Escolar Documentos

Profissional Documentos

Cultura Documentos

102 Encoder Checkingchanging of Drive Motor

Enviado por

onrabiDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

102 Encoder Checkingchanging of Drive Motor

Enviado por

onrabiDireitos autorais:

Formatos disponíveis

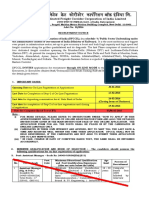

STANDARD OPERATING PROCEDURES

Form No. : EHSMSM

SOP No:01.04.2009 MUE/CRMBE / PL/102

date:

Form Rev. No. : 00

Effective Date

Section

Page

Responsibility (WHO)

SOP DESC

DEPARTMENT

Step No.

Effective

01.11.2011

REVISION No

00

PICKLING

01 Of 02

Process / tools / PPEs

Remarks / Reference

(HOW)

ENCODER CHECKING/CHANGING OF DRIVE MOTOR

MILLS & UTILITIES ELECRICAL MAINTENANCE

Activity

Associated

(WHAT)

Requirements/Hazards/Impa

cts

SAFETY: 1.use of all PPEs in good

1.1 Take working clearance from operation to work with particular motor drive.

If line is

condition.

1.2

Put

off

the

CFU/Isolator

of

that

drive

whose

encoder

is

to

be

checked/changed.

Running

Initial Preparation

IEM Persons

1.3 Apply positive isolation lock.

ENVIRONMENT: NA

QUALITY:

SAFETY: Chances of short circuit

Test power supply and card damage

at encoder

With the help of multimeter 24 V DC power to be tested at the Encoder connection

IEM Persons During opening the connection ,care must taken to avoid short circuit or ground.

ENVIRONMENT: NA

QUALITY: Multimeter should be

tested before use.

SAFETY: Hand injury during

opening.

3

Opening the

Encoder

QUALITY: open the cables one by

one.

SAFETY: Hand injury during

opening

Fitting of new

Encoder

IEM Person

First open the all six cables connection with proper size small screw driver. Before

opening the connection NOTE DOWN CABLE FERRULE NUMBER AND TB

NUMBER to avoid wrong connection. Now loosen the Encoder, then open all

Encoder mounting bolts with size spanner. Now take out the Encoder from coupling

carefully. Dont use hammering.

Insert the new Encoder with shaft carefully. Dont press hard or hammer the

Encoder during inserting. If the Encoder shaft not going easily into the shaft then

IEM Persons clean the shaft with emery paper and then insert. If inserted successfully then tight

all foundation bolts properly. Tight the coupling properly. Now connect the cable to

the Encoder .

QUALITY: Connect the cables one

by one.

SAFETY: Object

Visually Check

Encoder alignment

ENVIRONMENT: NA

with shaft

QUALITY: NA

IEM Persons

5.1Check Tightness with respective shaft.

5.2 Tools & tackles(spanner ,screw driver)

SAFETY: Handle With Care

6

Check Encoder

Electrical

Connection

IEM Persons

ENVIRONMENT: NA

QUALITY: NA

SAFETY: Handle With Care

Confirmation of

Encoder

healthiness

6.1 Check all Electrical Connection with

Tightness on both side

Motor side & Drive Side( on Respective

RTAC Card )

6.2 Tools & tackles: screw driver.

7.1 Check The Value of Speed Reference &

Feedback Respectively on HMI. It Should match

IEM Persons

ENVIRONMENT: NA

QUALITY: NA

Job clearance

PREPARED BY

Name and Desig : Manoj

Signature with Date : 30.10.2011

8.1 Return The Job

Clearance.

APPROVED BY

Name and Designs : P.K.Singh (Manager)

Signature with Date: 30.10.2011

Você também pode gostar

- IEL Result 184 IEM Result 24 PM Result 8 SFT Result 3 03/03/2019 Result 219 Total Result 219Documento45 páginasIEL Result 184 IEM Result 24 PM Result 8 SFT Result 3 03/03/2019 Result 219 Total Result 219onrabiAinda não há avaliações

- Me 2009 Gate PaperDocumento13 páginasMe 2009 Gate PaperSudheer ReddyAinda não há avaliações

- Schematic DrawingDocumento11 páginasSchematic DrawingonrabiAinda não há avaliações

- Kau-08 Ele. Engg. - II Set-ADocumento38 páginasKau-08 Ele. Engg. - II Set-AonrabiAinda não há avaliações

- Me 2009 Gate PaperDocumento13 páginasMe 2009 Gate PaperSudheer ReddyAinda não há avaliações

- PME EM ScheduleDocumento27 páginasPME EM ScheduleonrabiAinda não há avaliações

- Profibus ConfigurationDocumento6 páginasProfibus ConfigurationonrabiAinda não há avaliações

- ReligionsDocumento27 páginasReligionsonrabiAinda não há avaliações

- Protocol For Instruments Taken Online (Secondary Dedusting)Documento16 páginasProtocol For Instruments Taken Online (Secondary Dedusting)onrabiAinda não há avaliações

- Https WWW - Ieindia.org ListmemDocumento1 páginaHttps WWW - Ieindia.org ListmemonrabiAinda não há avaliações

- New Microsoft Excel WorksheetDocumento2 páginasNew Microsoft Excel WorksheetonrabiAinda não há avaliações

- Dry Fly Ash Bin Weighing SystemDocumento15 páginasDry Fly Ash Bin Weighing SystemonrabiAinda não há avaliações

- 7346285Documento11 páginas7346285onrabiAinda não há avaliações

- Abb Arc ListDocumento145 páginasAbb Arc ListonrabiAinda não há avaliações

- MediclaimDocumento24 páginasMediclaimonrabiAinda não há avaliações

- 3RD MarchDocumento1 página3RD MarchonrabiAinda não há avaliações

- Incoming Feeder FROM:-Panel No # Cable ConnectedDocumento1 páginaIncoming Feeder FROM:-Panel No # Cable ConnectedonrabiAinda não há avaliações

- Question Booklet & Answer Key For The Recruitment Test of Production Manager (Kapurthala) Held On 11.8.2013Documento9 páginasQuestion Booklet & Answer Key For The Recruitment Test of Production Manager (Kapurthala) Held On 11.8.2013onrabiAinda não há avaliações

- Lecture7 Read PDFDocumento15 páginasLecture7 Read PDFonrabiAinda não há avaliações

- ResumeDocumento2 páginasResumeonrabiAinda não há avaliações

- OMR Sheet 50 Questions PDFDocumento1 páginaOMR Sheet 50 Questions PDFChinmoy Baruah57% (7)

- Mhs Scrap Report, Dec'14Documento191 páginasMhs Scrap Report, Dec'14onrabiAinda não há avaliações

- Scrap ReceivingDocumento6 páginasScrap ReceivingonrabiAinda não há avaliações

- DFCCILDocumento13 páginasDFCCILChetan SrivastavaAinda não há avaliações

- BillDesk Payment GatewayDocumento1 páginaBillDesk Payment GatewayonrabiAinda não há avaliações

- OMR Sheet 50 Questions PDFDocumento1 páginaOMR Sheet 50 Questions PDFChinmoy Baruah57% (7)

- Recruitment of Various Post ADVERTISEMENT NO. 2 - 2015 - EsttDocumento3 páginasRecruitment of Various Post ADVERTISEMENT NO. 2 - 2015 - EsttonrabiAinda não há avaliações

- Anb Can TranlateDocumento1 páginaAnb Can TranlateonrabiAinda não há avaliações

- SyllabusDocumento2 páginasSyllabusonrabiAinda não há avaliações

- DGFHGHGFHFHFHM Multiple Choice Questions Sph3u0bDocumento3 páginasDGFHGHGFHFHFHM Multiple Choice Questions Sph3u0bonrabiAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Cosmic ConspiracyDocumento100 páginasThe Cosmic ConspiracyJai Delos Santos100% (4)

- RMMDocumento12 páginasRMMRameshAinda não há avaliações

- Copper Alloy Pipe (Amendments/Supplements To Astm B 111) : Technical SpecificationDocumento7 páginasCopper Alloy Pipe (Amendments/Supplements To Astm B 111) : Technical SpecificationSalahuddin FarooquiAinda não há avaliações

- Office 365 Introduction and Technical OverviewDocumento55 páginasOffice 365 Introduction and Technical OverviewBruce AmigoAinda não há avaliações

- Propak EnglishDocumento26 páginasPropak EnglishForum PompieriiAinda não há avaliações

- Din 8743 PDFDocumento35 páginasDin 8743 PDFSanjeev Reddy Kasula100% (2)

- Expression of Interest For The Appointment of Architects: IIIT RaichurDocumento31 páginasExpression of Interest For The Appointment of Architects: IIIT Raichurdivyanshu33Ainda não há avaliações

- Heta BhavsarDocumento3 páginasHeta Bhavsarmiss_jyoti_kapoorAinda não há avaliações

- CAPA Flow Procedure PDFDocumento1 páginaCAPA Flow Procedure PDFrbagriAinda não há avaliações

- BoschHeft9 E 01 PDFDocumento42 páginasBoschHeft9 E 01 PDFdiegomilitojAinda não há avaliações

- List Spare PartDocumento6 páginasList Spare Parthr.setiawanAinda não há avaliações

- Purchase Order For Air Relief ValveDocumento1 páginaPurchase Order For Air Relief Valvecsdcw fqefqfAinda não há avaliações

- DN Iso 5817Documento13 páginasDN Iso 5817Phani Sridhar ChAinda não há avaliações

- 04-10X SALES PAGES - The Value Prism PDFDocumento4 páginas04-10X SALES PAGES - The Value Prism PDFDikesh ShahAinda não há avaliações

- New Process Qualification Check ListDocumento7 páginasNew Process Qualification Check Listccocos7182Ainda não há avaliações

- Process Change NotificationDocumento3 páginasProcess Change NotificationchinnathambijAinda não há avaliações

- Lab Report-Study of Different Types of Chip and Determination of Chip Reduction CoefficientDocumento7 páginasLab Report-Study of Different Types of Chip and Determination of Chip Reduction Coefficientসুবোধ বালক50% (2)

- IEC Motor ControlDocumento192 páginasIEC Motor ControlFlo MircaAinda não há avaliações

- SAEP-1150 Inspection Coverage On ProjectsDocumento55 páginasSAEP-1150 Inspection Coverage On ProjectsAbdul Rahim Shaikh100% (5)

- Sample PDFDocumento4 páginasSample PDFmohsin alamAinda não há avaliações

- CV - Sakthi.pDocumento3 páginasCV - Sakthi.pVenkatesh KumarAinda não há avaliações

- Email: Cell: Professional Summary: Vankineni Ruthvik 832-786-1687Documento4 páginasEmail: Cell: Professional Summary: Vankineni Ruthvik 832-786-1687Mohan SubramaniAinda não há avaliações

- Universiti Pendidikan Sultan Idris, 35900 Tanjong Malim Perak Darul Ridzuan - English Language 4 (BIU 3042)Documento8 páginasUniversiti Pendidikan Sultan Idris, 35900 Tanjong Malim Perak Darul Ridzuan - English Language 4 (BIU 3042)Nor Yuhanis Mohd SalamAinda não há avaliações

- Lenovo Cust Satisfaction ProjDocumento58 páginasLenovo Cust Satisfaction ProjShams S71% (7)

- Operations Research Paper SampleDocumento8 páginasOperations Research Paper SampleAngelicaBernardoAinda não há avaliações

- Lotus Sametime 3DDocumento23 páginasLotus Sametime 3DsvrbchaudhariAinda não há avaliações

- TIME VoBB Business - 0Documento6 páginasTIME VoBB Business - 0Afiq AsyrafAinda não há avaliações

- Customer Satisfaction Towards Yamaha Bike FZ, Ambattur, ChennaiDocumento7 páginasCustomer Satisfaction Towards Yamaha Bike FZ, Ambattur, ChennaiprojectseasyAinda não há avaliações

- Preguntas de Certificación ABAPDocumento61 páginasPreguntas de Certificación ABAPGabriel Gonzalez SalazarAinda não há avaliações

- Fire Safety Enforcement 2013Documento71 páginasFire Safety Enforcement 2013NewCorella FireStation0% (1)