Escolar Documentos

Profissional Documentos

Cultura Documentos

Valves Reference PDF

Enviado por

Julio RodriguezDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Valves Reference PDF

Enviado por

Julio RodriguezDireitos autorais:

Formatos disponíveis

INDEX

INDEX

Content

Page

Figure Number

Gate Valves (ANSI 150 to 1500)

2-7

Globe Valves (ANSI 150 to 1500)

8-13

Swing Check Valves (ANSI 150 to 1500)

14-19

Electrically / Gear Operated Valves

20

Welding End Details

Ring Joint Connection between body and

21

Reference Standards and Specification

23

Comparison List for Casting and Forging

24

Chemical and Physical Properties

25

bonnet/cover

22

Gasket Material & Construction

26-27

Packing Material & Construction

28

Pressure Temperature Rating

29

Steel Pipe Flanges

30-31

Comparison Chart

32

MACHINERY AND TESTING FACILITIES

We have endeavoured in this catalogue to make the information as accurate as possible,

but cannot accept any responsibility should it found that in any respect the information is

inaccurate or incomplete or becomes so as a result of further developments.

FIGURE NUMBER

ANSI RATING

VALVE TYPE

01=ANSI 150

03=ANSI 300

06=ANSI 600

09=ANSI 900

15=ANSI 1500

25=ANSI 2500*

0=Plug

1=Gate

2=Globe

3=Swing

BODY/BONNET MATERIAL

END CONNECTION

1=Low Carbon Steel ASTM A352 LCB/LC3/LCC

2=Carbon Steel ASTM A216 Gr. WCB

3=Stainless Steel- ASTM A351 CF8M/CF3M/CF10M

4= Stainless Steel- ASTM A351 CF8/CF3/CF10

5= Stainless Steel- ASTM A351 CF8C (Type 347)

6=Stainless Steel- ASTM A351 CG8M / CG3M

7=Alloy Steel ASTM A217 WC1/WC6/WC9/C5/C12

8=Alloy 20 ASTM A351 CN7M

9=Duplex Stainless Steel

0=Hastelloy, Monel or Others

*Available on

request

B=Bevel Weld

F=Raised Face Flange

R=Ring Type Joint

TRIM MATERIAL

API

TRIM

NO

NOMINAL TRIM

1

2

3

4

5

5A

6

7

8

8A

9

10

11

12

13

14

F6

304

F310

Hard F6

Hardfaced

Hardfaced

F6 & Cu-Ni

F6 & Hard F6

F6 and Hardfaced

F6 and Hardfaced

Monel

316

Monel & Hardfaced

316 & HArdfaced

Alloy 20

Alloy 20 & Hardfaced

SEAT

SURFACE

HARDNESS

(Hba Min.)

b

c

c

750d

350d

350d

250f & 175f

300f & 750f

300f & 350f

300f & 350f

c

c

c

c

& 350f

& 350f

c

c

& 350f

API

TRIM

NO

SEAT

SURFACE

MATERIAL

12 Cr

18 Cr-8Ni

25 Cr-20Ni

Hard 13Cr

Co-Cr Ah

Ni-Cr

13Cr Cu-Ni

13Cr & Hard 13Cr

13Cr & Co-CR Ah

13Cr & Ni-Cr

Ni-Cu alloy

18Cr-8Ni

Ni-Cu alloy & Trim 5 or 5A

18Cr-8Ni & Trim 5 or 5A

19Cr-29Ni

19Cr-29Ni & Trim 5 or 5A

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

X

SEAT

SURFACE

HARDNESS

(Hba Min.)

NOMINAL TRIM

316(F-Stl)

316L(F-Stl)

304(F-Stl)

304 & Hardfaced

321 (F-Stl)

316L

347

304L

B335(Hastelloy B)

321

316L & Hardfaced

321 & Hardfaced

B574(Hastelloy C)

347 & Hardfaced

347 (F-Stl)

Special Materials

350 d

350 d

c

& 350f

350 d

c

c

c

c

c

c

c

c

& 350f

& 350f

c

c

& 350f

350 d

SEAT

SURFACE

MATERIAL

Co-Cr Ah

Co-Cr Ah

Co-Cr Ah

18Cr-8Ni & Co-CrAh

Co-Cr Ah

16Cr-12Ni-2Mo

18Cr-10Ni-Cb

18Cr-8Ni

Ni-Mo Alloy B

18Cr-10Ni-Ti

16Cr-12Ni-2Mo &Co-CrAh

18Cr-10Ni-Ti & Co-CrAh

Ni-Mo-Cr & Alloy C-276

18Cr-10Ni-Cb & Co-CrAh

Co-CrAh

NOTE:

e

Case hardened by nitriding to a thickness of 0.13mm

minimum

f

Hardness differential between body and gate shall

be manufacturer's std

g

Manufacturer's standard with 30 Ni minimum

h

This classification includes such trademarked

materials as Stellite 6, Stoody 6; and Wallex 6.

I

Manufacturer's standard hardfacing with 25 percent

Fe maximum

HB {formerly HBN} is the symbol for Brinell

Hardness per ASTM E10

b

Body and gate seat 250HB minimum, with 50 HB

minimum differential between the body and gate

seats

c

Manufacturer's standard hardness

d

Differential hardness between the body and gate

seat surfaces is not required

GENERAL NOTES FOR DIMENSIONAL TABLES

1 . All sizes given in millimeters and inches are approximate.

2. All weights given in Kgs are approximate.

3. Dimensions shown may be revised at any time. Use certified dimensional drawings for critical areas.

CAST STEEL GATE VALVES

2) Welded-in seat rings, designed in order to prevent

turbulence and avoid damages due to corrosion. Both

forged or rolled in one piece, for all dimensions, They

treated to obtain the requested surface hardness, and

perfectly cleaned before assembling.

any

are

are

are

STEM

The stem has a forged tee-head connection, with rolled or

cut ACME threads according to valve size, and is rolled or

rectified in the packing area in order to assure a long life

with a perfect tightness. We have calculated and checked

by means of experiment the stem-wedge connection in

order to prevent the turning or the disengagement of the

stem from the wedge while the gate valve is in service. The

strength of the connection exceeds the strength of the stem

at the root of its operating thread.

GLAND

The gland is made in two pieces: a cylindrical piece in

contact with the packing connected through a spherical joint

to the gland flange. The particular design of both pieces

assures a correct pressure on the packing without injuring

the stem through friction or corrosion.

KVC Gate valves are manufactured to API Std.600 and

tested to API Std.598

Gate Valves are the most commonly used shut-off valve in

the industry today. They are used where minimum pressure

drop and bi-directional on-off service is required. Gate

valves are not designed for throttling service. Prolonged

use in the partially open position will generally damage

seating surface.

STUFFING BOX

The design is API Std.600 for high pressure class valves

and over the stuffing box is provided with a lantern ring.

END CONNECTIONS

Our standard production covers valve with :

Flanged ends (RF) that conform to ANSI B16.5 and face to

face dimensions that conform to ANSI B16.10, with a raised

face serrated finish or, on request, with any other type of

finish;

Butt-welding ends (BW) with end to end dimensions that

conform ANSI B16.10

Customer must specify the type of schedule required, or

class of pipe, or diameter and bore.

Ring-joint flanged ends (RTJ) that conform to ANSI B16.5,

with end to end dimensions to ANSI B16.10

Other special end connections are supplied to customers'

special requirements.

BODY AND BONNET

The body and bonnet design is calculated to achieve the

most regular distribution of stress in all sides, as well as

the minimum turbulence and resistance to flow. Bonnets on

all valves are equipped with a back seat bushing.

BODY-BONNET JOINTS

Body-Bonnet Joints of gate valve are machined as follows:

on 150 class : plain faced

on 300 class : male and female

on 600, 900 and 1500 classes : ring joint

BODY-BONNET GASKET

Standard is P#6633, P#2601 & P#1500S

Also available in different type to meet customer

requirement upon request.

HANDWHEEL

Handwheels are of a particular design, for easy operation;

dimensions are according to API 600: they are made in

ductile iron.

WEDGE

GEAR OPERATED VALVES

Valves can be supplied with bevel gear operators

SOLID (TYPE S)

MOTOR OPERATED VALVES

Valves can be supplied equipped with, or prepared for

actuators, either electric or pneumatic or hydraulic, of the

best types, according to customers' requirements. The

customer is requested to specify all information, such as the

max. working differential pressure, service media, the

ambient temperature and humidity, electrical or air facilities,

desired closing time an all other requirements that can be

helpful to our engineers in choosing the more suitable

actuator for the specific working conditions.

FLEX (TYPE F)

The valve is normally supplied with a solid wedge for up to

2" and flexible wedge for above 2" as shown below. All

wedges are full guided.

SEAT RING

Seat rings are manufactured in two different ways,

depending on the class and type of valves:

1) Screwed seat rings, bottom seated type lapped on both

sides. They are dry assembled, with a controlled torque

dry assembled, with a controlled torque setting to the

body.

ACCESSORIES

We can supply valves fitted with other accessories such as

bypasses, locking devices, chain wheels, floor stands,

special extension stems and others.

CAST STEEL GATE VALVES ANSI 150

SPECIFICATION

Bolted Bonnet

Outside Screw and Yoke

Flexible Wedge

Oval Bonnet with intergral Yoke

Rising Stem Non-rising Handwheel

Welded-In/Threaded Seat Rings

Full Port

Raised Face Flanged Ends or Buttwelding Ends

Gear Operated recommended for size 14 above

PARTS AND MATERIAL LIST

No.

Part Name

01

Body

02

Bonnet

03

Yoke

04

Wedge*

07

Stem

09

Yoke Sleeve

11

Gland Flange

12

Packing Gland

14

Yoke Cap

15

Handwheel Nut

18

Handwheel

21

Body Seat Ring

23

Back Seat Ring

31

Bonnet Bolt

32

Yoke Bolt

33

Bonnet Nut

34

Gland Bolt

35

Gland Nut

35A

Yoke Nut

35B

Gland Nut

36

Hinge Pin

41

Set Screw

47

Grease Nipple

51

Packing Gland

56

Gasket*

73

Thrust Bearing

APPLICABLE STANDARDS

Design: API 600

End Flange : ANSI B16.5

Weld Ends : ANSI B16.25

Face-to-Face: ANSI B16.10

Shell and Seat Test: API 598

Size

2

2-1/2

3

4

6

8

10

12

14

16

18

20

24

30

Material

Carbon Steel

Carbon Steel

Carbon Steel

Carbon Steel

Stainless Steel

Ductile Iron

Forged Carbon Steel

Stainless Steel

Carbon Steel

Carbon Steel

Ductile Iron

Carbon Steel + Stellite No.6

Stainless Steel

Alloy Steel

Carbon Steel

Carbon Steel

Carbon Steel

Ductile Iron

Ductile Iron

Ductile Iron

Carbon Steel

Steel

Steel

Graphite + Carbon Fiber

(See note*)

Steel

FIG.0112F

ASTM Specification

ASTM A216 Gr.WCB

ASTM A216 Gr.WCB

ASTM A216 Gr.WCB

ASTM A217 CA15(*see note)

A276 410

A439 D2C

A105

A276 410

A108 1020

A108 1020

A536

A105 + Stellite No.6

A276 410

A193 B7

A307 B

A194 2H

A307 B

A563 B

A563 B

A563 B

A108 1020

Steel

Steel (Zn Plated)

P#6610 + #6528

(see Note*)

Steel

*Note: Wedge : Size 16 & above A216 WCB + 13Cr

Gasket : Size 12 & below Graphite Sheet P#6633. 14 & above Single

Jacket P#1650E

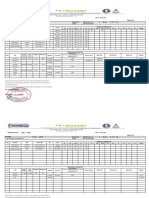

DIMENSIONAL DATA (MM)

Face-to-Face

Dia.of Bore

O.D.of Flange

of Bolt

Circle

O.D. OF RF

Thk of Flange

Ht. Of RF

L

177.8

190.5

203.2

228.6

266.7

292.1

330.2

355.6

381.0

406.4

431.8

457.2

508.0

609.6

d

50.8

63.5

76.2

101.6

152.4

203.2

254.0

304.8

336.6

38704

438.2

489.0

590.6

738.5

D

152.4

177.8

190.5

228.6

279.4

342.9

406.4

482.6

533.4

596.9

635.0

698.5

812.8

984.3

C

120.7

139.7

152.4

190.5

241.3

298.5

362.0

431.8

476.3

539.8

577.9

635.0

749.3

914.4

g

91.9

104.6

127.0

157.2

215.9

269.8

323.9

381.0

412.8

469.9

533.4

584.2

692.2

857.3

t

15.8

17.6

19.1

23.9

25.4

28.5

30.3

31.8

35.1

36.6

39.7

43.0

47.8

74.7

f

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

Non-shock pressure rating: 285 PSIG@-200F to 1000F per ANSI B16.34

of Bolt

Holes

n-h

4-19.1

4-19.1

4-19.1

8-19.1

8-22.2

8-22.2

12-25.4

12-25.4

12-28.4

16-28.4

16-31.8

20-31.8

20-35.1

28-34.9

of

Handwheel

O

200

200

224

250

300

350

400

450

500

600

600

680

760

1000

Height

H

365

398

450

553

753

950

1165

1370

1520

1795

1970

2215

2595

3117

Wall Thk

a min

8.6

9.7

10.4

11.2

11.9

12.7

14.2

16.0

16.8

17.5

18.5

19.1

20.6

23.1

Wt (kg)

17.1

24.5

32.8

45.9

85.8

137.6

187.0

280.0

420.0

530.0

580.0

870.9

1233.8

2508.0

CAST STEEL GATE VALVES ANSI 300

SPECIFICATION

Bolted Bonnet

Outside Screw and Yoke

Flexible Wedge

Oval Bonnet with intergral Yoke

Rising Stem Non-rising Handwheel

Welded-In/Threaded Seat Rings

Full Port

Raised Face Flanged Ends or Buttwelding Ends

Gear Operated recommended for size 14 above

APPLICABLE STANDARDS

Design: API 600

End Flange : ANSI B16.5

Weld Ends : ANSI B16.25

Face-to-Face: ANSI B16.10

Shell and Seat Test: API 598

PARTS AND MATERIAL LIST

No. Part Name

Material

01

Body

Carbon Steel

02

Bonnet

Carbon Steel

03

Yoke

Carbon Steel

04

Wedge*

Carbon Steel

07

Stem

Stainless Steel

09

Yoke Sleeve

Ductile Iron

11

Gland Flange

Forged Carbon Steel

12

Packing Gland

Stainless Steel

14

Yoke Cap

Carbon Steel

15

Handwheel Nut

Carbon Steel

18

Handwheel

Ductile Iron

21

Body Seat Ring

Carbon Steel + Stellite No.6

23

Back Seat Ring

Stainless Steel

31

Bonnet Bolt

Alloy Steel

32

Yoke Bolt

Carbon Steel

33

Bonnet Nut

Carbon Steel

34

Gland Bolt

Carbon Steel

35

Gland Nut

Ductile Iron

35A Yoke Nut

Ductile Iron

35B Gland Nut

Ductile Iron

36

Hinge Pin

Carbon Steel

41

Set Screw

Steel

47

Grease Nipple

Steel

51

Packing Gland

Graphite + Carbon Fiber

56

Gasket*

(See note*)

73

Thrust Bearing

Steel

FIG.0312F

ASTM Specification

ASTM A216 Gr.WCB

ASTM A216 Gr.WCB

ASTM A216 Gr.WCB

ASTM A217 CA15(*see note)

A276 410

A439 D2C

A105

A276 410

A108 1020

A108 1020

A536

A105 + Stellite No.6

A276 410

A193 B7

A307 B

A194 2H

A307 B

A563 B

A563 B

A563 B

A108 1020

Steel

Steel (Zn Plated)

P#6610 + #6528

(see Note*)

Steel

*Note: Wedge : Size 2 & above Solid ,3 & above - flexible

Size 14 & above A216 Gr.WCB + 13Cr

Gasket: 4 & below S.P.W.P#2600-E00. 6 & above S.P.W#2601-ESO

DIMENSIONAL DATA (MM)

Size

Face-to-Face

Dia.of Bore

O.D.of Flange

of Bolt

Circle

O.D. of RF

Thk of Flange

Ht. of RF

L

d

D

C

g

t

2

215.9

50.8

165.1

127.0

91.9

22.4

2-1/2

241.3

63.5

190.5

149.4

104.6

25.4

3

282.6

76.2

209.6

168.1

127.0

28.5

4

304.8

101.6

254.0

200.2

157.2

31.8

6

403.2

152.4

317.5

269.7

215.9

36.6

8

419.1

203.2

381.0

330.2

269.7

41.2

10

457.2

254.0

444.5

387.4

323.9

47.8

12

501.7

304.8

520.7

450.9

381.0

50.8

14

762.0

336.6

584.2

514.4

412.8

53.9

16

838.2

387.4

647.7

571.5

469.9

57.2

18

914.4

431.8

711.2

628.7

533.4

60.5

20

990.6

482.6

774.7

685.8

584.2

63.5

Non-shock pressure rating: 740 PSIG@-200F to 1000F per ANSI B16.34

f

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

of Bolt

Holes

n-h

8-22.2

8-22.2

8-22.2

8-22.2

12-22.2

12-25.4

16-28.4

16-31.8

20-31.8

20-35.1

24-35.1

24-35.1

of

Handwheel

O

200

200

225

250

350

400

450

500

600

600

680

760

Height

H

392

435

494

592

813

1034

1225

1434

1645

1845

2040

2310

Wall Thk

a min

9.7

11.2

11.9

12.7

16.0

17.5

19.1

20.6

22.4

23.9

25.4

26.9

Wt (kg)

25.3

43.1

55.0

79.4

129.5

215.4

299.0

467.0

789.0

970.3

1170.0

1429.0

CAST STEEL GATE VALVES ANSI 600

SPECIFICATION

Bolted Bonnet

Outside Screw and Yoke

Flexible Wedge

Yoke intergral with bonnet

Rising Stem Non-rising Handwheel

Welded-In/Threaded Seat Rings

Full Port

Raised Face Flanged Ends or Buttwelding Ends

Gear Operated recommended for size 8 above

APPLICABLE STANDARDS

Design: API 600

End Flange : ANSI B16.5

Weld Ends : ANSI B16.25

Face-to-Face: ANSI B16.10

Shell and Seat Test: API 598

PARTS AND MATERIAL LIST

No. Part Name

Material

01

Body

Carbon Steel

02

Bonnet

Carbon Steel

03

Yoke

Carbon Steel

04

Wedge*

Carbon Steel

07

Stem

Stainless Steel

09

Yoke Sleeve

Ductile Iron

11

Gland Flange

Forged Carbon Steel

12

Packing Gland

Stainless Steel

14

Yoke Cap

Carbon Steel

15

Handwheel Nut

Carbon Steel

18

Handwheel

Ductile Iron

21

Body Seat Ring

Carbon Steel + Stellite No.6

23

Back Seat Ring

Stainless Steel

31

Bonnet Bolt

Alloy Steel

33

Bonnet Nut

Carbon Steel

34

Gland Bolt

Carbon Steel

35

Gland Nut

Ductile Iron

35A Yoke Nut

Ductile Iron

35B Gland Nut

Ductile Iron

36

Hinge Pin

Carbon Steel

41

Set Screw

Steel

47

Grease Nipple

Steel

51

Packing Gland

Graphite + Carbon Fiber

56

Gasket*

S.P.W SS304/Graphite

73

Thrust Bearing

Steel

FIG.0612F

ASTM Specification

ASTM A216 Gr.WCB

ASTM A216 Gr.WCB

ASTM A216 Gr.WCB

ASTM A217 CA15(*see note)

A276 410

A439 D2C

A105

A276 410

A108 1020

A108 1020

A536

A105 + Stellite No.6

A276 410

A193 B7

A194 2H

A307 B

A563 B

A563 B

A563 B

A108 1020

Steel

Steel (Zn Plated)

P#6610 + #6528

P#2601-ESO

Steel

*Note: Wedge : Size 12 & above A216 WCB + 13Cr

Gasket : Size 16 & above Ring Joint Gasket P#1500S

DIMENSIONAL DATA (MM)

Size

2

2-1/2

3

4

6

8

10

12

14

16

Face-to-Face

Dia.of Bore

O.D.of Flange

of Bolt

Circle

O.D. of RF

Thk of Flange

Ht. of RF

L

292.1

330.2

355.6

431.8

558.8

660.4

787.4

838.2

889.0

990.6

d

50.8

63.5

76.2

101.6

152.4

199.9

247.7

298.5

328.9

374.7

D

165.1

190.5

209.6

273.1

355.6

419.1

508.0

558.8

603.3

685.8

C

127.0

149.4

168.1

215.9

292.1

349.3

431.8

489.0

527.1

603.3

g

91.9

104.6

127.0

157.2

215.9

269.7

323.9

381.0

412.6

469.9

t

25.4

28.5

31.8

38.1

47.8

55.7

63.5

66.6

69.9

76.2

f

6.4

6.4

6.4

6.4

6.4

6.4

6.4

6.4

6.4

6.4

Non-shock pressure rating: 1480 PSIG@-200F to 1000F per ANSI B16.34

of Bolt

Holes

n-h

8-19.1

8-22.2

8-22.2

8-25.4

12-28.4

12-31.8

16-35.1

20-35.1

20-38.1

20-41.2

of

Handwheel

O

200

200

250

300

450

500

630

710

630

710

Height

H

419

419

520

635

932

1035

1241

1440

1620

1835

Wall Thk

a min

11.2

11.9

12.7

16.0

19.1

25.4

28.7

31.8

35.1

38.1

Wt (kg)

36.0

43.1

65.0

116.0

217.7

410.0

660.0

943.4

1270.0

1500.0

CAST STEEL GATE VALVES ANSI 900

SPECIFICATION

Bolted Bonnet

Outside Screw and Yoke

Flexible Wedge

Yoke intergral with bonnet

Rising Stem Non-rising Handwheel

Welded-In/Threaded Seat Rings

Full Port

Raised Face Flanged Ends or Buttwelding Ends

or Ring Joint Flanged Ends

Gear Operated recommended for size 4 above

APPLICABLE STANDARDS

Design: API 600

End Flange : ANSI B16.5

Weld Ends : ANSI B16.25

Face-to-Face: ANSI B16.10

Shell and Seat Test: API 598

PARTS AND MATERIAL LIST

No. Part Name

Material

01

Body

Carbon Steel

02

Bonnet

Carbon Steel

03

Yoke

Carbon Steel

04

Wedge

Carbon Steel

07

Stem

Stainless Steel

09

Yoke Sleeve

Ductile Iron

11

Gland Flange

Forged Carbon Steel

12

Packing Gland

Stainless Steel

14

Yoke Cap

Carbon Steel

15

Handwheel Nut

Carbon Steel

18

Handwheel

Ductile Iron

21

Body Seat Ring

Carbon Steel + Stellite No.6

23

Back Seat Ring

Stainless Steel

31

Bonnet Bolt

Alloy Steel

33

Bonnet Nut

Carbon Steel

34

Gland Bolt

Carbon Steel

35

Gland Nut

Ductile Iron

35A Yoke Nut

Ductile Iron

35B Gland Nut

Ductile Iron

36

Hinge Pin

Carbon Steel

41

Set Screw

Steel

47

Grease Nipple

Steel

51

Packing Gland

Graphite + Carbon Fiber

56

Gasket

Ring Joint Gasket

73

Thrust Bearing

Steel

FIG.0912F

ASTM Specification

ASTM A216 Gr.WCB

ASTM A216 Gr.WCB

ASTM A216 Gr.WCB

ASTM A217 CA15

A276 410

A439 D2C

A105

A276 410

A108 1020

A108 1020

A536 60-40-18

A105 + Stellite No.6

A276 410

A193 B7

A194 2H

A307 B

A563 B

A563 B

A563 B

A108 1020

Steel

Steel (Zn Plated)

P#6610 + #6528

P#1500-S

Steel

DIMENSIONAL DATA (MM)

Size

2

3

4

6

8

10

12

Face-to-Face

Dia.of Bore

L

368.3

381.0

457.2

609.6

736.6

838.2

965.2

d

47.5

72.9

98.3

146.1

190.5

238.0

282.5

O.D.of Flange

of Bolt

Circle

O.D. of RF

Thk of Flange

Ht. of RF

D

215.9

241.3

292.1

381.0

469.9

546.1

609.6

C

165.1

190.5

235.0

317.5

393.7

469.9

533.4

g

91.9

127.0

157.2

215.9

269.7

323.9

381.0

t

38.1

38.1

44.5

55.7

63.5

69.9

79.3

f

6.4

6.4

6.4

6.4

6.4

6.4

6.4

Non-shock pressure rating: 2220 PSIG@-200F to 1000F per ANSI B16.34

of Bolt

Holes

n-h

8-25.4

8-25.4

8-31.8

12-31.8

12-38.1

16-38.1

20-38.1

of

Handwheel

O

250

300

350

500

600

680

760

Height

H

523

620

688

916

1107

1313

1528

Wall Thk

a min

19.1

19.1

21.3

26.2

31.8

36.6

42.2

Wt (kg)

85.0

111.0

165.0

394.6

594.0

865.0

960.0

CAST STEEL GATE VALVES ANSI 1500

SPECIFICATION

Bolted Bonnet

Outside Screw and Yoke

Flexible Wedge

Yoke intergral with bonnet

Rising Stem Non-rising Handwheel

Welded-In/Threaded Seat Rings

Full Port

Raised Face Flanged Ends or Buttwelding Ends

or Ring Joint Flanged Ends

Gear Operated recommended for size 3 above

APPLICABLE STANDARDS

Design: API 600

End Flange : ANSI B16.5

Weld Ends : ANSI B16.25

Face-to-Face: ANSI B16.10

Shell and Seat Test: API 598

PARTS AND MATERIAL LIST

No. Part Name

Material

01

Body

Carbon Steel

02

Bonnet

Carbon Steel

03

Yoke

Carbon Steel

04

Wedge

Carbon Steel

07

Stem

Stainless Steel

09

Yoke Sleeve

Ductile Iron

11

Gland Flange

Forged Carbon Steel

12

Packing Gland

Stainless Steel

14

Yoke Cap

Carbon Steel

15

Handwheel Nut

Carbon Steel

18

Handwheel

Ductile Iron

21

Body Seat Ring

Carbon Steel + Stellite No.6

23

Back Seat Ring

Stainless Steel

31

Bonnet Bolt

Alloy Steel

33

Bonnet Nut

Carbon Steel

34

Gland Bolt

Carbon Steel

35

Gland Nut

Ductile Iron

35A Yoke Nut

Ductile Iron

35B Gland Nut

Ductile Iron

36

Hinge Pin

Carbon Steel

41

Set Screw

Steel

47

Grease Nipple

Steel

51

Packing Gland

Graphite + Carbon Fiber

56

Gasket

Ring Joint Gasket

73

Thrust Bearing

Steel

FIG.1512F

ASTM Specification

ASTM A216 Gr.WCB

ASTM A216 Gr.WCB

ASTM A216 Gr.WCB

ASTM A217 CA15

A276 410

A439 D2C

A105

A276 410

A108 1020

A108 1020

A536

A105 + Stellite No.6

A276 410

A193 B7

A194 2H

A307 B

A563 B

A563 B

A563 B

A108 1020

Steel

Steel (Zn Plated)

P#6610 + #6528

P#1500-S

Steel

DIMENSIONAL DATA (MM)

Size

2

3

4

6

6

8

Face-to-Face

Dia.of Bore

L

368.3

419.1

469.9

546.1

546.1

704.9

d

47.5

57.2

69.9

92.0

136.4

177.8

O.D.of Flange

of Bolt

Circle

O.D. of RF

Thk of Flange

Ht. of RF

D

215.9

244.3

266.7

311.2

393.7

482.6

C

165.1

190.5

203.2

241.3

317.5

393.7

g

91.9

104.6

127.0

157.2

215.9

269.7

t

38.1

41.2

47.8

53.8

82.6

91.9

f

6.4

6.4

6.4

6.4

6.4

6.4

Non-shock pressure rating: 3705 PSIG@-200F to 1000F per ANSI B16

of Bolt

Holes

n-h

8-25.4

8-28.4

8-31.8

8-34.9

12-38.1

12-44.5

of

Handwheel

O

250

300

350

400

600

680

Height

H

561

633

670

759

1048

1246

Wall Thk

a min

19.1

22.4

23.9

28.7

38.1

47.8

Wt (kg)

131.5

172.4

226.8

335.6

662.0

1266.0

CAST STEEL GLOBE VALVES

SEAT RINGS

Screwed rings are bottom seated type. They are d

assembled with a controlled torque setting to the body.

Integral welded seat may be furnished.

Both are forged or roiled in one piece, for all dimensions.

They are heat treated to obtain the required surface

hardness; and are perfectly cleaned before assembling.

STEM

The stem is rolled or cut threads according to valve size;

and is rolled or rectified in the packing area to assure a long

life with perfect tightness.

GLAND

The gland is made in two pieces: a cylindrical piece in

contact with the packing connected through a spherical joint

to the gland flange.

The particular design of both pieces assures a correct load

on the packing without injuring the stem through friction or

corrosion.

STUFFING BOX

The design is to API Std.600 for high pressure class valves

and over the stuffing box is provided with a lantern ring.

END CONNECTIONS

Our standard production covers valves with :

Flanged ends (RF) that conform to ANSI B16.5 and face to

face dimensions that conform to ANSI B16.10, with a raised

face serrated finish or, on request; with any other type of

finish;

Butt-welding ends (BW) with end to end dimensions that

conform to ANSI B16.10

Customer must specify the type of schedule required; or

class of pipe; or diameter and bore

Ring-joint flanged ends (RTJ) that conform to ANSI

B16.5, with end to end dimensions to ANSI B16.10

Other special end connections are supplied to customers'

special requirements.

KVC Globe Valves are manufactured to BS1873 and

API Std.600, and tested to API Std.598

Globe Valves are used where throttling or both throttling and

shut-off are required. They can also be used for on-off

service; but because of high pressure drop; this is generally

confined to applications where the valve is normally closed

and drop is not important when the valve is open.

HANDWHEEL

Handwheels are of a particular design, for easy operation;

dimensions are according to API 600: they are made in

ductile iron.

BODY AND BONNET

Body spherical form, of large radius, allows for the stresses,

turbulence and resistance to flow to be kept to a minimum.

Bonnets on all valves are equipped with a back seat bushing.

GEAR OPERATED VALVES

Valves can be supplied with bevel gear operators.

BODY-BONNET JOINTS

Body-Bonnet Joints of globe valves are machined as follows:

on 150 and 300 classes : male and female.

on 600, 900 and 1500 class RTJ

MOTOR OPERATED VALVES

Valves can be supplied equipped with, or prepared for

actuators, either electric or pneumatic or hydraulic, of the

best types, according to customers' requirements. The

customer is requested to specify all information, such as

the max working differential pressure, service media, the

ambient temperature and humidity, electrical or air facilities,

desired closing time and all other requirements that can be

helpful to our engineers in choosing the more suitable

actuator for the specific working conditions.

DISC

The valve is normally supplied with plug type disc as shown

below

ACCESSORIES

We can supply valves fitted with other accessories such as

bypasses, locking devices, chain wheels, floor stands,

special extension stems and others.

CAST STEEL GLOBE VALVES ANSI 150

SPECIFICATION

Bolted Bonnet

Outside Screw and Yoke

Yoke intergral with bonnet

Rising Stem Handwheel

Welded-In/Threaded Seat Rings - Stellited

Full Port

Raised Face Flanged Ends or Buttwelding Ends

Gear Operated recommended for size 10 above

APPLICABLE STANDARDS

Design: ANSI B16.34

End Flange : ANSI B16.5

Weld Ends : ANSI B16.25

Face-to-Face: ANSI B16.10

Shell and Seat Test: API 598

PARTS AND MATERIAL LIST

No. Part Name

Material

01

Body

Carbon Steel

02

Bonnet

Carbon Steel

04

Disc*

Carbon Steel

07

Stem

Stainless Steel

10

Yoke Bush

Ductile Iron

11

Gland Flange

Forged Carbon Steel

12

Packing Gland

Stainless Steel

13

Disc Nut

Carbon Steel

15

Handwheel Nut

Carbon Steel

19

Handwheel

Ductile Iron

21

Body Seat Ring

Carbon Steel + Stellite No.6

23

Back Seat Ring

Stainless Steel

31

Bonnet Bolt

Alloy Steel

33

Bonnet Nut

Carbon Steel

34

Gland Bolt

Carbon Steel

35

Gland Nut

Ductile Iron

36

Hinge Pin

Carbon Steel

42

Washer

Carbon Steel

51

Packing

Graphite + Carbon Fiber

56

Gasket

(See Note*)

FIG.0122F

ASTM Specification

ASTM A216 Gr.WCB

ASTM A216 Gr.WCB

ASTM A217 CA15(*see note)

A276 410

A439 D2C

A105

A276 410

A276 410

A536B

A536

A105 + Stellite No.6

A276 410

A193 B7

A194 2H

A307 B

A563 B

A108 1020

A108 1020

P#6610 + #6528

(See Note*)

*Note: Disc: 10 & above A217 CA15. 12 & above-A216 Gr.WCB + 13Cr.

Gasket : Size 12 & below Graphite Sheet P#6633.

14 & above S.P.W. P#2601-ESO

DIMENSIONAL DATA (MM)

Size

2

2-1/2

3

4

6

8

10

12

Face-to-Face

Dia.of Bore

O.D.of Flange

of Bolt

Circle

L

203.2

215.9

241.3

292.1

406.4

495.3

622.3

698.5

d

50.8

63.5

76.2

101.6

152.4

203.2

254.0

304.8

D

152.4

177.8

190.5

228.6

279.4

342.9

406.4

482.6

C

120.7

139.7

152.4

190.5

241.3

298.5

362.0

431.8

O.D. of RF

Thk of Flange

Ht. of RF

g

91.9

104.6

127.0

157.2

215.9

269.7

323.9

381.0

t

15.8

17.6

19.1

23.9

25.4

28.5

30.3

31.8

f

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

Non-shock pressure rating: 285 PSIG@-200F to 1000F per ANSI B16.34

of Bolt

Holes

n-h

4-19.1

4-19.1

4-19.1

8-19.1

8-22.2

8-22.2

12-25.4

12-25.4

of

Handwheel

O

200

200

250

300

350

450

450

560

Height

Wall Thk

H

322

330

365

424

498

624

768

785

a min

8.6

9.7

10.4

11.2

11.9

12.7

14.2

16.0

Wt (kg)

21.6

23.6

29.7

41.6

109.0

187.0

232.0

508.0

CAST STEEL GLOBE VALVES ANSI 300

SPECIFICATION

Bolted Bonnet

Outside Screw and Yoke

Yoke intergral with bonnet

Rising Stem Handwheel

Welded-In/Threaded Seat Rings

Full Port

Raised Face Flanged Ends or Buttwelding Ends

Gear Operated recommended for size 8 above

APPLICABLE STANDARDS

Design: ANSI B16.34

End Flange : ANSI B16.5

Weld Ends : ANSI B16.25

Face-to-Face: ANSI B16.10

Shell and Seat Test: API 598

PARTS AND MATERIAL LIST

No. Part Name

Material

01

Body

Carbon Steel

02

Bonnet

Carbon Steel

04

Disc*

Carbon Steel

07

Stem

Stainless Steel

10

Yoke Bush

Ductile Iron

11

Gland Flange

Forged Carbon Steel

12

Packing Gland

Stainless Steel

13

Disc Nut

Carbon Steel

15

Handwheel Nut

Carbon Steel

19

Handwheel

Ductile Iron

21

Body Seat Ring

Carbon Steel + Stellite No.6

23

Back Seat Ring

Stainless Steel

31

Bonnet Bolt

Alloy Steel

33

Bonnet Nut

Carbon Steel

34

Gland Bolt

Carbon Steel

35

Gland Nut

Ductile Iron

36

Hinge Pin

Carbon Steel

42

Washer

Carbon Steel

51

Packing

Graphite + Carbon Fiber

56

Gasket*

(See Note*)

FIG.0122F

ASTM Specification

ASTM A216 Gr.WCB

ASTM A216 Gr.WCB

ASTM A217 CA15(*see note)

A276 410

A439 D2C

A105

A276 410

A276 410

A536B

A536

A105 + Stellite No.6

A276 410

A193 B7

A194 2H

A307 B

A563 B

A108 1020

A108 1020

P#6610 + #6528

(See Note*)

*Note: Disc: 10 & above A217 CA15. 12 & above-A216 Gr.WCB + 13Cr.

Gasket : Size 4 & below S.P.W.P#2600-EOO.

6 & above S.P.W. P#2601-ESO

DIMENSIONAL DATA (MM)

Size

2

2-1/2

3

4

6

8

10

12

Face-to-Face

Dia.of Bore

O.D.of Flange

of Bolt

Circle

O.D. of RF

Thk of Flange

Ht. of RF

L

266.7

292.1

317.5

355.6

444.5

558.8

622.3

711.2

d

50.8

63.5

76.2

101.6

152.4

203.2

254.0

304.8

D

165.1

190.5

209.6

254.0

317.5

381.0

444.5

520.7

C

127.0

149.4

168.1

200.2

269.7

330.2

387.4

450.9

g

91.9

104.6

127.0

157.2

215.9

269.7

323.9

381.0

t

22.2

25.4

28.5

31.8

36.6

41.2

47.8

50.8

f

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

Non-shock pressure rating: 740 PSIG@-200F to 1000F per ANSI B16.34

10

of Bolt

Holes

n-h

8-19.1

8-22.2

8-22.2

8-22.2

8-22.2

12-25.4

16-28.4

16-31.8

of

Handwheel

O

200

250

300

350

430

560

630

630

Height

Wall Thk

H

388

400

462

510

695

800

930

965

a min

9.7

11.2

11.9

12.7

16.0

17.5

19.1

20.6

Wt (kg)

35.0

48.5

61.0

71.6

161.9

232.0

381.0

664.0

CAST STEEL GLOBE VALVES ANSI 600

SPECIFICATION

Bolted Bonnet

Outside Screw and Yoke

Yoke intergral with bonnet

Rising Stem Handwheel

Welded-In/Threaded Seat Rings

Full Port

Raised Face Flanged Ends or Buttwelding Ends

Gear Operated recommended for size 4 above

APPLICABLE STANDARDS

Design: ANSI B16.34

End Flange : ANSI B16.5

Weld Ends : ANSI B16.25

Face-to-Face: ANSI B16.10

Shell and Seat Test: API 598

PARTS AND MATERIAL LIST

No. Part Name

Material

01

Body

Carbon Steel

02

Bonnet

Carbon Steel

04

Disc*

Carbon Steel

07

Stem

Stainless Steel

10

Yoke Bush

Ductile Iron

11

Gland Flange

Forged Carbon Steel

12

Packing Gland

Stainless Steel

13

Disc Nut

Carbon Steel

15

Handwheel Nut

Carbon Steel

19

Handwheel

Ductile Iron

21

Body Seat Ring

Carbon Steel + Stellite No.6

23

Back Seat Ring

Stainless Steel

31

Bonnet Bolt

Alloy Steel

33

Bonnet Nut

Carbon Steel

34

Gland Bolt

Carbon Steel

35

Gland Nut

Ductile Iron

36

Hinge Pin

Carbon Steel

42

Washer

Carbon Steel

51

Packing

Graphite + Carbon Fiber

56

Gasket

S.P.W SS304/Graphite

FIG.0122F

ASTM Specification

ASTM A216 Gr.WCB

ASTM A216 Gr.WCB

ASTM A217 CA15(*see note)

A276 410

A439 D2C

A105

A276 410

A276 410

A536B

A536

A105 + Stellite No.6

A276 410

A193 B7

A194 2H

A307 B

A563 B

A108 1020

A108 1020

P#6610 + #6528

P#2601-ESO

*Note: Disc: 6 & above A217 CA15. 8 & above-A216 Gr.WCB + 13Cr.

DIMENSIONAL DATA (MM)

Size

2

3

4

6

8

10

12

Face-to-Face

Dia.of Bore

O.D.of Flange

of Bolt

Circle

O.D. of RF

Thk of Flange

Ht. of RF

L

292.1

355.6

431.8

558.8

660.4

787.4

838.2

d

50.8

76.2

101.6

152.4

199.9

247.7

298.5

D

165.1

209.6

273.1

355.6

419.1

508.0

558.8

C

127.0

168.1

215.9

292.1

349.3

431.8

489.0

g

91.9

127.0

157.2

215.9

269.7

323.9

381.0

t

25.4

31.8

38.1

47.8

55.7

63.5

66.6

f

6.4

6.4

6.4

6.4

6.4

6.4

6.4

Non-shock pressure rating: 1480 PSIG@-200F to 1000F per ANSI B16.34

11

of Bolt

Holes

n-h

8-19.1

8-22.2

8-25.4

12-28.4

12-31.8

16-35.1

20-35.1

of

Handwheel

O

250

300

350

500

560

630

710

Height

H

392

478

530

675

721

972

1074

Wall Thk

a min

11.2

12.7

16.0

19.1

25.4

28.7

31.8

Wt (kg)

43.5

74.0

107.0

240.0

400.0

692.0

907.6

CAST STEEL GLOBE VALVES ANSI 900

SPECIFICATION

Bolted Bonnet

Outside Screw and Yoke

Yoke intergral with bonnet

Rising Stem Non-rising Handwheel

Welded-In/Threaded Seat Rings

Full Port

Raised Face Flanged Ends or Buttwelding Ends

Or Ring Joint Flanged Ends

Gear Operated recommended for size 3 above

PARTS AND MATERIAL LIST

No.

Part Name

01

Body

02

Bonnet

04

Disc

07

Stem

09

Yoke Sleeve

10

Yoke Bush

11

Gland Flange

12

Packing Gland

13

Disc Nut

14

Yoke Cap

15

Handwheel Nut

19

Handwheel *

29

Back Seat Ring

31

Bonnet Bolt

33

Bonnet Nut

34

Gland Bolt

35

Gland Nut

36

Hinge Pin

38

Guide Key

42

Washer

46

Guide Key

46A

Hammer Blow Key

49

Snap Ring

51

Packing

56

Gasket

73

Thrust Bearing

76*

Packing Washer(*see note)

B1

Hammer Blow

APPLICABLE STANDARDS

Design: ANSI B16.34

End Flange : ANSI B16.5

Weld Ends : ANSI B16.25

Face-to-Face: ANSI B16.10

Shell and Seat Test: API 598

Material

Carbon Steel

Carbon Steel

Carbon Steel

Stainless Steel

Ductile Iron

Ductile Iron

Forged Carbon Steel

Stainless Steel

Carbon Steel

Carbon Steel

Carbon Steel

Ductile Iron

Stainless Steel

Alloy Steel

Carbon Steel

Carbon Steel

Ductile Iron

Carbon Steel

Carbon Steel

Carbon Steel

Carbon Steel

Carbon Steel

Carbon Steel Chrome Plated

Graphite + Carbon Fiber

Ring Joint Gasket

Steel

Carbon Steel

Carbon Steel

FIG.0922F

ASTM Specification

ASTM A216 Gr.WCB

ASTM A216 Gr.WCB

ASTM A217 CA15

A276 410

A439 D2C

A439 D2C

A105

A276 410

A276 410

A108 1020

A536 B

A536 (*see note)

A276 410

A193 B7

A194 2H

A307 B

A563 B

A108 1020

A108 1045

A108 1020

A108 1045

A108 1045

SK5 + Cr. Plated

P#6610 + #6528

P#1500S

Steel

A276 410

ASTM A216 Gr.WCB

*Note: Handwheel : Size 6 above A216WCB

Item 76: Size 6 and below Spacer: A53 Type E(SS400)

DIMENSIONAL DATA (MM)

Size

Face-to-Face

Dia.of Bore

O.D.of Flange

of Bolt

Circle

O.D. OF RF

Thk of Flange

Ht. Of RF

L

d

D

C

g

t

f

2

368.3

47.5

215.9

165.1

91.9

38.1

6.4

3

381.0

72.9

241.3

190.5

127.0

38.1

6.4

4

457.2

98.3

292.1

235.0

157.2

44.5

6.4

6

609.6

146.1

381.0

317.5

215.9

55.7

6.4

8

736.6

190.5

469.9

393.7

269.7

63.5

6.4

Non-shock pressure rating: 2220 PSIG@-200F to 1000F per ANSI B16.34

12

of Bolt

Holes

n-h

8-25.4

8-25.4

8-31.8

12-31.8

12-38.1

of

Handwheel

O

350

430

450

450

750

Height

H

509

682

738

870

1227

Wall Thk

a min

19.1

19.1

21.3

26.2

31.8

Wt (kg)

120.0

132.0

209.0

503.6

903.0

CAST STEEL GLOBE VALVES ANSI 1500

SPECIFICATION

Bolted Bonnet

Outside Screw and Yoke

Yoke intergral with bonnet

Rising Stem Non-rising Handwheel

Welded-In/Threaded Seat Rings

Full Port

Raised Face Flanged Ends or Buttwelding Ends

Or Ring Joint Flanged Ends

Gear Operated recommended for size 2 above

APPLICABLE STANDARDS

Design: ANSI B16.34

End Flange : ANSI B16.5

Weld Ends : ANSI B16.25

Face-to-Face: ANSI B16.10

Shell and Seat Test: API 598

PARTS AND MATERIAL LIST

No.

Part Name

Material

01

Body

Carbon Steel

02

Bonnet

Carbon Steel

04

Disc

Carbon Steel

07

Stem

Stainless Steel

10

Yoke Bush

Ductile Iron

11

Gland Flange

Forged Carbon Steel

12

Packing Gland

Stainless Steel

13

Disc Nut

Carbon Steel

14

Yoke Cap

Carbon Steel

15

Handwheel Nut

Carbon Steel

19

Handwheel *

Carbon Steel

31

Bonnet Bolt

Alloy Steel

33

Bonnet Nut

Carbon Steel

34

Gland Bolt

Carbon Steel

35

Gland Nut

Ductile Iron

36

Hinge Pin

Carbon Steel

38

Guide

Carbon Steel

42

Washer

Carbon Steel

46

Guide Key

Carbon Steel

46A

Hammer Blow Key Carbon Steel

49

Snap Ring

Carbon Steel Chrome Plated

51

Packing

Graphite + Carbon Fiber

56

Gasket

Ring Joint Gasket

73

Thrust Bearing

Steel

76

Packing Washer

Carbon Steel

B1

Hammer Blow

Carbon Steel

FIG.1522F

ASTM Specification

ASTM A216 Gr.WCB

ASTM A216 Gr.WCB

ASTM A217 CA15

A276 410

A439 D2C

A105

A276 410

A276 410

A108 1020

A536 B

ASTM A216 Gr.WCB

A193 B7

A194 2H

A307 B

A563 B

A108 1020

A108 1045

A108 1020

A108 1045

A108 1045

SK5 + Cr. Plated

P#6610 + #6528

P#1500S

Steel

A276 410

ASTM A216 Gr.WCB

DIMENSIONAL DATA (MM)

Size

Face-to-Face

Dia.of Bore

O.D.of Flange

of Bolt

Circle

O.D. OF RF

Thk of Flange

Ht. Of RF

L

d

D

C

g

t

f

2

368.3

47.5

215.9

165.1

91.9

38.1

6.4

2-1/2

419.1

57.2

244.3

190.5

104.6

41.2

6.4

3

469.9

69.9

266.7

203.2

127.0

47.8

6.4

4

546.1

91.9

311.2

241.3

157.2

53.8

6.4

6

704.9

136.4

393.7

317.5

215.9

82.6

6.4

Non-shock pressure rating: 2220 PSIG@-200F to 1000F per ANSI B16.34

13

of Bolt

Holes

n-h

8-25.4

8-28.4

8-31.8

8-34.9

12-38.1

of

Handwheel

O

350

300

400

450

600

Height

H

537

633

615

689

1048

Wall Thk

a min

19.1

22.4

23.9

28.7

38.1

Wt (kg)

131.6

176.9

249.4

354.0

721.0

CAST STEEL SWING CHECK VALVES ANSI 300

KVC Swing Check Valves are manufactured to BS1868, API Std.6D and API Std.600, and tested to

API Std.598.

Swing check valves are used to prevent flow reversal in piping systems. They are suitable for service in horizontal or vertical

(flow up through valve only) piping runs. Swing check valves have low pressure drop and are best suited for moderated velocity

applications.

BODY

Its spherical form of large radius allow for the stresses, turbulence and resistance to flaw to be kept to a minimum.

BODY-BONNET JOINTS

Body-Bonnet Joints of check valves are machined as follows:

on 150 and 300 classes : male and female

on 600, 900 and 1500 classes: RTJ

SEAT RINGS

Seat rings are manufactured in two different ways, depending on the type of valves:

1) Screwed seat rings, bottom seated type lapped on both sides. They are dry assembled, with a controlled torque setting to the

body.

2) Welded-in seat rings, designed, in order to prevent any turbulence and avoid damages due to corrosion. Both are forged or

roiled in one piece, for all dimensions. They are heat treated to obtain the requested surface hardness, and are perfectly

cleaned before assembling.

END CONNECTIONS

Our standard production covers valves with:

Flanged ends (RF) that conform to ANSI B16.5 and face to face dimensions that conform to ANSI B16.10, with a raised face

serrated finish or, on request, with any other type of finish;

Butt-welding ends (BW) with end to end dimensions that conform to ANSI B16.10 Customer must

specify the type of schedule required, or class of pipe, or diameter and bore.

Ring joint flanged ends (RTJ) that conform to ANSI B16.5, with end to end dimensions to ANSI B16.10

Other special end connections are supplied to customers' special requirements.

14

CAST STEEL SWING CHECK VALVES ANSI 300

SPECIFICATION

Bolted Cover

For Horizontal or Vertical Lines (Up Flow Only)

Welded or Threaded Seat Ring

Full Port

Raised Face Flanged Ends or Buttwelding Ends

APPLICABLE STANDARDS

Design: ANSI B16.34

End Flange : ANSI B16.5

Weld Ends : ANSI B16.25

Face-to-Face: ANSI B16.10

Shell and Seat Test: API 598

PARTS AND MATERIAL LIST

FIG.0132F

No. Part Name

Material

ASTM Specification

01

Body

Carbon Steel

ASTM A216 Gr.WCB

02

Cover

ASTM A216 Gr.WCB

Carbon Steel

04

Disc *

ASTM A217 CA15 (*see note)

Carbon Steel

16

Arm

Carbon Steel

ASTM A216 Gr.WCB

21

Body Seat Ring

Carbon Steel + Stellite No.6

A105 + Stellite No.6

24

Plug Bolt

Carbon Steel

A108 1020

27

Pin

Stainless Steel

A276 410

31

Cover Bolt

Alloy Steel

A193 B7

33

Cover Nut

Carbon Steel

A194 2H

35

Disc Nut

Ductile Iron

A563 B

42

Washer

Carbon Steel

A108 1020

48

Eye Bolt (6 & above)

Carbon Steel

A108 1020

56

Gasket *

(*See Note)

(*See Note)

* Note: Disc: 12 & below A217 CA15. 14 & above A216 Gr.WCB + 12Cr

Gasket : Size 12 & below Graphite Sheet P#6633. 14 & above-S.P.W P#2601-ESO

DIMENSI DIMENSIONAL DATA (mm)ONAL DATA (mm) DIMENSIONAL DATA (mm) DIMENSIONAL DATA (m

DIMENSIONAL DATA (mm)

Size

2

2-1/2

3

4

6

8

10

12

14

16

18

20

24

Face-to-Face

L

203.2

215.9

241.3

292.1

355.6

495.3

622.3

698.5

787.4

863.6

977.9

977.9

1295.4

Dia.of Bore

O.D.of Flange

of Bolt

Circle

d

50.8

63.5

76.2

101.6

152.4

203.2

254.0

304.8

336.6

387.4

438.2

489.0

590.6

D

152.4

177.8

190.5

228.6

279.4

342.9

406.4

482.6

533.4

596.9

635.0

698.5

812.8

C

120.7

139.7

152.4

190.5

241.3

298.5

362.0

431.8

476.3

539.8

577.9

635.0

749.3

O.D. OF RF

g

91.9

104.6

127.0

157.2

215.9

269.7

323.9

381.0

412.8

469.9

533.4

584.2

692.2

Thk of Flange Ht. Of RF

t

15.8

17.6

19.1

23.9

25.4

28.5

30.3

31.8

35.1

36.6

39.7

43.0

47.8

Non-shock pressure rating: 285 PSIG@-200F to 1000F per ANSI B16.34

15

f

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

of Bolt Holes

n-h

4-19.1

4-19.1

4-19.1

8-19.1

8-22.4

8-22.4

12-25.4

12-25.4

12-28.4

16-28.4

16-31.8

20-31.8

20-35.1

Height

Wall Thk

H

156

158

186

218

240

279

315

355

376

402

512

597

651

a min

8.6

9.7

10.4

11.2

11.9

12.7

14.2

16.0

16.8

17.5

18.3

19.1

20.6

Wt (kg)

17.5

21.3

28.3

50.0

70.0

148.8

222.0

318.4

442.7

573.0

710.0

892.0

1576.0

CAST STEEL SWING CHECK VALVES ANSI 300

SPECIFICATION

Bolted Cover

For Horizontal or Vertical Lines (Up Flow Only)

Welded or Threaded Seat Ring

Full Port

Raised Face Flanged Ends or Buttwelding Ends

APPLICABLE STANDARDS

Design: ANSI B16.34

End Flange : ANSI B16.5

Weld Ends : ANSI B16.25

Face-to-Face: ANSI B16.10

Shell and Seat Test: API 598

PARTS AND MATERIAL LIST

FIG.0132F

No. Part Name

Material

ASTM Specification

01

Body

Carbon Steel

ASTM A216 Gr.WCB

02

Cover

ASTM A216 Gr.WCB

Carbon Steel

04

Disc *

ASTM A217 CA15 (*see note)

Carbon Steel

16

Arm

Carbon Steel

ASTM A216 Gr.WCB

21

Body Seat Ring

Carbon Steel + Stellite No.6

A105 + Stellite No.6

24

Plug Bolt

Carbon Steel

A108 1020

27

Pin

Stainless Steel

A276 410

31

Cover Bolt

Alloy Steel

A193 B7

33

Cover Nut

Carbon Steel

A194 2H

35

Disc Nut

Ductile Iron

A563 B

42

Washer

Carbon Steel

A108 1020

48

Eye Bolt (6 & above)

Carbon Steel

A108 1020

56

Gasket *

(*See Note)

(*See Note)

* Note: Disc: 12 & below A217 CA15. 14 & above A216 Gr.WCB + 13Cr

Gasket : Size 4 & below S.P.W.P#2600. 6 & above-S.P.W P#2601-ESO

DIMENSIONAL DATA (mm)

Size

2

2-1/2

3

4

6

8

10

12

14

16

18

20

24

Face-to-Face

L

266.7

292.1

317.5

355.6

444.5

533.4

622.3

711.2

838.2

663.5

977.9

1018.0

1346.2

Dia.of Bore

O.D.of Flange

of Bolt

Circle

d

50.8

63.5

76.2

101.6

152.4

203.2

254.0

304.8

336.6

387.4

431.8

482.6

564.2

D

165.1

190.5

209.6

254.0

317.5

381.0

444.5

520.7

584.2

647.7

711.2

774.7

914.4

C

127.0

149.4

168.1

200.2

269.7

330.2

387.4

450.9

514.4

571.5

628.7

665.8

812.6

O.D. OF

RF

Thk of Flange

g

91.9

104.6

127.0

157.2

215.9

269.7

323.9

381.0

412.8

469.9

533.4

584.2

692.2

t

22.2

25.4

28.5

31.8

36.6

41.2

47.8

50.8

53.9

57.2

60.5

63.5

69.9

Non-shock pressure rating: 740 PSIG@-200F to 1000F per ANSI B16.34

16

Ht. Of RF

f

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

of Bolt

Holes

n-h

8-19.1

8-22.2

8-22.2

8-22.2

8-22.2

12-25.4

16-28.4

16-31.8

20-31.8

20-35.1

24-35.1

24-35.1

24-41.2

Height

Wall Thk

H

172

194

213

251

285

330

360

390

423

460

550

650

820

a min

9.7

11.2

11.9

12.7

16.0

17.5

19.1

20.6

22.4

23.9

25.4

28.9

30.2

Wt (kg)

25.4

34.0

39.0

63.0

106.0

184.0

275.8

441.0

721.0

902.6

1002.4

1183.0

1941.0

CAST STEEL SWING CHECK VALVES ANSI 600

SPECIFICATION

Bolted Cover

For Horizontal or Vertical Lines (Up Flow Only)

Welded or Threaded Seat Ring

Full Port

Raised Face Flanged Ends or Buttwelding Ends

APPLICABLE STANDARDS

Design: ANSI B16.34

End Flange : ANSI B16.5

Weld Ends : ANSI B16.25

Face-to-Face: ANSI B16.10

Shell and Seat Test: API 598

PARTS AND MATERIAL LIST

FIG.0132F

No. Part Name

Material

ASTM Specification

01

Body

Carbon Steel

ASTM A216 Gr.WCB

02

Cover

ASTM A216 Gr.WCB

Carbon Steel

04

Disc *

ASTM A217 CA15 (*see note)

Carbon Steel

16

Arm

Carbon Steel

ASTM A216 Gr.WCB

21

Body Seat Ring

Carbon Steel + Stellite No.6

A105 + Stellite No.6

24

Plug Bolt

Carbon Steel

A108 1020

27

Pin

Stainless Steel

A276 410

31

Cover Bolt

Alloy Steel

A193 B7

33

Cover Nut

Carbon Steel

A194 2H

35

Disc nut

Ductile Iron

A563 B

42

Washer

Carbon Steel

A108 1020

48

Eye Bolt (4 & above) Carbon Steel

A108 1020

56

Gasket

S.P.W SS304/Graphite

P#2601-ESO

* Note: Disc: 12 & below A217 CA15. 14 & above A216 Gr.WCB + 13Cr

DIMENSIONAL DATA (mm)

Size

2

3

4

6

8

10

12

14

16

Face-to-Face

L

292.1

355.6

431.8

558.8

660.4

787.4

838.2

889.0

990.6

Dia.of Bore

O.D.of Flange

of Bolt

Circle

d

50.8

76.2

101.6

152.4

199.9

247.7

298.5

326.9

374.7

D

165.1

209.6

273.1

355.6

419.1

508.0

558.8

603.3

685.8

C

127.0

168.1

215.9

292.1

349.3

431.8

489.0

527.1

603.3

O.D. OF

RF

g

91.9

127.0

157.2

215.9

269.7

323.9

381.0

412.8

469.8

Thk of Flange

t

25.4

31.8

38.1

47.8

55.7

63.5

66.6

69.9

76.2

Non-shock pressure rating: 1480 PSIG@-200F to 1000F per ANSI B16.34

17

Ht. Of RF

f

6.4

6.4

6.4

6.4

6.4

6.4

6.4

6.4

6.4

of Bolt

Holes

n-h

8-19.1

8-22.2

8-25.4

12-28.4

12-31.8

16-35.1

20-35.1

20-38.1

20-41.2

Height

Wall Thk

H

187

210

256

329

363

464

486

572

680

a min

11.2

12.7

16.0

19.1

25.4

28.7

31.8

35.1

38.1

Wt (kg)

35.3

66.7

111.0

220.0

385.0

600.0

780.0

1364.0

1769.0

CAST STEEL SWING CHECK VALVES ANSI 900

SPECIFICATION

Bolted Cover

For Horizontal or Vertical Lines (Up Flow Only)

Welded or Threaded Seat Ring

Full Port

Raised Face Flanged Ends or Buttwelding Ends

Or Ring Joint Flanged Ends

PARTS AND MATERIAL LIST

No. Part Name

Material

01

Body

Carbon Steel

02

Cover

Carbon Steel

04

Disc

Carbon Steel

16

Arm

Carbon Steel

21

Body Seat Ring

Carbon Steel + Stellite No.6

24

Plug Bolt

Carbon Steel

25

Plug Gasket

Graphite + Carbon Fibre

27

Pin

Stainless Steel

31

Cover Bolt

Alloy Steel

33

Cover Nut

Carbon Steel

35

Disc nut

Ductile Iron

42

Washer

Carbon Steel

42A Plug Washer

Carbon Steel

48

Eye Bolt (4 & above) Carbon Steel

56

Gasket

S.P.W SS304/Graphite

APPLICABLE STANDARDS

Design: ANSI B16.34

End Flange : ANSI B16.5

Weld Ends : ANSI B16.25

Face-to-Face: ANSI B16.10

Shell and Seat Test: API 598

FIG.0932F

ASTM Specification

ASTM A216 Gr.WCB

ASTM A216 Gr.WCB

ASTM A217 CA15

ASTM A216 Gr.WCB

A105 + Stellite No.6

A108 1020

P#6610

A276 410

A193 B7

A194 2H

A563 B

A108 1020

A108 1020

A108 1020

P#1500S

DIMENSIONAL DATA (mm)

Size

2

3

4

6

8

10

Face-to-Face

L

368.3

381.0

457.2

609.6

736.6

836.2

Dia.of Bore

O.D.of Flange

of Bolt

Circle

d

47.5

72.9

98.3

146.1

190.5

236.0

D

215.9

241.3

292.1

381.0

469.9

546.1

C

165.1

190.5

235.0

317.5

393.7

469.0

O.D. OF

RF

g

91.9

127.0

157.2

215.9

269.7

323.9

Thk of Flange

Ht. Of RF

t

38.1

38.1

44.5

55.7

63.5

69.9

Non-shock pressure rating: 2220 PSIG@-200F to 1000F per ANSI B16.34

18

f

6.4

6.4

6.4

6.4

6.4

6.4

of Bolt

Holes

n-h

8-25.4

8-25.4

8-31.8

12-31.8

12-38.1

18-38.1

Height

Wall Thk

H

223

255

295

345

415

550

a min

19.1

19.1

21.3

26.2

31.8

36.6

Wt (kg)

78.0

88.5

181.4

313.0

467.0

1150.0

CAST STEEL SWING CHECK VALVES ANSI 1500

SPECIFICATION

Bolted Cover

For Horizontal or Vertical Lines (Up Flow Only)

Welded or Threaded Seat Ring

Full Port

Raised Face Flanged Ends or Buttwelding Ends

Or Ring Joint Ends

PARTS AND MATERIAL LIST

No. Part Name

Material

01

Body

Carbon Steel

02

Cover

Carbon Steel

04

Disc

Carbon Steel

16

Arm

Carbon Steel

21

Body Seat Ring

Carbon Steel + Stellite No.6

24

Plug Bolt

Carbon Steel

25

Plug Gasket

Graphite + Carbon Fibre

27

Pin

Stainless Steel

31

Cover Bolt

Alloy Steel

33

Cover Nut

Carbon Steel

35

Disc nut

Ductile Iron

42

Washer

Carbon Steel

42A Plug Washer

Carbon Steel

48

Eye Bolt (6 & above) Carbon Steel

56

Gasket

Ring Joint Gasket

APPLICABLE STANDARDS

Design: ANSI B16.34

End Flange : ANSI B16.5

Weld Ends : ANSI B16.25

Face-to-Face: ANSI B16.10

Shell and Seat Test: API 598

FIG.1532F

ASTM Specification

ASTM A216 Gr.WCB

ASTM A216 Gr.WCB

ASTM A217 CA15

ASTM A216 Gr.WCB

A105 + Stellite No.6

A108 1020

P#6610

A276 410

A193 B7

A194 2H

A563 B

A108 1020

A108 1020

A108 1020

P#1500S

DIMENSIONAL DATA (mm)

Size

2

2-1/2

3

4

6

8

10

Face-to-Face

L

368.3

419.1

469.9

546.1

704.9

831.9

990.6

Dia.of Bore

O.D.of Flange

of Bolt

Circle

d

47.5

57.2

69.9

91.9

136.4

177.8

222.3

D

215.9

244.3

266.7

311.2

393.7

482.6

584.2

C

165.1

190.5

203.2

241.3

317.5

393.7

482.6

O.D. OF

RF

g

91.9

104.6

127.0

157.2

215.9

269.7

323.9

Thk of Flange

Ht. Of RF

t

38.1

41.2

47.8

53.8

82.6

91.9

108.0

Non-shock pressure rating: 3705 PSIG@-200F to 1000F per ANSI B16.34

19

f

6.4

6.4

6.4

6.4

6.4

6.4

6.4

of Bolt

Holes

n-h

8-25.4

8-28.4

8-31.8

8-34.9

12-38.1

12-44.5

12-50.8

Height

Wall Thk

H

223

265

325

350

370

405

435

a min

19.1

22.4

23.9

28.7

38.1

47.8

57.2

Wt (kg)

122.4

167.8

195.0

290.3

430.9

675.8

1850.0

WELDING END DETAILS

ELECTRICALLY OPERATED VALVES

For production of an electrically operated valve (motor

operated valve), specifications such as listed below are

required :

1.

2.

3.

4.

5.

Type or model number of motor.

Type of construction : water-proof or explosion-proof

Type of manual operating device.

Open/close operating device.

Power source.

(for motor; voltage, Hz, 3-phase)

(for control; voltage, Hz, single-phase)

A. Type of valve.

B. Primary fluid pressure: kg f/cm2 max.

C. Differential pressure of a closed valve : kg f/cm2 max.

D. Fluid temperature: C max.

E. Atmospheric temperature: C max.

GEAR OPERATED VALVES

For production of a gear operated valve, specifications

such as listed below are required :

1.

2.

3.

4.

5.

6.

Size and figure number of valve.

Service media, Pressure and Temperature.

Max. pressure against which valve must close.

Any handwheel torque or rim-pull limitation.

Limitations, if any on the type or brand of actuator.

Other

20

WELDING END DETAILS

COMPOUND BEVEL

Connection Pipe Wall Thickness

Larger than 7/8 size

A

B

C

PLAIN BEVEL

Connection Pipe Wall Thickness

7/8 ans smaller size

= Outside diameter of matching pipe, wrought or fabricated component

= Nominal inside diameter

= Min. wall thickness

A Dimensions reference to ANSI B16.25

B Dimensions reference to ANSI B36.10

Valve

nominal

size

Tolerence

on A(mm)

Tolerence

on B(mm)

mm

15

20

25

40

50

65

80

100

150

200

250

300

350

400

450

500

600

in

1/2

3/4

1-1/2

2-1/2

10

12

14

16

18

20

24

+0

-0.8

0.8

1.6

21

3.2

-1.6

REFERENCE STANDARDS AND SPECIFICATION

RING JOINT CONNECTION BETWEEN BODY AND BONNET/COVER

GATE VALVES

SIZE

2

2-1/2

3

4

6

8

10

12

14

16

P

136.5

161.9

149.2

211.1

235.0

323.9

-

E

7.9

7.9

7.9

7.9

7.9

7.9

-

CLASS 900

F

11.9

11.9

11.9

11.9

11.9

11.9

-

E

7.9

7.9

7.9

7.9

7.9

-

CLASS 900

F

11.9

11.9

11.9

11.9

11.9

-

RING No

R35

R39

R37

R45

R99

R53

-

P

136.5

161.9

161.9

193.7

269.9

381.0

-

CLASS 1500

E

F

7.9

11.9

7.9

11.9

7.9

11.9

7.9

11.9

11.1

16.7

14.3

23.0

-

Ring No

R35

R39

R39

R44

R50

R58

-

CLASS 1500

E

F

7.9

11.9

7.9

11.9

7.9

11.9

11.1

16.7

-

Ring No

R30

R39

R44

R50

-

CLASS 1500

F

11.9

11.9

11.9

11.9

16.7

16.7

-

Ring No

R30

R35

R35

R44

R50

R54

-

GATE VALVES

SIZE

2

3

4

6

8

10

12

P

117.5

136.5

193.7

269.9

323.9

-

RING No

R30

R35

R44

R49

R53

-

P

117.5

161.9

193.7

269.9

-

SWING CHECK VALVES

SIZE

2

3

4

6

8

10

12

P

11.7.5

136.5

181.0

269.9

323.7

-

E

7.9

7.9

7.9

7.9

7.9

-

CLASS 900

F

11.9

11.9

11.9

11.9

11.9

-

RING No

R30

R41

R41

R49

R53

-

22

P

117.5

136.5

136.5

193.7

269.9

323.8

-

E

7.9

7.9

7.9

7.9

11.1

11.1

-

REFERENCE STANDARDS AND SPECIFICATION

KVC

valves are offered to meet the following Codes and Standards : Valves to BS Standard

DIN Standard as well as GOST Standard are available upon request.

ANSI STANDARDS - AMERICAN NATIONAL STANDARDS INSTITUTE

B1.1

Unified Screw Threads Acme Screw Threads

B1.5

Acme Screw Threads

B1.8

Stub Acme Screw Threads

B1.12

Class 5 Interference - Fit Thread

B2.1

Pipe Threads (Except Dryseal)

B16.5

Steel Pipe Flanges, and Flanged Fittings

B16.10

Face-to-Face and End-to-End Dimensions of Ferrous Valves

B16.11

Forged Steel Fittings, Socket Welding and Threaded

B16.20

Ring-Joint Gaskets and Grooves for Steel Pipe Flanges

B16.21

B16.25

B16.34

B18.2.2

B31.1.0

B31.2

B31.3

B31.4

B31.5

B31.6

B31.7

B31.8

B36.10

Non-metallic Gaskets for Pipe Flanges

Buttwelding Ends

Steel Valves

Square and Hex Nuts

Power Piping

Fuel Gas Piping

Petroleum Refinery Piping

Liquid Petroleum Transportation Piping Systems Refrigeration

Refrigeration Piping Systems

Chemical Process Piping

Nuclear Power Piping

Gas Transmission and Distribution Piping Systems

Wrought-Steel and Wrought-Iron Pipe

API STANDARDS - AMERICAN PETROLEUM INSTITUTE

6A

Specification for Wellhead Equipment

6D