Escolar Documentos

Profissional Documentos

Cultura Documentos

Power Plant Operations Assignment

Enviado por

Poojit Popli0 notas0% acharam este documento útil (0 voto)

64 visualizações8 páginasThe document provides procedures for coal mill changeover at a power plant. It outlines pre-start checks that include measuring mill clearances and calibrating coal feeders. During start-up, primary airflows and fuel line balances are checked. The post-start checks involve monitoring mill sounds, oil flows, roller rotation, and maintaining appropriate temperatures, airflows and reject rates. The procedures aim to safely transition load to the standby mill if the operating mill trips due to issues like valve closures or motor/fan failures.

Descrição original:

Power Plant Operations Assignment

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

DOCX, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThe document provides procedures for coal mill changeover at a power plant. It outlines pre-start checks that include measuring mill clearances and calibrating coal feeders. During start-up, primary airflows and fuel line balances are checked. The post-start checks involve monitoring mill sounds, oil flows, roller rotation, and maintaining appropriate temperatures, airflows and reject rates. The procedures aim to safely transition load to the standby mill if the operating mill trips due to issues like valve closures or motor/fan failures.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

64 visualizações8 páginasPower Plant Operations Assignment

Enviado por

Poojit PopliThe document provides procedures for coal mill changeover at a power plant. It outlines pre-start checks that include measuring mill clearances and calibrating coal feeders. During start-up, primary airflows and fuel line balances are checked. The post-start checks involve monitoring mill sounds, oil flows, roller rotation, and maintaining appropriate temperatures, airflows and reject rates. The procedures aim to safely transition load to the standby mill if the operating mill trips due to issues like valve closures or motor/fan failures.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

Você está na página 1de 8

POWER PLANT OPERATIONS

ASSIGNMENT

Topic:

Procedure for Coal mill changeover

Submit

ted by:

POOJI

T POPLI

03315

303712

3 RD YEAR

The coal pulverizer is the most important equipment to

govern the operability and reliability of coal burning

boilers. Therefore, an optimum mill type must be selected

from the comprehensive view point according to the coal

properties and the operation conditions.

Operation and maintenance

The operation of mill is simple and start/stop operation can

be completely automated. Also, the wide range of the mill

operation load adjustment is important for coal boiler

operability. The upright mill is available for 40-50%

turndown, but recently some types of upright mills have

become available for high-turndown operation up to 30%

or less. For mills operation, the maintenance of abrasive

parts is also extremely important. So, studies have been

conducted to develop abrasion-resistant materials and to

simplify the replacement of roll rings, liners, etc. As for the

material of rolls, in addition to conventional abrasionresistant cast iron, curing cladding-welding material with

several times abrasion-resistance of cast iron has also

been used. Because the life of the grinding section varies

with the coal properties and the operation conditions etc.,

it is necessary to measure periodically the abrasion depth

of the rolls or segments of each plant and to schedule the

intervals of replacement. Generally, rolls/rings/liners

replacement is conducted in such a manner that one unit

of extra mill per boiler is installed, and maintenance

intervals are set, and each mill is maintained sequentially.

In case of emergencies, mill changeover operation is done

in which the faulty mill is shut down and the load is

transferred to the standby mill.

Mill tripping might take place due to one of the following

reasons:

Mill discharge valves are closed

Loss of elevation D.C. supply for more than 2 secs.

Support ignition energy is removed Within 3 minutes of

feeder starting.

Motor protection operates.

One P.A. Fan trips (mill in excess of 3 will trip starting

from bottom).

In such a case the changeover to the other mill takes

place. Procedure for the changeover is:

Steps prior to putting the mill in service:

1.Measure and record internal clearances, tolerances,

and spring preloads.

2.Check and calibrate the coal feeders.

3.Functionally check the full movement and position

indication of all dampers.

4.Review primary airflow curves to ensure safe operation

throughout the operating range, ensuring adequate

minimum airflow as well as proper air-to-fuel ratios

when operating above minimum airflow.

5.After thoroughly checking mechanical tolerances and

clearances, close the mill and start primary airflows.

Warm the mill to normal operating temperature of 150F

mill outlet temperature (bituminous coal) and airflow at

minimum (normal minimum primary air [PA] flow).

6.Conduct a PA airflow measurement traverse by manual

pitot tube to verify that the indicated PA is correct

across the boiler operating range.

7.Conduct "clean air" 24-point traverses of all of the fuel

lines to measure and compare the balanced airflows

through each pipe. All coal pipes (and flows to all of the

burners from each respective pulverizer) should be

balanced and within 2% of the mean flow.

8.Perform a seal air check.

9.Begin the normal pulverizer start sequence.

10. Once normal coal flow is applied to the mill, a full

mill test should be conducted. This test should include

isokinetic coal sampling and dirty airflow

measurements through each fuel line to determine

air/fuel balance and coal fineness. Primary airflow "HotK" calibrations of the primary airflow measuring

element should also be conducted

Other pre start checks:

LOCAL (to be made by local operator)

Ensure R.C. Bunker level Satisfactory.

R.C feeder and mill properly boxed up and no

maintenance staff working.

Gear box oil level normal.

Lub. oil coolers charged.

Tramp Iron Gate open.

Cold air gate open. Hot air gate closed.

Mill outlet valve open.

Seal air valve open.

Mill firefighting system ready.

Take out emergency push button and give clearance

to UCB for starting.

U.C.B: (to be made by desk operator)

Ensure no PTW pending.

Ensure at least one P.A fan and a seal air fan is in

service. Check the header pressure for both primary

and seal air is normal.

Check that mill ignition energy is O.K.

Check that mill start permissive as per FSSS are

satisfied (for the help of operator these permissive are

written on FSSS panel and when the condition is

satisfied it is indicated by a glowing bulb).

Ensure E.P zones have been charged (for first mill ).

Ensure attemperation valves are ready for operation.

Inform turbine operator of mill start up.

Get the electrical supply for the mill.

Inform the local operator to be near mill for start up.

Start the mill.

POST START CHECKS

LOCAL

Check no abnormal sound from mill.

Check return oil flow from upper bearing is satisfactory.

Check all the rollers are rotating and the rate of reject

is normal (after the mill is loaded).

U.C.B

Check mill starting time and current. Ensure that they

are normal.

Open hot air gate.

Warm up the mill.

Start the R.C feeder and load the mill gradually.

Keep the air flow through mill-54 T/hr.

Keep watch on mill differential to avoid mill chocking.

Maintain mill outlet temperature between 75 degree

Celsius to 80 degree Celsius.

As the pressure, temperature of main steam shoots up

with coal firing proper check should be kept on these

parameters. (Especially for first mill).

Você também pode gostar

- Boiler House Procedures GuideDocumento18 páginasBoiler House Procedures GuidePrakash WarrierAinda não há avaliações

- Belt Drive Lab ReportDocumento10 páginasBelt Drive Lab ReportNadia Balqis0% (1)

- Boiler Commissioning and Operation Check ListDocumento14 páginasBoiler Commissioning and Operation Check Listtsrinivasan5083100% (3)

- General Commissioning and Operating Procedure of Ball Tube Mill BBD 4772Documento22 páginasGeneral Commissioning and Operating Procedure of Ball Tube Mill BBD 4772Azhar Islam100% (2)

- Maxim Firestar Manual - All VersionsDocumento84 páginasMaxim Firestar Manual - All VersionsdanhuizengaAinda não há avaliações

- Auto Start GuidelinesDocumento7 páginasAuto Start GuidelinesBabar Priyadi Mugi HangganaAinda não há avaliações

- Boiler Start-Up and Operational Procedures - 660MW DHIDocumento44 páginasBoiler Start-Up and Operational Procedures - 660MW DHIHemendra VermaAinda não há avaliações

- Precision Marketing for Dove Hair & SkinDocumento5 páginasPrecision Marketing for Dove Hair & SkinHarshit SinghAinda não há avaliações

- Trane xr80Documento16 páginasTrane xr80Victor Hugo Castillo AguirreAinda não há avaliações

- Tutorial 3Documento4 páginasTutorial 3Ngudo Ewart NephaweAinda não há avaliações

- HSPE-144M M6 HC Bifacial 450W Rev.00Documento2 páginasHSPE-144M M6 HC Bifacial 450W Rev.00Alejandro Holguin QuinteroAinda não há avaliações

- Coal pulverizer operation and maintenance proceduresDocumento7 páginasCoal pulverizer operation and maintenance proceduresPoojit PopliAinda não há avaliações

- CcOLD STARTUPDocumento15 páginasCcOLD STARTUPAnonymous ICKtnYvC100% (1)

- Power Plant OperationDocumento199 páginasPower Plant OperationVijay Bhargav Badam83% (6)

- Turbine Operation GuideDocumento27 páginasTurbine Operation GuidebhaskarAinda não há avaliações

- Ball and Tube Mill OperationDocumento5 páginasBall and Tube Mill OperationRakesh KiranAinda não há avaliações

- Turbine Operation - PreparationDocumento30 páginasTurbine Operation - PreparationMadhav Pande67% (3)

- Power Plant OperationDocumento0 páginaPower Plant OperationSHIVAJI CHOUDHURYAinda não há avaliações

- Bowl MillDocumento10 páginasBowl MillAvtarAinda não há avaliações

- Kiln OptimiztionDocumento13 páginasKiln Optimiztionslim_g911100% (1)

- MHI 700MW Turbine RollingDocumento51 páginasMHI 700MW Turbine RollingSomnath Gupta100% (3)

- Air Test of Pressure PartsDocumento3 páginasAir Test of Pressure PartsGohel mohitAinda não há avaliações

- Gas Turbine1Documento13 páginasGas Turbine1Saurabh BarangeAinda não há avaliações

- CONTRACT No.14023 DATE 20.03.2014 Sirajganj 225Mw Combined Cycle Power Plant Project (2 Unit-Dual Fuel)Documento11 páginasCONTRACT No.14023 DATE 20.03.2014 Sirajganj 225Mw Combined Cycle Power Plant Project (2 Unit-Dual Fuel)VictorAinda não há avaliações

- Chemical Cleaning of Boiler Pressure Parts As TheDocumento57 páginasChemical Cleaning of Boiler Pressure Parts As TheAnonymous 1OmAQ0u3Ainda não há avaliações

- Commissioning Guide LinesDocumento53 páginasCommissioning Guide LinesthurawinAinda não há avaliações

- General Procedures For Raising SteamDocumento3 páginasGeneral Procedures For Raising SteamAlma Dela PeñaAinda não há avaliações

- 7.summary of Boiler PerfDocumento46 páginas7.summary of Boiler PerfRAJESH KUMARAinda não há avaliações

- Philips Kiln ServicesDocumento20 páginasPhilips Kiln ServicesAbul Qasim QasimAinda não há avaliações

- Joshua Custodio Bsme 5B 1Documento4 páginasJoshua Custodio Bsme 5B 1Datu JonathanAinda não há avaliações

- Presentation On Steam Turbine Operation by S ChandDocumento36 páginasPresentation On Steam Turbine Operation by S Chandsomyaranjan das100% (1)

- Turbine Shutting Down From Full LoadDocumento7 páginasTurbine Shutting Down From Full Loadrohit_0123100% (1)

- T&C Procedure For Air Conditioning Chiller SystemDocumento11 páginasT&C Procedure For Air Conditioning Chiller SystemAli AimranAinda não há avaliações

- Operation and Maintenance of BoilersDocumento22 páginasOperation and Maintenance of BoilersZAHID HUSSAIN100% (1)

- Standard Procedure of Steam Blowing TestDocumento4 páginasStandard Procedure of Steam Blowing TestDennis B. YapAinda não há avaliações

- Vertical Mill PDFDocumento15 páginasVertical Mill PDFGregory100% (4)

- Boiler Sop RevDocumento17 páginasBoiler Sop RevDhilip AnAinda não há avaliações

- Welcome: Presentation ON Boilers & AuxiliariesDocumento58 páginasWelcome: Presentation ON Boilers & Auxiliariestanuja singhAinda não há avaliações

- BlowoutDocumento5 páginasBlowoutjmsponteAinda não há avaliações

- PPS Boiler Safe OperationDocumento9 páginasPPS Boiler Safe OperationAraAinda não há avaliações

- Steam Turbine Startup ProceduresDocumento30 páginasSteam Turbine Startup ProceduresVILLANUEVA_DANIEL2064100% (1)

- Santosh Kumar: Producl Engineer / BPP FBDocumento17 páginasSantosh Kumar: Producl Engineer / BPP FBjp mishraAinda não há avaliações

- POWER PLANT GENERATOR OPERATION & AUXILIARIESDocumento30 páginasPOWER PLANT GENERATOR OPERATION & AUXILIARIESrohit_0123100% (2)

- CCPP Operation ManualDocumento21 páginasCCPP Operation ManualEgit Bobyarta100% (5)

- Boiler OperationDocumento14 páginasBoiler OperationjmayurrAinda não há avaliações

- ArticleDocumento8 páginasArticleHassan Sami100% (1)

- AV-ME-WI-20 BoilerDocumento5 páginasAV-ME-WI-20 BoilerjfejfeAinda não há avaliações

- Procedure of vacuum leak detection in KWU steam turbines using steam pressurisationDocumento8 páginasProcedure of vacuum leak detection in KWU steam turbines using steam pressurisationTamara Lee100% (1)

- BARC Develops Fire Resistant Hydraulic Fluid Test FacilityDocumento28 páginasBARC Develops Fire Resistant Hydraulic Fluid Test Facilityrkp17Ainda não há avaliações

- Cold Startup ProcedureDocumento8 páginasCold Startup ProcedureRahul KurmiAinda não há avaliações

- Captive Power Plant OverviewDocumento122 páginasCaptive Power Plant OverviewPrudhvi RajAinda não há avaliações

- Boiler Q&A FurtherDocumento7 páginasBoiler Q&A FurtherRachitAinda não há avaliações

- Combined Cycle Power Plant Operation GuideDocumento21 páginasCombined Cycle Power Plant Operation GuideParmeshwar Nath Tripathi100% (3)

- 015Documento10 páginas015pf06Ainda não há avaliações

- Warm StartDocumento4 páginasWarm StartMowaten MasryAinda não há avaliações

- Unit Sart Up 800mwDocumento12 páginasUnit Sart Up 800mwVamsiKrishnaAinda não há avaliações

- Aph FireDocumento25 páginasAph Firesekhar_ntpcAinda não há avaliações

- Steam TurbineDocumento21 páginasSteam Turbinemellow100% (1)

- Everything You Need to Know About Steam TurbinesDocumento69 páginasEverything You Need to Know About Steam TurbinesNgo Van Tan100% (2)

- Boiler Emergencies - 2017Documento10 páginasBoiler Emergencies - 2017RAJKUMAR100% (1)

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SAinda não há avaliações

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitAinda não há avaliações

- Engineering Bulletin No 1: Boiler and Furnace TestingNo EverandEngineering Bulletin No 1: Boiler and Furnace TestingNota: 4.5 de 5 estrelas4.5/5 (2)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesAinda não há avaliações

- IIMT Explorica Round 2Documento4 páginasIIMT Explorica Round 2Poojit PopliAinda não há avaliações

- Ushr, The HR Club of Iim Shillong Presents - Enthral - An HR Case Study Competition As A Part of #HRDocumento1 páginaUshr, The HR Club of Iim Shillong Presents - Enthral - An HR Case Study Competition As A Part of #HRPoojit PopliAinda não há avaliações

- Energy ScenarioDocumento37 páginasEnergy ScenarioShashidhar14Ainda não há avaliações

- R12 RefrigerantDocumento48 páginasR12 RefrigerantPoojit PopliAinda não há avaliações

- Specific heat data for refrigerant R134a from -60 to 0°CDocumento56 páginasSpecific heat data for refrigerant R134a from -60 to 0°CPoojit PopliAinda não há avaliações

- Civil Vi Environmental Engineering I (10cv61) NotesDocumento142 páginasCivil Vi Environmental Engineering I (10cv61) NotesPoojit Popli100% (1)

- 5d22f01a4fdf4 Palmolive Transcend 2019 Case Study PDFDocumento16 páginas5d22f01a4fdf4 Palmolive Transcend 2019 Case Study PDFabhinavAinda não há avaliações

- BPCL - Riding Social Media WavesDocumento15 páginasBPCL - Riding Social Media WavesPoojit PopliAinda não há avaliações

- Solidwastemanagementppt Conversion Gate01Documento56 páginasSolidwastemanagementppt Conversion Gate01Melinda RafaelAinda não há avaliações

- 100 Mechanical Interview QuestionsDocumento17 páginas100 Mechanical Interview QuestionsPoojit Popli100% (1)

- Refrigeration and Air-Conditioning - S K MondalDocumento0 páginaRefrigeration and Air-Conditioning - S K MondalShaheen S. RatnaniAinda não há avaliações

- AutoCAD 2010 2D Introduction & Ribbon CommandsDocumento6 páginasAutoCAD 2010 2D Introduction & Ribbon CommandsPoojit PopliAinda não há avaliações

- Machine Design by S K MondalDocumento81 páginasMachine Design by S K Mondalreyrey19Ainda não há avaliações

- CS 1.6 Guide to Maps, Commands & ServersDocumento1 páginaCS 1.6 Guide to Maps, Commands & ServersFlorin ȘimoncaAinda não há avaliações

- Machine Design by S K MondalDocumento81 páginasMachine Design by S K Mondalreyrey19Ainda não há avaliações

- Btech DatesheetDocumento3 páginasBtech DatesheetNeeraj TiwariAinda não há avaliações

- WatertreatmentplantDocumento23 páginasWatertreatmentplantPoojit PopliAinda não há avaliações

- PracticalsDocumento18 páginasPracticalsPoojit PopliAinda não há avaliações

- Pam and TMDDocumento13 páginasPam and TMDPoojit PopliAinda não há avaliações

- IPGCLMYTOrderDocumento128 páginasIPGCLMYTOrderPankaj KumarAinda não há avaliações

- OkhlaDocumento55 páginasOkhlaPoojit Popli50% (2)

- Power Plant Project ReportDocumento66 páginasPower Plant Project ReportPoojit PopliAinda não há avaliações

- Mech (1) Fluid MechanicsDocumento31 páginasMech (1) Fluid MechanicsKarthik TejaAinda não há avaliações

- Gland Sealing SystemDocumento4 páginasGland Sealing SystemPoojit Popli100% (1)

- The Relay Protection Coordination For PHDocumento6 páginasThe Relay Protection Coordination For PHgrigore mirceaAinda não há avaliações

- Leaflet F LG Absorption ChillerDocumento4 páginasLeaflet F LG Absorption ChillerSaad PathanAinda não há avaliações

- Bomba Neumatica Milton RoyDocumento8 páginasBomba Neumatica Milton RoyGuillermo de la Fuente SantiagoAinda não há avaliações

- Exergy REP and S Series Industrial Heat PumpsDocumento5 páginasExergy REP and S Series Industrial Heat PumpsEmilio PublicAinda não há avaliações

- Grid-Connected System: Simulation Parameters: Project: Sim 100MWDocumento6 páginasGrid-Connected System: Simulation Parameters: Project: Sim 100MWrajid oumaimaAinda não há avaliações

- Screw Feeder CalculationDocumento5 páginasScrew Feeder CalculationHirenAinda não há avaliações

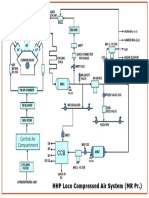

- HHP Compressed Air DrawingDocumento1 páginaHHP Compressed Air Drawingdhaneesh22Ainda não há avaliações

- D4B804B254B-Heating Ventilation and Air ConditioningDocumento323 páginasD4B804B254B-Heating Ventilation and Air ConditioningDaniel CharlesAinda não há avaliações

- Rotary Screw Compressor Units: MODELS: RXF-12 Through RXF-101Documento56 páginasRotary Screw Compressor Units: MODELS: RXF-12 Through RXF-101Miguel SoteloAinda não há avaliações

- Data 9x Containerized Gas Engine JGS 320 GS - SLDocumento2 páginasData 9x Containerized Gas Engine JGS 320 GS - SLBalast MetheeAinda não há avaliações

- 2014 1984 Chart and CodesDocumento2 páginas2014 1984 Chart and Codesnubaz0% (1)

- Accumulator Selection: Fawcett ChristieDocumento2 páginasAccumulator Selection: Fawcett ChristieAalap DerasaryAinda não há avaliações

- Notification Order Equipment DescriptionDocumento18 páginasNotification Order Equipment Descriptionઅનુરુપ સોનીAinda não há avaliações

- Maintenance Schedule Marine Auxiliary Diesel EnginesDocumento5 páginasMaintenance Schedule Marine Auxiliary Diesel EnginesAayush Agrawal100% (1)

- Assignment # 1Documento6 páginasAssignment # 1سید علی نقویAinda não há avaliações

- Compressor Theory: Technical TrainingDocumento55 páginasCompressor Theory: Technical TrainingAlka GoyalAinda não há avaliações

- VCB Detail of PSSDocumento189 páginasVCB Detail of PSSPawan Kumar RaiAinda não há avaliações

- 2Documento2 páginas2Tyron CastroAinda não há avaliações

- Saline Water Conversion Corporation Strategic Reservoirs at Makkah Phase Ii & Taif Phase IDocumento2 páginasSaline Water Conversion Corporation Strategic Reservoirs at Makkah Phase Ii & Taif Phase IAnonymous uLAATWpfAinda não há avaliações

- Range Fwe Version CT Size 08: CoolingDocumento2 páginasRange Fwe Version CT Size 08: Coolingvelikimag87Ainda não há avaliações

- Handbook Chapter15 DisplacementVentilationDocumento41 páginasHandbook Chapter15 DisplacementVentilationJoao Sousa100% (1)

- Ex: # 01: A Sample of Dry Anthracite Has The Following: 44kg CODocumento12 páginasEx: # 01: A Sample of Dry Anthracite Has The Following: 44kg COnicoolAinda não há avaliações

- Electric Boiler Adaption With External Tank KatalogDocumento2 páginasElectric Boiler Adaption With External Tank KatalogDaxom NavidensAinda não há avaliações

- Auha 36 LatnDocumento28 páginasAuha 36 LatnJuan Antonio Martinez MarinAinda não há avaliações

- MODULE 3 RAC Servicing and MaintenanceDocumento23 páginasMODULE 3 RAC Servicing and MaintenanceRonnel BarocAinda não há avaliações

- DuctulatorDocumento44 páginasDuctulatorgeorgeAinda não há avaliações