crank and

start.

d)

Release the key when the engine has started.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

TRACKING INSTRUCTIONS

3.1

Section 3

TRACKING THE MACHINE contd.

Note: Do not activate the starter for more than 20 seconds at a time.

You will protect the batteries if you wait one minute between each

starting attempt.

e. Set the engine revs to approximately 1000 r.p.m., this can be done by

adjusting the throttle scroll button (Pushing button up increases engine

revs, Pushing button down decreases engine revs).

Throttle Adjustment

- revs

+ revs

Increase Revs

Decrease Revs

Revs Displayed on LCD

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

TRACKING INSTRUCTIONS

3.2

Section 3

TRACKING THE MACHINE USING THE REMOTE CONTROL

Getting to know your remote control.

a

h

SIDE Y

SIDE X

b

f

SIDE X

A

B

C

D

E

F

G

H

I

J

SIDE Y

RHS track forward.

RHS track reverse

LHS track forward

LHS track reverse

Remote control activation & Tracks On/Off

Engine stop (only active when handset on)

Key Switch

Feeder on

Feeder off

Remote Control Lockout switch (Prevents remote from being used when

button is depressed.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

TRACKING INSTRUCTIONS

3.2

Section 3

TRACKING THE MACHINE USING THE REMOTE CONTROL contd.

The following procedure is to be carried out to allow operator to track the machine

using the remote control.

a) Firstly ensure that the isolator switch location on the main engine

canopy is in the ON position as shown below.

b) Ensure that the track switch (A) on the main engine starter panel is in

the ON position and that the control switch (B) is in the REMOTE

position.

A

B

c) Start the engine as per previous instructions (it is important that

instruction a) is carried out before starting engine).

d) Press button E on the remote control the beacon and siren will

automatically sound and the track system will activate allowing the

operator to begin moving the machine.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

TRACKING INSTRUCTIONS

3.2

Section 3

TRACKING THE MACHINE USING THE REMOTE CONTROL contd.

e) To track press relevant buttons on the remote control (refer to section

3.2 Getting to know your remote control), for safety reasons Tesab

have fitted a siren and orange beacon to make other persons in the

vacinity aware that the machine is going to or is being moved and it is

always important for the operator to be aware of his surroundings.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

TRACKING INSTRUCTIONS

3.3

Section 3

TRACKING THE MACHINE USING THE DOG LEAD

Tesab have also supplied a dog lead controller as another way of tracking the

machine

The following procedure is to be carried out to allow operator to track the

machine using the dog lead.

e)

Ensure that the control switch (B) is in the DOG LEAD position

and the Track Switch on the main engine starter panel is in the ON

position prior to operating the dog lead.

Track Switch

continued over...

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

TRACKING INSTRUCTIONS

3.3

Section 3

TRACKING THE MACHINE USING THE DOG LEAD contd.

f)

Start the engine as per previous instructions (it is important that

instruction a) is carried out before starting engine).

g)

Note: for safety reasons there is an emergency stop button (F) fitted

to the dog lead.

B

F

Important:

Once machine has been tracked

into place remove dog lead and

place in secure premises. (Ideally

works office or shovel cab)

h)

To track press relevant buttons on the dog lead control (as shown

above), for safety reasons Tesab have fitted a siren and orange

beacon to make other persons in the vacinity aware that the

machine is going to or is being moved and it is always important for

the operator to be aware of his surroundings.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

TRACKING INSTRUCTIONS

Section 3

3.4 REMOTE CONTROL BATTERY CHARGING

Follow the procedure below to charge the battery for the remote control.

Charger

Unit

1.

2.

3.

Green Indicator

Place battery into

charger unit.

Plug in charger unit and

switch on at mains.

The green indicator light

shows that the battery is

being charged.

Battery

NOTE:

This charger requires a 3 pin

European to UK mains adaptor if

being used in the UK or Ireland.

IMPORTANT SAFETY NOTE

ENSURE ISOL

ATOR SWITCH IS

ISOLA

IN OFF POSITION PRIOR TO

WELDING.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

RK1012T ROTOCRUSHER

Jan 2005 Issue

Section 4

SET-UP PROCEDURE

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.0 SET-UP PROCEDURE SAFETY

Please read this section carefully and become familiar with the signs used.

These signs are used frequently throughout this manual to indicate any potential warning or danger when operating this machine.

DANGER

ELECTRICAL HAZARD

1.

2.

3.

DANGER

Electrical Hazard. Risk of serious injury or

death.

Never work on the electrical system of any

equipment unless you are fully familiar with

system details.

Work on the electrical system must be

carried out by a qualified electrician.

NIP HAZARD

1.

2.

3.

DANGER

Nip Hazard. Do not reach into an

unguarded machine.

In-running nip points can cause

serious injury or death.

Switch off and lockout machine

before opening or removing guard doors.

FALL HAZARD

1.

2.

3.

Fall Hazard. Do not climb onto moving or

working machinery.

Switch off and lockout machine before

attempting maintenance on the machine.

Always use a suitable lifting platform before

attempting maintenance above 2m (6-6).

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

WARNING

Section 4

CRUSH HAZARD

1.

2.

3.

WARNING

Crush Hazard. Beware of dangerous hand

and foot crush points.

Do not use any body parts e.g. hands or

feet to check hole alignment or support

machinery.

Always use pins and/or mechanical

supports provided.

PROTECTION

1.

2.

3.

WARNING

Loose or baggy clothing can get caught in

running machinery.

Always wear correct fitting (EN/ANSI

approved) protective clothing.

Protective clothing includes Hard Hat,

Safety Clothing, Ear Defenders, Overalls,

Steel Toed Boots, and a High Visibility Vest.

CONSULT MANUAL

1.

2.

3.

WARNING

Read and understand the operators manual

before you work at this machine.

Study the different safety signs on this

machine.

Only qualified and trained personnel should

attempt to work at this machine.

LOCKOUT

1.

2.

3.

When performing maintenance or

adjustment to this machine always switch

off engine and remove the ignition key. (if

electric isolate power supply at source).

Keep ignition key on person during

maintenance.

Never work alone.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

WARNING

HIGH PRESSURE

1.

2.

3.

CAUTION

WARNING

2.

WARNING

Fall rock hazard. Do not walk near material

discharge areas. You are at risk of serious

injury or death.

Wear a Hard Hat at all times when working

in the vicinity of the machine.

BATTERY HAZARD

1.

2.

BATTERY

Burn or Heat Hazard. Beware of hot sur

faces at engine and exhaust areas.

HEAD PROTECTION

1.

EXPLOSIVE

Beware of escaping hydraulic oil. High

pressure hydraulic oil can penetrate the

skin causing serious injuries.

Always relieve pressure from the hydraulic

system before attempting maintenance.

If oil is injected under the skin, it must be

surgically removed or gangrene will result.

HOT SURFACE

1.

ACID

Section 4

Battery Hazard. Battery electrolyte contains

acid and can cause serious injury. Avoid

any contact.

Batteries give off flammable fumes which

can explode. Avoid the formation of sparks

and naked lights in the vicinity of the

batteries. Do not smoke when working in

this area.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

4.1

Section 4

INSTALLATION

The following section will take you step by step through the installation of your

RK 1012T ROTOCRUSHER.

Note:

Due to different transport and shipping regulations throughout the world the RK

1012T Rotocrusher will be delivered in different packing arrangements. For the

purposes of this manual it will be considered that the machine is delivered in its

most un-assembled configuration therefore some of the installation sections

may not be applicable. If this is the case ignore that particular instruction/section

and proceed to next section.

Before installing the RK1012T ROTOCRUSHER ensure that you have read all sections of this manual in order to familiarise yourself with the machine and its function,

paying particular attention to the SAFETY SECTION 2.

Installation, operation, and maintenance of the RK1012T ROTOCRUSHER mush

be carried out by reliable, authorised personnel only, statutory minimum age limits must be observed.

TESAB ENGINEERING Ltd. recommend that the installation of the RK1012T

ROTOCRUSHER is carried out by a recommended TESAB dealer and/or service

department.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

4.2

Section 4

LOADING AND OFF LOADING

Loading and off loading the RK1012T should be carried out by trained and experienced personnel only. They should first read the operation manual paying particular attention to the safety and installation sections.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

4.3

Section 4

STARTING THE ENGINE

IMPORTANT

THIS RK1012T ROTOCRUSHER IS FITTED WITH TWO MANUAL VALVES FOR

CONTROLING THE CRUSHING AND TRACKING OPERATIONS. PLEASE READ

THE FOLLOWING CAREFULLY SO AS TO UNDERSTAND THE OPERATION OF

THE SYSTEM.

PRIOR TO STARTING THE ENGINE

Before starting the engine please ensure that the two manual valves shown in the

picture below are in one of the following positions.

1.

2.

TRACK: When the machine has to be moved.

CRUSH: When the machine is in its working position and ready to work.

Both levers in

Track Position

WARNING

>

>

>

DO NOT ACTIVATE LEVERS WHILE ENGINE IS RUNNING.

ALWAYS ENSURE BOTH VALVES ARE IN THE TRACK OR CRUSH

POSITION PRIOR TO STARTING ENGINE.

NEVER OPERATE THE MACHINE WITH EITHER VALVE IN THE

NEUTRAL(middle) POSITION

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

4.3

Section 4

STARTING THE ENGINE contd.

The engine starter panel is located at the engine catwalk as highlighted below.

Starter Panel

Starter Panel

This area can be accessed by lowering the access steps (B). It is important, for

safety reasons, that when these steps have been lowered that they are locked

into position using clamps (C) at both sides. This is illustrated below.

C

C

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

4.4

Section 4

ENGINE STARTING PROCEDURE

Before staring the engine check diesel and engine oil levels.

Engine Control Panel

Throttle

scroll

button

A

B

IGNITION STARTER

a)

Check that no emergency stops are in the on position, if an emergency

stop is in the on position lamp A (green) will NOT be illuminated.

b)

Turn the starter ignition key C to position no. 1 which is the on position.

c)

Turn the key to position no. 3 and hold, the start delay siren will sound for

approximately 7 seconds then the engine will crank and start.

d)

Release the key when the engine has started.

Note:

e)

Do not activate the starter for more than 20 seconds at a time.

You will protect the batteries if you wait one minute between

each starting attempt.

Set the engine revs to approximately 1000 r.p.m., this can be

done by adjusting the throttle scroll button (Pushing button up increases

engine revs, pushing button down decreses engine revs).

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

4.4

Section 4

ENGINE STARTING PROCEDURE contd.

IMPORTANT NOTE:

Before tracking we recommend that you fold up the engine area access steps in

order to prevent them from fouling unneccessarily.

WARNING

ENSURE MACHINE IS CLEAR OF ALL OVER HEAD CABLES

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

4.5

Section 4

TRACKING FAMILIARISATION

READ THIS SECTION CAREFULLY BEFORE OPERATING TRACKS ON YOUR

TESAB RK1012T ROTOCRUSHER.

FAILURE TO DO SO COULD RESULT IN PERSONAL INJURY OR EQUIPMENT

DAMAGE.

1.

Familiarisation

The following terms/panel names have been used in this instruction leaflet, below

shows the names and there locations.

4

2

4

4

1

4

2

6 3

1.

Main engine starter panel.

2.

Remote control box.

3.

Dog lead controller.

4.

Emergency stop.

5.

Remote control

6.

Fast Track Console

Remote Control

Dog Lead Control

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

4.5

Section 4

TRACKING FAMILIARISATION contd.

IMPORTANT

THIS RK1012T ROTOCRUSHER IS FITTED WITH TWO MANUAL VALVES FOR

CONTROLING THE CRUSHING AND TRACKING OPERATIONS. PLEASE READ

THE FOLLOWING CAREFULLY SO AS TO UNDERSTAND THE OPERATION OF

THE SYSTEM.

WHEN TRACKING THE MACHINE

Please ensure the both levers inside the Fast Track Console are located in the Track

Operation position prior to starting the engine. This can be seen in the diagram

below.

Both levers in

Track Position

WARNING

>

>

>

DO NOT ACTIVATE LEVERS WHILE ENGINE IS RUNNING.

ALWAYS ENSURE BOTH VALVES ARE IN THE TRACK OR CRUSH

POSITION PRIOR TO STARTING ENGINE.

NEVER OPERATE THE MACHINE WITH EITHER VALVE IN THE

NEUTRAL(middle) POSITION

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.6 TRACKING THE MACHINE

The following sections describe how to track your machine read the complete

manual.

Before tracking check that there is a clear area around the machine and that all

control levers including clutch lever are in the neutral position.

1.

How to start the engine (Main engine starter panel)

Engine Control Panel

THROTTLE

SCROLL

BUTTON

IGNITION STARTER

a

b

a)

Check that no emergency stops are in the on position, if an emergency stop is in the on position lamp A (green) will NOT be illuminated.

b)

Turn the starter ignition key C to position no. 1 which is the on

position.

c)

Turn the key to position no. 3 and hold, the start delay siren will

sound for approximately 7 seconds then the engine will crank and

start.

d)

Release the key when the engine has started.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.6 TRACKING THE MACHINE contd.

Note: Do not activate the starter for more than 20 seconds at a

time. You will protect the batteries if you wait one minute between

each starting attempt.

g. Set the engine revs to approximately 1000 r.p.m., this can be

done observing the digital tachometer D on the starter panel

and adjustment of the throttle.

Throt

tle Adjustment

Throttle

Increase Revs

Decrease Revs

Revs Displayed on LCD

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

4.7

Section 4

TRACKING THE MACHINE USING THE REMOTE CONTROL

Getting to know your remote control.

a

h

SIDE Y

SIDE X

b

f

SIDE X

A

B

C

D

E

F

G

H

I

J

SIDE Y

RHS track forward.

RHS track reverse

LHS track forward

LHS track reverse

Remote control activation & Tracks On/Off

Engine stop (only active when handset on)

Key Switch

Feeder on

Feeder off

Remote Control Lockout switch (Prevents remote from being used when

button is depressed.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

4.7

Section 4

TRACKING THE MACHINE USING THE REMOTE CONTROL contd.

The following procedure is to be carried out to allow operator to track the machine

using the remote control.

a) Firstly ensure that the isolator switch located on the main engine

canopy is in the ON position

b) Ensure that the track switch (A) on the main engine starter panel is in

the ON position and that the control switch (B) is in the REMOTE

position.

A

B

c) Start the engine as per previous instructions (it is important that

instruction a) is carried out before starting engine).

d) Press button E on the remote control the beacon and siren will

automatically sound, the track system will activate allowing the

operator to begin moving the machine.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

4.7

Section 4

TRACKING THE MACHINE USING THE REMOTE CONTROL contd.

e) To track press relevant buttons on the remote control, for safety

reasons Tesab have fitted a siren and orange beacon to make other

persons in the vacinity aware that the machine is going to or is being

moved and it is always important for the operator to be aware of his

surroundings.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

4.8

Section 4

TRACKING THE MACHINE USING THE DOG LEAD

Tesab have also supplied a dog lead controller as another way of tracking the

machine

The following procedure is to be carried out to allow operator to track the

machine using the dog lead.

e)

Ensure that the control switch (B) on the main engine starter panel is

in the DOG LEAD position. Ensure that the Track Switch is in the on

position prior to operating the dog lead.

Track Switch

continued over...

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

4.8

Section 4

TRACKING THE MACHINE USING THE DOG LEAD contd.

g)

Start the engine as per previous instructions (it is important that

instruction a) is carried out before starting engine).

h)

Note: for safety reasons there is an emergency stop button (F) fitted

to the dog lead.

B

F

Important:

Once machine has been tracked

into place remove dog lead and

place in secure premises. (Ideally

works office or shovel cab)

i)

To track press relevant buttons on the dog lead control (as shown

above), for safety reasons Tesab have fitted a siren and orange

beacon to make other persons in the vacinity aware that the

machine is going to or is being moved and it is always important for

the operator to be aware of his surroundings.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.9 REMOTE CONTROL BATTERY CHARGING

Follow the procedure below to charge the battery for the remote control.

Charger

Unit

1.

2.

3.

Green Indicator

Place battery into

charger unit.

Plug in charger unit and

switch on at mains.

Battery is fully charged

when green indicator light

is on.

Battery

NOTE:

This charger requires a 3 pin

European to UK mains adaptor if

being used in the UK or Ireland.

IMPORTANT SAFETY NOTE

DISCONNECT BA

T TERY

BAT

TERMINALS AND REMOTE UNIT

PRIOR TO WELDING.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.10 POSITIONING

Before the RK 1012T Rotocrusher is positioned on site it is necessary to have a

level surface and spacious surroundings, if required level the work-site foundation

using a loading shovel.

The machine must be placed on solid ground capable of carrying its weight.

Track the machine into the desired position and ensure the machine is level. This

can be done with the aid of a spirit level.

(Ensure it is level both along the chassis and across the chassis.)

We recommend that when the machine is positioned correctly the dog lead and

the remote control are located in a safe place (i.e. works office or shovel cab).

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.11 PREPARING FOR INITIAL START-UP

i)

Unfold the handrails into the working position and bolt to secure (sections 1 & 2

first, then sections 3 & 4 and finally section 5). Ensure that the tab (6) is fitted

between the inside handrail (2) and the crusher for extra stability.

6

3

ii)

If required fit the pre-cleaner and exhaust. We would recommend that if the

machine has to be tracked for a long distance that you fit these items as soon

as possible.

Pre-Cleaner

iii)

Exhaust

For safety reasons once the machine is in the correct working position switch

the tracks off. This disables the system and prevents the machine from moving

if the remote or dog lead are touched accidentally. Move switch to off position

on control panel to disable tracks. See diagram over. It is also advisable to

switch the manual control valves to the CRUSH position in order prepare the

machine for working. See diagram over.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.11 PREPARING FOR INITIAL START-UP contd.

Both Levers in

CRUSH Position

Tracks

ON/OFF Switch

WARNING

DO NOT ACTIVATE LEVERS WHILE ENGINE IS RUNNING.

ALWAYS ENSURE BOTH VALVES ARE IN THE TRACK OR CRUSH

POSITION PRIOR TO STARTING ENGINE.

NEVER OPERATE THE MACHINE WITH EITHER VALVE IN THE

NEUTRAL(middle) POSITION

Remove any parts, which have been packed on the catwalks and hopper. This is to

give fully access to all control areas and reduces any fall hazards.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.12 DIRT CONVEYOR UNFOLDING

Important Safety Note:

Unfolding the Dirt Conveyor will require the use of a crane.

The fastening of loads and the instructing of crane operators should be entrusted to experienced personnel only.

Connect the crane lifting chains to the dirt conveyor at the two points

indicated A.

Take the weight of the top section to allow you to remove the transport

bracket (remember to put the transport bracket in the toolbox).

Lower the dirt conveyor top section carefully and pin together at points

indicated B.

Fit belt scrapper C.

B

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.13 CRIB FOLDING & ASSEMBLY

NOTE:

Bolts and pins required to carry out this set-up procedure can be found in the

machine toolbox.

i)

Firstly check around the cribs area to ensure there are no obstructions

and that the hydraulic hoses are not fouling.

ii)

Fold up side cribs approximately half way, one side at a time, using the

highlighted levers below.

Cribs RHS

Cribs LHS

iii)

Fold up rear cribs approximately half way using the highlighted lever

shown over the page.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.13 CRIB FOLDING & ASSEMBLY contd.

Cribs Rear

iv)

At this stage carefully fold up each crib alternately until the three sides are up

in position.

v)

Using the M30x110 bolts and M30 nuts (found in the toolbox) bolt the cribs in

position.

M30x110 bolt

(3 off each side)

M30 nut

(3 off each side)

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.13 CRIB FOLDING & ASSEMBLY contd.

vi)

Insert pins in rear cribs at point A as shown (Note: pins located in toolbox).

vii)

Fit cribs front cross tie and pin.

viii) Tesab have designed an extra crib cross tie above the grizzly bars. This is

designed to ensure that the material which passes this point is at the correct

height to enter the crusher. We highly recommend that this beam is fitted as it

will reduce any down-time due to crusher blockages.

The bolts for this can be found in the tool box. Ensure that the chains and shackles

are connected up appropriately.

Cross Tie & Pin

Securing Chains

Crib Cross Tie

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.14 FEEDER BEACON

The RK1012T has been fitted with a feeder beacon to warn the user when the feeder

has stopped, either by handlever, remote control or speed sensor activation. The

feeder beacon if fitted to a piece of angle that is bolted onto the hoist.

Feeder beacon location

(remember to connect wires

using couplings provided)

4.15 FEED-IN CHUTE

Due to differing height restrictions the assembled feed-in chute maybe too high.

Hence the feed-in extension box, which carries the feed chains, rubber and dust

suppression spray bar is packed separately.

Therefore the next stage of set-up is to fit this extension box as shown using lift points

A and connecting up the spray bar pipe at point B.

A

NOTE:

Fitting the extension box will require the use of a crane.

The fastening of loads and the instructing of crane operators should be

entrusted to experienced personnel.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.16 HOIST

Tesab may have supplied a swinging arm for use when changing hammers, etc.

(this is an optional extra). For transport purposes it is normally folded down. Elevate into the working position and bolt as shown.

Hoist in transport

position

Pivot hoist

around hinge

Bolt in place

using the 4 bolts

IMPORTANT:

Tesab only recommend that this arm is used for changing items up to a

maximum weight of one RK1012T Hammer (Part No 2-423-3) or 200kgs.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.17 CRUSHER SETTINGS

Before we start crushing the final stage of installation is to set the crusher gaps.

This means the distance between the hammers and the impact path at the three

impact areas, these are named as follows:

Top apron (stroke carrier).

Middle apron (stroke carrier)

Bar carrier

Manual adjustment is standard and a spanner is provided for this (found in the toolbox).

Middle apron and bar carrier hydraulic adjustment is an optional extra.

Warning:

The crusher settings must NOT be altered while the crusher is in operation.

Top apron adjustment

When first starting to crush adjust this apron fully open by adjustment at point A.

Adjust a small amount each side alternatively, this will prevent damaging the threads.

IMPORTANT

Clockwise rotation to

adjust apron fully open

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.17 CRUSHER SETTINGS contd.

Bar carrier manual adjustment

Open door B and measure the setting between the LOWER blow bar (grinding list)

and the hammer. Set the desired gap by adjusting the outer nuts at point C.

Note:

The setting is carried out at

the outer bolts of the yoke.

The pre-tension of the

spring unit is factory set at

the inner bolts and should

not require any adjustment.

IMPORTANT

Clockwise rotation to

adjust bar carrier forward

IMPORTANT

Anti-Clockwise rotation to

adjust bar carrier

backwards.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.17 CRUSHER SETTINGS contd.

Bar carrier hydraulic adjustment

Open door B and measure the setting between the LOWER blow bar (grinding list)

and the hammer (as shown on previous page). Set the desired gap as follows:

-

Using the control lever (D), very carefully extend the rams just enough to compress

the disc springs slightly (E).

Remove the shims (F) and again using the control lever, carefully close the

rams to allow the removal of the remaining shims (G).

Set the gap using the control lever. The gap can be checked through door B.

Once the gap is set, replace the shims (F &G) in the necessary order.

NOTE:

Once the bar carrier gap has been set, rotate the rotor to ensure that

there is enough clearance between the hammers and the blow bars. This

is necessary as, due to wear, the size of the blow bars can change.

D

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.17 CRUSHER SETTINGS contd.

Middle apron manual adjustment

Adjust the middle apron by adjusting the outer nuts at points H until it is overlapping

the top of the bar carrier by a MINIMUM of 15mm (as shown). The middle apron

should be adjusted by APPROXIMATELY twice the distance (or less) that the bar

carrier was adjusted. This distance can be checked by opening door B.

IMPORTANT

H

Clockwise rotation to

adjust apron forward

IMPORTANT

Anti-Clockwise rotation to

adjust apron backwards.

Minimum

15mm

Note:

The setting is carried out at the outer bolts of the

yoke. The pretension of the spring unit is factory

set at the inner bolts and should not require any

adjustment.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.17 CRUSHER SETTINGS contd.

Middle apron hydraulic adjustment

-

Using the control lever (J), very carefully extend the rams just enough to compress

the disc springs slightly (E).

Remove the shims (F) and again using the control lever, carefully close the

rams to allow the removal of the remaining shims (G).

Set the gap using the control lever. The gap can be checked through door B.

J

NOTE:

The middle apron should be adjusted by APPROXIMATELY twice the

distance (or less) that the bar carrier was adjusted. The middle apron

should overlap the top of the bar carrier by a MINIMUM of 15mm as

shown on the previous page.

Once the gap is set, replace the shims (F & G) in the necessary order.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.17 CRUSHER SETTINGS contd.

Important:

The measurement of the setting depends on the following:

(i)

The size of the feed material.

(ii)

Cubing or crushing required.

(iii)

Desired quantities of the different fractions produced.

The following applies in general:

(i)

Do not adjust the crusher settings to an unnecessarily narrow

gap.

(ii)

Study the produced material and use that as a guide-line for your

setting.

For additional advise on the settings on your RK 1012T Rotocrusher please

consult TESAB ENGINEERING LTD. or your local authorised TESAB dealer

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.18 DUST SUPPRESSION

The RK1012T may be fitted with a completely self sufficient system which includes

the following.

i)

Water Tank.

Water Tank

This tank should be topped up regularly to ensure an efficient dust

suppression system. The system is designed for approximately one fill of

water to last one 10 hour shift depending on nozzle adjustment, etc.

ii)

Manifold

This allows you to turn off and adjust spray bars independently, depending

on site conditions. An extra outlet has been fitted if required.

Important Notes

1)

There is a tap at the base of the manifold (A). It is important that the

manifold is drained at the end of each working day, especially in cold

conditions. This is to prevent freezing of water in the manifold and any

subsequent damage.

2)

The water tank should be drained during extreme cold conditions in order

to prevent any unnecessary damage caused by expansion.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

SET-UP PROCEDURE

Section 4

4.18 DUST SUPPRESSION contd.

iii)

Spray Bar Location

1

2

1.

2.

Feed into crusher

Feed out of crusher

iv)

Start / Stop

Button to start/stop

dust suppression

v)

Water Filtration

The tank has been fitted with a basic

water filter that should be changed

regularily and as when necessary

depending on the quality of the water

put into the tank.

Water Filter

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

RK1012T ROTOCRUSHER

Jan 2005 Issue

Section 5

OPERATION

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

OPERATION

Section 5

5.0 OPERATION SAFETY

Please read this section carefully and become familiar with the signs used.

These signs are used frequently throughout this manual to indicate any potential warning or danger when operating this machine.

DANGER

ELECTRICAL HAZARD

1.

2.

3.

DANGER

Electrical Hazard. Risk of serious injury or

death.

Never work on the electrical system of any

equipment unless you are fully familiar with

system details.

Work on the electrical system must be

carried out by a qualified electrician.

NIP HAZARD

1.

2.

3.

DANGER

Nip Hazard. Do not reach into an

unguarded machine.

In-running nip points can cause

serious injury or death.

Switch off and lockout machine

before opening or removing guard doors.

FALL HAZARD

1.

2.

3.

Fall Hazard. Do not climb onto moving or

working machinery.

Switch off and lockout machine before

attempting maintenance on the machine.

Always use a suitable lifting platform before

attempting maintenance above 2m (6-6).

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

OPERATION

WARNING

Section 5

CRUSH HAZARD

1.

2.

3.

WARNING

Crush Hazard. Beware of dangerous hand

and foot crush points.

Do not use any body parts e.g. hands or

feet to check hole alignment or support

machinery.

Always use pins and/or mechanical

supports provided.

PROTECTION

1.

2.

3.

WARNING

Loose or baggy clothing can get caught in

running machinery.

Always wear correct fitting (EN/ANSI

approved) protective clothing.

Protective clothing includes Hard Hat,

Safety Clothing, Ear Defenders, Overalls,

Steel Toed Boots, and a High Visibility Vest.

CONSULT MANUAL

1.

2.

3.

WARNING

Read and understand the operators manual

before you work at this machine.

Study the different safety signs on this

machine.

Only qualified and trained personnel should

attempt to work at this machine.

LOCKOUT

1.

2.

3.

When performing maintenance or

adjustment to this machine always switch

off engine and remove the ignition key. (if

electric isolate power supply at source).

Keep ignition key on person during

maintenance.

Never work alone.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

OPERATION

WARNING

HIGH PRESSURE

1.

2.

3.

CAUTION

WARNING

2.

WARNING

Fall rock hazard. Do not walk near material

discharge areas. You are at risk of serious

injury or death.

Wear a Hard Hat at all times when working

in the vicinity of the machine.

BATTERY HAZARD

1.

2.

BATTERY

Burn or Heat Hazard. Beware of hot sur

faces at engine and exhaust areas.

HEAD PROTECTION

1.

EXPLOSIVE

Beware of escaping hydraulic oil. High

pressure hydraulic oil can penetrate the

skin causing serious injuries.

Always relieve pressure from the hydraulic

system before attempting maintenance.

If oil is injected under the skin, it must be

surgically removed or gangrene will result.

HOT SURFACE

1.

ACID

Section 5

Battery Hazard. Battery electrolyte contains

acid and can cause serious injury. Avoid

any contact.

Batteries give off flammable fumes which

can explode. Avoid the formation of sparks

and naked lights in the vicinity of the

batteries. Do not smoke when working in

this area.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

OPERATION

Section 5

5.1 LOCKOUT PROCEDURE

WARNING

1.

2.

3.

When carrying out maintenance, repairs

or adjustment to the TESAB RK 1012T

ROTOCRUSHER the following lockout

procedure must be followed.

Deactivate all controls, switch off engine and remove key.

Activate, or, if fitted, lock one emergency stop button.

Relieve all pressures in the hydraulic system.

IMPORTANT: THE PERSON CARRYING OUT THE WORK ON THE

MACHINE MUST KEEP THE KEYS WITH THEM AT ALL

TIMES.

IMPORTANT SAFETY NOTICE

ENSURE ISOLATOR SWITCH IS IN THE OFF POSITION

PRIOR TO WELDING.

ISOLATOR IN OFF POSITION

ISOLATOR IN ON POSITION

Engine Access Catwalk

ENGINE CANOPY

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

OPERATION

Section 5

5.2 GENERAL INFORMATION

Please Note:

All crushing applications differ due to material composition and customer

requirements.

There are numerous adjustments that can be made in order to achieve

required results.

Therefore we recommend that you contact Tesab Engineering LTD or

your local Tesab dealer to advise you on the best customized Tesab

arrangement to suit your particular application.

For the purposes of this section we assume engine speed requirements

of 2000 rpm.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

OPERATION

Section 5

5.3 PRE-OPERATION CHECK LIST

Before operation check and ensure the following:

Nothing on product conveyor

Nothing on dirt conveyor

All guards are fitted correctly

The diesel tank has been topped up

Engine oil level has been checked and topped up if necessary

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

OPERATION

Section 5

5.4 FEEDER INFORMATION

IMPORTANT FEEDER INFORMATION

It is important to read this section carefully before operating in order to acquaint

yourself fully with the detailed operation of the feeder.

Tesab Engineering Ltd., Unit 7B Gortrush Industrial Estate, Omagh, N.Ireland.

RK1012T ROTOCRUSHER

OPERATION

5.5

Section 5

TRACKING FAMILIARISATION

READ THIS SECTION CAREFULLY BEFORE OPERATING TRACKS ON YOUR

TESAB RK1012T ROTOCRUSHER.

FAILURE TO DO SO COULD RESULT IN PERSONAL INJURY OR EQUIPMENT

DAMAGE.

Familiarisation

The following terms/panel names have been used in this instruction leaflet, below