Escolar Documentos

Profissional Documentos

Cultura Documentos

3D Trigate Transistor

Enviado por

Tejas DharaniDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

3D Trigate Transistor

Enviado por

Tejas DharaniDireitos autorais:

Formatos disponíveis

[Bhole, 2(10): October, 2013]

ISSN: 2277-9655

Impact Factor: 1.852

IJESRT

INTERNATIONAL JOURNAL OF ENGINEERING SCIENCES & RESEARCH

TECHNOLOGY

3D Tri-Gate Transistor Technology and Next Generation FPGAs

Mayur Bhole*1, Aditya Kurude2, Sagar Pawar3

*1, 2, 3

BE (E&TC), PVGs COET, Pune, India

mayurbhole123@gmail.com

Abstract

The 3D tri-gate transistors are a remarkable breakthrough in the realm of CMOS technology. These

transistors can be considered as a reinvention of the transistor, in a way that they have supplanted the conventional

"flat" 2D planar gate with an incredibly thin 3D silicon fin that rises up vertically from the silicon substrate. Such

tri-gate transistors have shown significantly improved electrostatics in terms of sub-threshold slope and drain

induced barrier lowering and hencebetter more scalability than planar transistors. This next-generation technology,

which target ultra high-performance systems for military, wire line communications, cloud networking, and compute

and storage applications, will enable breakthrough levels of performance and power efficiencies not otherwise

possible. These tri-gate transistors in concert with other key semiconductor technologies will enable a new era of

energy-efficient performance. This Paper discusses the 3-D Tri-Gate transistor technology, its developments and

integration with other silicon processing technologies, and its impact on the next generation FPGAs based on it.

Keywords: MOSFET, CMOS, FPGA, 3D tri-gate transistors, FinFET, DELTA.

Introduction

Tri-gate transistor is a MOSFET (metaloxide

the overall maturity and manufacturability of Tri-Gate

semiconductor field effect transistor) which incorporates

transistors on a mass production scale. In February 2013,

three gates into a single device. It is a type of multiple

ALTERA and Intel Corporation jointly announced that

gate field effect transistors (MuGFET). The three gates

the next generation of ALTERAs highest performance

may be controlled by a single gate electrode, wherein the

FPGA products would be manufactured using Intels 14

three gate surfaces act electrically as a single gate, or

nm 3-D Tri-Gate transistor technology exclusively. Next

they can be operated independently.

generation FPGAs based on 14 nm Tri-Gate design will

For over 50 years, integrated circuits were using

enjoy benefits from both, the transistor geometry shrink

planar transistors as its core, during this period the size

to 14 nm and from further density improvements allowed

of the individual transistors has steadily decreased.

by 3-D Tri-Gate transistor design.

Today, the transistor gate length in production is

approximately 28 nanometres. But there are several

History and Development of 3D TRI-Gate

limitations or drawbacks of these miniaturisations, most

Technology

significant are: excessive gate leakage current,

For over 50 years, MOSFET possessed the 2D

exponentially increasing source to drain sub-threshold

planar structure in which the current was flowing along

leakage current, gate stack reliability and channel

the surface of the silicon under the gate. In the last

mobility degradation from increasing electric field, rising

decade, advancements in strained silicon and High-K

dynamic power dissipation (CV2f) from non-scaled

metal gate technologies have panned out continuous

supply voltages, band to band tunnelling leakage at high

improvements in MOSFET performance and power.

body doping levels, device to device variation from

The 3D tri-gate technology (also known as

random dopant fluctuation effects.

wraparound gate transistor technology) was conceived

Compared to today's 65nm transistors,

in the year 1991. It was in this year when its potential

integrated tri-gate transistors can offer a 45 percent

and capabilities were acknowledged by scientists. This

increase in drive current (switching speed) or 50 times

proposed 3-D structure was called depleted lean-channel

reduction in off-current, and 35 percent reduction in

transistor, or DELTA.

transistor switching power.

In 1997, the Defence Advanced Research

At present, Intel Corporation is the only

Projects Agency (DARPA) awarded a contract to a

company to have made this design and manufacturing

research group at the University of California, Berkeley,

transition in 22 nm technology, and can provide data on

http: // www.ijesrt.com

(C) International Journal of Engineering Sciences & Research Technology

[2670-2675]

[Bhole, 2(10): October, 2013]

ISSN: 2277-9655

Impact Factor: 1.852

to develop a deep sub-micron transistor based on the

DELTA concept.

In 1999, the 3D transistor was called FinFET

for the fin-like structure at the centre of the transistor

geometry.

In 2002, to address the transistor off-state

leakage issue, Intel developed the worlds first CMOS

tri-gate transistor, which employed a novel threedimensional gate design that improves the drive current

while reducing the leakage current when the transistor is

in the off state. Intel has further improved the

performance and energy efficiency of the transistor by

integrating the tri-gate design with other silicon process

technology and material innovations, including strained

silicon, high-k gate dielectrics, metal gate electrodes, and

epitaxially raised source/drain.

On 4th May 2011, Intel Corporation proclaimed

their Tri-Gate transistor design that had been selected for

the design and manufacture of their 22 nm

semiconductor products.

It represented a solid acknowledgment of the

feasibility and cost-effectiveness of the Tri-Gate

transistor structure in semiconductor production.

Fig3 Tri-gate SRAM cells

Fig 4 Tri-gate RMG process flow

2011

Fig.5 32 nm Planar Transistors

Fig.6 22 nm Tri-Gate Transistors

Fig.1 Single-fin Transistor

Basic Structure of TRI-Gate Transistors

Fig2 Multi-fin Transistor

Fig.7 Structure of 3D Tri-Gate

The structure of 3D Tri-gate transistor

represents a fundamental departure from the 2D planar

transistor structure as shown in Fig.7. Tri-gate transistors

form conducting channels on three sides of a vertical fin

structure, thus they are fully depleted so that the entire

available silicon underneath the gate electrode is

http: // www.ijesrt.com

(C) International Journal of Engineering Sciences & Research Technology

[2670-2675]

[Bhole, 2(10): October, 2013]

depleted of carriers before the threshold condition is

reached.

Since fins are made vertical in nature, high

packing density can be achieved, by packing transistors

closer together. Further, to get even more performance

and energy-efficiency gains, designers also have the

ability to continue growing the height of the fins.

Tri gate transistor can be fabricated either on the

SOI substrate or standard bulk-silicon substrate. It has

one gate electrode on the top and other two gate

electrodes on the sides of the silicon body. This

additional gate control enables as much transistor current

flowing as possible when the transistor is in the 'on' state

(for performance), and as close to zero as possible when

it is in the 'off' state (to minimize power), and enables the

transistor to switch very quickly between the two states

(again, for performance).

Fig.8 Planar Structure

Fig.9 Tri-gate Structure

ISSN: 2277-9655

Impact Factor: 1.852

fin width ratio greater than 0.5. This also allows them to

reduce the channel doping which, in turn, reduces the

impurity scattering the channel, enhances volume

inversion effect and results in higher performance,

particularly at lower bias region.

Besides these advantages, there are several

known issues and characteristics of the 3-D gate

structure, which include the modelling of new parasitic

capacitance values not modelled in traditional planar

designs, layout dependent effects, and the use of doublepatterning techniques using current lithographic

equipment to form closely spaced fins.

Integration of TRI-Gate design with Other

Technologies

For improving the efficiency, the tri-gate design

is enhanced by using both high-k gate insulators with

metal gates to improve both on and off currents, and

adding strained silicon for enhanced mobility (speed),

further improving device performance.

Non-planar transistor integrated with other

silicon process technologies can provide 30 percent

higher NMOS drive current and 60 percent higher PMOS

drive current than the optimized, state-of-the-art 65nmnode planar transistors at the same off-state leakage.

Strain Modulation

Strain Modulation is a silicon process

technology used in planar CMOS for improving their

performance. Now, Intel is combining the benefits of

non-planar fully depleted tri-gate architecture with strain

engineering. Modulation of strain in transistor channel

enhances electron mobility and hole mobility and thereby

conductivity through the channel.

One key consideration in using strain

engineering in CMOS technologies is that PMOS and

NMOS respond differently to different types of strain.

Specifically, PMOS performance is best served by

applying compressive strain to the channel, whereas

NMOS receives benefit from tensile strain.

High-k/metal gate Technology

The term high-k dielectric refers to a material

with a high dielectric constant as compared to silicon

dioxide. The tri-gate CMOS transistors use a high-k

material to replace the transistors traditional silicon

dioxide dielectric, and also replace the conventional

poly-silicon gate electrode with metal gate electrodes

with work function close to the mid gap. Replacing the

silicon dioxide gate dielectric with a high- material

allows increased gate capacitance without the associated

leakage effects.

The metal gate technology eliminates polysilicon depletion and enhances transistor performance. In

addition, the use of metal electrodes with close-to-mid

The key performance advantage of Tri-Gate

transistor geometries over traditional planar geometries

can be found in the effective width of the conducting

channel.

Figure 8 shows a cross-sectional representation

of a traditional transistor. Its gate is built in a single plane

(thus the name planar). The effective width of the

channel is shown in yellow. Fig.9 shows a 3D tri-gate

transistor, demonstrating how a greater channel width is

achieved from the 3-D structure without increasing the

overall footprint of the transistor, which results in higher

performance without increased die area.

Without any impact on the layout area,

designers have a choice of extending the width in third

dimension in tri gate transistor structure; as a result the

effective channel width can be significantly enhanced

relative to a planar transistor.

Effective channel length and the effective fin

width of the device are used as the key knob for

controlling the short channel effects in 3D transistors.

Device designers design electro-statically well controlled

3D transistors by keeping the effective channel length to

http: // www.ijesrt.com

(C) International Journal of Engineering Sciences & Research Technology

[2670-2675]

[Bhole, 2(10): October, 2013]

ISSN: 2277-9655

Impact Factor: 1.852

gap work functions also allows the reduction of substrate

doping concentrations, thus enhancing transistor

motilities and hence overall transistor performance

Dual epitaxial raised source/drain structure

Through epitaxial deposition, the integrated

CMOS tri-gate transistor creates a unique source/drain

structure, in which epitaxial deposition of silicon is done

for NMOS transistor and Si-Ge for PMOS transistor.

For reducing the parasitic resistance, the source

and drain regions are raised with respect to the plane of

the gate oxide-silicon substrate interface. This improves

device performance. Intel has manufactured prototypes

of the integrated tri-gate CMOS transistors on SOI as

well as bulk-silicon substrates. The tri-gate transistor on

bulk silicon and on SOI demonstrates equivalent scaling

and short-channel performance and transistor drive

performance.

Researchers found that a process induced

vertical compressive strain improves the electron

mobility on the sidewall surface with (110) crystal

orientation for 3D NMOS, while the conventional

embedded Si-Ge source drain stressor can significantly

improve the hole mobility on the 110 sidewall for 3D

PMOS.

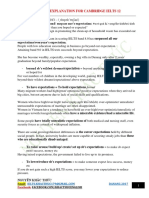

Fig.10 Graph of Transistor Gate Delay vs. Operating

Voltage

Fig.11, illustrates the channel current in a TriGate transistor vs. a planar transistor as a function of gate

voltage. When the gate voltage is at 0 V, there is an order

of magnitude lower amount of leakage current flowing

through the channel of the Tri-Gate transistor compared

to the planar transistor. Thus the Tri-Gate transistor

effectively minimises the leakage power.

Impact of 3D TRI-Gate Technology and Next

Generation FPGAs

The next generation of FPGAs stands poised to

benefit from the very latest semiconductor technology to

deliver high performance. The primary advantage of TriGate technology to FPGA-based electronic product

designer is the continuation of Moores Law in the

steady march of improvements in transistor density,

performance, power, and cost-per transistor. Moore's

Law is a forecast for the pace of silicon technology

development; it states that roughly every 2 years

transistor density will double.

FPGAs based on 3D tri-gate technology will

deliver dramatic performance gain at low operating

voltages. Fig.10 shows that 22nm 3D tri-gate FPGAs will

be 37% faster at low voltages than 32nm planar FPGAs.

Keeping a constant performance, these FPGAs can

operate at lower voltages, hence saving more than 50%

of power compared to 32nm planar FPGAs. This makes

them ideal for use in small handheld devices, which

operate using less energy to "switch" back and forth.

http: // www.ijesrt.com

Fig.11 Graph of Channel Current vs. Gate Voltage

Due to lower supply voltage requirement,

control over the static and active power dissipation of

FPGAs improves tremendously with the 3D tri-gate

technology. Figure 12 shows this active power reduction;

the trend in active power across process nodes has been

in the downward direction. However, as demonstrated by

the bend in the curve further downward from the 32 nm

planar node, the introduction of Tri-Gate transistors has

clearly further reduced the dynamic power beyond the

trend established by prior process geometry shrinks.

(C) International Journal of Engineering Sciences & Research Technology

[2670-2675]

[Bhole, 2(10): October, 2013]

ISSN: 2277-9655

Impact Factor: 1.852

process technology can meet the diverse requirements in

end equipment today.

Though 3D Tri-Gate technology will be a

foundation of next generation FPGAs to provide the

highest core performance at the lowest power, it may not

be the optimal solution for everyone. There are other

technologies such as TSMCs 20SoC and 55 EmbFlash

that can complement Intels Tri-Gate technology,

References

Fig.10 Graph of Active Power in Planar and Tri-Gate

Transistors

Other benefits of 3D tri-gate technology on

FPGAs includes: improved defect density curves in 22

nm Tri-Gate as compared to 32 nm planar design and

reductions in SEU incidence rates from four times to ten

times when moving from 32 nm planar to 22 nm TriGate design.

ALTERA Corporation and Intel Corporation

have entered into an agreement for the future

manufacture of ALTERA FPGAs (e.g. Stratix 10) on

Intels 14nm tri-gate transistor technology. Nextgeneration architectures will significantly improve core

performance when combined with leading-edge process

technology. It would allow for astonishing core speeds of

up to 1 GHz. It will bring tremendous improvement in

digital signal processing (DSP) capability. Already an

area where FPGAs excel, these DSP blocks will become

much more efficient in floating-point operations. FPGAs

enabled with them will allow for over 10 trillion floatingpoint operations per second (teraFLOPS) of

performance. These will be one of the highest

performance, power-efficient solutions at 100 giga

floating-point operations per second (GFLOPS) per watt.

This would be something unimaginable in existing DSPs

or graphics processing units (GPUs). It would allow for

breakthrough

capabilities

in

high-performance

computing data intensive applications in financial,

energy, cloud data analytics, and so on.

Conclusion

[1] Suman Datta, Recent advancements in high

performance CMOS Transistors: From Planar

to Non-Planar, in The Electrochemical Society

Interface, Spring 2013.

[2] Robert Chau, Suman Datta, Suman Datta, Brian

Doyle, Jack Kavalieros, and Matthew Metz,

High-k/Metal-Gate Stack and Its MOSFET

Characteristics

in

IEEE

ELECTRON

DEVICE LETTERS, VOL. 25, NO. 6, JUNE

2004

http://www.intel.com/technology/silicon/integra

ted_cmos.html

[3] Jack Kavalieros, Brian Doyle, Suman Datta,

Gilbert Dewey, Mark Doczy, Ben Jin, Dan

Lionberger, Matthew Metz, Willy Rachmady,

Marko Radosavljevic, Uday Shah, Nancy Zelick

and Robert Chau Tri-Gate Transistor

Architecture with High-k Gate Dielectrics,

Metal Gates and Strain Engineering, in 2006

Symposium on VLSI Technology Digest of

Technical Papers.

[4] Technical report by ALTERA, Arria 10 Device

Overview.

http://www.intel.com/technology/silicon/integra

ted_cmos.html

[5] White paper by ALTERA, Meeting the

performance and Power Imperative of the

Zettabyte Era with Generation 10.

[6] White Paper by ALTERA, The Breakthrough

Advantage for FPGAs with Tri-Gate

Technology.

[7] White paper by ALTERA, Expect a

Breakthrough Advantage in Next Generation

FPGAs.

[8] Technical report by Intel, Intel Reinvents

Transistors Using New 3-D Structure

3D Tri-Gate technology by Intel is an important

innovation needed to continue Moores Law. This

technology when embraced with other semiconductor

process technologies like strain engineering, high k/

metal gate, Dual epitaxial raised source/drain structure

etc. delivers unprecedented performance improvement

and power reduction in FPGAs. However, no single

http: // www.ijesrt.com

(C) International Journal of Engineering Sciences & Research Technology

[2670-2675]

Você também pode gostar

- Cover LetterDocumento1 páginaCover LetterTejas DharaniAinda não há avaliações

- Cmos and Finfet TechDocumento5 páginasCmos and Finfet TechTejas DharaniAinda não há avaliações

- PWMDocumento12 páginasPWMTejas DharaniAinda não há avaliações

- Race Condition in J-K LatchDocumento14 páginasRace Condition in J-K LatchTejas DharaniAinda não há avaliações

- Spare CellDocumento8 páginasSpare CellpravinAinda não há avaliações

- Static Timing AnalysisDocumento71 páginasStatic Timing Analysisapi-3762689100% (13)

- PCITarget 33 MHZ 32 Bit DocumentationDocumento14 páginasPCITarget 33 MHZ 32 Bit DocumentationTejas DharaniAinda não há avaliações

- Jay Vasavada's - Best of Best Article Collection by I-Love-GujaratiDocumento5 páginasJay Vasavada's - Best of Best Article Collection by I-Love-Gujaratii_love_gujarati83% (6)

- Race Condition in J-K LatchDocumento14 páginasRace Condition in J-K LatchTejas DharaniAinda não há avaliações

- StaDocumento2 páginasStaTejas DharaniAinda não há avaliações

- STA AssignmentsDocumento3 páginasSTA AssignmentsTejas DharaniAinda não há avaliações

- DTMF Using FPGADocumento16 páginasDTMF Using FPGATejas DharaniAinda não há avaliações

- Verilog Interview Questions and AnswersDocumento16 páginasVerilog Interview Questions and AnswersAashish AggarwalAinda não há avaliações

- Door Entry DetectionDocumento8 páginasDoor Entry DetectionTejas DharaniAinda não há avaliações

- 01 Trends in Embedded Software EngineeringDocumento46 páginas01 Trends in Embedded Software EngineeringTejas DharaniAinda não há avaliações

- Static Timing AnalysisDocumento71 páginasStatic Timing Analysisapi-3762689100% (13)

- Introduction To Logic Synthesis Using Verilog HDLDocumento84 páginasIntroduction To Logic Synthesis Using Verilog HDLritesh_necAinda não há avaliações

- JBL NewDocumento1 páginaJBL NewTejas DharaniAinda não há avaliações

- 8051 CoreDocumento88 páginas8051 CoreTejas DharaniAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- PharmacologyAnesthesiology RevalidaDocumento166 páginasPharmacologyAnesthesiology RevalidaKENT DANIEL SEGUBIENSE100% (1)

- NameDocumento5 páginasNameMaine DagoyAinda não há avaliações

- 5505 SW 138th CT, Miami, FL 33175 ZillowDocumento1 página5505 SW 138th CT, Miami, FL 33175 Zillowlisalinda29398378Ainda não há avaliações

- Insize Catalogue 2183,2392Documento1 páginaInsize Catalogue 2183,2392calidadcdokepAinda não há avaliações

- Equipment, Preparation and TerminologyDocumento4 páginasEquipment, Preparation and TerminologyHeidi SeversonAinda não há avaliações

- sl2018 667 PDFDocumento8 páginassl2018 667 PDFGaurav MaithilAinda não há avaliações

- Active and Passive Voice of Future Continuous Tense - Passive Voice Tips-1Documento5 páginasActive and Passive Voice of Future Continuous Tense - Passive Voice Tips-1Kamal deep singh SinghAinda não há avaliações

- Lesson 2 Mathematics Curriculum in The Intermediate GradesDocumento15 páginasLesson 2 Mathematics Curriculum in The Intermediate GradesRose Angel Manaog100% (1)

- Individual Assignment ScribdDocumento4 páginasIndividual Assignment ScribdDharna KachrooAinda não há avaliações

- Obligations and Contracts Bar Questions and Answers PhilippinesDocumento3 páginasObligations and Contracts Bar Questions and Answers PhilippinesPearl Aude33% (3)

- NPV Irr ArrDocumento16 páginasNPV Irr ArrAnjaliAinda não há avaliações

- AtmDocumento6 páginasAtmAnkit JandialAinda não há avaliações

- Clean Agent ComparisonDocumento9 páginasClean Agent ComparisonJohn AAinda não há avaliações

- Symmetry (Planes Of)Documento37 páginasSymmetry (Planes Of)carolinethami13Ainda não há avaliações

- Steps To Configure Linux For Oracle 9i Installation: 1. Change Kernel ParametersDocumento5 páginasSteps To Configure Linux For Oracle 9i Installation: 1. Change Kernel ParametersruhelanikAinda não há avaliações

- 10 Slides For A Perfect Startup Pitch DeckDocumento6 páginas10 Slides For A Perfect Startup Pitch DeckZakky AzhariAinda não há avaliações

- Mechanics of Deformable BodiesDocumento21 páginasMechanics of Deformable BodiesVarun. hrAinda não há avaliações

- Yanmar America publication listing for engine parts, service, and operation manualsDocumento602 páginasYanmar America publication listing for engine parts, service, and operation manualsEnrique Murgia50% (2)

- Inventarisasi Data Kondisi Jalan Ke Dalam Aplikasi Sistem Informasi Geografis (Sig)Documento10 páginasInventarisasi Data Kondisi Jalan Ke Dalam Aplikasi Sistem Informasi Geografis (Sig)Wiro SablengAinda não há avaliações

- Antiquity: Middle AgesDocumento6 páginasAntiquity: Middle AgesPABLO DIAZAinda não há avaliações

- Newcomers Guide To The Canadian Job MarketDocumento47 páginasNewcomers Guide To The Canadian Job MarketSS NairAinda não há avaliações

- Ali ExpressDocumento3 páginasAli ExpressAnsa AhmedAinda não há avaliações

- English Week3 PDFDocumento4 páginasEnglish Week3 PDFLucky GeminaAinda não há avaliações

- Restructuring Egypt's Railways - Augst 05 PDFDocumento28 páginasRestructuring Egypt's Railways - Augst 05 PDFMahmoud Abo-hashemAinda não há avaliações

- Report Daftar Penerima Kuota Telkomsel Dan Indosat 2021 FSEIDocumento26 páginasReport Daftar Penerima Kuota Telkomsel Dan Indosat 2021 FSEIHafizh ZuhdaAinda não há avaliações

- IELTS Vocabulary ExpectationDocumento3 páginasIELTS Vocabulary ExpectationPham Ba DatAinda não há avaliações

- Expressive Matter Vendor FaqDocumento14 páginasExpressive Matter Vendor FaqRobert LedermanAinda não há avaliações

- Installation Instruction XALM IndoorDocumento37 páginasInstallation Instruction XALM IndoorVanek505Ainda não há avaliações

- Investigatory Project Pesticide From RadishDocumento4 páginasInvestigatory Project Pesticide From Radishmax314100% (1)

- Exor EPF-1032 DatasheetDocumento2 páginasExor EPF-1032 DatasheetElectromateAinda não há avaliações