Escolar Documentos

Profissional Documentos

Cultura Documentos

Opti Va Finishing Paint

Enviado por

posta2014Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Opti Va Finishing Paint

Enviado por

posta2014Direitos autorais:

Formatos disponíveis

OPTIVA FINISHING PAINT

DESCRIPTION

EXAMPLES OF USE

DATA SHEET 01.01.2008

1 (2)

Semi-matt, low odour acrylic paint for use on interior substrates. Optiva

Finishing Paint can be used on a wide range of interior surfaces, and dries

to an attractive semi-matt finish which is hard wearing and easily cleaned.

Optiva Finishing paint will resist cleaning detergents and weak solvents.

Interior wood, paneling, doors, furniture, walls, MDF, etc. Optiva Finishing

Paint can be used on primed metal and for repainting interior surfaces

previously coated with waterborne, alkyd or acid- catalyzed paints.

TECHNICAL DATA

Density: 1.23 g/cm3

Scrub Resistance: > 3000 cycles (DIN 53778)

Chemical Resistance: Good

Finish: semi-matt

Base paints: A and C

Colour Range

Available in white and the complete Optiva Colour Collection. Plus British

Standard RAL and NCS colour ranges.

SPECIFICATIONS

Preparation

Surfaces must be clean, dry and free from grease, dirt, oil, wax, rust, all

loose material and surface contamination. Use recommended products for

mould removal and cleaning. Treat knots and resinous areas with Knotting

Lacquer. Use suitable fillers for filling cracks, nail holes, blemishes, etc.,

and leveling of uneven surfaces. Ensure that existing glossy, gloss painted

and filled surfaces are thoroughly flatted down. Ensure that all surfaces are

thoroughly prepared prior to priming and painting.

Priming

Prime bare interior wood overall and, if necessary, spot prime all bare areas

on previously painted surfaces with Optiva Finishing Paint thinned by 5%

with water. Optiva Primer Undercoat is preferable as a primer on wood that

contains substances which may bleed through and cause staining to the

finished surface. Prime all bare metal and potential rust spots with Optiva

Metal Primer.

Methods: Brush, roller or spray.

Thinning: If necessary by up to 5% with water.

APPLICATION

Painting Conditions

Painting

Coverage

All surfaces to be painted must be dry, the moisture content of the wood

below 20%, the temperature of the air at least +8OC, and the relative

humidity of the air below 80%.

Stir the paint thoroughly and apply two coats of Optiva Finishing Paint

overall.

8-10m2/litre per coat. Wet film thickness approximately 100-125 m per coat,

dry film approximately 40- 50 m per coat. The above should only be used

as a guide, as actual spreading rates will depend upon many factors

including texture, porosity and application method.

Manufacturer: TIKKURILA POLSKA S.A., ul: Mo cickiego 23, 39- 200 D bica, POLAND tel: + 48 14 680 56 00

OPTIVA FINISHING PAINT

Drying Times

Cleaning of Tools

DATA SHEET 01.01.2008

2 (2)

At 23OC and 50% relative humidity of the air: touch-dry in 1 hour and

recoatable after 16 hours. Final hardness will be achieved after 7 days. Low

temperature and high humidity will make drying times longer.

Clean with water immediately after use.

ENVIRONMENTAL

Empty cans and liquid waste should be recycled or disposed of in

accordance with local regulations.

HEALTH AND SAFETY

A Material Safety Data Sheet is available on request.

STORAGE AND

TRANSPORT

Protect from frost.

The above information, based on laboratory tests and practical experience, has been proved valid at the date marked on the product data sheet.

The quality of the product is ensured by our operational system, based on the requirements of ISO 9001 and ISO 14001. As a manufacturer we

cannot be responsible for any damages caused by using the product against our instructions or for inappropriate purposes.

For further information or advice contact: Valtti Specialist Coatings Ltd, Telephone (+44) 0131 334 4999 Fax (+44) 0131 334 3987

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Aroso 2015Documento7 páginasAroso 2015H Louis AcuñaAinda não há avaliações

- ABRIVATIONSDocumento14 páginasABRIVATIONSRoshan de SilvaAinda não há avaliações

- Bro-0008.7 Hvofsolutions enDocumento16 páginasBro-0008.7 Hvofsolutions enIzziAinda não há avaliações

- Final I.P.T ReportDocumento27 páginasFinal I.P.T ReportIndu GunasekaranAinda não há avaliações

- The Importance of Enhancing and Decorating The ProductDocumento5 páginasThe Importance of Enhancing and Decorating The ProductMa Junnicca Magbanua100% (1)

- Porosity and pore size distribution of recycled concreteDocumento9 páginasPorosity and pore size distribution of recycled concreteBagus Rizqi KurniawanAinda não há avaliações

- Safety Data Sheet X-CIDE 105: 1. Identification of The Substance/Preparation and The CompanyDocumento5 páginasSafety Data Sheet X-CIDE 105: 1. Identification of The Substance/Preparation and The Company123456ccAinda não há avaliações

- Biodiesel Production by A Continuous Process Using Hetergenous CatalystDocumento3 páginasBiodiesel Production by A Continuous Process Using Hetergenous Catalystdstar13Ainda não há avaliações

- 3LW - Types and Properties of Aviation OilsDocumento10 páginas3LW - Types and Properties of Aviation OilsZouhair ElmAinda não há avaliações

- 1 Brain Storm Chemistry Med FinalDocumento7 páginas1 Brain Storm Chemistry Med FinalShudhanshu KumarAinda não há avaliações

- Lesson 1 Electron Configuration and Octet RuleDocumento23 páginasLesson 1 Electron Configuration and Octet RuleAngel CapinpinAinda não há avaliações

- What Are Cermets PDFDocumento5 páginasWhat Are Cermets PDFKamranAinda não há avaliações

- BOQ - Hearts & Arrows Office 04sep2023Documento15 páginasBOQ - Hearts & Arrows Office 04sep2023ChristianAinda não há avaliações

- Deaerators: Technical BackgroundDocumento8 páginasDeaerators: Technical Backgroundกี๋ แต่งงามAinda não há avaliações

- Dewaxing ProcessesDocumento19 páginasDewaxing ProcessesMahi FatimaAinda não há avaliações

- Deflection of Simply-Supported Beams: Title of The ExperimentDocumento21 páginasDeflection of Simply-Supported Beams: Title of The Experimentopeyemi71Ainda não há avaliações

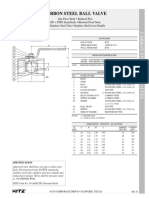

- Carbon Steel Ball Valve: Code # 50 (Aksctk)Documento1 páginaCarbon Steel Ball Valve: Code # 50 (Aksctk)thilina lakhithaAinda não há avaliações

- Client: Supplier: Location: Sheet: Item: Large Size Gear BoxDocumento1 páginaClient: Supplier: Location: Sheet: Item: Large Size Gear BoxirwanAinda não há avaliações

- 1.metal Semiconductor JunctionDocumento29 páginas1.metal Semiconductor JunctionJothibasu MarappanAinda não há avaliações

- Anochrome Coating Data Sheet 15-10-14Documento3 páginasAnochrome Coating Data Sheet 15-10-14ellisforheroesAinda não há avaliações

- NC-559-ASM Rev 0510Documento2 páginasNC-559-ASM Rev 0510electrosysro8560Ainda não há avaliações

- Cotton ListDocumento22 páginasCotton ListL.N.CHEMICAL INDUSTRYAinda não há avaliações

- Msds AluminaDocumento6 páginasMsds AluminayaderAinda não há avaliações

- Coal, Types of Coal, Analysis of CoalDocumento4 páginasCoal, Types of Coal, Analysis of CoalSaad AhmedAinda não há avaliações

- Friction in Metal CuttingDocumento18 páginasFriction in Metal Cuttingaj87_goswami71% (7)

- Moles and Equations WorksheetDocumento3 páginasMoles and Equations WorksheetArshad KhanAinda não há avaliações

- Wilma Ty Nueva SpecificationsDocumento10 páginasWilma Ty Nueva SpecificationsJubs DejitoAinda não há avaliações

- Comparison Between Different Heat Sources Types in Thin-Plate Welding Simulation-Hashemzadeh-2014Documento8 páginasComparison Between Different Heat Sources Types in Thin-Plate Welding Simulation-Hashemzadeh-2014DonatasAinda não há avaliações

- International Management Institute, BhubaneshwarDocumento9 páginasInternational Management Institute, BhubaneshwarDiksha LathAinda não há avaliações

- Caesar II Static TrainingDocumento312 páginasCaesar II Static TrainingMed Rjeb100% (1)