Escolar Documentos

Profissional Documentos

Cultura Documentos

Metal Separator

Enviado por

Ali RamosDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Metal Separator

Enviado por

Ali RamosDireitos autorais:

Formatos disponíveis

R

RAPID COMPACT 30-120 metal

separator for free-fall applications

Areas of application

Even the smallest metallic impurities can bring complete production lines to a standstill. The RAPID COMPACT metal separators separate ferrous and non-ferrous metals starting from

a size of 0.3 mm from free-falling pourable bulk materials.

This helps to avoid costly failures and repairs and considerably

increases productivity. In addition the metal separator is an

important component of quality assurance. It is used both for

intermediate testing after certain production stages and for

the inspection of outgoing goods.

In the plastics industry the RAPID COMPACT is often integrated in a pipe after a cutting mill, a cyclone or a dosing unit

(rotary valve, vibro chute). The metal separator can be

mounted on a mobile rack and offers many individual possibilities of application, such as for example the cleaning of smaller

batches.

Of course the RAPID COMPACT is also suitable for similar

applications in other branches of industry (e.g. food, feed,

chemical and pharmaceutical industry).

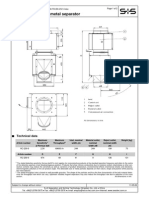

Example: RAPID COMPACT 30-120

metal separator

1

2

3

4

Pipe

Detection coil

Frame

Metal impurity

5 Eject flap

6 Reject outlet

7 Material outlet

Functional and performance charateristics

The decisive advantage of these metal separators is their extremely low overall height. They can therefore be easily installed in (already existing) pipe systems. The extremely low

height is achieved by:

1. the newly developed separating system with its extremely

fast-acting eject flap ("Quick Flap System")

2. round standard connections ("Jacob" system) at the inlet

and at the material and reject outlet, because no additional

special transition pieces are required.

An other essential advantage of this "Quick Flap System" is the

minimum loss of good material in the separation of metal impurities.

When the optimum customer-specific scanning sensitivity and

eject duration have been set, the metal separator operates

completely automatically without any production interruption.

Automatic self-balancing, permanent self-monitoring and temperature compensation are further important performance

characteristics of the RAPID COMPACT metal separator. Various supplemental devices such as warning systems and

counters can be controlled by means of relay outputs that are

activated in case of metal or error detection.

In case of an error of the metal separator or in case of a

mains failure the separating flap remains in "eject" position

until the error has been remedied. If the equipment must be

installed at a hard to access location, the control unit can be

mounted at a distance of up to 10 meters.

Functional principle: RAPID COMPACT

metal separator

QUALITY PERFORMANCE REPUTATION

Dimensions RAPID COMPACT 30-70 (Type 1)

295

80

240

5

78

55

310

300

app. 300

1

Inlet

Material outlet

Reject outlet

Control unit

Compressed-air connection

Type

Article

number

Nominal passage width

max. Scanning

sensitivity1)

RAPID COMPACT 30

RC030

28 mm

0,3 mm

400 l/h

23 kg

30 mm

RAPID COMPACT 50

RC050

46 mm

0,5 mm

2000 l/h

23 kg

50 mm

RAPID COMPACT 70

RC070

71 mm

0,6 mm

5000 l/h

23 kg

70 mm

1)

2)

max.

throughput2)

Weight

Fe-ball (The sensibility depends on the type and shape of the metal contaminant. A possible product effect is not taken into consideration).

The throughput volume is dependent on the flow ability and density of the bulk material as well as the installation situation of the metal separator.

Technical data RAPID COMPACT 30-70 (Type 1) and RAPID

COMPACT 100-120 (Type 2)

Housing:

Sheet steel, varnished (RAL

2004) or V2A

Mains cable:

1,8 m with plug

Parts in contact with

the product:

V2A, aluminium chemically

nickel-plated, PP, teflon

Compressed-air connection:

5-8 bar; 6/8 mm tube

connection

Fall height (bulk material):

max. 500 mm above equipment top edge

Type of production:

IP 65

Temperature range:

-10 C to 60 C

Compressed-air consumption:

0,4 litre / switch operation

Operating voltage:

230/115 VAC 10% (selectable), 50/60 Hz

Eject duration:

adjustable from 0,2 to

2,5 sec

Current input:

approx. 80/160 mA

Scanning sensitivity:

infinitely adjustable

QUALITY

PERFORMANCE

REPUTATION

QUALITY

PERFORMANCE

REPUTATION

Dimensions RAPID COMPACT 100-120 (Type 2)

300

80

260

33

380

0

0

60

2

app. 300

Inlet

Material outlet

Reject outlet

Control unit

Compressed-air connection

Type

Article

number

Nominal passage width

max. Scanning

sensitivity1)

RAPID COMPACT 100

RC100

104 mm

0,8 mm

12000 l/h 25 kg

100 mm

RAPID COMPACT 120

RC120

119 mm

1,0 mm

16000 l/h 25 kg

120 mm

1)

2)

max.

Weight

A

throughput2)

(Jacob system)

Fe-ball (The sensibility depends on the type and shape of the metal contaminant. A possible product effect is not taken into consideration).

The throughput volume is dependent on the flow ability and density of the bulk material as well as the installation situation of the metal separator.

Standard version of delivery, accessories, special versions

Included in standard version:

Round pipe connectors (Jacob system)

Round pipe connectors (Jacob system) at the material and reject outlet RC 30-70 optional

Button for function test

Accessories:

Feed hopper (only RC 30-70)

Grid magnet (only RC 30-70)

Blinkers (with horn)

Horn

Counter

Button external Reset

Flap position monitor

Compressed-air monitor

Pipe transition pieces with flanges

Mobile rack

Special versions:

Special supply voltages

Special varnishes

Special version for higher termperature range

Control unit set off up to 10 m

Subject to change without notice.

QUALITY

PERFORMANCE

REPUTATION

QUALITY

PERFORMANCE

REPUTATION

Eclipse metal separators, metal detectors and magnets for the

plastics industry

DLS tunnel metal detector

Metal detection prior to size reduction machines

(for large material feeding heights)

Grid and pipe magnets

Separation of ferrous metals in feed hoppers

and pipes

MES metal separator

Metal separation on the material input of

an injection moulding machine

PT area metal detector

Metal detection prior to size reduction machines

(for small material feeding heights)

GF metal separator

Metal separation in pneumatic conveyor sections

(for horizontal and vertical installation)

MFE metal separator

Metal separation on the material inlet of an

extruder

Please ask for our detailed information material!

R

Eclipse Magnetics Ltd.

Units 1- 4 Vulcan Road, Sheffield, S9 1EW England

Tel: 0114 225 0555. Fax: 0114 225 0525

E-mail: enquiries@eclipse-magnetics.co.uk Website: www.magneticseparation.co.uk

QUALITY PERFORMANCE REPUTATION

Você também pode gostar

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987No EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonAinda não há avaliações

- Mil STD 810h HumidityDocumento22 páginasMil STD 810h Humiditymariela baigorriaAinda não há avaliações

- Geomet 500bDocumento1 páginaGeomet 500bellisforheroesAinda não há avaliações

- Iso 527 4 2021Documento12 páginasIso 527 4 2021Joana Costa VieiraAinda não há avaliações

- 43901699a-02 - High Pressure Connectors - Section 2Documento12 páginas43901699a-02 - High Pressure Connectors - Section 2Ralph SanchesAinda não há avaliações

- AerFilmLHRHVA ApplicationDocumento4 páginasAerFilmLHRHVA ApplicationAleksandr Tsymbal100% (1)

- International Standard: Plastics - Determination of Charpy Impact Properties - Non-Instrumented Impact TestDocumento11 páginasInternational Standard: Plastics - Determination of Charpy Impact Properties - Non-Instrumented Impact Testamnajam100% (1)

- ISO-n Exponent PDFDocumento12 páginasISO-n Exponent PDFjavidokAinda não há avaliações

- D 5628 - 96 R01 - Rdu2mjg - PDFDocumento10 páginasD 5628 - 96 R01 - Rdu2mjg - PDFJuan Pablo ApazaAinda não há avaliações

- EDM Surface Finish ChartsDocumento2 páginasEDM Surface Finish ChartssansagithAinda não há avaliações

- Iso 527 2 2012 PDFDocumento16 páginasIso 527 2 2012 PDFRafael CastroAinda não há avaliações

- Isoval 11 HKBDocumento2 páginasIsoval 11 HKBjalilemadiAinda não há avaliações

- Tinius Olsen - Ref 30 - 60000lb Cal Super L - B117GDocumento8 páginasTinius Olsen - Ref 30 - 60000lb Cal Super L - B117Gjr_satish6965Ainda não há avaliações

- Astm E96-96m 2014Documento13 páginasAstm E96-96m 2014tsalemnoushAinda não há avaliações

- DIN ISO 3302-1: Nominal Dimension Class M1 Class M2 Class M3 Class M4Documento1 páginaDIN ISO 3302-1: Nominal Dimension Class M1 Class M2 Class M3 Class M4Augusto PeinadoAinda não há avaliações

- Slydring GB PDFDocumento70 páginasSlydring GB PDFBruno BrepohlAinda não há avaliações

- Din 50018 Sulfur Dioxide Corrosion TestDocumento3 páginasDin 50018 Sulfur Dioxide Corrosion TestJoao Pedro Rendeiro Correia de SousaAinda não há avaliações

- Iso 5085 1 1989Documento9 páginasIso 5085 1 1989Zeeshan KhanAinda não há avaliações

- Unicor - Corrugated Pipe For Future DemandsDocumento49 páginasUnicor - Corrugated Pipe For Future DemandsLam ChAinda não há avaliações

- Stiffness Properties of Plastics As A Function of Temperature by Means of A Torsion TestDocumento11 páginasStiffness Properties of Plastics As A Function of Temperature by Means of A Torsion TestCristian DíazAinda não há avaliações

- ASTM D2228 04 - Standard Test Method For Rubber Property-Relative Abrasion Resistance by Pico Abrader MethodDocumento9 páginasASTM D2228 04 - Standard Test Method For Rubber Property-Relative Abrasion Resistance by Pico Abrader MethodAndre Rodriguez Spirim100% (1)

- DC 781 Acetoxy SealantDocumento3 páginasDC 781 Acetoxy SealantL.S.Ainda não há avaliações

- Astm F 439-02 E03 PDFDocumento8 páginasAstm F 439-02 E03 PDFJORGE ARTURO TORIBIO HUERTAAinda não há avaliações

- D 1415 - 88 R99 - Rde0mtu - PDFDocumento5 páginasD 1415 - 88 R99 - Rde0mtu - PDFGyna SHAinda não há avaliações

- Material Specification: Specification: Revision Date: Revision LevelDocumento2 páginasMaterial Specification: Specification: Revision Date: Revision LevelReginaldo Santos100% (1)

- Astm 472 PDFDocumento3 páginasAstm 472 PDFJOSEPH REFUERZOAinda não há avaliações

- BS Iso 00048-4-2018Documento24 páginasBS Iso 00048-4-2018Samwel TarimoAinda não há avaliações

- ASTM D4218-15 Contenido NHDocumento3 páginasASTM D4218-15 Contenido NHNelson VivancoAinda não há avaliações

- Specification:: Test Item Test Data Data Unit Test MethodDocumento2 páginasSpecification:: Test Item Test Data Data Unit Test Methodcharan100% (1)

- Cellasto A Microcellular Polyurethane ElastomerDocumento12 páginasCellasto A Microcellular Polyurethane ElastomerHari SuthanAinda não há avaliações

- D968-17 6.01Documento5 páginasD968-17 6.01Siti MusabikhaAinda não há avaliações

- HDT 3-6 Vicat GB-AP911-06Documento6 páginasHDT 3-6 Vicat GB-AP911-06Diego Fernado AvendañoAinda não há avaliações

- ASTEM D955 00 - Standard Test Method of Measuring Shrinkage From Mold Dimensions of Thermoplastics PDFDocumento5 páginasASTEM D955 00 - Standard Test Method of Measuring Shrinkage From Mold Dimensions of Thermoplastics PDFAndre Rodriguez SpirimAinda não há avaliações

- Suzuki StandardsDocumento2 páginasSuzuki Standardsjitendertalwar1603100% (1)

- Measuring The Force-Displacement of A Membrane Switch: Standard Test Method ForDocumento5 páginasMeasuring The Force-Displacement of A Membrane Switch: Standard Test Method Formasoud132Ainda não há avaliações

- Iso 9352 - 1995Documento9 páginasIso 9352 - 1995Eduard-Marius LungulescuAinda não há avaliações

- Proceso de LimpiezaDocumento17 páginasProceso de LimpiezaPatricioAinda não há avaliações

- Iso 16048-2003Documento9 páginasIso 16048-2003張曉文100% (1)

- International Standard: Stainless Steels For Springs - WireDocumento8 páginasInternational Standard: Stainless Steels For Springs - WireAfzal ImamAinda não há avaliações

- ASTM Material Changes: CCFSS Technical BulletinDocumento6 páginasASTM Material Changes: CCFSS Technical BulletinkfctcoAinda não há avaliações

- D 5720-95Documento9 páginasD 5720-95ipkm123Ainda não há avaliações

- Is53 Iso - 5836 - 1988Documento8 páginasIs53 Iso - 5836 - 1988elvisonderAinda não há avaliações

- Rubber Hose: Standard Test Methods ForDocumento10 páginasRubber Hose: Standard Test Methods ForSubhasis DeyAinda não há avaliações

- Astm F-568M - 98Documento8 páginasAstm F-568M - 98awesome_600Ainda não há avaliações

- Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesDocumento8 páginasHot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesradziAinda não há avaliações

- ASTM F 382 Experiment - 1 - FoyDocumento2 páginasASTM F 382 Experiment - 1 - FoyLucas MlbAinda não há avaliações

- Astm D4000 2004 PDFDocumento19 páginasAstm D4000 2004 PDFHARSHAAinda não há avaliações

- Jis D0203 PDFDocumento6 páginasJis D0203 PDFsabaris ksAinda não há avaliações

- John Deere Design, Process, and Assembly ReviewDocumento33 páginasJohn Deere Design, Process, and Assembly ReviewcucuAinda não há avaliações

- ISO 2505-2 1994 Cor 1 1997Documento12 páginasISO 2505-2 1994 Cor 1 1997Muhammad SyarifAinda não há avaliações

- Tolerance of Position (TOP) - 1Documento34 páginasTolerance of Position (TOP) - 1maddy_scribdAinda não há avaliações

- Coated Fab Iso ListDocumento4 páginasCoated Fab Iso ListSte BoydAinda não há avaliações

- 11.03 Iso-6272-1-2011Documento9 páginas11.03 Iso-6272-1-2011hoanvuAinda não há avaliações

- ISO 3302-1:1996 (E) : M-ClassDocumento2 páginasISO 3302-1:1996 (E) : M-ClassMarcos Antonio RossiAinda não há avaliações

- D2990 01Documento20 páginasD2990 01alifaramarzAinda não há avaliações

- ASTM C272 Water Absorption of Core Materials For Sandwich PDFDocumento4 páginasASTM C272 Water Absorption of Core Materials For Sandwich PDFSílvio Xavier SantosAinda não há avaliações

- Rapid Compact 250 Metal Separator: Technical Data SheetDocumento2 páginasRapid Compact 250 Metal Separator: Technical Data Sheetanacer55Ainda não há avaliações

- Muestreador PDFDocumento2 páginasMuestreador PDFSamantha PowellAinda não há avaliações

- productPDF 8096Documento2 páginasproductPDF 8096Jose ReedAinda não há avaliações

- Austentite Steel Thermal StabilizationDocumento17 páginasAustentite Steel Thermal StabilizationArangamar KumaranAinda não há avaliações

- NSK Cat E1267Documento9 páginasNSK Cat E1267Anonymous 5RUnMVLMPAinda não há avaliações

- Meco Eas FTL Seal TechnologyDocumento2 páginasMeco Eas FTL Seal Technologycristobal_tl2277Ainda não há avaliações

- Fosroc Catalogue 2011Documento112 páginasFosroc Catalogue 2011Bahtiar AntanaAinda não há avaliações

- Assignment ERPDocumento10 páginasAssignment ERPSameer ZaidiAinda não há avaliações

- Turning Tools - Tooling SystemsDocumento94 páginasTurning Tools - Tooling Systemssaotinhyeu307783Ainda não há avaliações

- Pollution Abatement AssignmentDocumento10 páginasPollution Abatement AssignmentNyakondo StephenAinda não há avaliações

- Draft: Mechanical AssemblyDocumento22 páginasDraft: Mechanical Assemblysarath6725Ainda não há avaliações

- Handbook Parting Off 2009 enDocumento44 páginasHandbook Parting Off 2009 enGilberto ManhattanAinda não há avaliações

- Quality of Care Between Donabedian Model and Iso9001v2008 PDFDocumento14 páginasQuality of Care Between Donabedian Model and Iso9001v2008 PDFyaminmuh100% (1)

- Waterproofing Materials Commonly Applied To Commercial BuildingDocumento21 páginasWaterproofing Materials Commonly Applied To Commercial BuildingBer Salazar Jr100% (1)

- Harry Okolo Jr. - CV 10th Jan 2013Documento5 páginasHarry Okolo Jr. - CV 10th Jan 2013Nuno Sa PunsoAinda não há avaliações

- 516 Vs 515Documento2 páginas516 Vs 515Madan YadavAinda não há avaliações

- Sustainable ProcurementDocumento8 páginasSustainable ProcurementZhi Xiong TristanAinda não há avaliações

- SAP TcodesDocumento184 páginasSAP TcodesAshutosh Agarwal100% (1)

- Conveyor Idler StandardsDocumento10 páginasConveyor Idler StandardsObiwan1483100% (1)

- Pakistan Tobacco CompanyDocumento23 páginasPakistan Tobacco CompanyMohsen SirajAinda não há avaliações

- 2016-09-22 Coatings As Functional Competitive Advantage FINALDocumento22 páginas2016-09-22 Coatings As Functional Competitive Advantage FINALSHRIPAD AMATEAinda não há avaliações

- Nippon Vinilex 2000 Water-Based Wall Sealer: DescriptionDocumento2 páginasNippon Vinilex 2000 Water-Based Wall Sealer: Descriptionlimitless853Ainda não há avaliações

- Chapter 19-Bulk Deformation Processes IDocumento67 páginasChapter 19-Bulk Deformation Processes IMohsin AliAinda não há avaliações

- Process Selection and Capacity PlanningDocumento54 páginasProcess Selection and Capacity Planningankita_16jansingh0% (1)

- Internship Report On Manufacturing Industry at ThermicaDocumento63 páginasInternship Report On Manufacturing Industry at ThermicaAnkita Gharai100% (4)

- Everis Training: SAP PP Training Chapter 3 - Overview of Production Planning December, 2007Documento19 páginasEveris Training: SAP PP Training Chapter 3 - Overview of Production Planning December, 2007GilbertoAinda não há avaliações

- Sumiten 780SDocumento2 páginasSumiten 780Sdiah131Ainda não há avaliações

- Planning Project Quality Unit 5 SPM MCA FINALDocumento60 páginasPlanning Project Quality Unit 5 SPM MCA FINALSaurabh KhatriAinda não há avaliações

- CENTRAL KITCHENS Chapter - 9 PDFDocumento24 páginasCENTRAL KITCHENS Chapter - 9 PDFKrishna Gopal DubeyAinda não há avaliações

- Piping Insulation Project Planned Schedule-Rev2Documento1 páginaPiping Insulation Project Planned Schedule-Rev2Anene EmmanuelAinda não há avaliações

- Case Study On Warehouse ManagementDocumento2 páginasCase Study On Warehouse ManagementSafijo AlphonsAinda não há avaliações

- Surface Preparation and Painting of Structural SteelDocumento6 páginasSurface Preparation and Painting of Structural SteelRakesh Ranjan0% (1)

- PERISSINOTO PUMP - 88A-06 - 503 AOTD-B3 - Rev.1Documento10 páginasPERISSINOTO PUMP - 88A-06 - 503 AOTD-B3 - Rev.1Joako TorresAinda não há avaliações