Escolar Documentos

Profissional Documentos

Cultura Documentos

Using stainless steel for high pressure piping in SWRO plants

Enviado por

Andreea FieraruTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Using stainless steel for high pressure piping in SWRO plants

Enviado por

Andreea FieraruDireitos autorais:

Formatos disponíveis

Stainless Steel for

High Pressure Piping

in SWRO Plants

The Malta

Experience

Are there any

Options?

Introduction

Summary

Malta, an archipelago of three

islands situated 50 miles south of

Sicily in the middle of the clear blue

Mediterranean Sea, is blessed with

an abundance of sunshine. These

idyllic conditions are, however,

marred by the sparse annual rainfall

of only 250 to 450 mm. The Islands,

whose dense population now

numbers about 350,000, have until

recently been perpetually plagued

with problems of obtaining fresh

water. Over the years, special efforts

have been required to cope with this

adverse situation.

Service experience from 27 seawater

reverse osmosis (SWRO) plants

confirms that there is an evident risk

of corrosion if wrong steel grade is

used for the high pressure piping.

Neither 316L nor 317L possesses

sufficient corrosion resistance. Not

even highly alloyed grades like 2205

and 904L show reliable service

performance. However, no corrosion

has been reported for 254 SMO,

which has been used in 16 full

strength SWRO plants and several

plants using high salinity brackish

water.

To be continued on page 2.

To be continued on page 7.

3-1995

acom

Desalination of

Seawater by

Reverse Osmosis

AVESTA SHEFFIELD

CORROSION MANAGEMENT

AND APPLICATION

ENGINEERING

Pembroke R.O. Plant, Malta

acom No. 3-95

Desalination of Seawater by Reverse Osmosis

The Malta Experience

by

Michael F. Lamendola and Arthur Tua, Polymetncs Seawater Systems, Inc., Malta

Introduction

Malta, an archipelago of three

islands situated 50 miles south of

Sicily in the middle of the clear blue

Mediterranean Sea, is blessed with

an abundance of sunshine. These

idyllic conditions are, however,

marred by the sparse annual rainfall

of only 250 to 450 mm. The Islands,

whose dense population now

numbers about 350,000, have until

recently been perpetually plagued

with problems of obtaining fresh

water. Over the years, special efforts

have been required to cope with this

adverse situation.

Efforts Over the Years

Ancient temples predating Christ by a

few thousand years were built with

cisterns, so that to this day, rainwater

can be collected and stored.

To meet demads of the new city of

Valletta in 1610, the Knights of St.

John of Jerusalem started work on an

aqueduct to transport water for over

15 km by gravity from Rabat. The

water was collected by subterranean

conduits from several natural springs

and galleries cut into limited fresh

water aquifer.

Since water was such a scarce and

difficult resource, the Knights made it

a requirement by law, that each

house and building have its own

cistern.

Towards the end of the nineteenth

century, as the demand for fresh

water increased, bore holes and

subterranean collection galleries

were cut, in order to exploit the mean

sea level aquifer1). During the same

period sizable covered reservoirs

were built in strategic locations. These

were further developed in the early

) A fresh water lens or body lying over a layer

of salt (sea) water.

post World War II years, and

covered storage now exceeds

3

450,000 m .

Desalination Makes an Early

Appearance

Desalination made an early appearance in Malta. In 1881 a thermal

distillation plant installed by the

government was desalting sea water

for distribution to the local population. Further thermal desalination in

the form of multistage flash (MSF)

evaporators followed more recently

between 1966 and 1969.

12 Years of Reverse Osmosis

Desalination

As the 1980s began, Malta's water

needs became more critical. The

Island evolved from a military base

under British rule to an independent

country with a growing industry and

tourist trade.

It was at this point that the Malta

Government made its first investment

in Reverse Osmosis (RO) Desalination.

In 1983, after a construction period of

only 11 months, the 20/000 m 3/day

Ghar Lapsi2) Seawater RO facility

became operational. This was soon

followed by a second 4500 m 3/day

highly brackish RO facility in Marsa.

(See Figure 1.)

The high reliability (i.e., on-line

factors >96%) and the relatively low

cost of water from these plants, led

the Malta Government to expand

these plants and to purchase another

three seawater RO facilities. All of the

Malta RO plants have been installed,

operated and maintained by

Polymetncs.

2

) For many years, this facility was the largest

SWRO plant in the world.

Figure 1.

History of RO desalination in Malta. Except for Marsa all plants desalt seawater.

acom No. 3-95

Plant Description

The Malta SWRO systems utilize

boreholes as the raw water intake

system. Acid (H2SO4l and micron

filtration pre-treat the seawater, prior

to its arrival to the high pressure

pumping system and membranes.

The product is post-treated by

decarbonation, lime addition and

chlorination. Figure 2 is a simplified

flow diagram for a typical plant.

RO Plant Features

Reliability through simplicity and

automation, low energy requirements

and a stable supply of seawater

provided from wells, have been the

salient design features of all five

facilities.

Key Design Features

Reduced pre-treatment requirements

by taking advantage of the local

geology and drawing seawater

through boreholes. Pre-treatment

consists only of acid injection and

micron filtration

Each plant is sub-divided into a

number of independent RO systems,

referred to as trains

Single pass operation, utilizing

Permasep B10, aramid, hollow fiber

membranes

Energy recovery turbines reduce

power consumption by 40%. Except

for the last phase of the Pembroke

plant, KSB Guinard integrated

turbo-pumps are used

Simplified hydraulic controls, such

that the only operating adjustments

are one valve per train

An advanced control and

monitoring system that enables one

person in a central control room to

operate the entire plant

Use of corrosion free plastic material for low pressure (<10 bar)

piping

Use of GRP cartridge filter vessels 3)

Use of corrosion resistant 6% Mo

SSTL (Avesta Sheffield SMO 254 UNS S31254) and epoxy coated

(Scotch Kotea fusion bonded

epoxy by 3M) carbon steel for high

pressure piping (up to 85 bar)

3

) On the older Ghar Lapsi and Tigne plants,

rubber lined steel is used.

Figure 2.

Typical Process Flow for a Seawater Plant.

Pembroke Control Room

Corrosion

Piping Materials

As extensions or newer plants were

built, enhancements were added to

the facilities, several of which were

also retro-fitted to existing plants.

One of the most notable of these

changes was the material used for

the high pressure manifolds and

permeator connections. The Ghar

Lapsi and Tigne plants originally

utilized 316L SSTL (UNS S31603)

which experienced severe pitting and

crevice corrosion in the high chloride

environments encountered in seawater desalination. A service life of

3

less than 2 years was not uncommon.

An attempt was made to reduce this

corrosion by changing the construction methods and altering the geometry, in particular the removal of 'O'

ring grooves and seals. Although we

did see some improvements, this did

not produce satisfactory results.

After switching to a 6% Mo SSTL

such as UNS S31254, no pitting or

crevice corrosion has been observed

in over 5 years of service. The results

obtained with 6% Mo Stainless steel

have also allowed us to revert to

using 'O' rings which provide better

seals.

acom No. 3-95

Operations

On-line Factors

Polymetrics is obliged by its Operation and Maintenance contract with

the Client, The Water Services

Corporation (WSC), to maintain

minimum levels of production and to

maintain minimum plant on-line levels.

Failure to meet these obligations

would result in large penalties. These

obligations have already been met.

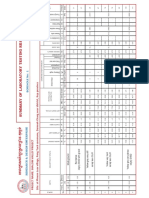

Table 1 outlines the on-line performance for all the plants for the

last three years.

SDI

Cirkewwa R.O. Plant

General

The ambient environment in a SWRO

plant is relatively corrosive. On the

Lapsi plant structural steel works and

other non plastic or non stainless steel

components deteriorated very rapidly, resulting in a shoddy appearance

and a need for regular maintenance.

This led to an increased use of nonmetallic components, the use of SSTL

for fasteners and the hot dip galvanizing of all structural steel work.

Particular examples of these

changes include the exclusive use

of plastic valves for low pressure

applications (as opposed to lined

steel valves) and the use of GRP

cartridge filter vessels.

Membranes

All of the Malta Plants make exclusive

use of DuPont "Permasep" B10

permeators. Initially at the Ghar Lapsi

several problems were experienced

particularly with regard to Salt

Passage. This was attributed to

a) particular permeators which were

defective and replaced under

warranty and b) rapid loss of Pt-B4).

The latter problem took some time to

resolve and after considerable effort

by both Polymetrics and Permasep a

solution was found. This consisted in

lowering the pH. It is interesting to

note that the pH required to maintain

a stable or controllable Salt Passage

4

) Tannic Acid which is used to enhance

membrane rejection.

is site dependent and is normally

determined experimentally. It is also

interesting to note that no specific

cause has been identified for this

rapid loss of Pt-B.

Analysis of the flow performance

of the Malta Plants shows that the

guarantees by the membrane manufacturer have always been met.

Pumps and Energy

Recovery Turbine

As part of the 27,600 m 3/day extension of the Pembroke RO plant, multistage split case pumps and energy

5

recovery turbines ), manufactured by

Byron Jackson, were selected for high

pressure service. For all RO units on

Malta, commissioned prior to the

Pembroke extension, integrated turbopumps (TPMDX), manufactured by

KSB Guinard were installed and have

given exceptional service, particularly

on the Lapsi plant, where the total

down time, due to pumps, was less

than 2000 train hours 6) in over 12

years of operation.

The change from integrated turbopumps to multi-stage split case pumps

and energy recovery turbines has

resulted in an energy reduction of

0.28 kWh/m 3 of product, and a

reduction in the noise level due to

lower operating speed.

5

6

) Francis turbinea pump running in reverse.

) The Lapsi Plant has a total of twelve trains,

each with a nominal capacity of 2000

m3/day.

One of the most Important parameters for meeting contractual

obligations and obtaining high

on-line factors is the SDI of the

feedwater. Through the use of

properly constructed and maintained

Seawater boreholes, we have a

continuous supply of low (<3.0)

feedwater.

We have found that as boreholes

are used and age, the SDI improves.

On the older Lapsi plant the SDI of

the raw feed is in the range of 0.6 to

1.3 and the cartridge filters may last

as long as 6 months before they

require replacement.

Conclusion

Malta is a fine example of successful

RO desalination, where over 60% of

the islands' water needs are being

met by this technology. This success

can be attributed to two main factors:

the simplicity of the process, particularly the use of boreholes as a seawater intake system;

and the use of a qualified and

experienced operations and

maintenance contractor from the

private sector.

The government of Malta, by using

Reverse Osmosis and the Mediterranean Sea as a source (reservoir), can

now be assured of an adequate and

reliable supply of fresh water. As of

the time of this writing the available

fresh water supply actually exceeds

demand.

acom No. 3-95

Table 1.

On-line numbers for the last 3 years.

Down Time

Caused by

Polymetrics

Down Time

Requested by

WSC*

Down Time

due to Lack of

Power

Overall

On-line

Time

Polymetrics

On-line

Time**

1992

Lapsi

Tigne

Cirkewwa

Pembroke

1.87%

2.31%

2.01%

3.94%

0.28%

0.49%

2.68%

0.85%

1.73%

4.21%

1.22%

0.68%

96.11%

95.79%

94.09%

94.54%

98.09%

97.58%

97.91%

96.00%

1993

Lapsi

Tigne

Cirkewwa

Pembroke

1.46%

1.23%

1.39%

1.60%

0.56%

1.44%

2.26%

1.35%

1.98%

3.32%

2.17%

0.91%

96.65%

97.23%

95.15%

96.78%

98.50%

98.71%

98.55%

98.36%

1994

Lapsi

Tigne

Cirkewwa

Pembroke

1.25%

0.92%

1.03%

1.04%

1.63%

2.16%

2.39%

6.86%

2.99%

0.29%

2.21%

0.37%

94.12%

96.63%

94.37%

91.74%

98.69%

99.06%

98.92%

98.88%

* WSCWater Service Corporation.

** Calculation based on system availability i.e. the denominator excludes down time by others.

References

Andrews W.T. and R.A. Bergman: The Malta

Seawater RO Facilities, First Congress on

Desalination and Water Re-use, Florence Italy,

May 1983.

Andrews W.T: The Malta Seawater RO

FacilitiesUpdate on the first two years of

Operations, Second Congress on Desalination

and Water Re-use, Bermuda, Nov 1985

Winning the War for Water, DuPont Magazine

Vol 82 No 6, Nov/Dec 1988

Schembri R.: Reverse Osmosis Water Costs in

Malta, Workshop On Production Cost of

Water, May 1988

This paper was originally published in

DESALINATION & WATER REUSE,

Vol. 5/1, p. 18-22. See also 'A Note

from the Editor' on page 6.

Ghar Lapsi R.O. Plant

acom No. 3-95

A Note from the Editor of

DESALINATION & WATER REUSE

The Malta desalting experience is an

outstanding example of current

desalination technology. This article

not only provides data on reverse

osmosis unit design and experience

but also provides a valuable insight

as to the benefits of seawater supply

via boreholes when the site geology

permits.

In keeping with D&WR editorial

policy of seeking desalting water cost

data, it seemed fitting to supplement

the information in this article with

some water cost data from one of the

references, as presented at the

Bahrain Workshop on Production

Cost of Water, May 1988 by Mr R.

Schembri of the Malta government.

The cost data was later conformed to

the format endorsed by IDA, and

presented in a paper published in

"Desalination 81" (1991) entitled

"Total Water Costs on a Standard

Basis for Three Large, Operating

SWRO Plants". The original cost data

(1988) has been adjusted to reflect

the outstanding on-line performance

for this plant as shown in this article,

97.23%, and an excerpt is shown to

the right:

Plant Capacity

Total Direct & Indirect Costs

Annual Fixed Charge Rate

Annaul Costs

Operating & Maintenance

Fixed Charge

Electric Energy @ $0.10/kWh

Chemicals

Membrane Replacement

Total Annual Cost

Total Water Cost

$/m3

$/1000 US Gal

15.000m3/day (4MGD)

$14,458,000

0.1272

$979,000

1,838,000

3,164,000

40,000

In Fixed Charge

$6,021,000

$1.13

$4.28

Você também pode gostar

- Desalination Research and Federal RoleDocumento18 páginasDesalination Research and Federal RoleDudy FredyAinda não há avaliações

- Saehan Industries Inc. KoreaDocumento13 páginasSaehan Industries Inc. Koreadalton2004Ainda não há avaliações

- History of Desalination Cost EstimationsDocumento17 páginasHistory of Desalination Cost EstimationsGiovanniStirelliAinda não há avaliações

- Effluent Treatment Plant (ETP) - Process Flow DiagramDocumento4 páginasEffluent Treatment Plant (ETP) - Process Flow DiagramshimanthAinda não há avaliações

- Eco-Friendly Chemical-Free Desalination Solution IDE PROGREENTMDocumento4 páginasEco-Friendly Chemical-Free Desalination Solution IDE PROGREENTMlifemillion2847Ainda não há avaliações

- TP40 - 18 On TechnologyDocumento20 páginasTP40 - 18 On TechnologykurisuchinessAinda não há avaliações

- Sea Water System OperationsDocumento28 páginasSea Water System Operationsrmm99rmm99Ainda não há avaliações

- Description of Different Water Intakes For SWRO PlantsDocumento19 páginasDescription of Different Water Intakes For SWRO PlantsAnonymous eCD5ZRAinda não há avaliações

- T4S5O4 Paper PDFDocumento17 páginasT4S5O4 Paper PDFtrung2iAinda não há avaliações

- AL-BIRK SWRO Plant Performance Comparison of Toyobo vs DuPont MembranesDocumento11 páginasAL-BIRK SWRO Plant Performance Comparison of Toyobo vs DuPont MembranesSantiago BorzoneAinda não há avaliações

- Water Desalination Processes and TechnologiesDocumento34 páginasWater Desalination Processes and TechnologiesDina BorhanAinda não há avaliações

- Air BechtelDocumento34 páginasAir BechtelBhargav ChaudhariAinda não há avaliações

- Swro PretreatmentDocumento8 páginasSwro PretreatmentprakashAinda não há avaliações

- Sea Water Intake & Outfall System For Coastal Power ProjectsDocumento3 páginasSea Water Intake & Outfall System For Coastal Power ProjectsAldy NovaldyAinda não há avaliações

- Desalination Plant of TobrukDocumento21 páginasDesalination Plant of TobrukMotaz ZgogoAinda não há avaliações

- Economic and Technical Assessment of Desalination Technologies PDFDocumento46 páginasEconomic and Technical Assessment of Desalination Technologies PDFIbrahim Al-MutazAinda não há avaliações

- Evaporation and Transpiration Factors Chapter 5Documento56 páginasEvaporation and Transpiration Factors Chapter 5Muhammad Shuja ArshadAinda não há avaliações

- TSPL GST Petition - AnnexuresDocumento407 páginasTSPL GST Petition - AnnexuresVIVEK anandAinda não há avaliações

- Water Systems: Larsen & Toubro Limited Epc Power Training ManualDocumento43 páginasWater Systems: Larsen & Toubro Limited Epc Power Training ManualParmeshwar Nath TripathiAinda não há avaliações

- Multi Stage Flash Desalination Plant With Brine-Feed Mixing and CoolingDocumento8 páginasMulti Stage Flash Desalination Plant With Brine-Feed Mixing and CoolingMuhammadEhtishamSiddiquiAinda não há avaliações

- Journal of Environmental Chemical Engineering: SciencedirectDocumento11 páginasJournal of Environmental Chemical Engineering: SciencedirectJavierAinda não há avaliações

- Groundwater Management Plan for Iloilo CityDocumento92 páginasGroundwater Management Plan for Iloilo CityMae Ann GonzalesAinda não há avaliações

- Siemens Forty X Disc Filters Tech. Specs.Documento25 páginasSiemens Forty X Disc Filters Tech. Specs.Alfonso José García LagunaAinda não há avaliações

- Workshop on Water Optimization in Thermal Power PlantsDocumento55 páginasWorkshop on Water Optimization in Thermal Power PlantsAhmed AnsariAinda não há avaliações

- Deionized For Cooling Tower PDFDocumento8 páginasDeionized For Cooling Tower PDFThipsuree KornboonraksaAinda não há avaliações

- Overview of The Cost of Desalinated Wate PDFDocumento14 páginasOverview of The Cost of Desalinated Wate PDFAhmed AnsariAinda não há avaliações

- Od-Ops-Syst-003 Procedure For Testing and Maintenance To Avoid Excessiveover Speeding of Prime MoversDocumento1 páginaOd-Ops-Syst-003 Procedure For Testing and Maintenance To Avoid Excessiveover Speeding of Prime MoversDeepak KansalAinda não há avaliações

- Hvac Factsheet BasicsDocumento3 páginasHvac Factsheet BasicsAnwar SyedAinda não há avaliações

- Voutchkov (2010) CoinsiderationdForSelectionOfSeawaterFiltrationPretrementSystem Desalination (261 354-364Documento12 páginasVoutchkov (2010) CoinsiderationdForSelectionOfSeawaterFiltrationPretrementSystem Desalination (261 354-364Shamma DamaniAinda não há avaliações

- PumpingAndMixingSpecialistsForTheCPI en E10272Documento24 páginasPumpingAndMixingSpecialistsForTheCPI en E10272Michael PiñaAinda não há avaliações

- Purification of Brackish Water Using Hybrid CDI-EDI TechnologyDocumento30 páginasPurification of Brackish Water Using Hybrid CDI-EDI TechnologyamtAinda não há avaliações

- Cost Comp - MF UF Vs TraditionalDocumento8 páginasCost Comp - MF UF Vs TraditionalahanraAinda não há avaliações

- Clarifying Treatment FlotationDocumento9 páginasClarifying Treatment FlotationYuri SmithAinda não há avaliações

- Report 4Documento52 páginasReport 4Deo DoktorAinda não há avaliações

- Problems in DesalinationDocumento5 páginasProblems in DesalinationAbdelrahman AboudAinda não há avaliações

- Reverse Osmosis ReportDocumento25 páginasReverse Osmosis ReportMuhammad Ishfaq100% (1)

- Investigation of Critical Sand-Deposition Velocity in Horizontal Gas/ Liquid Stratified FlowDocumento10 páginasInvestigation of Critical Sand-Deposition Velocity in Horizontal Gas/ Liquid Stratified Flowthlim19078656Ainda não há avaliações

- Lamella Clarifier Leopold TexlerDocumento4 páginasLamella Clarifier Leopold TexlerAntony ThanosAinda não há avaliações

- Nemmeli DesalDocumento4 páginasNemmeli DesalTushar NeelratanAinda não há avaliações

- Reading Coal Flame in Tangentially Fired BoilerDocumento4 páginasReading Coal Flame in Tangentially Fired Boilerbhaskar1rkumar4092Ainda não há avaliações

- Combined Cycle Gas Turbine Gyanendra Sharma NPTI DelhiDocumento148 páginasCombined Cycle Gas Turbine Gyanendra Sharma NPTI DelhiNPTIAinda não há avaliações

- Ultra DafDocumento1 páginaUltra DafMD SHARIQUEAinda não há avaliações

- Tidal Wetland Living Machine Technology DescriptionDocumento6 páginasTidal Wetland Living Machine Technology DescriptionKai KhanAinda não há avaliações

- DOW Ultrafiltration SFD 2660Documento2 páginasDOW Ultrafiltration SFD 2660juliancardonaAinda não há avaliações

- Comparing Common Wastewater Aeration SolutionsDocumento2 páginasComparing Common Wastewater Aeration SolutionsprannoyAinda não há avaliações

- VGB-B 030 Desalination Contents FINALDocumento11 páginasVGB-B 030 Desalination Contents FINALLydia NgAinda não há avaliações

- WateReuse Desal Cost White Paper PDFDocumento20 páginasWateReuse Desal Cost White Paper PDFnimzaiAinda não há avaliações

- 2.3.3 Intake Design: 2 Design Considerations For Tunnelled Seawater Intakes 25Documento2 páginas2.3.3 Intake Design: 2 Design Considerations For Tunnelled Seawater Intakes 25Abdul Asad100% (1)

- Bioleaching of Enargite 5ADocumento235 páginasBioleaching of Enargite 5AFélix Vargas SantillánAinda não há avaliações

- Desalination and Water TreatmentDocumento10 páginasDesalination and Water Treatmentl209Ainda não há avaliações

- TC Owtu 502 PDFDocumento288 páginasTC Owtu 502 PDFRon100% (1)

- Life Cycle Assessment of Desalination ProcessesDocumento9 páginasLife Cycle Assessment of Desalination ProcessesN KAinda não há avaliações

- SWRO Assessment and Pretreatment of Fouling and Scaling 2021 IWADocumento300 páginasSWRO Assessment and Pretreatment of Fouling and Scaling 2021 IWAAbdulAziz shahidAinda não há avaliações

- Boiler Effy AssessmentDocumento38 páginasBoiler Effy Assessmentraja020Ainda não há avaliações

- Reference Standards For Thermal Power PlantsDocumento29 páginasReference Standards For Thermal Power PlantsSenthil Kumar SubramanianAinda não há avaliações

- Sajid HussainDocumento48 páginasSajid HussainTimothy GarciaAinda não há avaliações

- Sanitary Engineer II: Passbooks Study GuideNo EverandSanitary Engineer II: Passbooks Study GuideAinda não há avaliações

- Applied Catalysis B: EnvironmentalDocumento11 páginasApplied Catalysis B: EnvironmentalAndreea FieraruAinda não há avaliações

- MRP3Documento10 páginasMRP3Andreea FieraruAinda não há avaliações

- MRP2Documento24 páginasMRP2Andreea FieraruAinda não há avaliações

- Pub 10164909Documento8 páginasPub 10164909Mohammed S. HussainAinda não há avaliações

- Economic Analysis of Reverse Osmosis Desalination of Water For AgDocumento59 páginasEconomic Analysis of Reverse Osmosis Desalination of Water For AgAndreea FieraruAinda não há avaliações

- Enzymes Used in DetergentsDocumento9 páginasEnzymes Used in DetergentsAlina Baciu100% (3)

- Enzymes Used in DetergentsDocumento9 páginasEnzymes Used in DetergentsAlina Baciu100% (3)

- Desalination and Membrane Technologies: Federal Research and Adoption IssuesDocumento18 páginasDesalination and Membrane Technologies: Federal Research and Adoption IssuesAndreea FieraruAinda não há avaliações

- AntiderapantDocumento239 páginasAntiderapantAndreea FieraruAinda não há avaliações

- PlantDocumento32 páginasPlantZafar IqbalAinda não há avaliações

- Wind Power Reduces Environmental Impacts of Desalination PlantsDocumento1 páginaWind Power Reduces Environmental Impacts of Desalination PlantsAndreea FieraruAinda não há avaliações

- 1629, RoDocumento8 páginas1629, RoYury LorenzAinda não há avaliações

- Business 1Documento10 páginasBusiness 1predarebecaAinda não há avaliações

- Interest and Choices2Documento8 páginasInterest and Choices2Andreea FieraruAinda não há avaliações

- MiningDocumento2 páginasMiningAndreea FieraruAinda não há avaliações

- Flintasu Andreea RalucaDocumento13 páginasFlintasu Andreea RalucaAndreea FieraruAinda não há avaliações

- Experience 3Documento6 páginasExperience 3Andreea FieraruAinda não há avaliações

- English L TestDocumento3 páginasEnglish L TestAndreea FieraruAinda não há avaliações

- Exercise 1 PDFDocumento2 páginasExercise 1 PDFAndreea FieraruAinda não há avaliações

- Arrangements 4Documento6 páginasArrangements 4Andreea FieraruAinda não há avaliações

- Advantages of Sustainable Agriculture FarmingDocumento2 páginasAdvantages of Sustainable Agriculture FarmingRupesh UpadhyayAinda não há avaliações

- C098 Germano Soil Laboratory 9Documento1 páginaC098 Germano Soil Laboratory 9Jacky Lou GermanoAinda não há avaliações

- FFM 1 - Overview of Forests and Forestry & ManagementDocumento49 páginasFFM 1 - Overview of Forests and Forestry & ManagementankurkunduAinda não há avaliações

- Geotech FE ReviewDocumento99 páginasGeotech FE ReviewAltammar13Ainda não há avaliações

- Elective QuizDocumento2 páginasElective QuizClaudine MedalladaAinda não há avaliações

- Concept Note For A Solar Energy DriveDocumento3 páginasConcept Note For A Solar Energy Driverajesh rAinda não há avaliações

- Geog LORMS Food Problematic GRDocumento2 páginasGeog LORMS Food Problematic GRacsbr4science1100% (1)

- Presentataion TATA SteelDocumento16 páginasPresentataion TATA SteelRAGHVENDRA100% (1)

- Soil Test ReportDocumento3 páginasSoil Test ReportPhanna MongAinda não há avaliações

- Ce 505 Pangan PinedaDocumento89 páginasCe 505 Pangan Pinedahaidee panganAinda não há avaliações

- Gap II Funding - Project Listing - Final - April 18 2018Documento4 páginasGap II Funding - Project Listing - Final - April 18 2018The Republican/MassLive.comAinda não há avaliações

- Hand ToolsDocumento21 páginasHand ToolsRazel M. TeodosioAinda não há avaliações

- Liebherr T 282 C Job Report Peabody North Antelope Rochelle MineDocumento2 páginasLiebherr T 282 C Job Report Peabody North Antelope Rochelle MineNicolás Alberto RojasAinda não há avaliações

- 10 Munketal2016 PDFDocumento28 páginas10 Munketal2016 PDFSaulAinda não há avaliações

- MR Deepak GadhiaDocumento17 páginasMR Deepak GadhiaJignesh ChaudharyAinda não há avaliações

- Integrated Biodiversity ManagementDocumento3 páginasIntegrated Biodiversity ManagementJohari JalinasAinda não há avaliações

- Food Security Refers To The Availability of Food and One's AccessDocumento6 páginasFood Security Refers To The Availability of Food and One's AccessLearner84100% (1)

- CBSE Class 10 Geography Chapter 3 Notes - Water ResourcesDocumento4 páginasCBSE Class 10 Geography Chapter 3 Notes - Water Resourcesrishabh gaunekarAinda não há avaliações

- Design methods to control violent pillar failures in room-and-pillar minesDocumento9 páginasDesign methods to control violent pillar failures in room-and-pillar mineskatta_sridharAinda não há avaliações

- WWTDocumento10 páginasWWTRajan RanjanAinda não há avaliações

- Power Resources Exercise 2059/02Documento4 páginasPower Resources Exercise 2059/02mishi moshAinda não há avaliações

- Concentrating Solar Power: Clean Energy For The Electric GridDocumento14 páginasConcentrating Solar Power: Clean Energy For The Electric Gridfran01334Ainda não há avaliações

- Land Management Processes for Sustainable DevelopmentDocumento2 páginasLand Management Processes for Sustainable DevelopmentMichaelah Reinne Alcaraz ConvocarAinda não há avaliações

- Principles of HydrologyDocumento2 páginasPrinciples of HydrologyDewi RhomilaAinda não há avaliações

- Energy Survey ReportDocumento7 páginasEnergy Survey ReportGood Energies Alliance IrelandAinda não há avaliações

- Agricultureinalb 1997 AlbeDocumento36 páginasAgricultureinalb 1997 AlbeDorselAinda não há avaliações

- Forest and Wildlife Protection ActDocumento17 páginasForest and Wildlife Protection ActAmith AmanAinda não há avaliações

- Business Road Map: Solar EPC, Solar Power PlantDocumento24 páginasBusiness Road Map: Solar EPC, Solar Power PlantCheema HnpsAinda não há avaliações

- Tutorial 2 Water PollutionDocumento2 páginasTutorial 2 Water PollutionWong Li XuanAinda não há avaliações

- Ekologika Profile October-2022Documento12 páginasEkologika Profile October-2022NinilAinda não há avaliações